In industrial applications, choosing the wrong pipe material can lead to costly failures, corrosion issues, and safety hazards. Understanding stainless steel pipes is crucial for making informed decisions.

Stainless steel pipes are corrosion-resistant tubular products containing at least 10.5% chromium, available in various grades and sizes. They offer superior durability, hygiene, and performance in demanding environments.

When selecting piping materials for critical applications, engineers and procurement specialists must consider multiple factors. This guide explores the essential characteristics, materials, and applications of stainless steel pipes to help you make informed decisions.

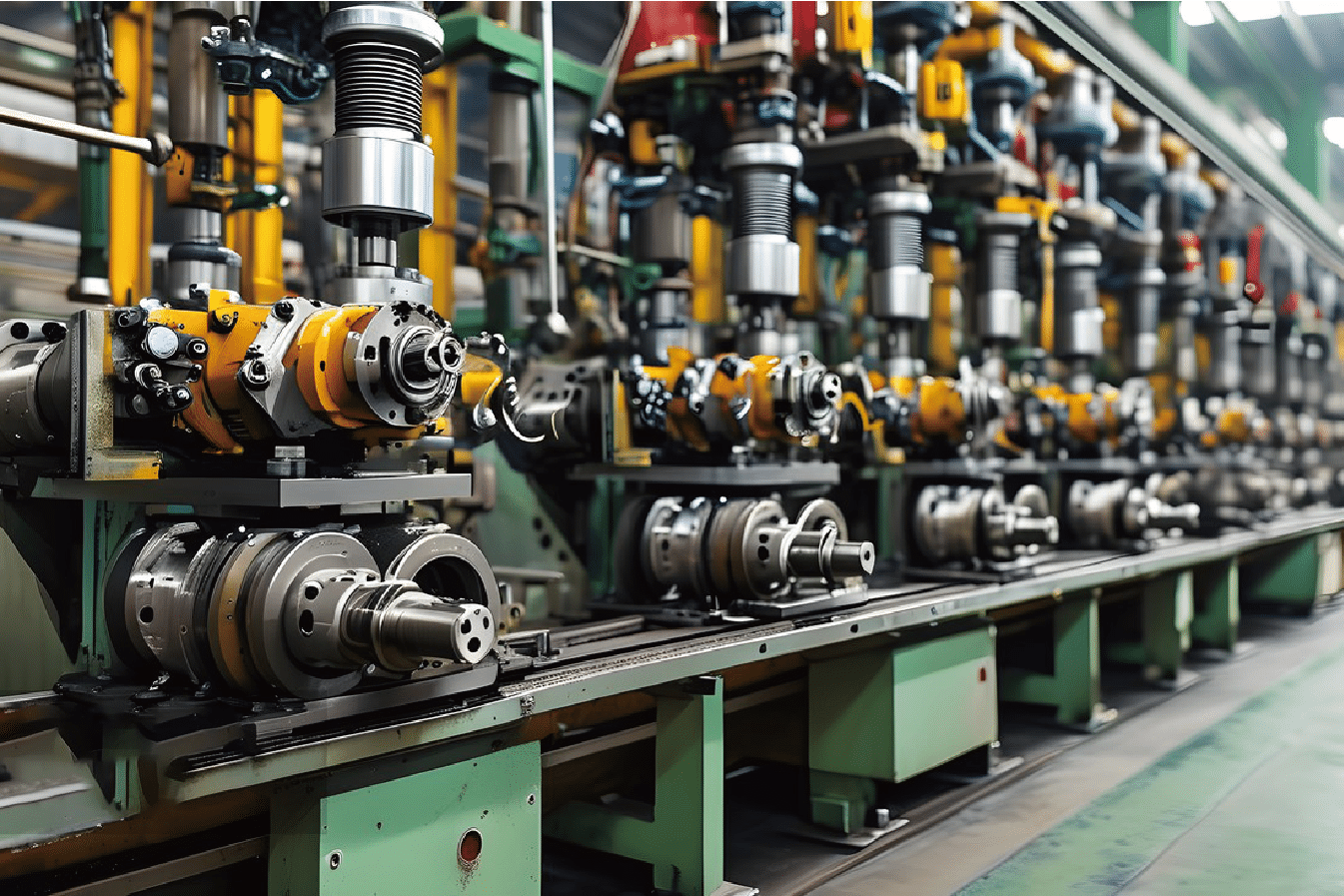

The evolution of stainless steel pipe technology has revolutionized industrial processes, offering solutions that combine strength, durability, and corrosion resistance. Let's examine the key aspects that make stainless steel pipes indispensable in modern industry.

What Are the Key Characteristics of Stainless Steel Pipes?

Understanding the fundamental characteristics of stainless steel pipes is essential for proper material selection and application.

Key characteristics include corrosion resistance, mechanical strength, temperature tolerance, and surface finish options, with properties varying by grade and manufacturing process.

Physical Properties

| Property | Range | Influencing Factors |

|---|---|---|

| Tensile Strength | 515-1100 MPa | Grade, heat treatment |

| Hardness | 150-400 HB | Composition, processing |

| Density | 7.7-8.0 g/cm³ | Alloy content |

Corrosion Resistance Features

Essential corrosion resistance characteristics:

- Passive oxide layer formation

- Resistance to various environments

- Self-healing properties

- Pitting resistance

Dimensional Standards

| Standard | Size Range | Application |

|---|---|---|

| Schedule 5S | 1/8" - 12" | Light duty |

| Schedule 10S | 1/8" - 24" | General purpose |

| Schedule 40S | 1/8" - 30" | Heavy duty |

What Materials and Grades Are Used to Make Stainless Steel Pipes?

Material selection impacts performance, cost, and longevity of stainless steel pipes in specific applications.

Common grades include 304/304L1, 316/316L2, and 321 stainless steel3, each offering different combinations of corrosion resistance, strength, and cost-effectiveness.

Popular Grades Comparison

| Grade | Chromium % | Nickel % | Key Benefits |

|---|---|---|---|

| 304/304L | 18-20 | 8-12 | General purpose |

| 316/316L | 16-18 | 10-14 | Enhanced corrosion resistance |

| 321 | 17-19 | 9-12 | High temperature stability |

Material Selection Criteria

Important factors in grade selection:

- Operating environment

- Temperature requirements

- Pressure ratings

- Cost considerations

Chemical Composition Impact

| Element | Purpose | Effect on Properties |

|---|---|---|

| Chromium | Corrosion resistance | Passive layer formation |

| Nickel | Structure stability | Improved ductility |

| Molybdenum | Pitting resistance | Enhanced durability |

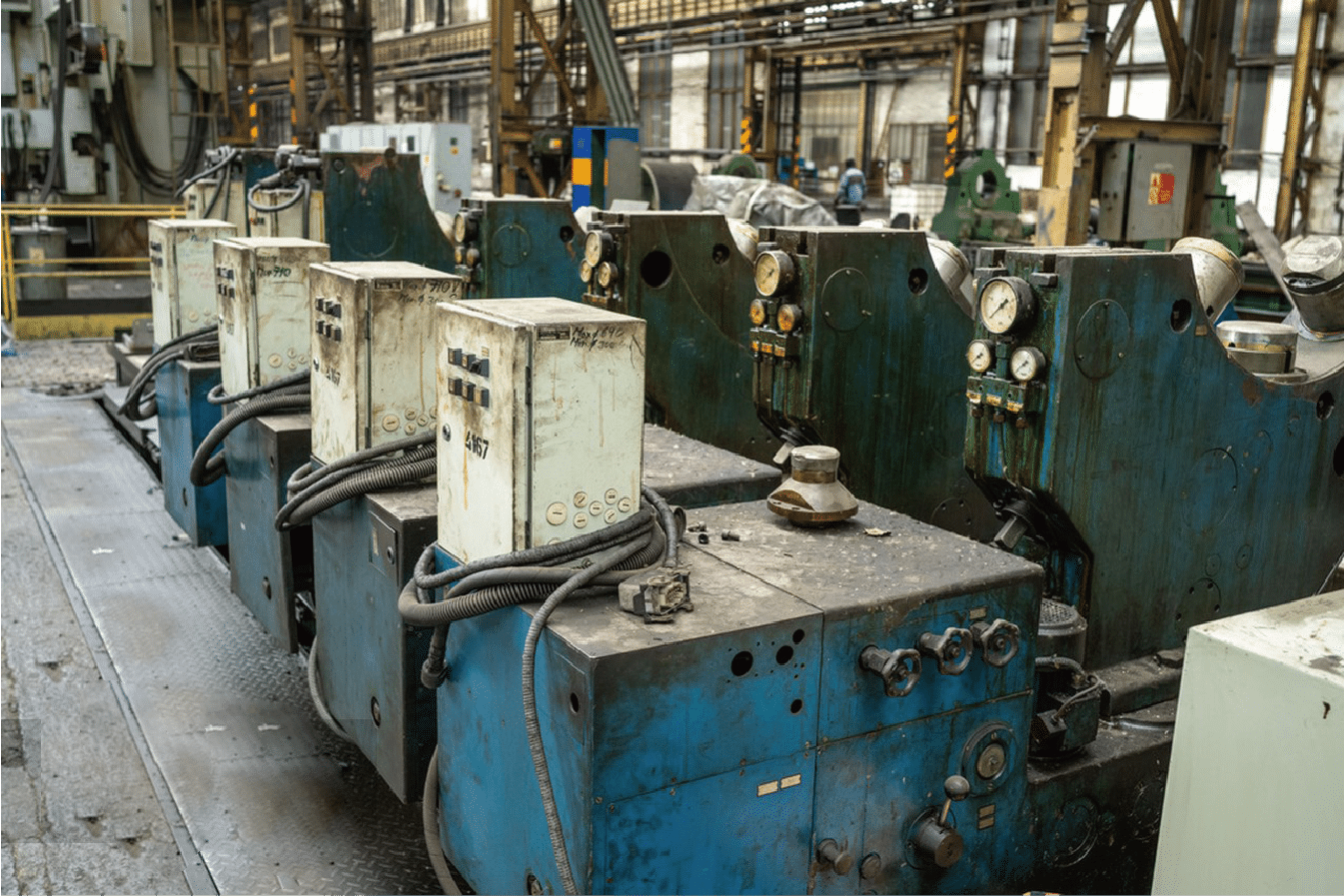

How Do Stainless Steel Pipes Differ from Other Types of Metal Pipes?

Understanding these differences helps in making informed decisions for specific applications and environments.

Stainless steel pipes offer superior corrosion resistance, longer service life, and better hygiene compared to carbon steel4, copper5, or aluminum pipes6.

Comparative Analysis

| Property | Stainless Steel | Carbon Steel | Copper |

|---|---|---|---|

| Corrosion Resistance | Excellent | Poor | Good |

| Initial Cost | Higher | Lower | Medium |

| Maintenance | Minimal | High | Medium |

| Service Life | 50+ years | 15-30 years | 25-40 years |

Performance Characteristics

Key differentiating factors:

- Corrosion resistance

- Temperature tolerance

- Pressure ratings

- Maintenance requirements

Cost-Benefit Analysis

| Factor | Stainless Steel | Alternative Materials |

|---|---|---|

| Initial Investment | Higher | Lower |

| Maintenance Cost | Minimal | Significant |

| Replacement Frequency | Low | Higher |

| Total Lifecycle Cost | Lower | Higher |

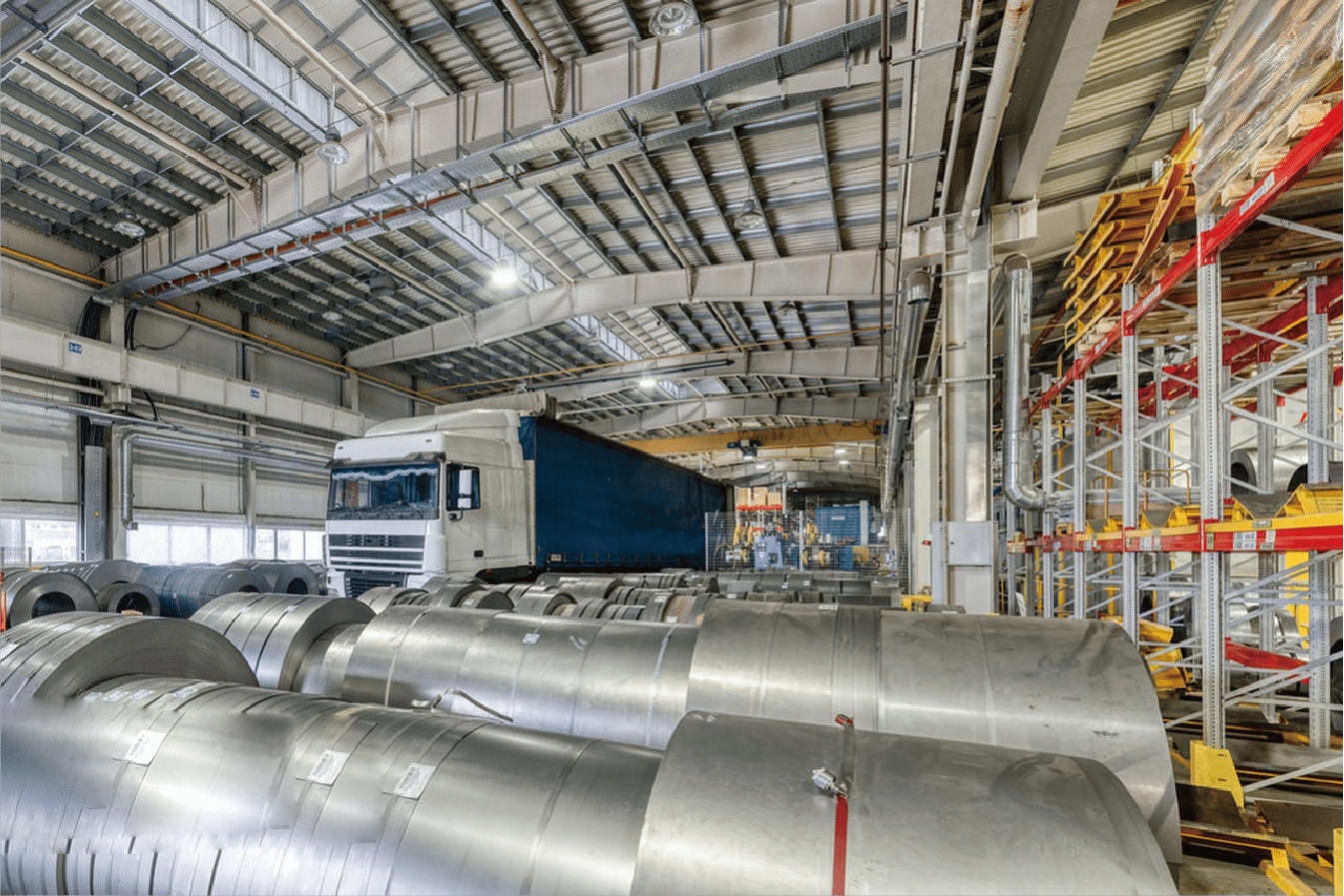

What Are the Common Applications of Stainless Steel Pipes in Various Industries?

Stainless steel pipes find extensive use across multiple industries due to their versatile properties.

Applications range from food and beverage processing7 to chemical transport, pharmaceutical manufacturing, and offshore installations.

Industry-Specific Applications

| Industry | Application | Key Requirements |

|---|---|---|

| Food & Beverage | Process lines | Hygiene, cleanability |

| Chemical | Transport | Corrosion resistance |

| Pharmaceutical | Clean steam | Purity, sterility |

| Oil & Gas | Offshore platforms | Durability |

Application-Based Grade Selection

Critical selection factors:

- Media compatibility

- Operating conditions

- Regulatory requirements

- Cost considerations

Performance Requirements

| Application | Grade | Critical Properties |

|---|---|---|

| Potable Water | 304/304L | Corrosion resistance |

| Acid Transport | 316/316L | Chemical resistance |

| High Temperature | 321 | Heat stability |

What Are the Advantages of Using Stainless Steel Pipes Over Other Materials?

Understanding the benefits helps justify the investment in stainless steel piping systems.

Advantages include superior corrosion resistance, minimal maintenance requirements, excellent hygiene properties, and long service life.

Key Benefits Analysis

| Benefit | Impact | Value Proposition |

|---|---|---|

| Corrosion Resistance | Reduced maintenance | Lower lifecycle cost |

| Durability | Extended service life | Better ROI |

| Hygiene | Better product quality | Regulatory compliance |

Environmental Considerations

Sustainability advantages:

- Recyclability8

- Reduced chemical treatment

- Lower environmental impact

- Energy efficiency

Economic Benefits

| Factor | Short-term Impact | Long-term Impact |

|---|---|---|

| Initial Cost | Higher investment | Lower total cost |

| Maintenance | Minimal expenses | Cost savings |

| Replacement | Rarely needed | Reduced downtime |

Conclusion

Stainless steel pipes offer superior performance, durability, and cost-effectiveness for demanding industrial applications, justifying their selection over alternative materials.

-

Learn about the versatility and common uses of 304/304L stainless steel ↩

-

Discover the advantages of 316/316L in corrosive environments ↩

-

Understand the high-temperature stability of 321 stainless steel ↩

-

Compare mechanical and corrosion resistance properties ↩

-

Evaluate the pros and cons of copper piping ↩

-

Assess application scenarios for aluminum piping ↩

-

Explore hygienic and safety benefits in food processing ↩

-

Learn about sustainability and recycling of stainless steel ↩