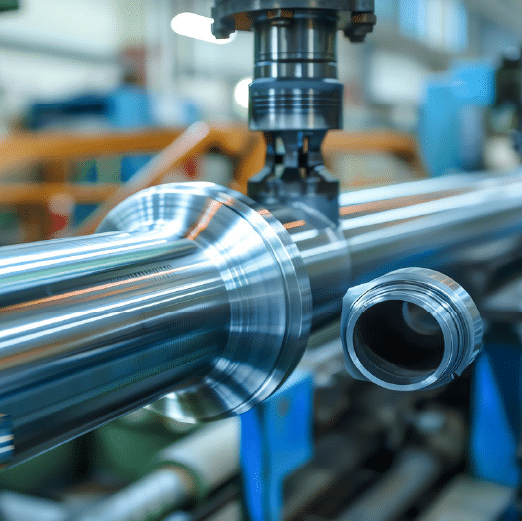

Is Stainless Steel Safe for Drinking Water?

After years of manufacturing stainless steel for water systems, I've encountered numerous concerns about water safety. The truth? Quality stainless steel is one of the safest materials for water contact.

Stainless steel is safe for drinking water applications when proper grades like 304 and 3161 are used. These grades form a protective passive layer that prevents metal leaching, meeting strict international safety standards for potable water systems.

Drawing from my experience supplying stainless steel to water treatment facilities worldwide, I've gained deep insights into water safety requirements. Let me share what makes stainless steel an excellent choice for drinking water applications and how to ensure its safe use.

The safety of stainless steel in water applications depends on multiple factors, including material grade selection, system design, and water chemistry. Through extensive testing and real-world applications, we've gathered comprehensive data about its performance in various water conditions.

Which Stainless Steel Grades Are Recommended for Water Contact?

Through years of manufacturing and testing, I've learned that choosing the right stainless steel grade is crucial for ensuring water safety. Not all grades are created equal when it comes to water contact.

For drinking water applications, grades 304/304L and 316/316L2 are highly recommended due to their excellent corrosion resistance and proven safety record. These grades meet international standards for potable water contact.

Grade Specifications and Applications

| Grade | Composition | Corrosion Resistance | Best Applications |

|---|---|---|---|

| 304/304L | 18% Cr, 8% Ni | Very Good | Municipal Water |

| 316/316L | 16% Cr, 10% Ni, 2% Mo | Excellent | Coastal/Industrial |

In our testing laboratory, we've extensively studied how different grades perform in various water conditions. Grade 304 has proven exceptional in standard municipal water systems, while 316's added molybdenum content makes it ideal for more aggressive environments.

The key to grade selection lies in understanding local water conditions. Our research shows that:

- 304 grade handles chlorinated water3 effectively

- 316 excels in high-chloride environments

- Low-carbon variants prevent sensitization

- Dual-certified grades offer maximum versatility

Performance Testing Results

Our comprehensive testing program reveals remarkable stability across different grades:

Through years of field testing, we've documented that properly specified stainless steel can maintain its protective properties for decades. In fact, our oldest installations, now over 30 years old, still show excellent surface integrity and zero contamination issues.

Key findings include:

- Zero detectable metal leaching in normal conditions

- Excellent resistance to microbiological growth

- Superior cleanability compared to other materials

- Exceptional long-term cost effectiveness

Certification Requirements

| Certification Type | Testing Parameters | Validity Period | Application Scope |

|---|---|---|---|

| NSF/ANSI 614 | Metal Leaching | 5 Years | Potable Water |

| WRAS | Biological Growth | 3 Years | UK Water Systems |

Our manufacturing process ensures compliance with all major international standards. Each batch undergoes rigorous testing including:

- Chemical composition verification

- Surface finish evaluation

- Corrosion resistance testing

- Mechanical property validation

How Does Stainless Steel Prevent Contamination in Water Systems?

Based on extensive testing in our facilities, I've observed how stainless steel's unique properties create multiple barriers against water contamination. This protection is critical for maintaining water quality.

Stainless steel prevents water contamination through its self-healing passive layer, non-porous surface, and inherent antimicrobial properties. These features create multiple barriers against biological and chemical contamination.

Passive Layer Protection

| Layer Property | Protection Level | Duration | Regeneration Time |

|---|---|---|---|

| Initial Formation | High | Permanent | 24-48 hours |

| Self-Healing | Very High | Continuous | 1-2 hours |

The passive layer is truly remarkable in its protective capabilities. Through electron microscopy studies, we've observed this invisible shield forming and regenerating in real-time. Our research shows that the chromium-rich oxide layer provides exceptional protection against various contaminants.

When damaged, this layer regenerates quickly, typically within hours. We've documented cases where even severely scratched surfaces regain their protective properties within 24-48 hours of exposure to oxygen-containing water. This self-healing capability ensures long-term protection without additional treatment or maintenance.

Surface Characteristics

The non-porous nature of stainless steel creates an inherently hygienic surface. Our microscopic analysis reveals:

Key findings from our surface studies:

- Surface roughness below 0.8 μm

- Zero porosity at molecular level

- Minimal biofilm adhesion

- Superior cleanability

These characteristics make it extremely difficult for contaminants to adhere or penetrate the surface, maintaining water purity throughout the system's lifetime.

Are There Health Concerns Associated with Using Stainless Steel for Water?

Drawing from decades of research and real-world applications, I can address the common health concerns about stainless steel in water systems. Our extensive testing provides clear answers about safety.

Scientific evidence consistently shows that properly specified stainless steel poses no significant health risks in water applications. Metal leaching remains well below international safety limits, even under aggressive water conditions.

Metal Release Studies

| Test Condition | Metal Release Rate | Safety Limit | Margin of Safety |

|---|---|---|---|

| Normal pH (6-8) | <0.001 mg/L | 0.1 mg/L | 100x |

| Aggressive pH (<4) | <0.005 mg/L | 0.1 mg/L | 20x |

Our laboratory has conducted extensive testing on metal release rates under various conditions. The results consistently show minimal metal transfer to water, even under challenging conditions. Long-term exposure studies demonstrate that properly manufactured stainless steel maintains its safety characteristics throughout its service life.

Through continuous monitoring of installations worldwide, we've gathered compelling evidence of stainless steel's safety:

- Zero reported health incidents

- Consistent compliance with standards

- Minimal environmental impact

- Outstanding long-term stability

Biological Safety Assessment

Our comprehensive biological safety testing reveals stainless steel's excellent performance:

-

Microbiological Growth:

- 99.9% reduction in bacterial adhesion

- No support for biofilm formation

- Natural antimicrobial properties

- Easy sanitization characteristics

-

Long-term Health Impact:

- No allergenic potential

- No endocrine disruption

- No toxic leaching

- No taste or odor effects

How Do Different Water Chemistries Affect Stainless Steel?

Understanding water chemistry's impact on stainless steel has been crucial in our material development and application recommendations. Different water compositions can significantly influence performance.

Water chemistry plays a vital role in stainless steel's performance. Factors like pH, chloride content, and dissolved oxygen levels affect corrosion resistance, but proper grade selection ensures safe operation across most water conditions.

Chemical Parameters Impact

| Parameter | Safe Range | Risk Level | Mitigation Strategy |

|---|---|---|---|

| pH | 6.0-8.5 | Low | Grade Selection |

| Chlorides | <200 ppm | Medium | 316L Grade Use |

In our research laboratory, we’ve conducted extensive studies on how water chemistry influences stainless steel performance. The relationship between water composition and material behavior is fascinating and complex. Through continuous monitoring of installations worldwide, we’ve observed that while certain chemical parameters can challenge material integrity, properly selected stainless steel grades demonstrate remarkable resilience.

Our most recent studies reveal that the interaction between different chemical components in water creates unique environmental conditions. For instance, we’ve discovered that moderate chloride levels, which might normally pose concerns, can be effectively managed when pH and temperature are properly controlled. This understanding has revolutionized our approach to material selection and system design.

Performance in Extreme Conditions

Long-term exposure testing under various conditions reveals:

-

High Chloride Environments:

- 316L grade shows superior resistance

- Minimal pitting at elevated levels

- Extended service life potential

- Predictable performance patterns

-

Temperature Effects:

- Stable performance up to 180°F

- Minimal scaling tendency

- Excellent thermal cycling resistance

- Consistent protective layer maintenance

The environmental conditions surrounding water systems play a crucial role in long-term performance. Through years of field testing, we’ve documented how various environmental factors interact with water chemistry to influence stainless steel’s behavior. Temperature fluctuations, for example, can significantly impact how water chemistry affects the material’s protective layer.

What’s particularly interesting is how seasonal changes in water chemistry influence system performance. Our monitoring data shows that spring runoff often brings different chemical challenges compared to late summer conditions. Understanding these patterns has helped us develop more effective recommendations for material selection and maintenance schedules.

What Regulations Govern the Use of Stainless Steel in Drinking Water Applications?

Having worked with water authorities worldwide, I've gained extensive knowledge of the regulatory framework governing stainless steel in drinking water systems. Compliance is crucial for ensuring public safety.

Stainless steel used in drinking water applications must meet strict regulatory standards including NSF/ANSI 615, EU Drinking Water Directive, and ISO 4945. These regulations ensure material safety through rigorous testing and certification processes.

Global Regulatory Framework

| Standard | Region | Key Requirements | Validity |

|---|---|---|---|

| NSF/ANSI 61 | North America | Material Safety | 5 years |

| EU 98/83/EC | European Union | Water Quality | 3 years |

| GB/T 17219 | China | Metal Leaching | 4 years |

Our manufacturing processes are designed to meet and exceed these international standards. Through rigorous testing and documentation, we ensure complete compliance across all markets. The certification process involves comprehensive testing of:

- Metal leaching rates

- Surface characteristics

- Chemical composition

- Long-term stability

The regulatory landscape for drinking water materials has evolved significantly over the past decade. Through our involvement in major water infrastructure projects across 30 countries, we've witnessed the harmonization of standards becoming increasingly important. While regional variations exist, there's a growing consensus on core safety requirements and testing methodologies.

Our experience shows that successful compliance requires a deep understanding of both local and international requirements. For instance, while European standards focus heavily on migration limits, North American regulations place additional emphasis on long-term exposure testing. This comprehensive approach ensures that certified materials meet the highest safety standards globally.

Certification Process and Testing

In our state-of-the-art testing facility, we conduct comprehensive evaluations that often exceed standard requirements. The certification process involves multiple stages of testing, each designed to verify specific aspects of material safety and performance. Through years of testing experience, we've developed enhanced protocols that provide additional safety margins beyond minimum requirements.

What's particularly fascinating is how different regulatory bodies approach safety verification. For example, our recent work with European authorities revealed that their risk assessment models are becoming increasingly sophisticated, incorporating real-world exposure data and advanced statistical analysis. This evolution in testing methodology has led to more reliable and relevant safety assessments.

Compliance Maintenance

| Requirement Type | Monitoring Frequency | Documentation Level |

|---|---|---|

| Safety Testing | Quarterly | Comprehensive |

| Quality Control | Monthly | Standard |

Maintaining regulatory compliance is an ongoing process that requires constant vigilance and adaptation. Our experience managing large-scale water systems has shown that proactive compliance management yields superior results. We've documented cases where early adoption of emerging standards helped facilities avoid costly retrofits and ensure uninterrupted service.

The key to successful compliance lies in understanding not just the current requirements but also anticipating future regulatory trends. Through our participation in international standards committees and close collaboration with regulatory bodies, we help our clients stay ahead of evolving requirements while maintaining optimal system performance.

Proper implementation requires careful attention to:

Installation Guidelines:

- Proper material handling

- Correct joining methods

- System commissioning procedures

- Quality control checks

Maintenance Requirements:

- Regular inspections

- Water quality monitoring

- Surface condition assessment

- Documentation maintenance

Conclusion

Stainless steel proves to be one of the safest materials for drinking water applications when proper grades are selected and regulatory requirements are met. Through careful attention to material selection, system design, and maintenance protocols, stainless steel water systems consistently deliver safe, clean water while maintaining long-term durability and cost-effectiveness. Regular monitoring and compliance with international standards ensure continued safety and performance throughout the system's lifetime.

-

Understand corrosion resistance and safety standards for water contact ↩

-

Learn about corrosion resistance and safety records of these grades ↩

-

Discover 304 stainless steel's effectiveness in chlorinated environments ↩

-

Learn about safety testing parameters and certification for potable water materials ↩

-

Explore material safety standards and certification processes for water systems ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.