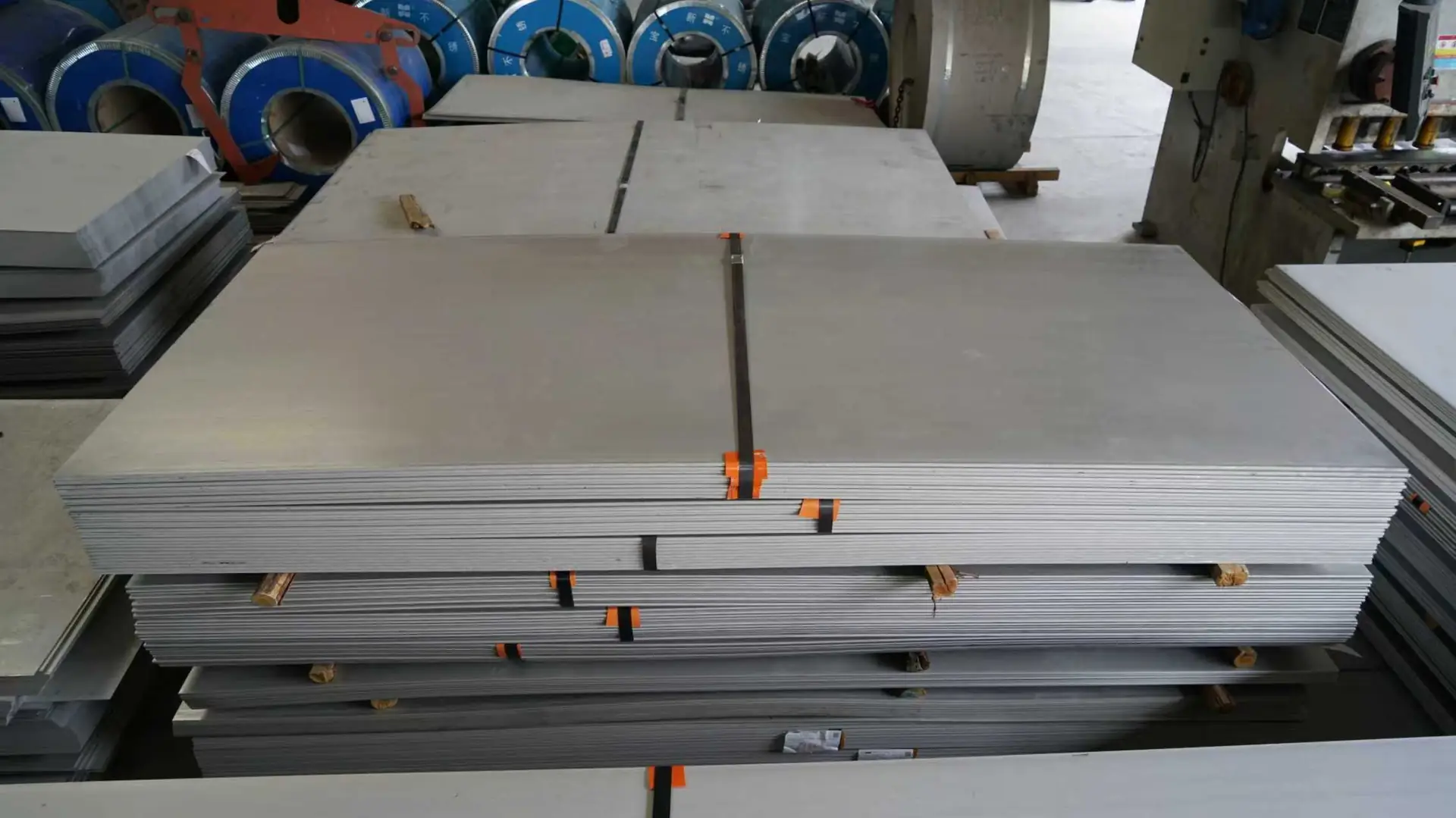

Precision Stainless Steel Cut-to-Length Services (For Sheets)

Standard-sized sheets create waste and slow down your projects. This inefficiency costs you money and time. Precision cut-to-length services deliver exact specifications, boosting your productivity and bottom line.

Precision stainless steel cut-to-length (CTL) services are essential because they provide customized sheet sizes directly from coils. This minimizes material waste, reduces production lead times, and aligns perfectly with the demands of lean manufacturing, enhancing overall project efficiency and cost-effectiveness for modern industries.

In my role as Global Business Director at MFY, I’ve seen a fundamental shift in the industry. It's no longer just about sourcing stainless steel; it's about sourcing it intelligently. The demand for materials that fit seamlessly into automated, high-efficiency production lines has skyrocketed. This is where precision cut-to-length services become a game-changer. It’s about moving from a one-size-fits-all approach to a tailored, strategic partnership that drives value from the very first cut. Let's explore how this process works and why it's so critical for your success.

How do you assess the requirements for cut-to-length stainless steel sheets?

Miscalculating your sheet needs leads to costly errors. Guesswork causes delays and budget overruns. A systematic assessment ensures you get the right material, size, and finish every time.

To assess requirements, you must define the application's specific needs, including the stainless steel grade, thickness, width, length, and required tolerances. Also, consider the finish, edge condition, and any secondary processing needed to ensure the final product meets all project specifications.

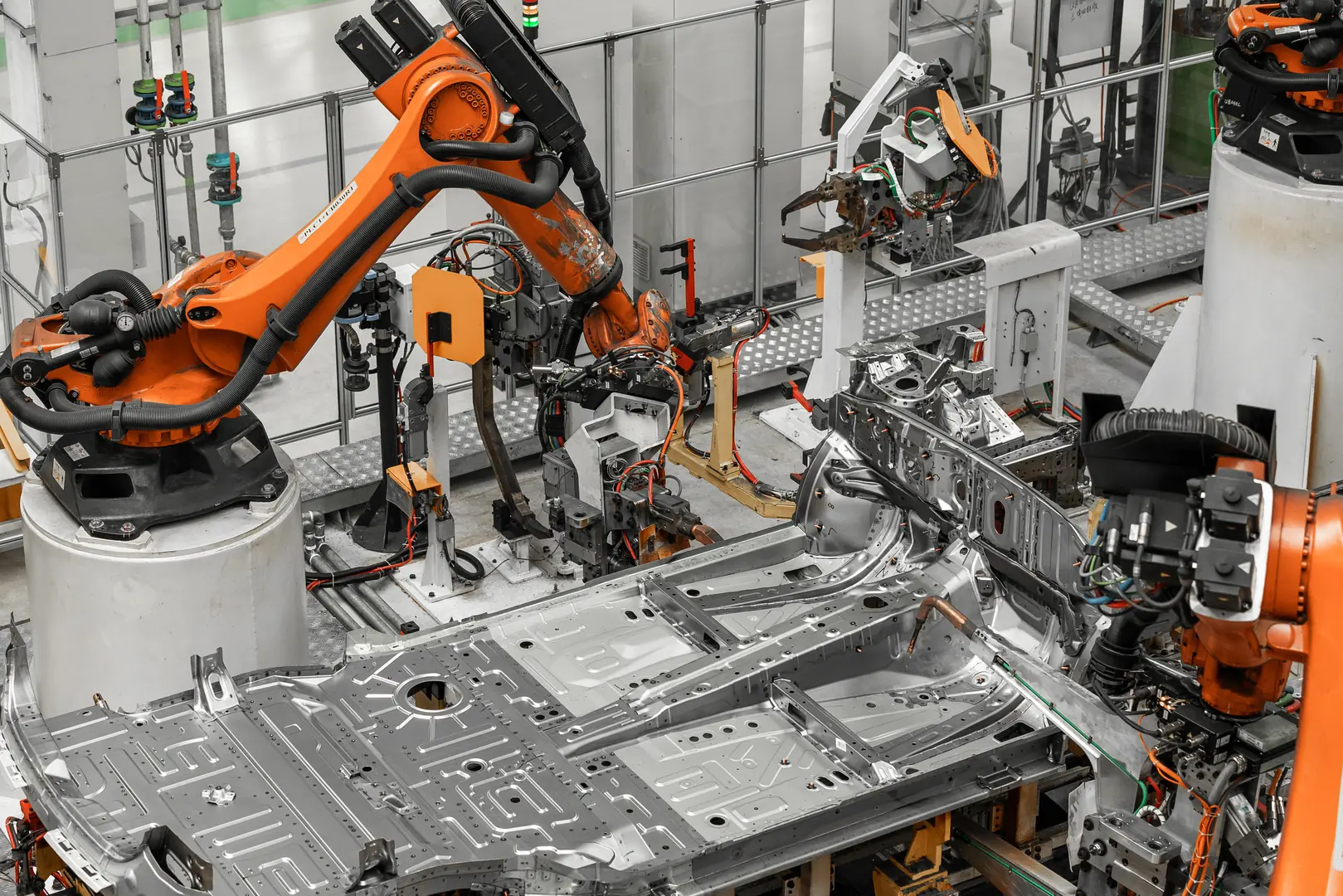

The assessment phase is where the principles of lean manufacturing truly begin. Getting this right prevents the most significant source of waste: ordering the wrong material. I remember a client in the automotive sector who was experiencing high scrap rates. By working with them to reassess their initial requirements, we discovered that a slightly different sheet dimension could dramatically improve their stamping process efficiency. This simple change, identified during a thorough assessment, saved them thousands. It’s not just about what you need; it’s about deeply understanding why you need it. This deeper analysis allows for optimization that ripples through your entire production cycle. At MFY, we treat this as a collaborative process, because your success is directly tied to the precision of our materials.

Material Specifications

The first layer of assessment is the material itself. You must go beyond just the grade of stainless steel. Think about the specific demands of the end-use environment. Will it be exposed to corrosive elements? Does it need to withstand high temperatures? This determines the grade, but also the required surface finish. A 2B finish[^1] is very different from a No. 4 brushed finish, and choosing the wrong one can impact both performance and aesthetics.

Operational Considerations

Next, we look at your operational needs. How will the sheets be handled and processed in your facility? This impacts specifications for flatness, edge condition (e.g., slit edge vs. mill edge), and packaging. We also need to define tolerances with extreme clarity. How much deviation in length, width, and thickness is acceptable? Tighter tolerances often require more advanced machinery and quality control, which is a key part of the value we provide.

| Assessment Parameter | Key Question to Ask | Why It Matters |

|---|---|---|

| Grade & Finish | What is the end-use application and environment? | Determines corrosion resistance, strength, and aesthetics. |

| Dimensions & Tolerance | What are the exact length, width, and thickness needed? | Minimizes scrap and ensures a perfect fit in manufacturing. |

| Flatness | Will the sheet be used in laser cutting or stamping? | Poor flatness can cause machine jams and inaccurate parts. |

| Edge Condition | Is a clean, burr-free edge required for safety or fit? | Impacts handling safety and how parts assemble. |

What equipment is essential for precision cut-to-length services?

Outdated machinery produces inconsistent cuts. This poor quality compromises your final product. Modern, integrated CTL lines are the solution for achieving the precision your projects demand.

Essential equipment for a precision cut-to-length line includes a decoiler, a leveler to ensure flatness, a high-precision shear or laser cutter, and a stacking system. Advanced lines also integrate digital controls and sensors for automation and quality monitoring, which are crucial for accuracy.

The difference between a standard cut and a precision cut comes down to the technology. At MFY, our investment in state-of-the-art CTL lines is a direct response to the market's need for greater agility and reliability. These are not just individual machines; they are fully integrated systems where each component communicates with the next. This digital integration, a core driver of modern manufacturing, allows us to make real-time adjustments, monitor quality continuously, and deliver a level of consistency that was impossible a decade ago. This technological advantage is what allows us to confidently supply materials for even the most demanding applications, from medical devices to aerospace components. It’s a clear example of how investing in advanced capabilities is crucial for maintaining a competitive edge in today's global market.

The Uncoiling and Leveling Stage

The process starts with robust equipment designed for control. The decoiler must handle massive coils without damaging the material, while the leveler is arguably the most critical component for quality. It uses a series of precisely calibrated rollers to remove "coil set[^2]"—the natural curve of the steel—to produce a perfectly flat sheet. Without a high-quality leveler, no amount of cutting precision matters.

The Cutting and Stacking Stage

This is where precision is delivered. High-speed shears with hardened blades make clean, square cuts based on digital inputs. For even more complex shapes or delicate materials, laser cutters offer unparalleled accuracy. After the cut, an automated stacking system carefully places the sheets onto a pallet, often with protective layering, to prevent surface scratches. This automation ensures consistency and protects the final product.

| Equipment | Primary Function | Impact on Precision |

|---|---|---|

| Decoiler | Securely holds and unspools the master coil. | Provides consistent tension for smooth feeding. |

| Leveler | Flattens the steel by removing coil-set. | Critical for ensuring the final sheet is perfectly flat. |

| High-Precision Shear | Cuts the flattened steel to the specified length. | Determines the final dimensional accuracy of the sheet. |

| Stacker | Neatly stacks the finished sheets for packaging. | Prevents surface damage and ensures safe handling. |

What is the step-by-step guide to performing cut-to-length operations on stainless steel sheets?

The cutting process seems complex. A mistake at any stage can ruin an entire coil. Following a clear, systematic process ensures a smooth operation and perfect results.

The process begins with loading a stainless steel coil onto the decoiler. The material is then fed through a leveler to remove coil-set. Next, it moves to the shear, where it is cut to a pre-programmed length. Finally, the cut sheets are stacked for packaging.

Understanding the process flow is key to appreciating the value it creates. Each step is a control point, an opportunity to ensure the final product meets the customer's exact needs. The beauty of a modern, digitized CTL line is that these steps flow together seamlessly. An operator inputs the required length and quantity into a central control unit, and the system takes over. This automation doesn't just improve speed; it enhances precision by removing the potential for human error. It’s this seamless integration from raw material to finished product that allows suppliers like us to offer reduced lead times and highly customized solutions, directly addressing the core needs of agile manufacturing and construction firms.

From Coil to Flat Sheet

The first half of the journey is about preparation.

- Coil Loading: A master coil of stainless steel, which can weigh several tons, is carefully loaded onto the decoiler's mandrel.

- Threading: The leading edge of the steel is fed into the line, passing through pinch rolls that guide it forward.

- Leveling: The steel runs through the multi-roll leveler. The operator makes micro-adjustments to the roller pressure to achieve perfect flatness, a skill that requires significant experience.

Precision Cutting and Final Handling

The second half is about execution.

- Feeding and Measuring: The flattened strip is fed forward. A high-precision encoder wheel or laser sensor measures the exact length of material that passes through.

- Cutting: Once the pre-programmed length is reached, the line pauses for a fraction of a second, and the shear activates, making a clean, instantaneous cut.

- Stacking and Packaging: The freshly cut sheet travels down a conveyor and is gently placed onto a stack. The process repeats until the order is complete, at which point the stack is secured for shipment.

How do you ensure quality and precision in stainless steel cut-to-length processes?

Inconsistent cuts can derail your entire project. These defects lead to rejection and costly rework. A robust quality control system is the only way to guarantee precision every time.

Quality is ensured through a combination of advanced machinery with tight tolerances, regular calibration, and in-process monitoring using sensors and vision systems. Post-cut inspections for dimensional accuracy, flatness, and surface finish are also critical steps to guarantee the final product meets exact specifications.

Quality isn't a final inspection; it's a continuous process embedded in every step. This is a core value at MFY. We had a client in the food processing equipment industry who required absolute perfection in their sheet dimensions to ensure their welded seams were flawless. Our integrated quality checks, which combine automated sensor readings with manual verifications by our skilled technicians, were the reason they chose us. Our system flagged a minor calibration drift in the shear before it became a problem, preventing an entire batch from being cut out of tolerance. This proactive approach to quality control is what builds trust and turns a supplier into a long-term partner. It demonstrates that we are committed to protecting our clients' production processes and final product integrity.

Technological Safeguards

Modern CTL lines are equipped with an array of sensors that act as the first line of defense. Laser micrometers check thickness in real-time, while vision systems can inspect for surface defects. The digital control system constantly monitors the encoder that measures length, ensuring every cut is identical to the last. These automated systems provide a level of consistency that is simply not possible with older equipment.

Human Expertise and Process Control

Technology is powerful, but it must be managed by skilled professionals. Our operators and quality control technicians are trained to perform regular checks throughout a production run. They use calibrated tools like micrometers, calipers, and tape measures to verify the machine's output against the customer's specifications. This blend of automated monitoring and human oversight creates a comprehensive quality assurance system.

| Quality Check | Method | Tolerance Goal |

|---|---|---|

| Length Accuracy | Digital Encoder & Manual Tape Measure | +/- 0.5 mm |

| Width Accuracy | Manual Caliper Measurement | +/- 0.5 mm |

| Diagonal Difference | Manual Tape Measure (for squareness) | < 1.0 mm |

| Surface Inspection | Visual Check & Automated Vision System | No scratches or defects |

What are the best practices for maintaining machinery used in cut-to-length services?

Machine downtime unexpectedly halts production. These delays are expensive and frustrating. A proactive maintenance schedule keeps your equipment running smoothly and reliably, protecting your investment.

Best practices include a regular preventative maintenance schedule, daily checks of key components like shear blades and leveler rolls, proper lubrication, and keeping the equipment clean. Staff training on proper operation and immediate reporting of issues are also essential for longevity and performance.

We see our machinery not as a depreciating asset, but as the engine of our precision and reliability. Therefore, maintenance is not a chore; it is a critical business function that protects our ability to serve our clients. A well-maintained machine is a precise machine. Worn shear blades lead to burrs and inaccurate cuts. Dirty leveler rolls can transfer debris onto the steel's surface, ruining the finish. By adhering to a strict preventative maintenance schedule, we ensure that the quality we promise is the quality we deliver, every single day. This commitment to operational excellence is foundational to our vision of being the leading international trade and service brand in China’s stainless steel industry.

Preventative Maintenance Schedules

A structured approach is essential. Maintenance tasks should be broken down into daily, weekly, and monthly schedules. Daily tasks are simple checks that the operator can perform, while monthly tasks are more in-depth procedures handled by a dedicated maintenance team. This proactive approach catches small problems before they become major, costly failures.

The Role of Operator Training

The machine operator is the first line of defense. Proper training ensures they not only run the machine efficiently but also understand its sounds and behaviors. A well-trained operator can often detect a potential issue, like a change in motor sound or a slight vibration, long before it causes a breakdown. Empowering them to report these observations immediately is a key part of an effective maintenance culture.

| Frequency | Maintenance Task Example | Purpose |

|---|---|---|

| Daily | Clean leveler rolls and inspect shear blades. | Prevents surface contamination and ensures clean cuts. |

| Weekly | Check and top up lubrication reservoirs. | Reduces friction and wear on moving parts. |

| Monthly | Calibrate measuring encoders and sensors. | Guarantees continued dimensional accuracy. |

| Annually | Full mechanical and electrical inspection. | Comprehensive health check of the entire line. |

Conclusion

Precision cut-to-length services are no longer a luxury; they are a strategic necessity. By embracing this technology, you reduce waste, accelerate timelines, and build a more agile, competitive, and sustainable supply chain. MFY is here to help you make that transition.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.