Wondering how raw materials transform into the gleaming, corrosion-resistant stainless steel products you rely on? Understanding this complex process helps ensure you choose the right manufacturing partner.

Stainless steel production involves carefully combining iron, chromium, nickel, and other elements through sophisticated melting, refining, and finishing processes to create corrosion-resistant alloys.

For manufacturers and buyers in the metal industry, understanding the production process is crucial for quality assessment and supplier selection. Let's explore each step of stainless steel manufacturing to help you make informed decisions.

The journey from raw materials to finished stainless steel products involves precise control of multiple variables, advanced technology, and strict quality standards. This complex process determines the final properties and performance of the material.

What Raw Materials Are Used to Produce Stainless Steel?

Selecting and sourcing the right raw materials significantly impacts the final product quality. Poor material selection can lead to inconsistent properties and reduced performance.

Stainless steel production requires high-quality iron ore1, chromium2, nickel3, and other alloying elements, along with recycled stainless steel scrap, which can comprise up to 60% of the raw material input.

Primary Raw Materials

Essential components for production:

| Material | Purpose | Typical Content |

|---|---|---|

| Iron/Steel Scrap | Base material | 60-70% |

| Chromium | Corrosion resistance | 10.5-30% |

| Nickel | Structure/Properties | 0-22% |

| Molybdenum | Enhanced protection | 0-6% |

Quality Requirements

Material specifications:

| Component | Quality Parameters | Impact |

|---|---|---|

| Scrap | Cleanliness, composition | Final properties |

| Ferroalloys | Purity levels | Process efficiency |

| Additives | Chemical composition | Grade accuracy |

Material Sources and Supply

Supply chain considerations:

- Recycled material availability

- Global sourcing strategies

- Quality certification requirements

- Supply chain sustainability

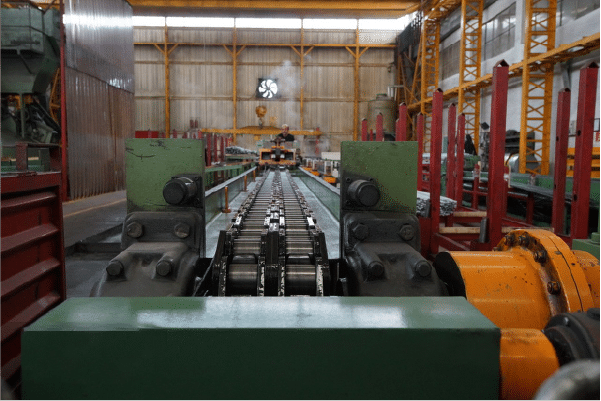

What Are the Key Steps in the Stainless Steel Manufacturing Process?

The manufacturing process complexity often leads to quality variations. Understanding each step helps identify critical control points for consistent quality.

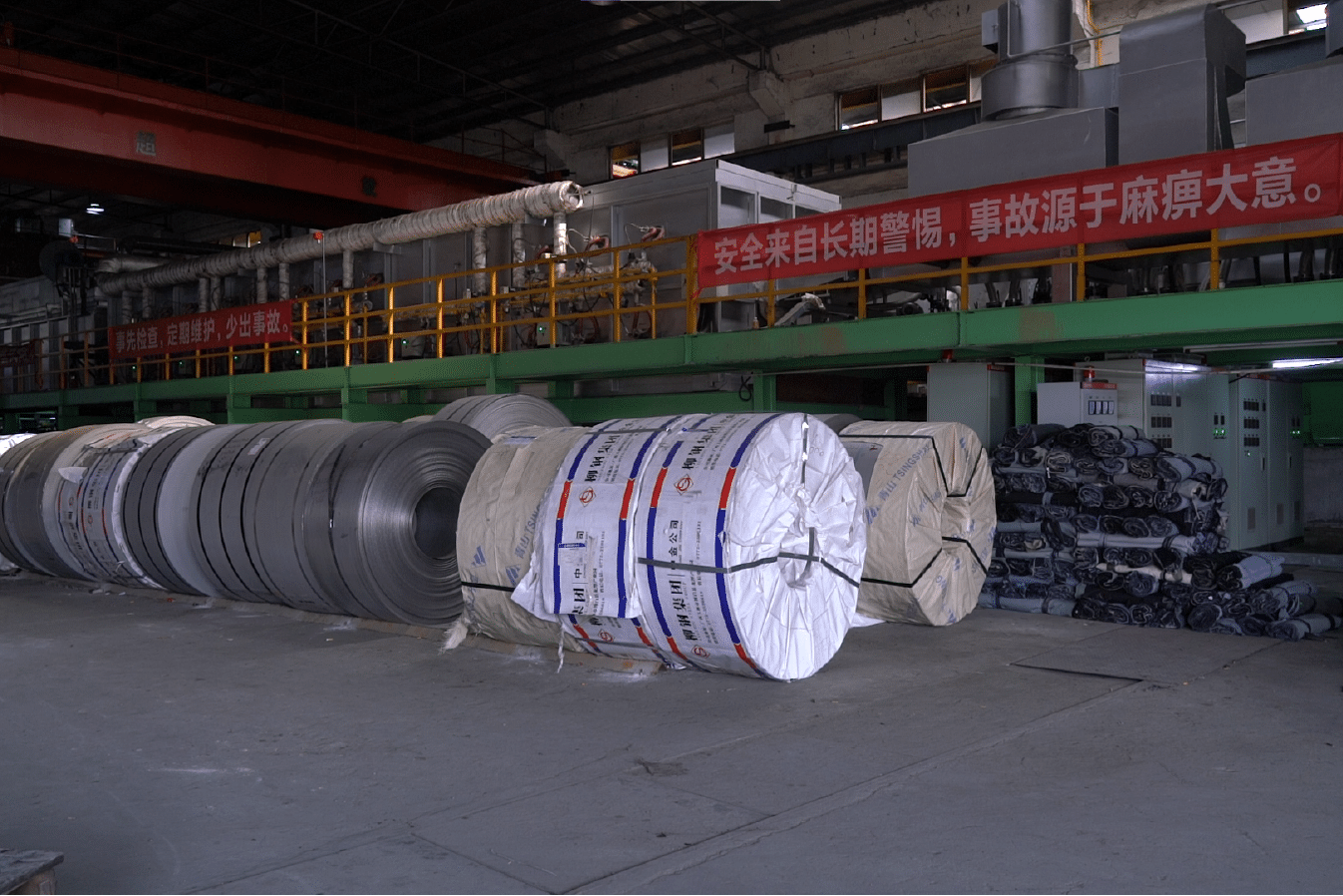

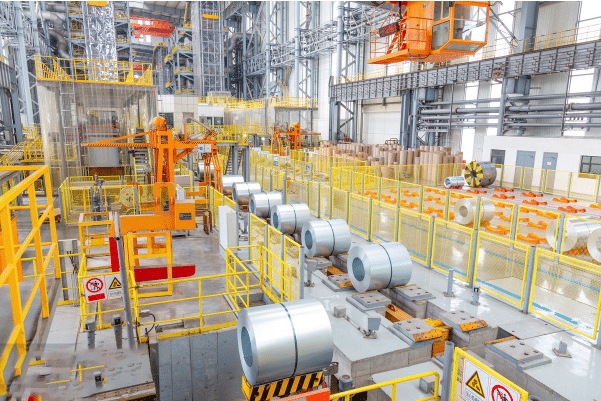

Stainless steel manufacturing involves melting, refining, casting, hot rolling, cold rolling, and finishing processes. Each step requires precise control to achieve desired material properties.

Primary Production Stages

Manufacturing sequence:

| Stage | Process | Control Parameters |

|---|---|---|

| Melting | Electric Arc Furnace4 | Temperature, chemistry |

| Refining | AOD Process5 | Oxygen, nitrogen levels |

| Casting | Continuous casting6 | Cooling rate, thickness |

| Rolling | Hot/cold reduction | Dimensional accuracy |

Quality Control Points

Critical checkpoints:

- Chemical composition testing

- Physical property verification

- Surface quality inspection

- Dimensional tolerance checking

Production Technologies

Modern manufacturing methods:

| Technology | Advantage | Application |

|---|---|---|

| VOD | Ultra-low carbon | L-grade steels |

| ESR | Superior cleanliness | Special grades |

| Strip casting | Energy efficiency | Thin products |

How Is Chromium Added to Create Corrosion Resistance in Stainless Steel?

The addition of chromium is a critical step that determines stainless steel's corrosion resistance. Improper chromium integration can compromise the material's fundamental properties.

Chromium is added primarily as ferrochrome7 during the melting process, with precise control of temperature and oxygen levels to ensure proper dissolution and uniform distribution throughout the steel.

Chromium Addition Process

Key process steps:

| Stage | Process Control | Quality Impact |

|---|---|---|

| Pre-heating | Temperature control | Dissolution efficiency |

| Addition timing | Sequence optimization | Distribution uniformity |

| Mixing | Stirring parameters | Homogenization |

Quality Verification Methods

Ensuring proper chromium integration:

| Test Method | Parameter | Acceptance Criteria |

|---|---|---|

| Spectrometry | Cr content | Grade specifications |

| Microstructure | Distribution | Uniformity standards |

| Corrosion testing | Resistance | Performance requirements |

Process Optimization

Critical factors:

- Temperature control systems

- Oxygen level management

- Mixing efficiency

- Recovery rate optimization

What Role Does Melting and Casting Play in Stainless Steel Production?

The melting and casting stages are fundamental in determining the final product quality. Problems at these stages can create defects that are impossible to correct in later processing.

Melting and casting establish the chemical composition and initial structure of stainless steel. Modern processes use electric arc furnaces and continuous casting technology for optimal quality and efficiency.

Melting Process Technologies

Modern melting methods:

| Technology | Advantages | Applications |

|---|---|---|

| EAF | High flexibility | All grades |

| AOD | Superior refining | Premium grades |

| ESR | Ultimate cleanliness | Special grades |

Casting Parameters Control

Critical variables:

| Parameter | Control Method | Impact |

|---|---|---|

| Temperature | Automated monitoring | Solidification quality |

| Cooling rate | Zone control | Structure formation |

| Casting speed | Process automation | Surface quality |

Defect Prevention Strategies

Quality assurance measures:

- Online monitoring systems

- Automated control systems

- Real-time adjustments

- Preventive maintenance

How Is Stainless Steel Finished and Polished for Different Applications?

Surface finishing determines both aesthetic appeal and functional performance. Different applications require specific surface treatments for optimal results.

Stainless steel finishing involves multiple processes from mechanical grinding to electropolishing, creating surfaces ranging from matte to mirror finish, each suited for specific applications.

Surface Finish Types

Standard finish options:

| Finish Type | Process | Common Applications |

|---|---|---|

| 2B | Cold rolled, heat treated | General purpose |

| BA | Bright annealed | Decorative |

| No.4 | Brushed | Food equipment |

| Mirror | Fine polished | Architectural |

Finishing Technologies

Modern finishing methods:

| Method | Characteristics | Best For |

|---|---|---|

| Mechanical | Consistent texture | Industrial |

| Chemical | Uniform etching | Medical |

| Electropolishing | Superior smoothness | High-purity |

Quality Standards

Finish specifications:

| Standard | Requirements | Verification |

|---|---|---|

| ASTM | Surface roughness | Profilometry |

| EN | Visual appearance | Visual inspection |

| JIS | Cleanliness | Contamination testing |

Conclusion

The production of high-quality stainless steel requires precise control of raw materials, manufacturing processes, and finishing techniques to meet specific application requirements.

-

Learn how iron ore contributes to stainless steel's structural integrity ↩

-

Discover the importance of chromium in preventing rust and corrosion ↩

-

Understand nickel's role in improving stainless steel's properties ↩

-

Find out how electric arc furnaces contribute to efficient steel melting ↩

-

Learn about AOD refining and its impact on stainless steel quality ↩

-

Explore the benefits of continuous casting in producing quality steel ↩

-

Understand how ferrochrome adds chromium to stainless steel ↩