What is the standard size of stainless steel coils?

Are you struggling to find the right stainless steel coil sizes for your project? The wrong dimensions can lead to costly material waste and production delays, potentially jeopardizing your entire manufacturing process.

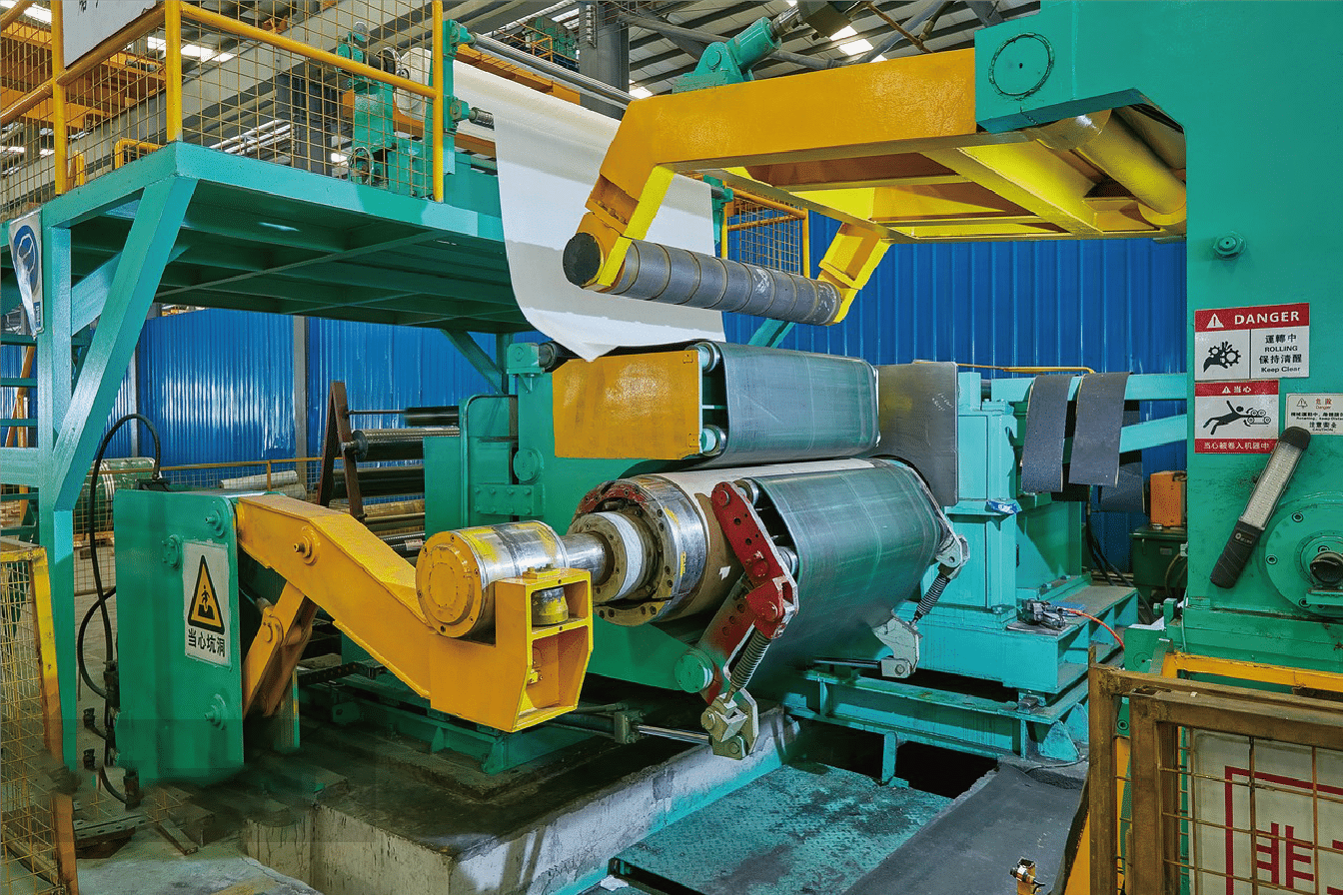

Standard stainless steel coil sizes vary in width (600mm-1600mm), thickness (0.1mm-6.0mm), and inner diameter (508mm or 610mm). However, specifications can differ based on industry needs and manufacturer capabilities, making it crucial to understand these variations for optimal material selection.

As a seasoned professional in the stainless steel industry, I've seen countless clients grapple with size specifications. It's not just about following industry standards; it's about optimizing your production efficiency and ensuring compatibility with your equipment. Let me guide you through the intricacies of stainless steel coil dimensions, drawing from my extensive experience working with diverse industries and applications.

Understanding the standard sizes of stainless steel coils is more complex than it might seem at first glance. It involves a delicate balance between manufacturing capabilities, industry-specific requirements, and practical considerations for handling and processing. Throughout my career, I've worked with clients across various sectors, from automotive to construction, and I've observed how crucial it is to grasp these nuances. Let's dive deeper into each aspect of coil sizing to help you make informed decisions for your specific needs.

What are the standard width measurements for stainless steel coils?

I recently assisted a client who was losing thousands of dollars monthly due to incorrect width specifications. Their story underscores the importance of understanding standard width measurements in stainless steel coils.

Standard stainless steel coil widths typically range from 600mm to 1600mm, with common increments of 50mm or 100mm. The most frequently used widths are 1000mm, 1219mm, and 1500mm, chosen based on industry standards and processing equipment specifications.

The width of stainless steel coils plays a crucial role in manufacturing efficiency and material utilization. Through my years of experience working with various industries, I've found that choosing the right width can significantly impact production costs and waste reduction.

Impact of Width on Processing and Material Yield

The relationship between coil width and processing capabilities is critical. I've observed that wider coils generally offer better production efficiency but require more robust handling equipment. Here's what I've learned:

- Optimal width selection can reduce slitting operations by up to 40%, significantly improving production speed and reducing waste.

- Proper width selection can improve material yield by 15-25%, a substantial cost-saving factor in large-scale production.

- Coils wider than 1500mm often require specialized lifting equipment, which can impact handling costs and factory layout considerations.

Width Tolerances and Industry Standards

Precision in width measurements is crucial for many manufacturing processes. Based on international standards like ASTM A480 and EN 10088-2, width tolerances typically range from ±1mm to ±5mm, depending on the total width and material grade.

| Width Range (mm) | Standard Tolerance (mm) | Precision Tolerance (mm) |

|---|---|---|

| 600-1000 | ±5 | ±3 |

| 1001-1250 | ±6 | ±4 |

| 1251-1600 | ±7 | ±5 |

Industry-Specific Width Requirements

Different sectors have varying preferences for coil widths:

- Automotive Industry: Often requires widths between 900mm and 1250mm for optimal compatibility with stamping and forming equipment.

- Construction Sector: Typically uses wider coils, ranging from 1000mm to 1500mm, to maximize material coverage in applications like roofing and cladding.

- Home Appliance Manufacturers: Generally prefer widths between 600mm and 1200mm, tailored to specific component sizes.

Through my experience, I've found that understanding these industry-specific requirements is crucial for suppliers and manufacturers alike. It allows for better inventory management and more efficient production planning.

Common widths: 1000mm, 1219mm, 1500mmTrue

These widths are frequently used based on industry standards and equipment specifications.

All coils are wider than 1600mmFalse

Standard widths for stainless steel coils typically range from 600mm to 1600mm.

What are the standard thickness measurements for stainless steel coils?

During a recent consultation with a major appliance manufacturer, I encountered significant quality issues stemming from incorrect thickness specifications. This experience reinforced the critical importance of understanding standard thickness measurements in stainless steel coils.

Stainless steel coil thickness typically ranges from 0.1mm to 6.0mm, with common increments of 0.05mm for thin gauges and 0.1mm for thicker materials. The most frequently used thicknesses are 0.5mm, 1.0mm, 1.5mm, and 2.0mm, catering to a wide range of applications.

Understanding thickness specifications is crucial for both manufacturing efficiency and end-product performance. Through years of working with diverse industries, I've gathered extensive knowledge about how thickness selection impacts various applications and processing methods.

Thickness Tolerances and Quality Control

Maintaining precise thickness tolerances is critical for high-quality stainless steel products. Based on international standards and our manufacturing experience:

| Thickness Range (mm) | Standard Tolerance (mm) | Precision Tolerance (mm) |

|---|---|---|

| 0.1-0.5 | ±0.02 | ±0.01 |

| 0.5-1.0 | ±0.04 | ±0.02 |

| 1.0-2.0 | ±0.06 | ±0.03 |

| 2.0-4.0 | ±0.08 | ±0.04 |

| 4.0-6.0 | ±0.10 | ±0.05 |

Application-Specific Thickness Requirements

Different applications demand specific thickness ranges:

-

Food Processing Industry: Typically requires thicknesses between 0.8mm and 2.0mm for equipment manufacturing. I recently supplied a series of 1.5mm thick coils to a food equipment manufacturer, which provided optimal strength while maintaining cost-effectiveness.

-

Construction Sector: Often uses thicker gauges, ranging from 2.0mm to 6.0mm, for structural applications. One of our projects involved supplying 3.0mm thick coils for a major infrastructure development, where the material needed to meet strict structural integrity requirements.

-

Automotive Industry: Uses a wide range of thicknesses, from thin 0.5mm sheets for body panels to thicker 2.0mm-3.0mm coils for structural components.

Processing Considerations for Different Thicknesses

The thickness of stainless steel coils significantly impacts processing methods and capabilities:

- Thinner gauges (0.1-0.5mm) require specialized handling equipment and precise tension control to prevent tearing or wrinkling during processing.

- Medium thicknesses (0.5-2.0mm) offer the most versatile processing options, suitable for a wide range of forming and welding techniques.

- Thicker gauges (2.0-6.0mm) may require more powerful processing equipment and specific heating/cooling protocols to maintain material properties during forming.

Common thicknesses: 0.5mm, 1.0mm, 1.5mm, 2.0mmTrue

These thicknesses cater to a wide range of applications in various industries.

All coils are thicker than 6.0mmFalse

Stainless steel coil thickness typically ranges from 0.1mm to 6.0mm.

What are the standard inner and outer diameter measurements for stainless steel coils?

In my experience, understanding coil diameter specifications is crucial for both logistics and processing efficiency. I once worked with a client who faced significant production delays due to incompatible coil diameters with their uncoiling equipment.

Standard inner diameters for stainless steel coils are typically 508mm (20 inches) or 610mm (24 inches). Outer diameters usually range from 1000mm to 2000mm, depending on the coil weight and thickness. These specifications are critical for compatibility with handling and processing equipment.

The choice of coil diameter impacts everything from transportation efficiency to processing speed. Let me share some insights I've gained from working with various manufacturers and processors over the years.

Inner Diameter Considerations

- Equipment Compatibility: Most processing equipment is designed to accommodate either 508mm or 610mm inner diameters. Choosing the right size ensures smooth integration with existing machinery.

- Coil Weight Distribution: Larger inner diameters can help distribute the weight of heavier coils more evenly, reducing the risk of deformation during storage and transport.

- Processing Speed: In some cases, a larger inner diameter can allow for faster uncoiling speeds, potentially increasing production efficiency.

Outer Diameter Factors

- Transportation Limits: The maximum outer diameter is often constrained by transportation regulations. In my experience, most standard trucks can accommodate coils up to 1800mm in outer diameter.

- Storage Capacity: Larger outer diameters allow for more material per coil, which can reduce handling and changeover times in high-volume production environments.

- Material Thickness Impact: Thicker materials will result in smaller outer diameters for a given coil weight, while thinner materials allow for larger outer diameters.

Industry-Specific Diameter Preferences

Different sectors often have specific preferences for coil diameters:

- Automotive Industry: Generally prefers smaller outer diameters (1200mm-1500mm) for easier handling in automated production lines.

- Construction Sector: Often uses larger outer diameters (up to 2000mm) to minimize coil changes during large-scale projects.

- Appliance Manufacturing: Typically opts for medium-sized coils (1500mm-1800mm outer diameter) to balance handling ease with production efficiency.

Standard inner diameters: 508mm, 610mmTrue

These inner diameters are common for compatibility with handling and processing equipment.

All outer diameters are less than 1000mmFalse

Outer diameters usually range from 1000mm to 2000mm.

How do standard sizes of stainless steel coils vary by industry or application?

Throughout my career, I've observed that while there are general standards for stainless steel coil sizes, specific industries often have unique requirements that deviate from these norms. Understanding these variations is crucial for both suppliers and end-users.

Stainless steel coil sizes vary significantly across industries. While general standards exist, sectors like automotive, construction, and appliance manufacturing often have specific requirements for width, thickness, and diameter that are optimized for their production processes and end products.

Let me share some insights I've gained from working with various industries, highlighting how their specific needs shape the stainless steel coil sizes they use.

Automotive Industry

The automotive sector has some of the most stringent requirements for stainless steel coils:

- Width: Typically ranges from 900mm to 1250mm, optimized for stamping and forming processes.

- Thickness: Varies widely, from 0.5mm for body panels to 2.0-3.0mm for structural components.

- Inner Diameter: Often prefers 508mm (20 inches) for compatibility with automated handling systems.

- Outer Diameter: Usually limited to 1500mm to ensure easy manipulation in robotic production lines.

I recently worked with a major auto parts manufacturer who required custom 1100mm wide coils with a thickness of 1.2mm. This specific size allowed them to maximize material utilization in their stamping process, reducing waste by nearly 20%.

Construction Industry

The construction sector often requires larger coil sizes:

- Width: Commonly uses wider coils, from 1000mm to 1600mm, for applications like roofing and cladding.

- Thickness: Ranges from 0.5mm for lightweight cladding to 6.0mm for heavy structural elements.

- Inner Diameter: Both 508mm and 610mm are common, depending on the handling equipment.

- Outer Diameter: Can go up to 2000mm for large-scale projects to minimize coil changes.

A recent project I consulted on involved supplying 1500mm wide, 3.0mm thick coils for a major stadium construction. The larger coil size significantly reduced installation time and material waste.

Appliance Manufacturing

The appliance industry often requires more diverse coil sizes:

- Width: Typically ranges from 600mm to 1200mm, depending on the specific appliance components.

- Thickness: Usually between 0.4mm to 2.0mm, with thinner gauges for aesthetic parts and thicker for structural components.

- Inner Diameter: 508mm is most common for compatibility with existing production lines.

- Outer Diameter: Generally between 1200mm to 1800mm, balancing handling ease with production efficiency.

I recently assisted an appliance manufacturer in optimizing their material usage by switching to 1000mm wide coils, which perfectly matched their new production line capabilities, resulting in a 15% reduction in processing time.

Industry-specific requirements varyTrue

Different industries have unique needs for width, thickness, and diameter specifications.

All industries use the same coil sizesFalse

Different sectors like automotive, construction, and appliance manufacturing have specific coil size requirements.

Where can I find detailed specifications for standard sizes of stainless steel coils?

As someone who has spent years in the stainless steel industry, I understand the challenge of finding comprehensive and reliable information on coil specifications. Let me guide you through the best resources I've come across and used throughout my career.

Detailed specifications for standard stainless steel coil sizes can be found in international standards like ASTM A480 and EN 10088-2, industry association publications, and reputable manufacturer catalogs. These sources provide comprehensive information on dimensions, tolerances, and material grades.

Finding accurate and up-to-date information is crucial for making informed decisions in material selection and procurement. Here's a breakdown of the most reliable sources I recommend:

International Standards Organizations

-

ASTM International (American Society for Testing and Materials):

- ASTM A480: This standard specifically covers flat-rolled stainless and heat-resisting steel plate, sheet, and strip.

- Website: www.astm.org1

- I've found this to be an excellent resource for detailed tolerances and dimensional standards.

-

European Committee for Standardization (CEN):

- EN 10088-2: This standard covers technical delivery conditions for sheet/plate and strip of corrosion resisting steels for general purposes.

- Website: www.cen.eu2

- Particularly useful for projects involving European suppliers or customers.

Industry Associations

-

International Stainless Steel Forum (ISSF):

- Provides comprehensive guides and technical reports on stainless steel specifications.

- Website: www.worldstainless.org3

- I often refer clients here for general industry information and trends.

-

Nickel Institute:

- Offers detailed technical guides on stainless steel grades and their applications.

- Website: www.nickelinstitute.org4

- Excellent for understanding the relationship between material composition and properties.

Online Databases and Tools

-

MatWeb:

- A comprehensive materials database that includes detailed specifications for various stainless steel grades.

- Website: www.matweb.com

- Useful for quick reference and comparison of different grades and their properties.

-

AZoM (The A to Z of Materials):

- Offers a wide range of articles and data on stainless steel specifications.

- Website: www.azom.com

- I find their articles particularly helpful for understanding the context behind specific specifications.

When using these resources, I always advise clients to cross-reference information from multiple sources to ensure accuracy. It's also crucial to consider that while these resources provide standard specifications, actual available sizes may vary by manufacturer.

In my experience, building a relationship with reliable suppliers is equally important. They can often provide the most up-to-date and relevant information specific to their production capabilities. For instance, at MFY Steel, we maintain a comprehensive database of our coil specifications, which we regularly update based on our latest manufacturing capabilities and industry demands.

Remember, while these resources provide valuable information, the specific requirements of your project may necessitate custom sizes. Always consult with your supplier or an industry expert to ensure you're selecting the most appropriate specifications for your application.

ASTM A480 covers flat-rolled stainless steelTrue

This standard provides details on dimensions, tolerances, and material grades.

All information is found in one sourceFalse

Accurate information should be cross-referenced from multiple sources like ASTM, EN standards, and manufacturers.

Conclusion

Understanding standard stainless steel coil sizes is crucial for efficient manufacturing and optimal material utilization. Width, thickness, and diameter specifications vary by industry and application, requiring careful consideration in material selection and procurement processes.

-

Understand the precise tolerances for stainless steel widths to ensure manufacturing accuracy. ↩

-

Learn how selecting the right coil width can improve material utilization and reduce waste. ↩

-

Get detailed information on standard thickness tolerances to maintain quality control. ↩

-

Ensure compatibility with processing equipment by understanding standard inner diameter sizes. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.