Having spent over 15 years in China's stainless steel industry, I've seen countless importers struggle with sourcing quality materials. The challenges of finding reliable suppliers and navigating complex regulations can be overwhelming.

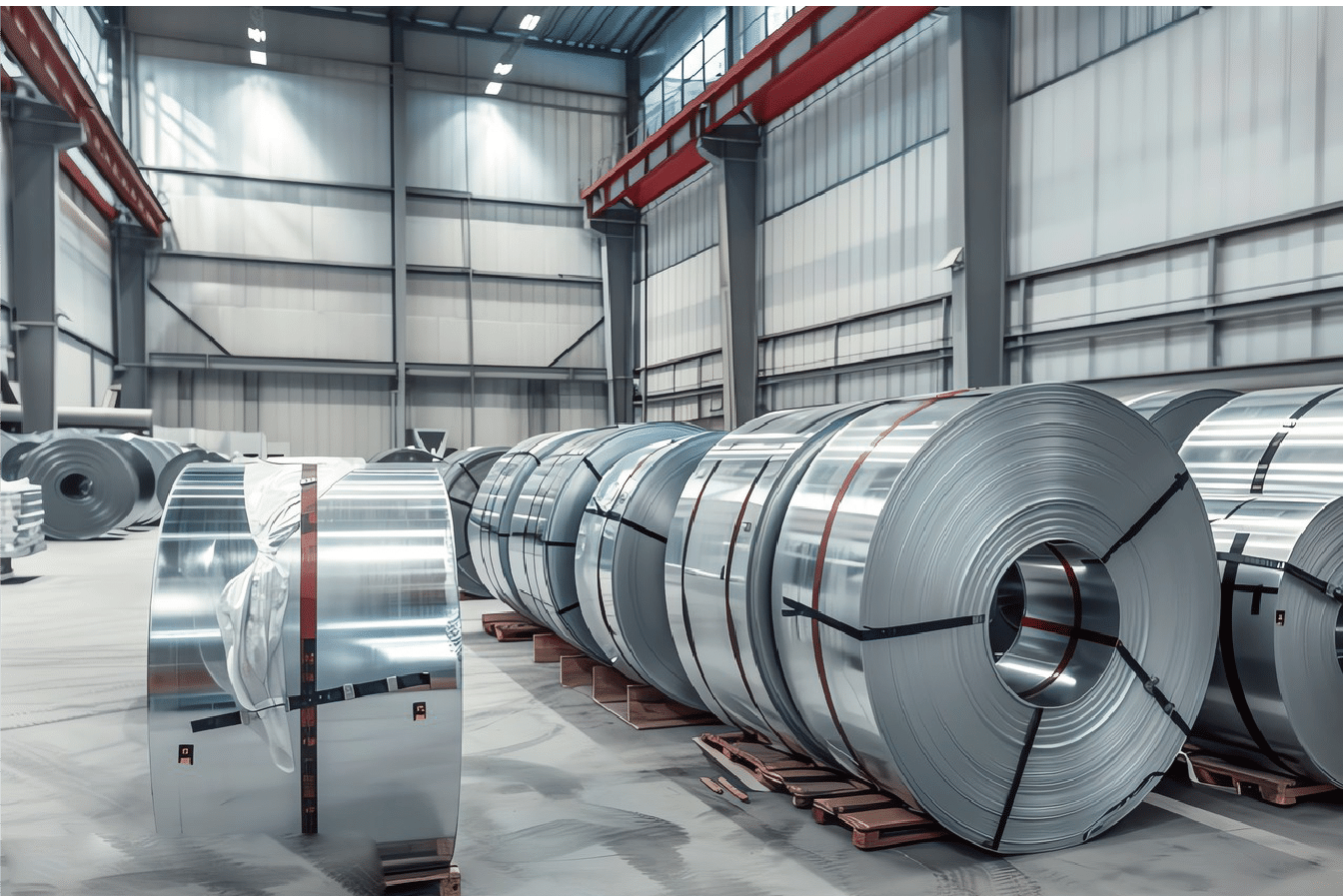

Importing stainless steel coils from China involves identifying reliable suppliers, verifying product quality, negotiating terms1, arranging logistics, and managing customs documentation. Success requires understanding market dynamics, quality standards, and regulatory requirements while building strong supplier relationships.

Let me guide you through the essential steps of importing stainless steel coils from China. With my experience working with global buyers like David from India, I've developed a comprehensive understanding of what makes import operations successful.

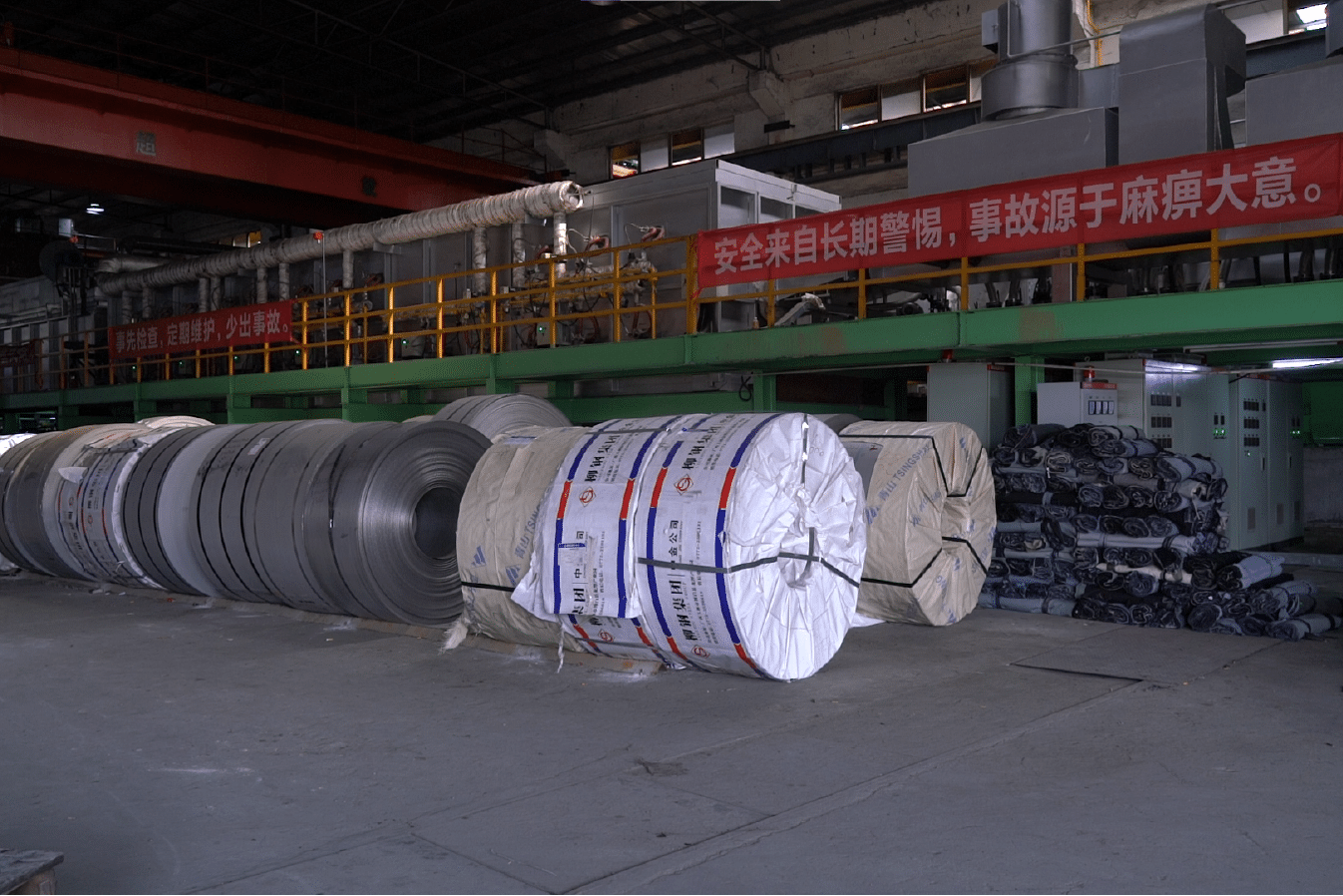

The stainless steel market in China has evolved significantly, with increasing emphasis on quality control and international standards compliance. Recent industry data shows that Chinese manufacturers now account for over 50% of global stainless steel production2, offering competitive prices while maintaining high-quality standards. Through my work at MFY Steel, I've witnessed firsthand how proper planning and supplier selection can make the difference between a successful import operation and a costly mistake.

What Are the Initial Steps to Take Before Importing Stainless Steel Coils from China?

The journey of importing stainless steel coils begins with understanding your specific requirements and the Chinese market dynamics. I've seen many buyers rush into purchases without proper preparation, leading to costly mistakes and quality issues.

Before importing stainless steel coils from China, conduct thorough market research3, define exact product specifications, understand quality standards4, assess your budget constraints, and research import regulations in your country. This preparation is crucial for successful sourcing.

Walking you through my experiences with numerous clients, including a recent case with a manufacturing company from India, I've observed that proper preparation can prevent up to 80% of common importing problems.

Understanding Technical Requirements

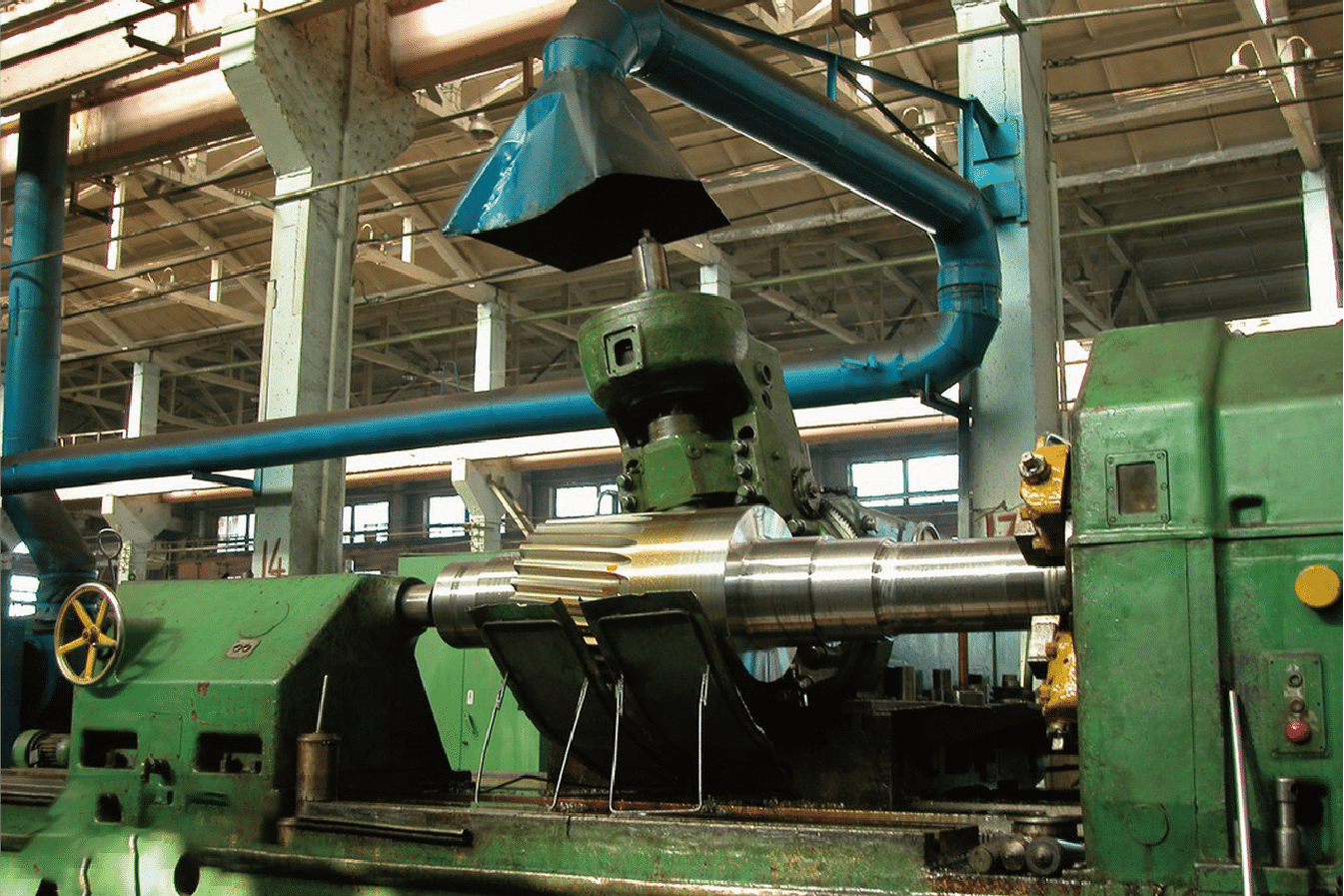

When I first started working with David's manufacturing company in India, we spent considerable time defining their exact technical requirements. This process involved analyzing their production processes, end-product specifications, and quality standards. Their facility required SUS 304 grade stainless steel coils with specific width tolerances for their automotive parts manufacturing.

We conducted detailed material analysis and testing, which revealed that their previous quality issues were largely due to mismatched material specifications. By establishing clear technical parameters, including:

- Material grade specifications

- Dimensional tolerances

- Surface finish requirements

- Mechanical properties

- Chemical composition requirements

Market Research and Price Analysis

The stainless steel market is highly volatile, with prices fluctuating based on raw material costs and global demand. Our research showed that prices can vary by up to 15-20% among different Chinese manufacturers.

| Price Factor | Impact Level | Considerations |

|---|---|---|

| Raw Material Cost | High | Nickel price fluctuations |

| Order Volume | Medium | Bulk discounts available |

| Surface Finish | Medium | Additional processing costs |

| Grade | High | Alloy content variation |

| Market Demand | High | Seasonal fluctuations |

Legal and Regulatory Compliance

Working with our legal team, we've developed a comprehensive understanding of import regulations across different regions. This includes:

Environmental compliance requirements have become increasingly stringent in recent years. In India, for example, the Bureau of Indian Standards (BIS) certification5 is mandatory for certain grades of stainless steel imports. Understanding these requirements early in the process has helped our clients avoid costly delays and regulatory issues.

Through systematic preparation and research, my experience has shown that importers can significantly reduce their risk exposure and improve their chances of successful procurement. For instance, David's company was able to reduce their import-related issues by 60% after implementing our recommended preparation procedures.

Proper preparation is crucial.True

Thorough research and preparation can prevent common import issues.

Market research is unnecessary.False

Market research is essential to understand price fluctuations and quality standards.

How to Find and Verify Reliable Stainless Steel Coil Suppliers in China?

In my 15 years of experience at MFY Steel, I've learned that finding the right supplier is like building a foundation for a house - it's crucial to get it right from the start. Many importers face challenges in distinguishing reliable manufacturers from intermediaries.

To find and verify reliable stainless steel coil suppliers in China, utilize multiple sourcing channels including trade shows, industry directories, and professional networks. Conduct thorough due diligence through factory audits, sample testing, and verification of certifications and licenses.

With global stainless steel trade reaching unprecedented levels, the importance of supplier verification cannot be overstated. Let me share insights from my recent experience helping a major Indian manufacturer establish their supply chain in China.

Effective Supplier Sourcing Strategies

Throughout my career, I've developed a systematic approach to supplier identification and verification. Last year, when working with David's manufacturing company, we implemented a comprehensive sourcing strategy that proved highly successful.

The digital transformation of B2B sourcing has revolutionized how we find suppliers. However, traditional methods still hold significant value. Our research indicates that a multi-channel approach yields the best results. Consider these findings from our recent supplier evaluation project:

Modern sourcing platforms have evolved significantly. While platforms like Alibaba and Made-in-China remain popular, industry-specific platforms have emerged as valuable resources. We've found that combining online research with physical verification yields the most reliable results.

| Sourcing Channel | Reliability Score | Best For |

|---|---|---|

| Trade Shows | 9/10 | Direct Contact |

| Industry Directories | 7/10 | Initial Research |

| Professional Networks | 8/10 | Verified Leads |

| Online Platforms | 6/10 | Broad Search |

| Direct Referrals | 9/10 | Quality Assurance |

Comprehensive Supplier Verification Process

The verification process we've developed at MFY Steel involves multiple layers of assessment. When David's company approached us, they had previously encountered issues with product quality and delivery delays. Our thorough verification process helped them avoid similar problems.

Our verification protocol includes extensive background checks and site visits. During a recent audit of a potential supplier in Jiangsu province, we discovered that while their online presence was impressive, their actual production capacity was significantly lower than claimed. This finding saved our client from potential supply chain disruptions.

Key verification steps include:

- Reviewing business licenses and export certificates

- Conducting factory audits and production capacity assessments

- Evaluating quality control systems and certifications

- Checking financial stability and credit reports

- Assessing past performance and client references

Quality Control and Sample Testing

One of the most critical aspects of supplier verification is quality assessment. In my experience working with manufacturers across Asia, I've found that comprehensive sample testing is non-negotiable. When working with a new supplier in Guangdong, we discovered through detailed testing that their material composition varied significantly from batch to batch.

Our quality control process involves:

- Initial sample testing with third-party laboratories

- Regular production monitoring

- Pre-shipment inspections

- Documentation verification

- Material traceability systems

The implementation of these procedures has helped our clients reduce quality-related issues by up to 75%. For instance, David's company saw defect rates drop from 5% to less than 1% after implementing our suggested quality control measures.

Multiple sourcing channels are beneficial.True

Using various channels helps find reliable suppliers and verify their credentials.

Sample testing is optional.False

Sample testing is critical to ensure product quality and consistency.

How to Negotiate Terms and Prices with Suppliers?

After years of negotiations with Chinese manufacturers, I've learned that successful price negotiations require a deep understanding of market dynamics and cultural nuances. Many buyers make the mistake of focusing solely on price without considering the total cost of ownership.

Effective negotiation with Chinese stainless steel suppliers involves understanding market prices, establishing clear quality specifications, considering payment terms, and building long-term relationships. Focus on creating win-win situations rather than just securing the lowest price.

In my role at MFY Steel, I've facilitated countless negotiations between international buyers and Chinese suppliers. Let me share proven strategies that have helped our clients secure favorable terms while maintaining quality standards.

Understanding Price Components and Market Dynamics

Through years of market analysis and direct negotiations, I've gained deep insights into the factors affecting stainless steel pricing. During a recent negotiation for David's company, we broke down each cost component to identify areas for potential savings.

Price composition in stainless steel manufacturing involves various elements that affect the final cost. Our analysis shows that raw material costs typically account for 60-70% of the total price, with processing, overhead, and profit margins making up the remainder.

| Cost Component | Percentage | Negotiability |

|---|---|---|

| Raw Materials | 65% | Low |

| Processing | 20% | Medium |

| Overhead | 10% | Low |

| Profit Margin | 5% | High |

Strategic Negotiation Techniques

My experience has taught me that successful negotiations go beyond price discussions. When we helped an Indian manufacturer negotiate a long-term supply contract, our comprehensive approach resulted in a 12% cost reduction while maintaining quality standards.

Effective negotiation strategies include:

- Building strong supplier relationships

- Understanding supplier cost structures

- Leveraging market data and trends

- Negotiating payment and delivery terms

- Including quality assurance clauses

The relationship-building aspect of negotiations cannot be overstated. During a recent deal with a Jiangsu-based supplier, establishing a personal connection led to more flexible payment terms and priority production scheduling.

Contract Terms and Risk Management

Contract negotiations require careful attention to detail and protection against potential risks. I've seen many cases where unclear contract terms led to disputes and supply chain disruptions.

Key contract elements to consider:

- Detailed product specifications

- Quality control requirements

- Payment terms and conditions

- Delivery schedules

- Force majeure clauses

- Dispute resolution mechanisms

During a recent contract negotiation for a major project, we included specific quality control benchmarks and penalty clauses for non-compliance. This approach has proven highly effective in ensuring consistent product quality and timely deliveries.

Understanding market dynamics is vital.True

Knowing the factors affecting prices helps in effective negotiation.

Focus only on the lowest price.False

Consider the total cost of ownership for a more comprehensive negotiation.

What Are the Shipping and Logistics Processes Involved in Importing Stainless Steel Coils?

Drawing from my experience managing international shipments at MFY Steel, I've seen how proper logistics planning can make or break an importing operation. Last month, we helped a client save $12,000 in unnecessary storage fees through strategic shipping arrangements.

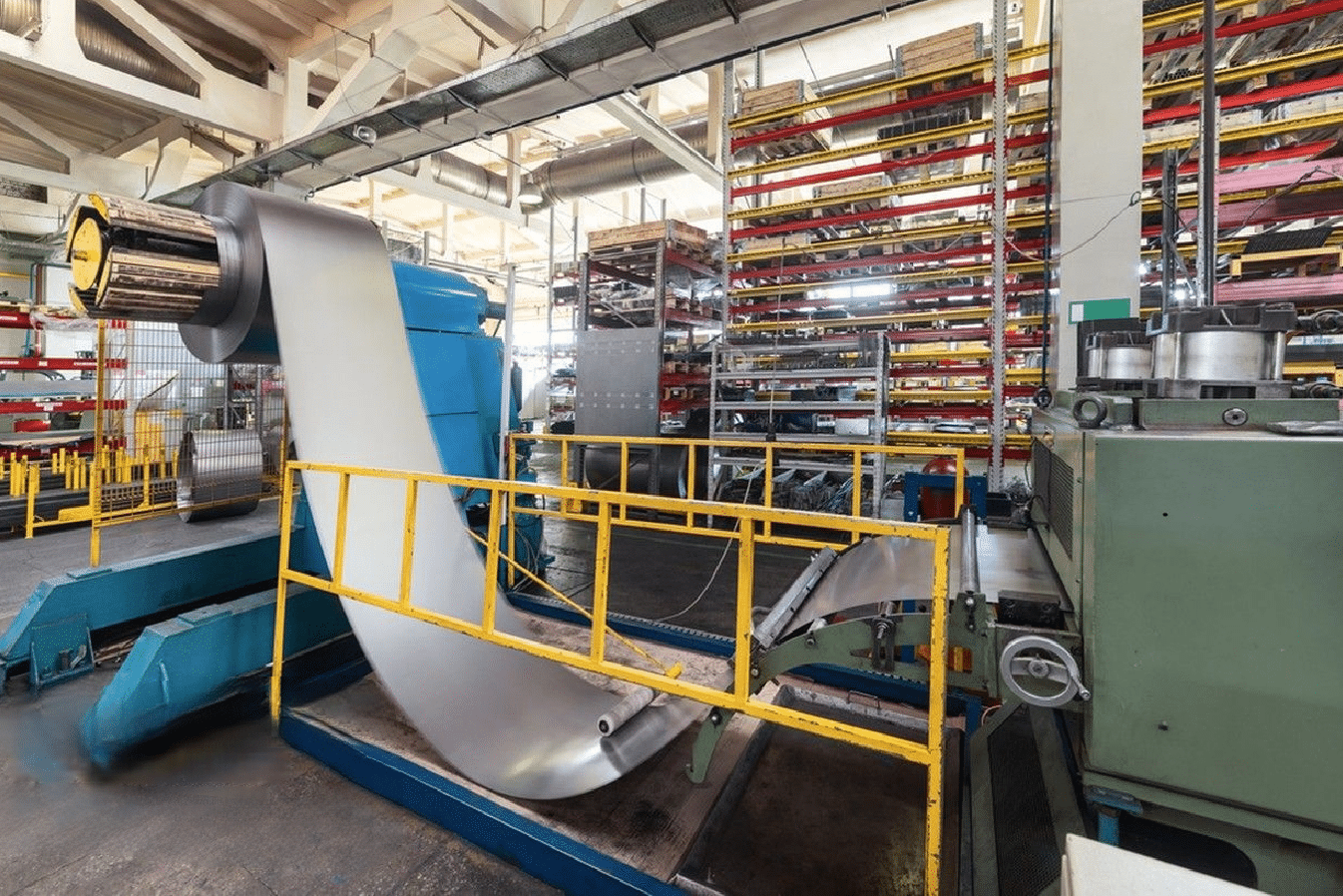

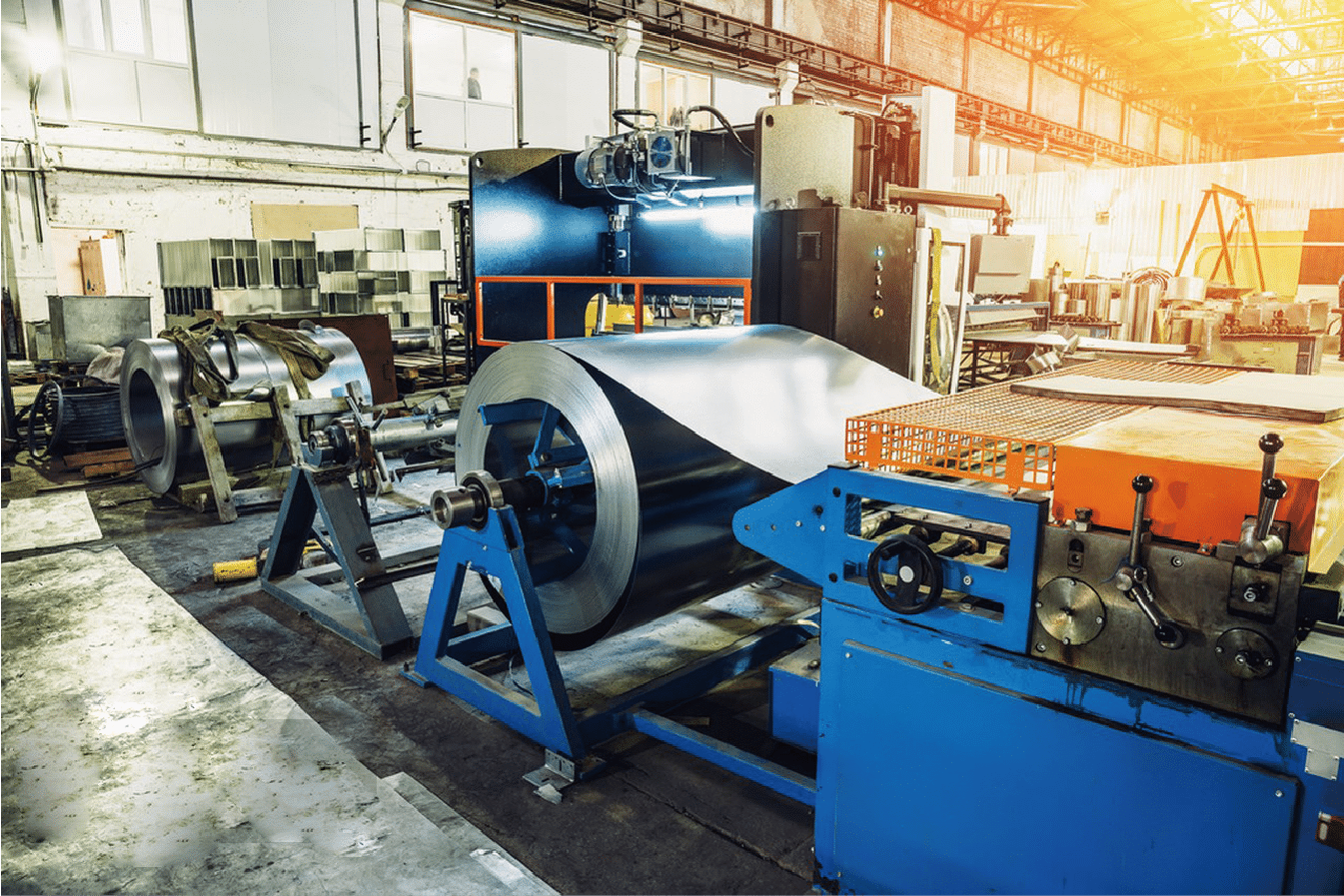

The shipping process for stainless steel coils involves selecting appropriate transportation methods, arranging proper packaging, choosing reliable freight forwarders, planning loading and unloading procedures, and coordinating delivery schedules. Each step requires careful attention to prevent damage and delays.

My years of coordinating shipments across Asia have taught me that successful logistics management requires a comprehensive understanding of both technical requirements and practical constraints. Let me share insights from our recent experiences.

Transportation Method Selection

Working closely with David's company in India, we developed a systematic approach to transportation planning that has significantly reduced their logistics costs and delivery times. Our experience shows that choosing the right shipping method depends on multiple factors.

Ocean freight remains the primary mode of transportation for stainless steel coils, but the specifics of each shipment require careful consideration. Recently, we helped a client optimize their shipping strategy by analyzing various factors:

| Transport Factor | Considerations | Impact on Cost |

|---|---|---|

| Container Type | 20ft/40ft/Open Top | High |

| Shipping Route | Direct/Transshipment | Medium |

| Port Selection | Handling Capabilities | Medium |

| Transit Time | Standard/Express | High |

| Season | Peak/Off-peak | Medium |

Packaging and Protection Requirements

Through years of handling delicate stainless steel shipments, I've learned that proper packaging is crucial for preventing damage during transit. When working with a major Indian manufacturer, we developed specific packaging protocols that reduced transit damage by 85%.

Our comprehensive packaging approach includes:

- Moisture-resistant wrapping

- Edge protectors

- Anti-rust treatments

- Secure strapping systems

- Weather-proof covering

The importance of proper packaging became evident during a recent shipment to Mumbai, where our enhanced protection methods prevented any damage despite rough sea conditions. Our standard packaging protocol now includes:

- Moisture-resistant wrapping

- Edge protectors

- Anti-rust treatments

- Secure strapping systems

- Weather-proof covering

Freight Forwarding and Documentation

Managing relationships with freight forwarders has taught me the importance of clear communication and documentation. Last quarter, we streamlined our documentation process, reducing processing time by 40%.

The key aspects of freight forwarding management include:

- Carrier selection and rate negotiation

- Documentation preparation and verification

- Loading supervision and coordination

- Transit monitoring and tracking

- Insurance coverage arrangements

Working with David's company, we established a systematic approach to freight forwarding that has significantly improved their shipping efficiency. Our documented procedures now serve as a benchmark for other clients.

Proper packaging is essential.True

Proper packaging prevents damage during transit and ensures product integrity.

Documentation is secondary.False

Accurate documentation is crucial for efficient logistics and customs processes.

What Customs and Documentation Requirements Must Be Met for Importing Stainless Steel Coils?

Through managing thousands of international shipments, I've learned that proper documentation is crucial for smooth customs clearance. A single missing document can lead to weeks of delays and substantial additional costs.

Importing stainless steel coils requires complete documentation including bills of lading, commercial invoices, packing lists, certificates of origin, material test certificates, and import licenses. Compliance with both export and import country regulations is essential for successful customs clearance.

Let me share insights from our recent experiences helping clients navigate complex customs requirements across different markets. Understanding these requirements has helped us maintain a 98% on-time clearance rate.

Essential Documentation Requirements

My experience with customs clearance has taught me the importance of meticulous documentation preparation. Working with various customs authorities, we've developed a comprehensive checklist that ensures smooth clearance.

| Document Type | Purpose | Required By |

|---|---|---|

| Bill of Lading | Proof of Shipment | Customs/Bank |

| Commercial Invoice | Value Declaration | Customs |

| Packing List | Cargo Details | Customs/Port |

| Certificate of Origin | Origin Proof | Customs |

| Material Test Certificate | Quality Verification | Customs/Buyer |

Customs Compliance and Regulations

Through years of managing international trade, I've developed deep expertise in customs compliance. Recently, we helped David's company navigate complex regulatory changes that could have severely impacted their imports.

Key compliance areas include:

- HS code classification

- Duty calculation and payment

- Import license requirements

- Quality standard compliance

- Anti-dumping regulations

Our experience shows that proactive compliance management can prevent costly delays. For instance, we recently helped a client save $25,000 in potential penalties by ensuring proper HS code classification.

Complete documentation is crucial.True

Proper documentation ensures smooth customs clearance and prevents delays.

Customs compliance is optional.False

Compliance with regulations is mandatory for successful import operations.

Conclusion

Successfully importing stainless steel coils from China requires careful attention to supplier selection, negotiation strategies, logistics planning, and customs compliance. By following these guidelines and learning from real industry experiences, importers can establish efficient and profitable supply chains while minimizing risks and delays.

-

Learn effective strategies for negotiating favorable terms and prices with suppliers to ensure quality and cost-efficiency. ↩

-

Understand the dominance of Chinese manufacturers in the global stainless steel market and their competitive advantages. ↩

-

Gain insights into conducting thorough market research to identify reliable suppliers and market trends. ↩

-

Learn about the quality standards that stainless steel coils must meet to ensure compliance and product reliability. ↩

-

Understand the BIS certification requirements and process to ensure compliance when importing stainless steel into India. ↩