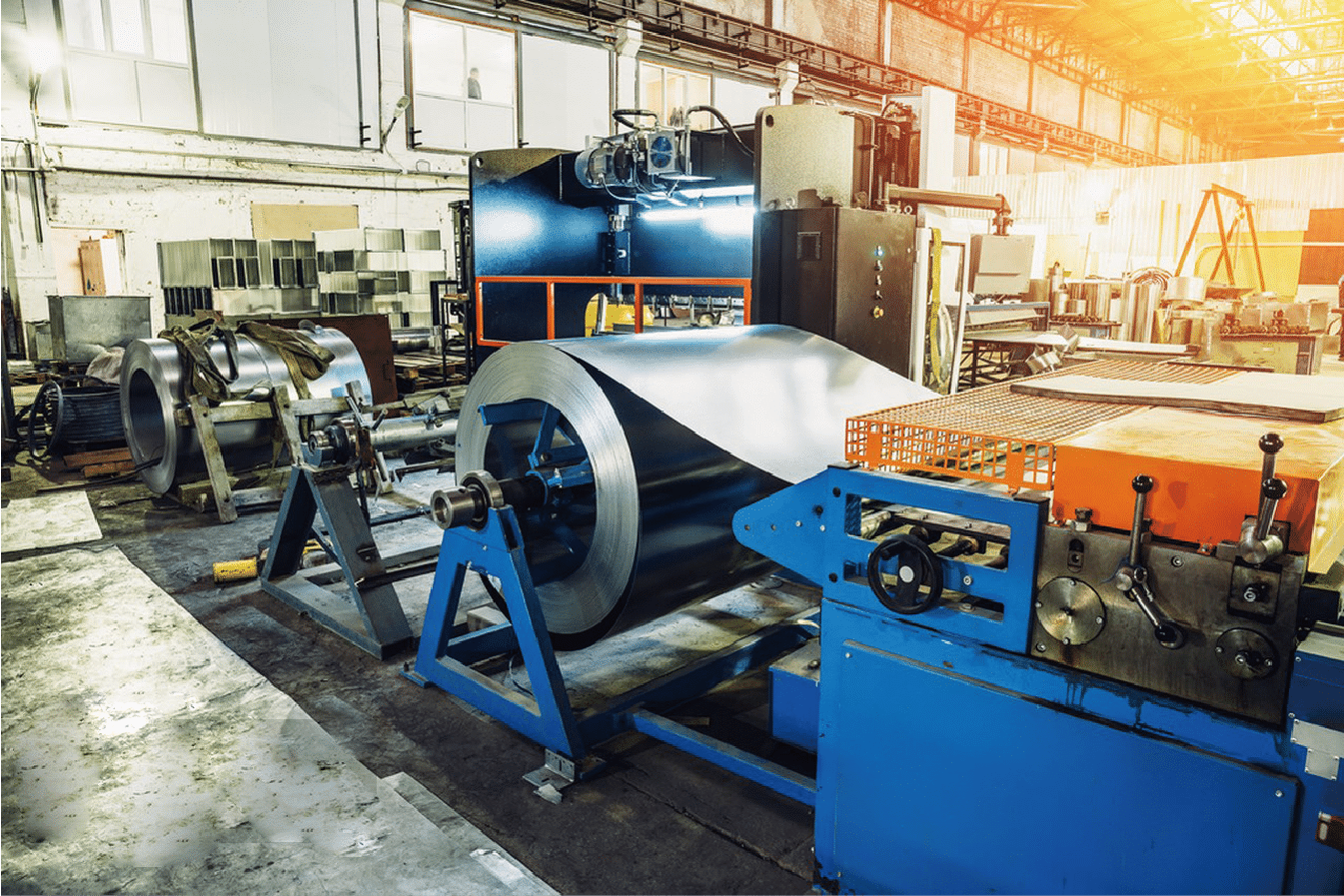

After 15 years in the stainless steel industry, I've witnessed countless projects transformed by the remarkable properties of stainless steel sheets. Their versatility continues to amaze both manufacturers and end-users alike.

The advantages of stainless steel sheets extend far beyond their striking appearance. These versatile materials offer exceptional corrosion resistance1, remarkable durability, sustainable characteristics, and low maintenance requirements, making them ideal for numerous industrial and architectural applications.

Transition paragraph: As a leading manufacturer of stainless steel products, I've collaborated with clients across various industries, from construction to food processing. Their experiences consistently highlight how stainless steel sheets outperform alternative materials in demanding applications. Let me share some insights about why these materials have become indispensable in modern manufacturing and construction.

Dive-Deeper paragraph: The superior performance of stainless steel sheets stems from their unique metallurgical properties. The addition of chromium2 (at least 10.5%) creates a self-healing passive layer that provides exceptional corrosion resistance. When working with clients like David Zhang, who operates a large manufacturing facility in India, I've observed how this inherent corrosion resistance significantly reduces maintenance costs and extends product lifespan. Furthermore, the material's high strength-to-weight ratio3, temperature resistance, and aesthetic appeal make it a versatile choice for diverse applications, from industrial equipment to architectural facades.

How Does Corrosion Resistance Make Stainless Steel Sheets Desirable?

In my experience supplying stainless steel sheets to humid coastal regions in Southeast Asia, corrosion resistance has consistently been the primary factor driving material selection decisions.

Stainless steel sheets resist corrosion through a self-healing chromium oxide layer4 that forms on their surface. This passive film provides continuous protection against rust and degradation, even in challenging environments like coastal areas and chemical processing facilities.

Transition paragraph: Last year, I worked with a major food processing plant in India that was struggling with rapid equipment deterioration due to constant exposure to cleaning chemicals and salt. Their switch to grade 316 stainless steel sheets resulted in significantly reduced maintenance costs and improved operational efficiency. This case exemplifies why understanding corrosion resistance is crucial for making informed material choices.

The Science Behind Corrosion Resistance

The exceptional corrosion resistance of stainless steel sheets stems from their unique chemical composition. When chromium in the steel reacts with oxygen in the air, it forms an invisible protective layer that continuously regenerates when damaged. This self-healing property ensures long-term protection against various forms of corrosion.

Environmental Impact on Corrosion Resistance

Different environments require different grades of stainless steel to ensure optimal corrosion resistance. Through our extensive testing and field experience, we've developed a comprehensive understanding of grade selection based on environmental conditions.

| Environment Type | Recommended Grade | Corrosion Resistance Level |

|---|---|---|

| Indoor/Mild | 304 | Excellent |

| Coastal/Marine | 316 | Superior |

| Chemical Processing | 317L | Outstanding |

| Food Processing | 316L | Superior |

Cost-Benefit Analysis of Corrosion Resistance

While the initial investment in stainless steel sheets may be higher than alternative materials, the long-term cost benefits are substantial. For instance, a client in the Middle East saved approximately 40% on maintenance costs over five years by choosing grade 316 stainless steel for their chemical processing equipment instead of carbon steel with protective coating.

Stainless steel resists corrosion.True

The self-healing chromium oxide layer prevents rust and degradation.

Stainless steel sheets last for only a few years.False

They provide long-term protection and reduce maintenance costs.

Which Industries Benefit From the Strength and Durability of Stainless Steel?

Throughout my career supplying stainless steel sheets to global markets, I've witnessed their transformative impact across numerous industries. The material's exceptional strength-to-weight ratio and durability continue to drive innovation in manufacturing and construction.

Stainless steel sheets provide crucial benefits to industries including food processing5, chemical manufacturing, construction, automotive, and healthcare. Their high strength, impact resistance, and ability to maintain structural integrity under extreme conditions make them invaluable.

Transition paragraph: Recently, I collaborated with a major automotive parts manufacturer in India who was seeking materials that could withstand high-stress environments while maintaining precise tolerances. Their experience demonstrates how stainless steel's strength and durability can revolutionize manufacturing processes and product quality. Let me share some insights about how different industries leverage these properties to their advantage.

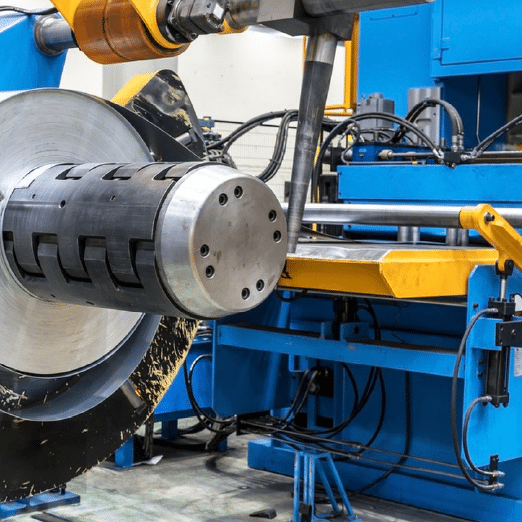

Manufacturing and Heavy Industry Applications

In the manufacturing sector, stainless steel sheets have become indispensable due to their exceptional mechanical properties. One of our clients, a large-scale industrial equipment manufacturer, replaced their traditional carbon steel components with 304 stainless steel, resulting in a 30% increase in equipment lifespan and significantly reduced maintenance requirements.

The material's high yield strength, typically ranging from 200-300 MPa for austenitic grades, enables it to withstand substantial mechanical stress without deformation. This property is particularly valuable in heavy machinery components and structural applications where maintaining dimensional stability is crucial.

Construction and Infrastructure

The construction industry has embraced stainless steel sheets for their outstanding structural integrity and long-term performance. Working with several major construction projects in Southeast Asia, I've observed how stainless steel's durability provides superior value in challenging environments.

| Application | Grade Used | Key Benefits |

|---|---|---|

| Structural Support | 316 | High load capacity, corrosion resistance |

| Facade Cladding | 304 | Weather resistance, aesthetic appeal |

| Industrial Roofing | 430 | Cost-effective durability |

| Bridge Components | 2205 | Superior strength, stress resistance |

Food and Beverage Processing

The food and beverage industry relies heavily on stainless steel's durability combined with its hygienic properties. Through our work with food processing facilities, we've documented how grade 316L stainless steel maintains its structural integrity even under aggressive cleaning regimes and constant exposure to various food acids and sanitizing chemicals.

Stainless steel has high strength.True

Its high yield strength makes it valuable in heavy industry.

Stainless steel is rarely used in construction.False

It is widely used due to its structural integrity and durability.

Are Stainless Steel Sheets Environmentally Friendly?

As someone deeply involved in stainless steel production, I've witnessed a growing emphasis on environmental sustainability among our clients. The material's recyclability and long lifespan make it an increasingly attractive option for environmentally conscious projects.

Stainless steel sheets are highly sustainable materials, with a recycling rate exceeding 85% globally. Their long service life, minimal maintenance requirements, and complete recyclability contribute to reduced environmental impact and resource conservation.

Transition paragraph: Last month, I advised a manufacturing client in India who was seeking to improve their environmental credentials while maintaining production efficiency. Their transition to using recycled stainless steel6 content not only reduced their carbon footprint but also proved cost-effective in the long run. This experience exemplifies the growing synergy between environmental responsibility and business success.

Lifecycle Assessment and Sustainability

Our analysis of stainless steel's lifecycle reveals impressive environmental credentials. The material's ability to be recycled indefinitely without quality degradation sets it apart from many alternatives. Through our manufacturing processes, we've achieved a recycled content rate of over 60% in our stainless steel production.

Energy Efficiency and Carbon Footprint

Modern stainless steel production methods have significantly reduced energy consumption and emissions. Working with our global partners, we've implemented energy-efficient technologies that have decreased our carbon footprint by approximately 25% over the past decade.

| Sustainability Aspect | Impact Measure | Industry Average |

|---|---|---|

| Recycling Rate | >85% | 75% |

| Lifespan | 30+ years | 15-20 years |

| Recycled Content | 60-85% | 40-60% |

| Energy Savings | 25% reduction | 15% reduction |

Resource Conservation Benefits

The durability and longevity of stainless steel sheets directly contribute to resource conservation. Through our client case studies, we've documented how stainless steel installations typically last 3-4 times longer than alternative materials, reducing the need for replacement and conserving raw materials.

Stainless steel is highly recyclable.True

Its recycling rate exceeds 85% globally, reducing environmental impact.

Stainless steel has a short lifespan.False

It typically lasts over 30 years, reducing the need for replacements.

Does Ease of Maintenance and Cleaning Add Value?

Drawing from countless conversations with facility managers and maintenance teams, I can confidently say that the easy maintenance of stainless steel sheets significantly reduces operational costs and downtime.

Stainless steel sheets require minimal maintenance, featuring simple cleaning procedures and resistance to harsh chemicals. This characteristic makes them ideal for hygiene-critical environments and reduces long-term operational costs compared to alternative materials.

Transition paragraph: Recently, I consulted with a food processing plant manager who was struggling with high maintenance costs for their equipment surfaces. After switching to grade 316 stainless steel sheets, they reported a 40% reduction in cleaning time and significant savings on cleaning agents. Their experience demonstrates how proper material selection can transform maintenance operations.

Cost-Effective Maintenance Procedures

Through years of working with industrial clients, I've observed how stainless steel's maintenance advantages translate into substantial cost savings. The material's non-porous surface prevents bacterial growth and resists staining, simplifying cleaning protocols and reducing the need for aggressive cleaning agents.

Industry-Specific Maintenance Benefits

Different sectors benefit from stainless steel's easy maintenance characteristics in unique ways. For instance, healthcare facilities appreciate the material's ability to withstand frequent sanitization, while food processing plants value its resistance to acidic food products and cleaning chemicals.

| Industry | Maintenance Advantage | Cost Savings |

|---|---|---|

| Healthcare | Easy sanitization | 30% reduction in cleaning costs |

| Food Processing | Chemical resistance | 40% reduction in maintenance time |

| Chemical Plants | Minimal corrosion care | 50% longer service intervals |

| Architecture | Simple surface cleaning | 35% lower upkeep expenses |

Long-Term Value Proposition

The initial investment in stainless steel sheets is offset by reduced maintenance requirements over time. Our data shows that properly maintained stainless steel installations can last decades with minimal intervention, providing excellent return on investment.

Stainless steel is easy to maintain.True

Its non-porous surface simplifies cleaning and reduces costs.

Stainless steel is high-maintenance.False

It requires minimal maintenance, reducing long-term operational costs.

How Do Aesthetics Factor Into the Appeal of Stainless Steel Sheets?

In my experience working with architects and designers, the visual appeal of stainless steel sheets often becomes a deciding factor in material selection, particularly for visible applications.

Stainless steel sheets offer versatile aesthetic options through various surface finishes, from mirror-like polish to brushed textures. Their modern appearance, combined with durability, makes them popular in architectural applications and high-end commercial spaces.

Transition paragraph: Just last month, I collaborated with an architectural firm designing a modern office complex in Southeast Asia. Their decision to use stainless steel facades wasn't just about durability – they were equally impressed by the material's ability to create striking visual effects and maintain its appearance over time.

Surface Finish Options and Applications

The versatility of stainless steel's appearance comes from various available surface finishes. Through our manufacturing processes, we can achieve everything from highly reflective mirror finishes to subtle, matt textures. Each finish serves specific aesthetic and functional purposes.

Light Interaction and Visual Impact

One of the most compelling aspects of stainless steel sheets is their interaction with light. Modern architectural designs often leverage this property to create dynamic visual effects that change throughout the day. For example, a recent project in Dubai utilized brushed finish panels to create subtle light patterns that enhanced the building's appearance.

| Finish Type | Visual Effect | Common Applications |

|---|---|---|

| Mirror Polish | High reflection | Decorative panels |

| Brushed | Subtle metallic | Commercial facades |

| Patterned | Textured look | Interior design |

| Matte | Non-reflective | Industrial aesthetic |

Design Flexibility and Modern Appeal

The ability to combine different finishes and patterns allows for creative design solutions. Our experience shows that stainless steel's modern appearance continues to attract architects and designers looking to create contemporary spaces that maintain their appeal over time.

Stainless steel is aesthetically versatile.True

Various finishes provide different visual effects for design flexibility.

Stainless steel has limited design options.False

Its finishes range from mirror-like polish to matte textures.

Conclusion

The advantages of stainless steel sheets – from corrosion resistance and durability to easy maintenance and aesthetic appeal – make them an exceptional choice for various applications. Their combination of practical benefits and visual appeal continues to drive their adoption across industries.

-

Learn about the benefits of corrosion resistance in various applications ↩

-

Discover how chromium contributes to the properties of stainless steel ↩

-

Understand the benefits of high strength-to-weight ratio in stainless steel applications ↩

-

Learn about the self-healing properties of the chromium oxide layer in stainless steel ↩

-

Explore the advantages of using stainless steel in the food processing industry ↩

-

Discover how recycled stainless steel contributes to sustainability ↩