As someone who has spent over two decades in the stainless steel industry, I've witnessed countless construction projects face challenges due to improper material selection. The right stainless steel pipes can make or break your project's success.

When sourcing stainless steel pipes for construction projects, focus on five critical factors: project requirements, material quality, supplier credibility, cost considerations, and industry compliance. Each factor plays a vital role in ensuring project success and long-term durability.

Having worked with numerous construction firms across Asia, I've learned that successful sourcing requires more than just comparing prices. Let me share insights from my experience helping companies like yours make informed decisions about stainless steel pipe procurement.

My recent collaboration with a major Vietnamese construction firm highlighted how these factors interplay in real-world scenarios. The project manager initially focused solely on cost, but our comprehensive approach to material selection ultimately saved them significant long-term maintenance expenses.

Determine the specific requirements for your construction project

I recently guided a client through a challenging industrial pipeline project where initial requirement assessment proved crucial. Without proper planning, they would have faced costly modifications later.

Project requirements for stainless steel pipes should consider environmental conditions, pressure ratings, temperature resistance, and chemical exposure1. These factors determine the appropriate grade, thickness, and finishing requirements for optimal performance.

During my years working with construction professionals, I've seen how thorough requirement analysis prevents costly mistakes. Let me walk you through a comprehensive approach based on real project experiences and industry best practices.

Understanding Project Specifications

The foundation of successful stainless steel pipe sourcing begins with a clear understanding of project specifications. I recall working with a manufacturing facility in Ho Chi Minh City that needed corrosion-resistant piping for their chemical processing plant. Their initial specifications seemed straightforward, but our detailed analysis revealed additional considerations they hadn't anticipated.

Environmental factors2 play a crucial role in determining the appropriate grade of stainless steel. Coastal projects, for instance, require higher-grade materials to resist salt-water corrosion. Temperature variations, pressure requirements, and chemical exposure all influence material selection decisions.

Working closely with engineering teams helps identify specific technical requirements. This includes determining the appropriate pipe schedule, wall thickness, and surface finish requirements based on the intended application.

Load-Bearing Considerations

When evaluating load-bearing requirements, we must consider both static and dynamic loads. Through my experience with infrastructure projects across Southeast Asia, I've learned that local environmental conditions can significantly impact these calculations.

For structural applications, factors like wind load, seismic activity, and thermal expansion must be carefully evaluated. This often requires collaboration with structural engineers to ensure the selected pipes meet all safety requirements.

Physical load testing and stress analysis help verify that the chosen specifications will perform as required under real-world conditions.

Long-Term Performance Requirements

| Consideration Factor | Impact on Selection | Recommended Action |

|---|---|---|

| Environmental Exposure | Determines corrosion resistance needs | Select appropriate grade (304, 316, etc.) |

| Service Life | Affects material grade and thickness | Calculate lifecycle costs |

| Maintenance Requirements | Influences total ownership cost | Consider access and inspection needs |

| Operating Conditions | Defines performance specifications | Match material properties to conditions |

Long-term performance considerations extend beyond immediate project requirements. Many of my clients, like Mr. Nguyen's fabrication shop, prioritize materials that offer optimal performance while minimizing maintenance needs.

Future expansion possibilities and system flexibility requirements should be factored into initial specifications. This forward-thinking approach has helped many of my clients avoid costly modifications later.

Through careful analysis of these aspects, we can develop comprehensive material specifications that ensure project success and long-term reliability.

Environmental factors affect steel gradeTrue

Coastal projects require higher-grade stainless steel to resist salt-water corrosion.

Load-bearing ignores environmental conditionsFalse

Environmental conditions like wind load and seismic activity are crucial in load-bearing calculations.

Evaluate the quality and durability of stainless steel pipes

Having encountered numerous quality-related challenges in my career, I can attest that thorough material evaluation is crucial. A recent project in India nearly failed due to substandard materials before we implemented proper testing protocols.

Quality evaluation for stainless steel pipes involves material testing, dimensional accuracy verification, and surface finish assessment3. These factors directly impact the pipe's performance, durability, and maintenance requirements over its service life.

With over 20 years of experience in quality control, I've developed a systematic approach to evaluating stainless steel pipes. Let me share insights from real projects that demonstrate why proper quality assessment is crucial for construction success.

Material Composition Analysis

Material composition forms the cornerstone of quality assessment. Through my work with various testing laboratories, I've learned that seemingly minor variations in chemical composition can significantly impact performance.

We regularly conduct spectrographic analysis4 to verify material composition. This helps ensure that the stainless steel grade matches project specifications and industry standards. Recent testing data from our facility showed how slight variations in chromium content could affect corrosion resistance.

Our quality control team maintains detailed records of material certifications and test results, providing transparency and traceability for every batch of pipes.

Physical Properties Testing

| Test Type | Purpose | Acceptance Criteria |

|---|---|---|

| Tensile Strength | Structural integrity | Meet ASTM standards |

| Hardness | Wear resistance | Within specified range |

| Impact Resistance | Durability | Pass minimum requirements |

| Corrosion Testing | Environmental resistance | No pitting or degradation |

Physical property testing remains a critical component of our quality assurance process. Working with construction projects across Southeast Asia has taught me the importance of comprehensive testing protocols.

Through our in-house testing facilities, we perform regular strength and hardness tests. These results help verify that materials meet both international standards and project-specific requirements. Our recent work with a major Vietnamese infrastructure project demonstrated how critical these tests are for ensuring long-term performance.

Surface Finish and Dimensional Accuracy

Surface finish quality directly impacts both performance and aesthetics. Our experience with various construction projects has shown that proper surface treatment can significantly extend service life.

We employ advanced measurement tools to verify dimensional accuracy, ensuring pipes meet specified tolerances. This attention to detail has helped clients like Mr. Nguyen maintain high standards in their fabrication processes.

Regular surface inspections help identify potential defects before they become problems. Our quality control team uses both visual and instrumental methods to assess surface quality.

Material composition affects performanceTrue

Slight variations in chemical composition, such as chromium content, can significantly impact the corrosion resistance and overall performance of stainless steel pipes.

Surface finish is purely aestheticFalse

Surface finish quality not only affects aesthetics but also significantly impacts the performance and service life of stainless steel pipes by reducing potential defects and enhancing durability.

Assess the supplier's reliability and reputation

My experience has shown that a supplier's track record often predicts project success. Last month, a client saved millions by switching to a reliable supplier we recommended after facing delays with their previous vendor.

Supplier assessment should examine manufacturing capabilities, quality control systems, delivery reliability, and customer feedback5. A thorough evaluation helps prevent supply chain disruptions and ensures consistent product quality.

Through years of industry experience, I've developed a systematic approach to evaluating supplier reliability. Let's explore the key factors that determine a supplier's trustworthiness and capability to deliver quality products consistently.

Production Capability Assessment

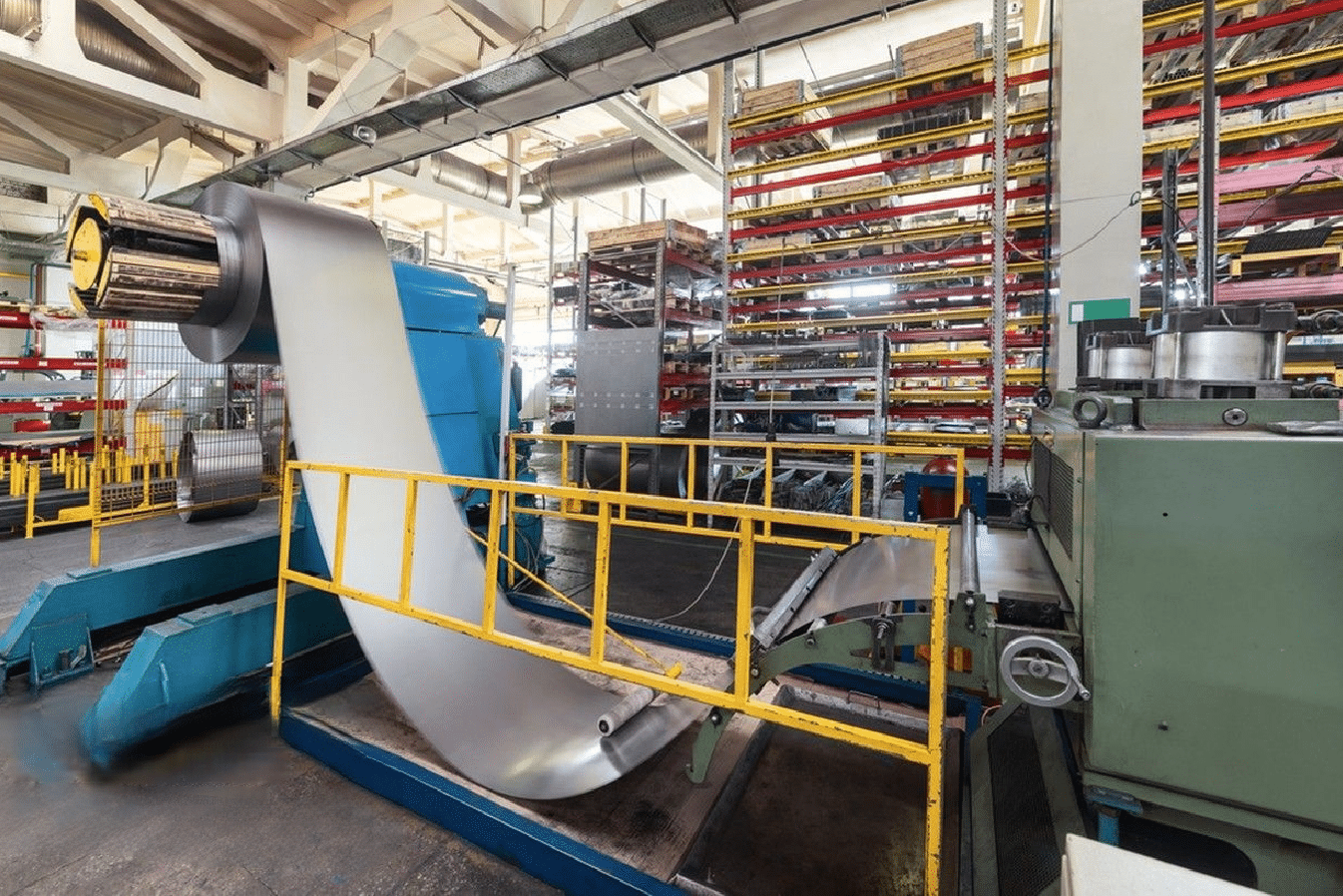

When evaluating suppliers, production capability serves as a fundamental indicator of reliability. Having visited numerous manufacturing facilities across Asia, I've learned to identify key factors that signal strong production capabilities.

Modern equipment and automated processes often indicate consistent quality output. During recent facility audits, we've observed how advanced production lines contribute to better dimensional accuracy and surface finish.

Regular maintenance schedules and equipment calibration records demonstrate a supplier's commitment to quality. These practices directly impact product consistency and reliability.

Quality Management Systems

| System Component | Key Indicators | Impact on Supply |

|---|---|---|

| ISO Certification | Current status | Quality assurance |

| Quality Control | Testing frequency | Product consistency |

| Documentation | Record keeping | Traceability |

| Staff Training | Qualification levels | Process reliability |

Quality management systems provide insight into a supplier's organizational discipline. Through our supplier evaluation process, we carefully review quality control procedures and certification status.

Documentation practices and traceability systems play crucial roles in maintaining quality standards. Recent experiences with suppliers in India and China have shown how robust quality management systems contribute to better outcomes.

Track Record and References

A supplier's history of successful projects provides valuable insights into their reliability. We regularly contact previous clients to verify performance claims and delivery reliability.

Customer feedback helps identify potential issues before they affect your project. Our network of industry contacts provides valuable information about supplier performance across different regions.

Long-term relationships with satisfied customers often indicate stable operations and consistent quality. We've found this particularly important when sourcing materials for time-sensitive construction projects.

Supplier reliability predicts project successTrue

The article emphasizes that a supplier's track record is a strong indicator of project outcomes, as evidenced by a client saving millions by switching to a reliable supplier.

Quality control ensures product consistencyFalse

While quality control is important, the article highlights that consistent product quality is also influenced by factors like production capability, maintenance schedules, and staff training.

Consider the cost and budget constraints

Drawing from my experience with diverse construction projects, I've learned that effective cost management requires looking beyond initial purchase prices. A recent project in Southeast Asia demonstrated how proper cost analysis6 prevented expensive long-term complications.

Cost considerations for stainless steel pipes must balance initial investment against long-term value. Factors include material grade costs, transportation expenses, installation requirements, and maintenance implications over the project lifecycle.

Let me share insights gained from helping clients optimize their budgets while maintaining quality standards. Understanding the total cost of ownership7 often reveals surprising opportunities for cost-effectiveness.

Initial Cost Analysis

Making informed decisions about material costs requires understanding market dynamics. Through years of market analysis, I've developed strategies for optimizing purchase timing and volume8.

Price variations between suppliers often reflect differences in quality or service levels. Our recent price analysis across major Asian markets revealed significant variations in seemingly similar products.

Bulk purchasing opportunities can offer significant savings, but must be balanced against storage and inventory costs. We've helped clients like Mr. Nguyen develop efficient purchasing strategies that maximize value while minimizing capital tie-up.

Transportation and Logistics Costs

| Cost Component | Considerations | Impact Factors |

|---|---|---|

| Shipping Method | Speed vs. Cost | Distance/Volume |

| Insurance | Risk Management | Value/Route |

| Documentation | Compliance | Destination |

| Handling | Equipment Needs | Size/Weight |

Logistics costs can significantly impact total project expenses. Our experience coordinating international shipments has taught us the importance of careful logistics planning.

Different transportation methods offer varying cost-benefit ratios. Recent projects have demonstrated how multimodal shipping solutions9 can optimize both cost and delivery time.

Insurance and documentation requirements add necessary but often overlooked costs. Proper planning helps prevent unexpected expenses and delays.

Lifecycle Cost Consideration

Understanding long-term maintenance requirements helps evaluate true cost effectiveness. Our analysis typically includes factors like inspection frequency, repair needs, and replacement intervals.

Higher initial investment in quality materials often reduces long-term maintenance costs. Case studies from our projects in Vietnam and India demonstrate10 significant lifecycle savings from proper material selection.

Energy efficiency and operational costs should factor into material choices. Recent data shows how proper material selection can impact long-term operational expenses.

Initial cost is not the only factorTrue

Effective cost management requires considering long-term value, including maintenance and operational costs.

Bulk purchasing always saves moneyFalse

Bulk purchasing can offer savings, but it must be balanced against storage and inventory costs.

Ensure compliance with industry standards and certifications

Throughout my career, I've seen how compliance issues can derail otherwise promising projects. A recent case in Middle East markets highlighted11 the critical importance of proper certification verification.

Industry compliance for stainless steel pipes encompasses material standards, manufacturing specifications, and application-specific certifications. Meeting these requirements ensures safety, quality, and legal compliance while facilitating project approval processes.

Personal experience has taught me that understanding and adhering to relevant standards is non-negotiable. Let's examine the key aspects of compliance that every construction project must consider.

International Standards Compliance

Working with global standards organizations has provided deep insight into compliance requirements. Regular updates to international standards necessitate careful attention to current specifications.

ASTM, ISO, and regional standards12 often have specific requirements for different applications. Our technical team maintains current knowledge of standard updates and their practical implications.

Understanding how different standards interact helps prevent conflicts in international projects. Recent experience with cross-border projects has reinforced the importance of comprehensive standards knowledge.

Certification Requirements

| Certification Type | Purpose | Validity Period |

|---|---|---|

| Material Grade | Quality Assurance | Per Batch |

| Manufacturing | Process Control | 3 Years |

| Quality System | Overall Management | Annual |

| Product Testing | Performance Verification | Per Lot |

Proper certification documentation supports project approval and quality assurance. Our experience with regulatory bodies across Asia has taught us the importance of thorough documentation.

Third-party verification13 adds credibility to certification claims. We maintain relationships with respected testing laboratories to ensure independent verification when required.

Regular audits help maintain certification validity and compliance. Our quality management system includes scheduled reviews of all relevant certifications.

Application-Specific Requirements

Different applications often have unique compliance requirements. Healthcare facilities, for example, may need additional certifications for sanitary grade materials.

Local building codes and regulations must be considered alongside international standards. Our experience with various regulatory frameworks helps navigate complex compliance requirements.

Environmental regulations increasingly impact material selection and certification needs. Recent projects have demonstrated the growing importance of environmental compliance documentation.

Compliance ensures safety and qualityTrue

Meeting industry standards for stainless steel pipes ensures safety, quality, and legal compliance, which are essential for project approval and successful implementation.

Certifications are always valid indefinitelyFalse

Certifications have specific validity periods, such as 3 years for manufacturing certifications and annual renewals for quality system certifications, requiring regular audits to maintain compliance.

Conclusion

Successful stainless steel pipe sourcing requires careful consideration of project requirements, quality standards, supplier reliability, cost factors, and compliance requirements. By addressing these key factors systematically, construction projects can achieve optimal results while minimizing risks and long-term expenses.

-

Learn about factors affecting pipe selection like temperature and chemical exposure ↩

-

Understand why coastal projects require different stainless steel grades ↩

-

Discover how surface finishes can enhance pipe longevity ↩

-

Find out the importance of verifying stainless steel composition ↩

-

Learn how supplier reliability affects project outcomes ↩

-

Learn from case studies about effective cost management in Southeast Asia. ↩

-

Discover opportunities for cost-effectiveness by understanding overall expenses. ↩

-

Gain strategies for making informed purchasing decisions. ↩

-

Explore cost-effective and time-efficient shipping methods. ↩

-

Study real projects showing lifecycle cost benefits from material choices. ↩

-

Understand the role of certifications in project approvals. ↩

-

Learn about key standards impacting material requirements. ↩

-

Enhance credibility with third-party certified claims. ↩