5 Steps to a Superior Stainless Steel Coil Manufacturing Process

Inconsistent stainless steel coil quality creates project risks. This leads to costly rework, material waste, and supply chain delays. Mastering these five core manufacturing steps ensures superior, reliable results.

The five essential steps to superior stainless steel coil manufacturing are: meticulous raw material preparation, precision cold rolling, quality-enhancing annealing and pickling, perfective surface finishing, and rigorous final quality control. Each stage builds upon the last to guarantee the final product's integrity and performance.

As the Global Business Director at MFY, I've seen firsthand how a disciplined manufacturing process separates the best from the rest. It's not about a single action, but a sequence of carefully executed steps that guarantees the quality our clients in construction, manufacturing, and engineering demand. Let's walk through each of these critical stages together.

How Do You Ensure Quality in the Initial Preparation of Raw Materials?

Poor raw materials will always compromise your final product. This creates hidden structural weaknesses and surface defects. Starting with certified, high-grade materials is the only way to build a strong foundation.

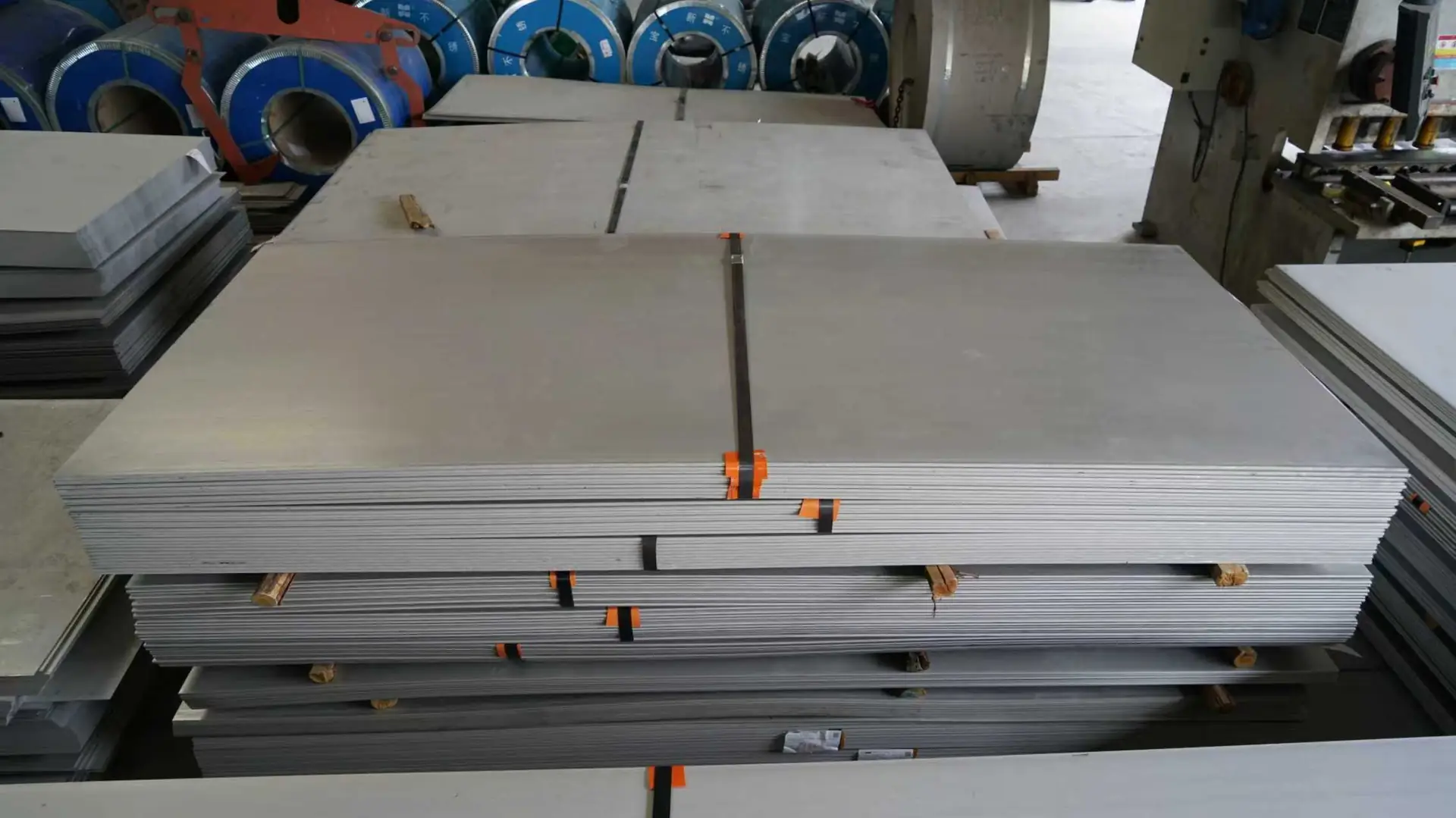

Superior raw material preparation involves sourcing certified alloys, meticulously cleaning surfaces to remove impurities, and precisely slitting hot-rolled coils. This foundational step is critical for preventing defects and ensuring the final product's chemical and mechanical integrity from the very beginning.

The old saying "you can't make a silk purse out of a sow's ear" is especially true in our industry. Everything that follows depends on the quality of what you start with. At MFY, we consider this step to be non-negotiable, because a small oversight here can have massive ripple effects downstream. I remember a case with a client in Germany where a tiny, almost undetectable impurity in the raw material led to micro-fractures after the metal was formed. That experience reinforced our commitment to an uncompromising approach to sourcing and preparation.

Sourcing and Certification

It all begins with selecting the right hot-rolled black coil. We work only with suppliers who can provide full material traceability and certification that aligns with international standards like ASTM and EN[^1]. This documentation isn't just paperwork; it's a guarantee of the steel's chemical composition and inherent properties. We verify every batch to ensure it meets the precise grade requirements—whether it's 304, 316L, or another alloy—for the intended application.

The Importance of Cleaning and Slitting

Once the material is verified, it undergoes preparation. This includes uncoiling and slitting the wider hot-rolled coils into the required widths for the cold-rolling mill. More importantly, the surface is prepared to remove any scale or oxides. An imperfectly cleaned surface can lead to embedded defects during the immense pressure of cold rolling. This meticulous preparation ensures a smooth, clean start, which is essential for achieving the flawless surface finish our partners expect.

| Preparation Step | Key Action | Purpose |

|---|---|---|

| Verification | Check Mill Test Certificate (MTC) | Confirms chemical & mechanical properties |

| Cleaning | Surface descaling | Removes impurities that cause defects |

| Slitting | Cut to precise widths | Prepares coil for the cold rolling mill |

What Makes the Cold Rolling Process Critical for Stainless Steel Coils?

Inaccurate coil thickness ruins precision applications. This causes equipment malfunctions, assembly problems, and project failure. Advanced cold rolling is the only way to achieve uniform thickness and superior mechanical properties.

The cold rolling process is critical because it reduces the coil's thickness to precise specifications, enhances its strength through work-hardening, and improves the surface finish. This is achieved by passing the steel between powerful rollers at room temperature, ensuring exceptional dimensional accuracy.

Cold rolling is where the steel's final character is truly forged. It’s a process of immense force and incredible precision. The goal is to transform a thicker, hot-rolled band into a thin, smooth, and strong coil with uniform thickness from edge to edge and end to end. In modern facilities like ours, this is no longer just a mechanical process. We integrate IoT sensors throughout our cold rolling mills to provide real-time data on thickness, tension, and flatness. This allows our systems to make micro-adjustments on the fly, ensuring every meter of the coil meets the exact specification. This level of digital oversight is key to reducing waste and guaranteeing the consistency required for automated manufacturing lines.

Achieving Dimensional Accuracy

The primary function of cold rolling is thickness reduction. The coil is passed multiple times through a series of rollers, each pass reducing the thickness by a small, controlled amount. The pressure is immense, and maintaining an even gap between the rollers is paramount. For our clients in the automotive or precision electronics sectors, a deviation of even a few microns can be the difference between a perfect part and a rejected batch.

Enhancing Mechanical Properties

Cold rolling does more than just make the steel thinner. The process fundamentally changes the steel's grain structure, a phenomenon known as work-hardening. This significantly increases its tensile strength and hardness. While this makes the steel stronger, it also reduces its ductility, making it more brittle. This is a critical trade-off that we manage in the next step of the process.

| Property | Before Cold Rolling | After Cold Rolling |

|---|---|---|

| Thickness | High | Low (to specification) |

| Tensile Strength | Lower | Significantly Higher |

| Hardness | Lower | Significantly Higher |

| Ductility | High | Low |

Why Are Annealing and Pickling Essential for Quality Enhancement?

Cold rolling makes steel hard but also brittle. This internal stress can lead to cracking during forming or use. Annealing and pickling are the solution, restoring ductility and ensuring a clean surface.

Annealing is a controlled heat treatment that softens the steel, relieves internal stresses, and restores its ductility after cold rolling. Pickling follows, using an acid bath to remove the oxide scale formed during heating, ensuring a clean, corrosion-resistant surface.

This two-part stage is the great "reset" in the manufacturing journey. After the intense pressure of cold rolling, the steel is strong but stressed. Annealing is like a therapeutic spa day for the steel, allowing its crystalline structure to relax and realign. We worked with a construction partner in the Middle East whose project demanded high formability for complex architectural panels. Perfecting our annealing cycle was the key to giving them a material that was both strong and pliable enough to achieve their vision without cracking. Following this, pickling cleanses the surface, which is vital for corrosion resistance. As the industry moves towards greener production, we're continuously innovating in this area, implementing acid recycling systems and exploring more environmentally friendly solutions to minimize our impact.

The Science of Annealing

During annealing, the coil is heated to a specific temperature (which varies by steel grade) and held there for a set time before being cooled. This process, known as recrystallization[^2], reforms the grain structure that was deformed during cold rolling. This relieves the internal stresses and restores the steel's ductility, making it possible to bend, stamp, and form it without fracturing. Precise temperature control is crucial here; too hot or too cold, and you won't achieve the desired mechanical properties.

The Purpose of Pickling

Heating steel in the presence of oxygen creates a thin layer of oxide scale on its surface. This scale must be removed, as it can interfere with subsequent processes and compromise the steel's natural corrosion resistance. The coil is passed through a series of acid tanks (pickling) and then rinsed thoroughly. This leaves the surface metallurgically clean and ready for the final finishing touches.

How Are Finishing Touches Applied for Surface Perfection?

A rough or inconsistent surface is unacceptable for most applications. It looks unprofessional and can trap contaminants. Finishing processes create the specific texture, reflectivity, and appearance your project demands.

Finishing touches involve processes like temper rolling (skin passing) to improve flatness and prevent stretcher strains, and surface grinding or polishing to achieve specific finishes like 2B, BA, or No. 4. This step defines the coil's final aesthetic and functional surface quality.

The finish is often the first thing a customer notices, and it plays a huge role in both performance and aesthetics. Whether it's the reflective finish for a building facade or the sanitary finish for food processing equipment, this step is where we tailor the product to its end-use. It’s a meticulous process that adds significant value. The choice of finish is not just cosmetic; a smoother, non-porous surface is easier to clean and more resistant to bacterial growth, a critical requirement for our clients in the medical and culinary industries. This stage is about delivering on the specific, tangible qualities that our partners rely on for their own products.

Temper Rolling and Leveling

After annealing, the coil is often given a very light cold roll, known as a skin pass or temper roll. This doesn't significantly reduce the thickness but instead improves the flatness, minimizes the risk of surface imperfections known as stretcher strains during forming, and imparts the desired surface texture, such as the common 2B finish[^3].

A Guide to Common Surface Finishes

The surface can be further processed to achieve different looks and textures. This is where we create the finishes that are so familiar in the industry.

| Finish Code | Description | Common Applications |

|---|---|---|

| 2B | Smooth, moderately reflective cold-rolled finish | General purpose, industrial equipment, chemical plants |

| BA | Bright Annealed; highly reflective, mirror-like | Architectural trim, kitchenware, decorative items |

| No. 4 | Brushed finish with fine polishing lines | Food processing equipment, elevators, kitchen sinks |

| HL | Hairline; long, continuous polishing lines | Architectural panels, interior design |

What Quality Control Measures Guarantee Superior Coil Production?

Undetected defects can cause catastrophic failures down the line. This puts your reputation, investment, and safety at risk. Rigorous, multi-stage quality control is the only way to guarantee flawless performance.

Rigorous quality control involves a series of inspections at every stage, from raw material analysis to final product testing. This includes checking chemical composition, mechanical properties (tensile strength, hardness), dimensional accuracy, and surface quality to ensure full compliance with international standards.

At MFY, quality control is not a final step; it's a continuous process woven into the fabric of our production. We believe that you cannot "inspect" quality into a product at the end. You have to build it in from the start. This is where we leverage technology most heavily. Every coil has a digital "birth certificate" that tracks it through each stage. AI-powered visual inspection[^4] systems scan the surface for defects invisible to the human eye, and data from every process is analyzed to predict and prevent potential issues before they occur. This comprehensive, data-driven approach to QC is how we provide the assurance our clients need to build with confidence. It transforms quality control from a simple checkpoint into an intelligent, proactive system that ensures excellence.

Multi-Stage Inspection Protocols

We implement strict quality checks at the conclusion of each of the four preceding steps. Samples are taken to test for tensile strength, hardness, and chemical composition in our labs. Instruments measure thickness and width continuously. Our teams visually inspect for any surface imperfections. This ensures that any deviation is caught and corrected immediately, preventing a flawed product from ever moving to the next stage.

Final Inspection and Traceability

Before a coil is packaged and shipped, it undergoes a final, comprehensive inspection. We verify all physical dimensions, surface finish quality, and mechanical properties against the customer's order and relevant international standards. Each coil is marked with a unique identification number, linking it back to its entire production history. This full traceability is crucial for our partners in regulated industries.

Conclusion

Mastering these five steps—from raw material preparation to final, tech-enabled inspection—is non-negotiable for producing superior stainless steel coils. At MFY, this disciplined process is how we deliver the quality, consistency, and reliability that your business can build upon.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.