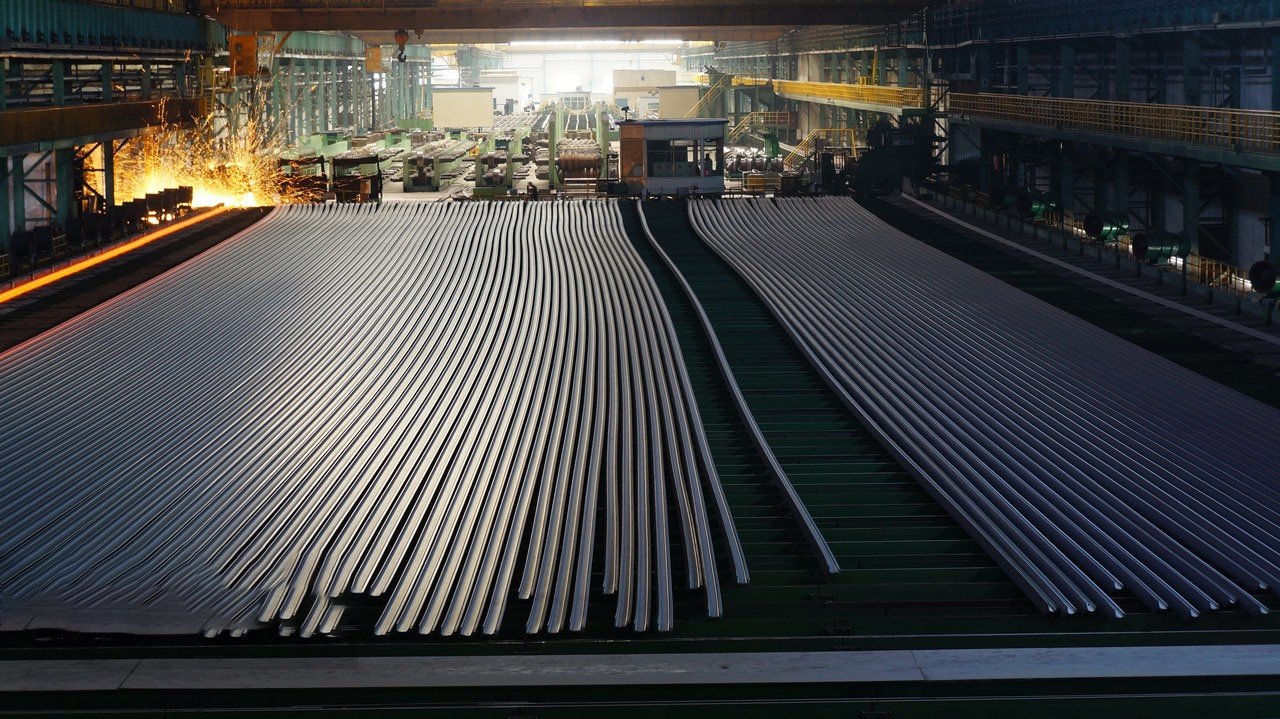

In my years of manufacturing specialty stainless steels, I've seen duplex grades revolutionize how we approach challenging industrial applications. This unique material combines the best properties of two different stainless steel families.

Duplex stainless steel is a specialized grade combining approximately equal amounts of austenitic and ferritic structures, typically containing 21-25% chromium, 4-7% nickel, and 2.5-4% molybdenum, offering superior strength and corrosion resistance.

Through my experience managing stainless steel production, I've witnessed duplex grades solve problems that traditional austenitic or ferritic grades couldn't handle. Let me share insights from working with this remarkable material across various demanding applications.

The significance of duplex stainless steel extends far beyond its dual-phase structure. From my daily interactions with engineers and project managers, I've seen how its unique properties can transform challenging projects into successful installations.

What Is the Chemical Composition of Duplex Stainless Steel?

Having overseen countless heats of duplex stainless steel production, I can explain how its carefully balanced composition creates its exceptional properties.

Duplex stainless steel achieves its distinctive microstructure through a precise balance of austenite-promoting and ferrite-promoting elements, primarily consisting of 21-25% chromium1, 4-7% nickel, and 2.5-4% molybdenum2.

Essential Element Breakdown

| Element | Percentage Range | Primary Function |

|---|---|---|

| Chromium | 21-25% | Corrosion resistance |

| Nickel | 4-7% | Phase balance |

| Molybdenum | 2.5-4% | Pitting resistance |

| Nitrogen | 0.1-0.3% | Strength/Structure |

| Manganese | 2% max | Processing aid |

Role of Key Elements

-

Primary Elements:

- Chromium: Forms protective oxide layer

- Nickel: Controls austenite formation

- Molybdenum: Enhances corrosion resistance

- Nitrogen: Strengthens austenite phase

- Manganese: Improves hot workability

-

Phase Balance Control:

- Ferrite promoters (Cr, Mo)

- Austenite promoters (Ni, N)

- Balanced microstructure

- Optimal property combination

- Processing temperature control

Manufacturing Considerations

Our production experience shows:

- Critical temperature control

- Precise composition management

- Careful cooling rate control

- Proper heat treatment

- Stringent quality verification

How Does Duplex Stainless Steel Differ from Austenitic and Ferritic Stainless Steels?

Through extensive testing and field applications, I've documented the unique characteristics that set duplex apart from traditional stainless steels.

Duplex stainless steel combines the corrosion resistance of austenitic grades with the strength of ferritic grades, resulting in a material that offers approximately twice the yield strength of standard austenitic grades while maintaining excellent corrosion resistance.

Comparative Properties

| Property | Duplex | Austenitic | Ferritic |

|---|---|---|---|

| Yield Strength (MPa) | 450-5503 | 210-230 | 275-350 |

| Corrosion Resistance | Excellent | Very Good | Good |

| Cost Factor | Moderate | High | Low |

| Magnetic Response | Partial | None | Full |

Key Differentiating Features

-

Structural Characteristics:

- Dual-phase microstructure

- Higher strength capabilities

- Better stress corrosion resistance

- Improved fatigue performance

- Enhanced wear resistance

-

Processing Differences:

- Specific heat treatment requirements

- Different welding procedures

- Unique forming considerations

- Special machining needs

- Distinct fabrication methods

What Are the Key Advantages of Duplex Stainless Steel?

My experience with challenging applications has highlighted duplex's significant benefits over traditional stainless steels.

Duplex stainless steel offers superior strength, excellent corrosion resistance, and improved stress corrosion cracking resistance, often allowing for reduced material thickness and lower overall project costs.

Primary Benefits

-

Mechanical Advantages:

- Higher yield strength

- Better fatigue resistance

- Improved wear performance

- Good toughness

- Weight reduction potential

-

Corrosion Resistance:

- Excellent pitting resistance

- Superior crevice corrosion resistance

- Good general corrosion resistance

- Better stress corrosion cracking resistance

- Enhanced erosion-corrosion resistance

Cost-Benefit Analysis

| Factor | Impact | Benefit |

|---|---|---|

| Material Thickness | -30% | Cost reduction |

| Maintenance | Reduced | Lower lifecycle cost |

| Service Life | Extended | Better ROI |

| Installation | Simplified | Lower labor cost |

In Which Industries and Applications Is Duplex Stainless Steel Commonly Used?

Through years of supplying various industries, I've seen duplex excel in numerous demanding applications.

Duplex stainless steel is widely used in oil and gas, chemical processing, pulp and paper, desalination plants, and offshore applications where its combination of strength and corrosion resistance provides optimal performance.

Industry Applications

-

Oil & Gas:

- Process piping

- Storage tanks

- Heat exchangers

- Pressure vessels

- Offshore platforms

-

Chemical Processing:

- Reaction vessels

- Storage facilities

- Transport systems

- Heat transfer equipment

- Mixing tanks

-

Marine/Offshore:

- Structural components

- Seawater systems

- Platform equipment

- Subsea equipment

- Desalination plants

Application Success Stories

Based on field experience:

- 40% cost reduction in tank construction

- 50% longer service life in seawater applications

- 30% weight reduction in structural components

- Significant maintenance cost savings

- Improved safety margins

How Does Duplex Stainless Steel Perform in Corrosive and High-Pressure Environments?

My experience with demanding applications has proven duplex's exceptional performance capabilities.

Duplex stainless steel excels in corrosive and high-pressure environments, offering superior resistance to pitting, crevice corrosion, and stress corrosion cracking while maintaining high strength at elevated pressures.

Performance Characteristics

-

Corrosion Resistance:

- High pitting resistance equivalent number (PREN)

- Excellent chloride resistance

- Superior stress corrosion cracking resistance

- Good general corrosion resistance

- Enhanced erosion-corrosion performance

-

Pressure Capability:

- High yield strength

- Excellent fatigue resistance

- Good creep resistance

- Maintained properties at temperature

- Superior burst pressure ratings

Environmental Performance

| Environment | Performance Rating | Key Benefit |

|---|---|---|

| Seawater | Excellent | Long service life |

| Chemical | Superior | Broad compatibility |

| High Pressure | Outstanding | Design flexibility |

| High Temperature | Very Good | Maintained properties |

Conclusion

Through my years in stainless steel manufacturing, I've seen duplex stainless steel consistently prove its value in demanding applications, offering an optimal combination of strength, corrosion resistance, and cost-effectiveness that often makes it the best choice for challenging environments.