In industrial applications, pipe failure due to corrosion or material degradation can lead to costly downtime, safety hazards, and environmental risks.

Stainless steel is preferred for pipe manufacturing due to its exceptional corrosion resistance1, high strength-to-weight ratio, temperature tolerance, and hygienic properties, making it ideal for demanding industrial applications.

The selection of piping materials significantly impacts system reliability and lifecycle costs. This guide explores why stainless steel has become the material of choice for critical piping applications across various industries.

Modern industrial processes demand piping materials that can withstand increasingly challenging conditions while maintaining safety and efficiency. Stainless steel's unique properties make it exceptionally well-suited for these demanding requirements.

What Are the Corrosion-Resistant Properties of Stainless Steel Pipes?

Corrosion resistance is perhaps the most significant advantage of stainless steel pipes, protecting against various forms of degradation.

The corrosion resistance of stainless steel pipes comes from their chromium content (minimum 10.5%)2, which forms a self-healing passive oxide layer that protects against environmental degradation.

Types of Corrosion Protection

| Corrosion Type | Protection Mechanism | Effectiveness |

|---|---|---|

| General Corrosion | Passive oxide layer | Excellent |

| Pitting | Chromium/Molybdenum content | Very good |

| Stress Corrosion | Nickel content | Grade dependent |

Environmental Resistance

Key resistance factors:

- Chemical exposure

- Atmospheric conditions

- Temperature effects

- pH tolerance

Grade-Specific Protection

| Grade | Corrosion Resistance | Typical Environment |

|---|---|---|

| 304/304L3 | Good general resistance | Mild environments |

| 316/316L4 | Enhanced chloride resistance | Marine/chemical |

| 22055 | Superior resistance | Aggressive media |

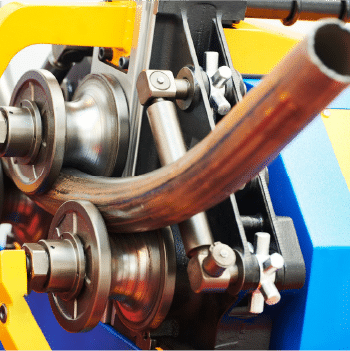

How Does Stainless Steel Enhance the Strength and Durability of Pipes?

Stainless steel pipes offer exceptional mechanical properties that ensure long-term reliability.

The combination of high tensile strength, yield strength, and ductility makes stainless steel pipes capable of handling various mechanical stresses while maintaining structural integrity.

Mechanical Properties

| Property | Value Range | Benefit |

|---|---|---|

| Tensile Strength6 | 515-1100 MPa | High load capacity |

| Yield Strength7 | 205-910 MPa | Deformation resistance |

| Elongation | 30-60% | Good formability |

Strength Characteristics

Important strength factors:

- Impact resistance

- Fatigue strength

- Hardness

- Work hardening

Performance Comparison

| Material | Strength-to-Weight | Durability Rating |

|---|---|---|

| Stainless Steel | Excellent | Superior |

| Carbon Steel | Good | Moderate |

| Plastic | Poor | Limited |

Why Is Stainless Steel Ideal for High-Pressure and High-Temperature Applications?

Stainless steel's superior performance under extreme conditions makes it ideal for demanding applications.

Stainless steel pipes maintain their strength and integrity at temperatures ranging from cryogenic to over 800°C8, while handling high pressures due to their excellent mechanical properties.

Temperature Performance

| Temperature Range | Performance Characteristics | Typical Applications |

|---|---|---|

| Cryogenic | Maintains ductility | LNG transport |

| Room temperature | Full strength | General purpose |

| High temperature | Retains properties | Steam systems |

Pressure Capabilities

Key pressure considerations:

- Schedule selection

- Grade properties

- Temperature effects

- Safety factors

Application Requirements

| Application | Temperature Range | Pressure Rating |

|---|---|---|

| Steam Systems | Up to 650°C | High |

| Cryogenic | Below -196°C | Moderate |

| Chemical Processing | -100 to 400°C | Very high |

What Makes Stainless Steel Pipes Suitable for Hygienic and Food-Grade Applications?

Stainless steel's inherent cleanliness and ease of sanitization make it ideal for hygienic applications.

The smooth, non-porous surface of stainless steel pipes prevents bacterial growth and allows for easy cleaning, meeting strict hygiene standards in food, beverage, and pharmaceutical industries.

Hygienic Properties

| Feature | Benefit | Industry Impact |

|---|---|---|

| Non-porous surface | Prevents bacterial growth | Food safety |

| Easy cleaning | Maintains sanitation | Reduced contamination |

| Chemical resistant | No taste transfer | Product quality |

Industry Standards Compliance

Essential compliance areas:

- FDA requirements

- 3-A Sanitary Standards

- ASME BPE

- ISO standards

Surface Finish Options

| Finish Type | Ra Value | Application |

|---|---|---|

| 2B | 0.1-0.5μm | General purpose |

| BA | <0.1μm | Dairy/beverage |

| Electropolished | <0.25μm | Pharmaceutical |

How Does the Longevity and Low Maintenance of Stainless Steel Pipes Reduce Costs?

The long-term economic benefits of stainless steel pipes often outweigh their higher initial cost.

Stainless steel pipes typically last 50+ years with minimal maintenance, resulting in lower lifecycle costs compared to alternative materials that require frequent replacement or maintenance.

Lifecycle Cost Analysis

| Cost Factor | Stainless Steel | Alternative Materials |

|---|---|---|

| Initial Cost | Higher | Lower |

| Maintenance | Minimal | Regular |

| Service Life | 50+ years | 15-30 years |

Maintenance Requirements

Cost-saving factors:

- Minimal inspection needs

- Reduced cleaning costs

- Lower replacement rate

- Less downtime

Economic Benefits

| Benefit Type | Short-term Impact | Long-term Impact |

|---|---|---|

| Installation | Higher cost | One-time expense |

| Maintenance | Lower cost | Significant savings |

| Replacement | Rare | Major cost avoidance |

Conclusion

Stainless steel's combination of corrosion resistance, strength, temperature tolerance, and hygienic properties makes it the optimal choice for critical piping applications.

-

Learn about the elements that contribute to stainless steel's corrosion resistance ↩

-

Discover the role of chromium in forming a protective layer on stainless steel ↩

-

Understand when to use 304 stainless steel in applications ↩

-

Explore why 316 stainless steel resists chloride corrosion ↩

-

Learn about the superior corrosion resistance of 2205 stainless steel ↩

-

Compare tensile strength values of stainless steel and other materials ↩

-

Understand the importance of yield strength in pipe applications ↩

-

Discover how stainless steel maintains performance under extreme temperatures ↩