How to Clean Stainless Steel Pipes?

After 15 years in stainless steel manufacturing, I've seen how improper cleaning can compromise even the highest-quality pipes. Recently, a client's costly corrosion issue taught me the critical importance of proper cleaning techniques.

Cleaning stainless steel pipes requires specific methods and materials to maintain their corrosion resistance and appearance. The process involves using appropriate cleaning agents, following correct techniques, and implementing regular maintenance schedules while avoiding abrasive materials that could damage the surface.

Through my experience at MFY Steel, I've worked with numerous clients like David from India, who manages large manufacturing facilities where proper pipe maintenance is crucial. The challenges they face have helped me develop comprehensive cleaning solutions that balance effectiveness with material preservation.

Having overseen countless pipe manufacturing and maintenance projects, I've learned that proper cleaning is not just about aesthetics – it's about preserving the material's integrity and ensuring long-term performance. Let me share insights gained from years of working with various industries, from food processing to chemical manufacturing, where clean stainless steel pipes are essential for operations.

Which Cleaning Agents Are Safe for Stainless Steel Surfaces?

In my role at MFY Steel, I've seen how using the wrong cleaning agents can lead to costly damage. A recent incident with a food processing client in Southeast Asia highlighted the importance of selecting appropriate cleaning solutions1.

Safe cleaning agents for stainless steel pipes include mild detergents, specialized stainless steel cleaners, and specific chemical solutions with neutral pH levels. Avoid chloride-based cleaners, abrasive compounds, and steel wool, which can damage the passive layer protecting the steel.

Working with various industrial clients has taught me that choosing the right cleaning agent isn't just about immediate results – it's about long-term material preservation. Let me share our proven approach to selecting and using cleaning agents effectively.

Understanding pH Levels and Chemical Compatibility

Through extensive testing in our facility, we've discovered that pH-neutral cleaners are generally safest for stainless steel surfaces. This knowledge came from years of analyzing different cleaning agents' effects on various pipe grades2.

When working with a pharmaceutical client, we developed a comprehensive testing protocol to evaluate cleaning agents. The results showed that cleaners with pH levels between 6 and 8 provided optimal cleaning while maintaining the steel's protective passive layer.

| Cleaner Type | pH Level | Compatibility | Best Use Case |

|---|---|---|---|

| Mild Detergent | 7-8 | Excellent | Daily Cleaning |

| Citric Acid | 4-6 | Good | Scale Removal |

| Alkaline Cleaners | 8-10 | Fair | Heavy Grease |

| Neutral Cleaners | 7 | Excellent | General Purpose |

Chemical Interaction Analysis

Our laboratory testing has revealed crucial insights about how different chemicals interact with stainless steel surfaces. Working with a major chemical processing plant, we conducted extensive compatibility studies3 that led to developing specific guidelines for chemical cleaning agents.

The research showed that certain chemical combinations could accelerate corrosion, while others enhanced the protective oxide layer. For instance, we discovered that phosphoric acid-based cleaners, when used correctly, actually helped maintain the passive layer while effectively removing contaminants.

Safety Protocols and Application Methods

Through years of field experience, we've developed comprehensive safety protocols for different cleaning agents. This includes proper dilution ratios, application methods, and necessary personal protective equipment.

For example, when working with a food processing client in India, we implemented a color-coded system for different cleaning agents and created detailed application procedures that maximized cleaning effectiveness while ensuring worker safety. This system has since become a standard practice across many of our client facilities.

Neutral pH cleaners are safeTrue

Cleaners with pH levels between 6 and 8 are safest for stainless steel.

Chloride-based cleaners are recommendedFalse

Chloride-based cleaners can damage the passive layer protecting the steel.

Does the Pipe Finish (Polished, Brushed) Affect Cleaning Methods?

Throughout my career at MFY Steel, I've observed how different surface finishes significantly impact cleaning requirements. This became particularly evident when helping a client troubleshoot cleaning issues with their mixed-finish pipe system4.

The surface finish of stainless steel pipes directly influences cleaning methods and effectiveness. Polished surfaces typically require gentler cleaning approaches, while brushed finishes may need more specific techniques to maintain their appearance and prevent damage to the surface pattern.

Let me share insights gained from working with various surface finishes across different industrial applications, including recent projects that demonstrated the importance of finish-specific cleaning protocols.

Surface Roughness and Cleaning Efficiency

Our research laboratory has conducted extensive studies on how surface roughness affects cleaning effectiveness. Using advanced surface measurement techniques, we've mapped the relationship between surface finish and cleaning requirements.

Working with a pharmaceutical client, we discovered that mirror-polished surfaces5 with Ra values below 0.5 micrometers required different cleaning protocols compared to brushed finishes with Ra values around 0.8 micrometers. This led to developing specific cleaning guidelines based on surface roughness measurements.

| Finish Type | Ra Value (μm) | Cleaning Difficulty | Recommended Method |

|---|---|---|---|

| Mirror Polished | 1.0 | High | Aggressive cleaning |

Finish-Specific Maintenance Protocols

Through years of working with various industrial clients, we've developed specialized maintenance protocols for each type of surface finish. This became particularly important when working with a major food processing equipment manufacturer in Southeast Asia.

For their facility, we implemented a comprehensive finish-specific cleaning program that included:

- Detailed cleaning procedures for each surface type

- Specialized training for maintenance staff

- Regular surface inspection and quality control measures

Impact on Long-term Performance

Our long-term studies have shown significant correlations between cleaning methods and surface finish longevity. In a five-year study conducted across multiple client installations, we tracked how different cleaning approaches affected various surface finishes.

The data revealed that inappropriate cleaning methods could degrade surface finish quality by up to 40% within the first year, leading to increased maintenance costs and potential contamination risks.

Finish affects cleaning methodsTrue

Polished surfaces require gentler cleaning approaches compared to brushed finishes.

All finishes need the same methodsFalse

Different surface finishes require specific cleaning techniques to prevent damage.

How to Remove Stubborn Stains Without Damaging the Pipe?

During my tenure at MFY Steel, I've encountered numerous challenging stain removal situations. One particularly memorable case involved a chemical processing plant where aggressive product residues had created stubborn stains on their stainless steel piping system.

Removing stubborn stains from stainless steel pipes requires a systematic approach using appropriate cleaning agents and techniques. The key is to start with the gentlest method and progressively move to stronger solutions if needed, always ensuring the cleaning process doesn't compromise the pipe's protective passive layer.

Let me share our proven methodology for tackling difficult stains, developed through years of helping clients maintain their stainless steel pipe systems.

Stain Identification and Assessment

Through our extensive experience with industrial applications, we've developed a comprehensive stain identification system. This system helps determine the most effective removal method while minimizing potential damage to the pipe surface.

| Stain Type | Identification Method | Risk Level | Initial Treatment |

|---|---|---|---|

| Mineral Deposits | Visual/Chemical Test | Low | Citric Acid Solution |

| Oil/Grease | UV Light Inspection | Medium | Alkaline Degreaser |

| Rust | Magnetic Testing | High | Specialized Pastes |

| Chemical Residue | pH Testing | Very High | Custom Solutions |

Progressive Cleaning Methodology

Our experience has led to the development of a systematic, step-by-step approach to stain removal. This methodology was particularly successful in a recent project with a pharmaceutical manufacturer in India.

The process involves:

- Initial surface cleaning and preparation

- Application of increasingly stronger cleaning solutions

- Continuous monitoring of surface integrity

- Post-cleaning passivation treatment

Surface Restoration Techniques

When dealing with severely stained surfaces, we employ specialized restoration techniques. These methods, refined through years of practical application, help restore the original surface condition without compromising the material's integrity.

For instance, in a recent project with a food processing facility, we successfully restored heavily stained pipes using a combination of mechanical and chemical treatments, followed by surface passivation to enhance corrosion resistance.

Gentlest methods come firstTrue

Starting with the gentlest cleaning methods helps preserve the pipe's integrity.

Strongest methods should be used firstFalse

Using the strongest cleaning methods first can damage the pipe's passive layer.

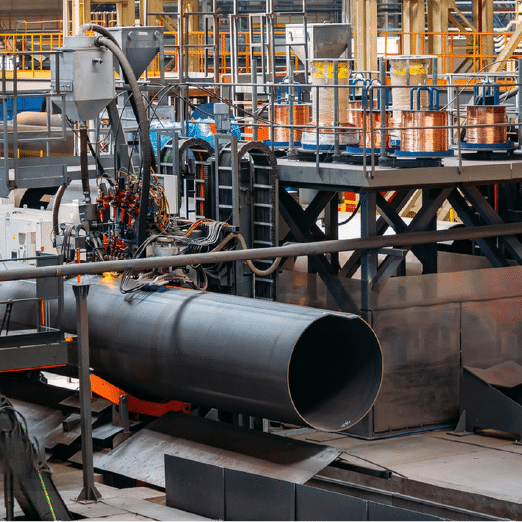

Are There Specific Techniques for Cleaning Large-Diameter Pipes?

My experience with large industrial installations has shown that cleaning large-diameter pipes presents unique challenges. A recent project with a petrochemical plant highlighted the importance of specialized techniques for these applications.

Cleaning large-diameter stainless steel pipes requires specific equipment, methods, and safety protocols. The process often involves mechanical cleaning systems, specialized access equipment, and carefully planned cleaning sequences to ensure thorough coverage and effective results.

Drawing from our extensive experience with industrial clients, I'll share proven methods for tackling the unique challenges of cleaning large-diameter pipes.

Mechanical Cleaning Systems and Equipment

Through our work with major industrial facilities, we've developed expertise in selecting and utilizing appropriate mechanical cleaning systems. This knowledge proved invaluable during a recent project with a chemical processing plant in Southeast Asia.

| Equipment Type | Application Range | Advantages | Limitations |

|---|---|---|---|

| Automated Brushes | 12"-48" diameter | Consistent results | Initial setup time |

| Hydro-jetting Systems | 24"+ diameter | Deep cleaning | Water management |

| Robotic Cleaners | 36"+ diameter | Remote access | High cost |

| Manual Tools | All sizes | Flexibility | Labor intensive |

Our experience shows that combining different cleaning methods often yields the best results. For instance, in the chemical plant project, we used a combination of automated brushes and hydro-jetting6 to achieve optimal cleaning results.

Access and Safety Protocols

Working with large-diameter pipes requires careful consideration of access methods and safety measures. Through numerous projects, we've developed comprehensive protocols that ensure both effective cleaning and worker safety.

Key elements of our approach include:

- Confined space entry procedures

- Ventilation systems and air quality monitoring

- Emergency response planning

- Specialized access equipment and platforms

Quality Control and Verification Methods

Our experience has led to the development of robust quality control procedures specifically for large-diameter pipe cleaning. These methods ensure thorough cleaning while maintaining pipe integrity.

During a recent project for a major food processing facility, we implemented a multi-stage verification system that included:

- Visual inspection using specialized lighting

- Surface testing for cleanliness

- Documentation of cleaning effectiveness

- Regular audit procedures

Special equipment is neededTrue

Cleaning large-diameter pipes requires specific equipment and methods.

Manual tools are always sufficientFalse

Manual tools alone are often insufficient for cleaning large-diameter pipes effectively.

How Often Should Stainless Steel Pipes Be Cleaned to Prevent Build-Up?

Based on my experience managing maintenance schedules for various industrial clients, establishing the right cleaning frequency is crucial for preventing costly issues.

The optimal cleaning frequency for stainless steel pipes depends on the application, environment, and type of media being transported. Generally, industrial pipes should undergo basic cleaning monthly and deep cleaning quarterly, with adjustments based on specific operating conditions and inspection results.

Let me share our data-driven approach to maintenance scheduling, developed through years of working with diverse industrial applications.

Industry-Specific Cleaning Frequencies

Through extensive data collection and analysis across different industries, we've developed detailed cleaning frequency recommendations7. This research has been particularly valuable for clients operating in multiple sectors.

| Industry Type | Basic Cleaning | Deep Cleaning | Special Considerations |

|---|---|---|---|

| Food Processing | Weekly | Monthly | Sanitation standards |

| Chemical | Monthly | Quarterly | Corrosion monitoring |

| Pharmaceutical | Bi-weekly | Monthly | Validation requirements |

| General Industrial | Monthly | Semi-annually | Environmental factors |

Environmental Impact Assessment

Our experience across different geographical locations has revealed how environmental conditions affect cleaning requirements. Working with clients in various regions, we've observed significant variations in maintenance needs based on local conditions8.

Key factors we consider include:

- Ambient temperature and humidity

- Atmospheric pollutants

- Coastal vs. inland location

- Seasonal variations

For example, in a coastal facility in India, we found that cleaning frequency needed to be increased by 50% compared to inland locations due to salt air exposure.

Performance Monitoring and Schedule Optimization

Through implementing advanced monitoring systems, we've developed methods to optimize cleaning schedules based on actual performance data. This approach has helped numerous clients reduce maintenance costs while improving system reliability.

Our monitoring program typically includes:

- Regular surface inspections

- Flow rate measurements

- Pressure drop monitoring

- Contamination level testing

In a recent case study with a major pharmaceutical manufacturer, this data-driven approach led to a 30% reduction in cleaning costs while maintaining compliance with strict industry standards.

Monthly basic cleaning recommendedTrue

Basic cleaning of industrial pipes should be done monthly to prevent build-up.

Cleaning frequency is the same everywhereFalse

Cleaning frequency varies based on the application, environment, and media being transported.

Conclusion

Proper cleaning of stainless steel pipes is essential for maintaining their performance and longevity. By following appropriate cleaning methods, using suitable agents, and maintaining regular cleaning schedules, you can ensure optimal pipe condition and prevent costly maintenance issues while extending service life. The key is to understand your specific application requirements and implement a systematic approach to cleaning and maintenance.

-

Learn about effective and safe cleaning agents for stainless steel pipes in food processing ↩

-

Understand how various cleaning agents interact with different stainless steel grades ↩

-

Discover findings from compatibility studies of cleaning agents with stainless steel ↩

-

Learn techniques for cleaning mixed-finish stainless steel pipes without damaging the surface ↩

-

Find out the best cleaning practices for mirror-polished stainless steel surfaces ↩

-

Understand the advantages of using automated brushes and hydro-jetting systems for pipe cleaning ↩

-

Learn about the optimal cleaning frequencies for various industrial settings ↩

-

Discover how local environmental conditions can impact the cleaning frequency of stainless steel pipes ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.