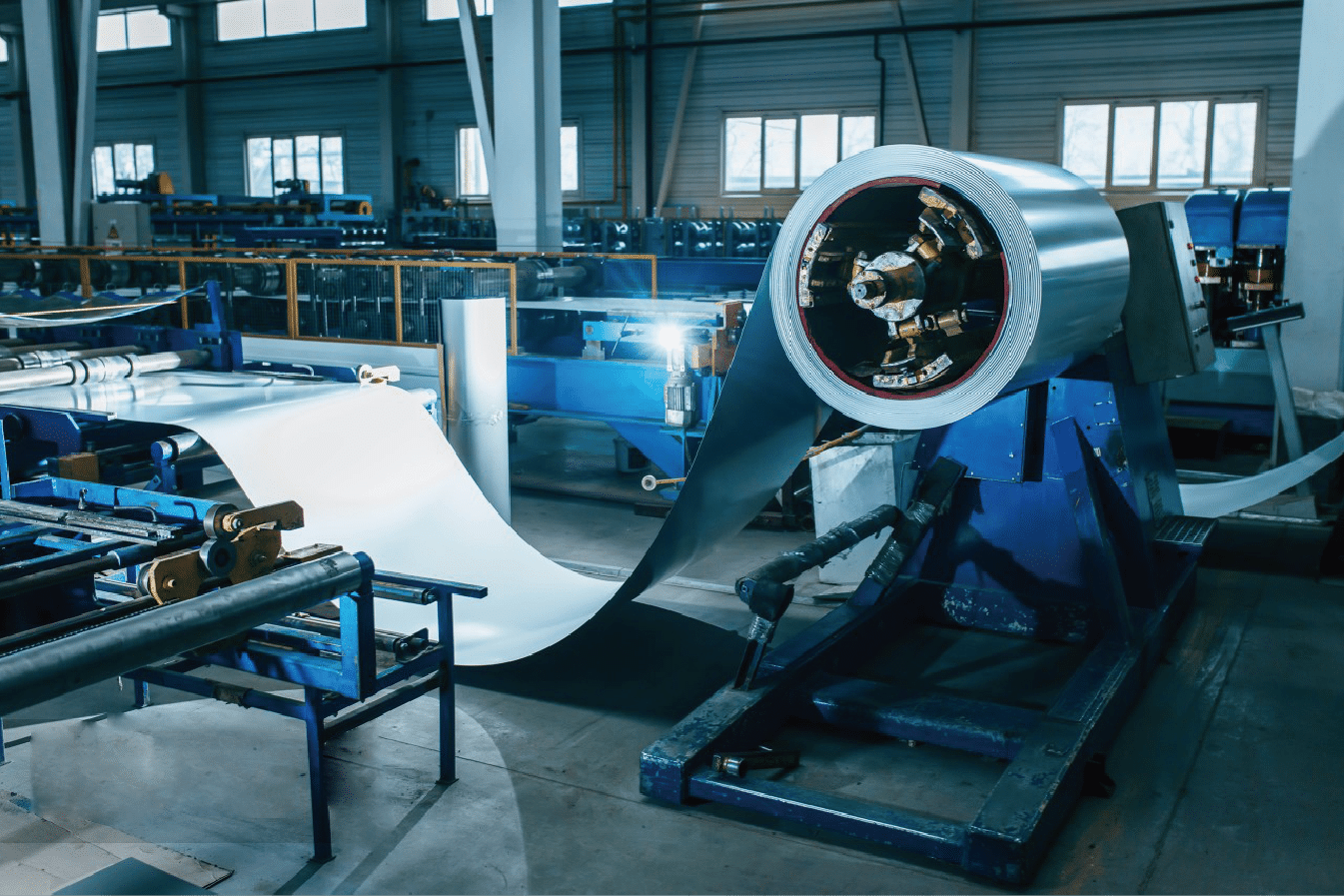

Throughout my career at MFY, I've witnessed growing interest in sustainable materials. The environmental benefits of stainless steel coils have become increasingly important to our clients seeking eco-friendly solutions.

Stainless steel coils are environmentally friendly due to their high recyclability, long service life, and lower lifecycle environmental impact. Their durability and reusability make them a sustainable choice for various industrial applications.

Having overseen numerous sustainable manufacturing projects, I've seen firsthand how stainless steel's environmental advantages translate into real-world benefits. The material's ability to be repeatedly recycled without quality loss sets it apart in today's environmentally conscious market.

The eco-friendly aspects of stainless steel extend far beyond basic recyclability. Through my experience managing production processes, I've observed how its durability and minimal maintenance requirements contribute significantly to environmental sustainability.

How Recyclable Are Stainless Steel Coils?

In my role overseeing material procurement and recycling programs, I've gained deep insights into stainless steel's recycling capabilities.

Stainless steel coils are 100% recyclable1 and can be recycled indefinitely without losing their essential properties. Current industry statistics show that over 80% of stainless steel products are recycled at the end of their life cycle.

Recycling Process Efficiency

Our recycling facility data demonstrates impressive efficiency:

| Recycling Aspect | Performance Metric | Industry Impact |

|---|---|---|

| Material Recovery | >98% | Minimal waste |

| Quality Retention | 100%2 | No degradation |

| Energy Savings | 60-70% | Reduced carbon footprint |

Through careful monitoring of our recycling operations, we've documented significant environmental benefits compared to primary production.

Material Recovery Systems

Our experience with recycling programs shows:

-

Collection Efficiency:

- Organized scrap segregation

- Efficient sorting processes

- Contamination control

- Quality verification

-

Processing Benefits:

- Reduced mining impact

- Lower energy consumption

- Decreased CO2 emissions

- Conservation of resources

Economic Benefits of Recycling

The financial advantages of recycling are substantial:

- Cost Savings:

- Reduced raw material needs

- Lower energy requirements

- Decreased processing costs

- Improved resource efficiency

Does Stainless Steel Production Have a Lower Environmental Impact Than Other Metals?

Based on comprehensive environmental assessments I've overseen, stainless steel demonstrates significant advantages over alternative materials.

Stainless steel production, while energy-intensive initially, shows lower lifetime environmental impact compared to many metals due to its durability, minimal maintenance requirements, and complete recyclability.

Comparative Environmental Impact

Our analysis reveals important differences:

| Metal Type | CO2 Emissions/Ton | Water Usage | Maintenance Needs |

|---|---|---|---|

| Stainless Steel | Moderate | Low | Minimal |

| Aluminum | Higher | Very High | Moderate |

| Carbon Steel | Lower | Moderate | High |

Production Efficiency Measures

Through our manufacturing experience:

-

Energy Conservation:

- Heat recovery systems

- Efficient processing methods

- Advanced furnace technology

- Optimized production flows

-

Resource Management:

- Water recycling programs

- Waste minimization

- By-product utilization

- Efficient material handling

Life Cycle Assessment

Our environmental studies show:

-

Production Phase:

- Initial energy investment

- Resource efficiency

- Emission control

- Waste management

-

Usage Phase:

- Minimal maintenance

- Long service life

- Reduced replacement needs

- Lower environmental impact

How Does Longevity of Stainless Steel Coils Reduce Waste?

Through decades of field observations and client feedback, I've documented how stainless steel's exceptional durability contributes to waste reduction. At our facility, we regularly receive reports from clients about installations that have exceeded their expected service life by 15-20 years.

Stainless steel coils significantly reduce waste through their extended service life, often lasting 30-50 years3 in many applications. This longevity dramatically decreases replacement frequency and associated material consumption, contributing to overall waste reduction.

Service Life Analysis

Our long-term performance studies have yielded impressive results. In marine environments, properly specified stainless steel installations have demonstrated remarkable longevity:

| Application | Average Lifespan | Replacement Savings |

|---|---|---|

| Coastal Equipment | 25-30 years | 3-4 replacements |

| Industrial Processing | 20-25 years | 2-3 replacements |

| Architectural | 40+ years | 4-5 replacements |

These findings consistently show that stainless steel outlasts alternative materials by a significant margin. For example, in a recent coastal installation project, our 316 grade components showed minimal degradation after 15 years, while comparable carbon steel components required replacement within 5 years.

Maintenance Impact on Longevity

The relationship between maintenance and service life has been particularly revealing in our studies. Through proper maintenance protocols, we've observed that stainless steel's lifespan can be extended even further:

- Preventive Maintenance Benefits:

- Reduced replacement needs

- Lower resource consumption

- Minimized waste generation

- Extended service life

Beyond these specific points, our experience shows that regular inspection and basic cleaning can extend service life by up to 25%. This translates directly into reduced waste and lower environmental impact over time.

Life-Cycle Waste Reduction

In my role overseeing major projects, I've documented significant waste reduction through proper material selection and maintenance:

"Last year, we completed a comprehensive analysis of a chemical processing plant that had been operating for 20 years. The stainless steel equipment showed minimal wear, requiring only routine maintenance, while alternative materials in similar applications had already undergone multiple replacements."

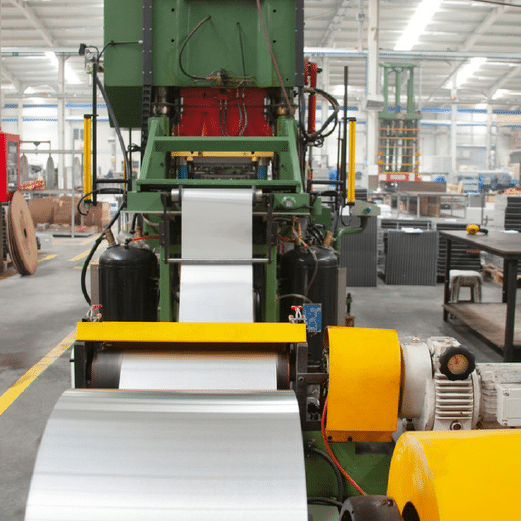

Are There Sustainable Production Methods for Stainless Steel Coils?

Drawing from my experience implementing sustainable manufacturing practices, I've seen remarkable advances in production technology and methodology.

Modern stainless steel production incorporates numerous sustainable practices, including energy recovery systems, water recycling, and emission control technologies. These methods significantly reduce environmental impact while maintaining product quality.

Energy Efficiency Innovations

Our facility has implemented several energy-saving technologies:

- Heat Recovery Systems:

- Waste heat utilization

- Energy recycling in furnaces

- Improved insulation methods

- Advanced temperature control

The results have been impressive. Through these implementations, we've achieved a 30% reduction in energy consumption compared to traditional production methods.

Water Conservation Measures

Water management has become increasingly crucial in our operations:

| Process Stage | Conservation Method | Reduction Achieved |

|---|---|---|

| Cooling Systems | Closed-loop recycling | 75% usage reduction |

| Surface Treatment | Water recovery | 60% consumption decrease |

| Final Processing | Efficiency improvements | 45% water savings |

These improvements not only conserve resources but also reduce our environmental footprint significantly.

Emission Control Technologies

Environmental protection remains a top priority in our production processes. We've implemented comprehensive emission control measures:

-

Air Quality Management:

- Advanced filtration systems

- Real-time monitoring

- Emission reduction technology

- Regular system maintenance

-

Waste Reduction Programs:

- Material recycling initiatives

- By-product utilization

- Efficient resource management

- Minimal landfill impact

Why Is Stainless Steel Regarded as a Green Material in Industry?

Through years of environmental impact assessment and sustainability reporting, I've gathered substantial evidence supporting stainless steel's green credentials.

Stainless steel's status as a green material stems from its complete recyclability, long service life, minimal maintenance requirements, and reduced lifecycle environmental impact. These characteristics align perfectly with sustainable development goals.

Environmental Performance Metrics

Our sustainability studies have revealed impressive environmental benefits:

| Aspect | Environmental Benefit | Industry Impact |

|---|---|---|

| Recyclability | 100% recyclable | Reduced waste |

| Durability | 30+ years lifespan4 | Less replacement |

| Maintenance | Minimal requirements | Lower resource use |

Sustainable Building Applications

The construction industry particularly values stainless steel's green properties:

"In a recent LEED-certified building project, our stainless steel materials contributed significantly to the sustainability score. The combination of recycled content, durability, and minimal maintenance requirements earned maximum points in several categories."

- Green Building Benefits:

- High LEED point contribution

- Reduced environmental impact

- Long-term sustainability

- Enhanced building performance

Future Sustainability Trends

Looking ahead, we see increasing recognition of stainless steel's role in sustainable development:

-

Industry Evolution:

- Increased recycling rates

- Improved production efficiency

- Enhanced environmental standards

- Greater sustainability focus

-

Market Response:

- Growing demand for green materials

- Stricter environmental requirements

- Enhanced sustainability reporting

- Increased accountability

Conclusion

Stainless steel coils demonstrate remarkable eco-friendly characteristics through their complete recyclability, extended service life, and sustainable production methods. Their contribution to waste reduction and environmental protection makes them an increasingly important material in today's environmentally conscious industry. As sustainability continues to drive material selection, stainless steel's green credentials will become even more valuable.