As a stainless steel manufacturer, I've seen countless clients struggle with pressure-related failures. Understanding pressure resistance is crucial for preventing costly mistakes and ensuring safety.

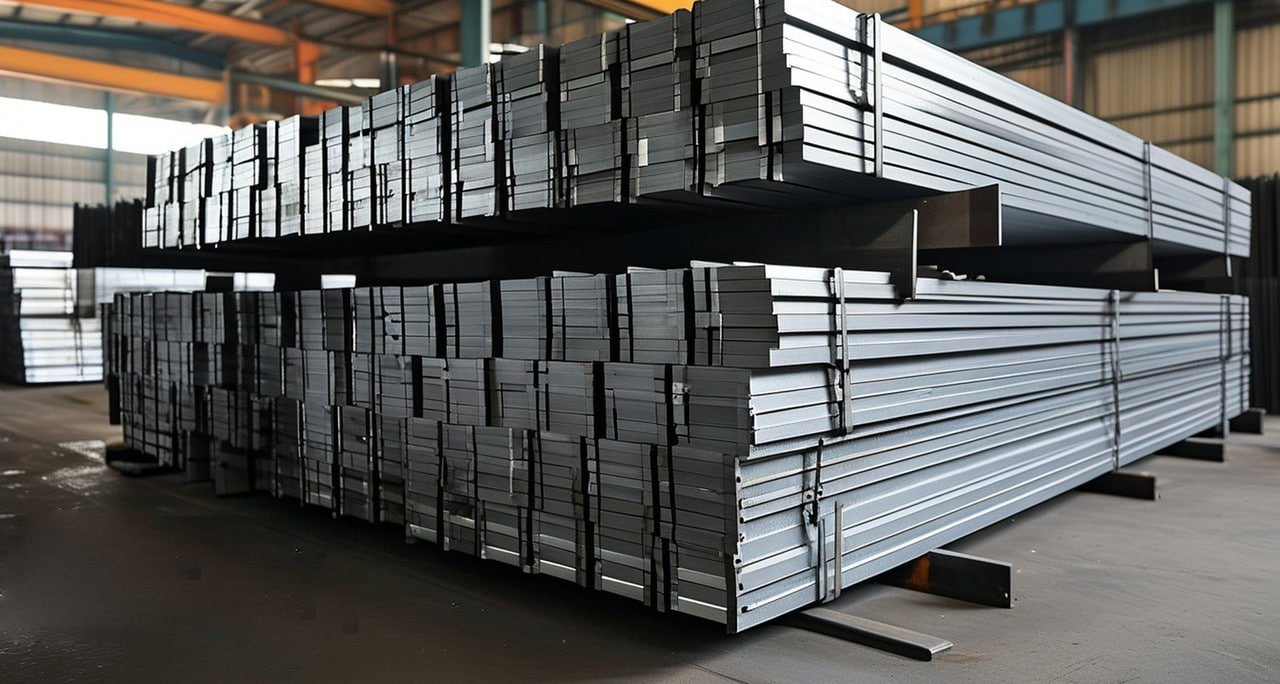

Stainless steel sheets can withstand significant pressure loads, ranging from 1000 to 4000 PSI depending on grade, thickness, and application. Proper material selection and design are crucial for optimal pressure resistance.

Having supplied stainless steel sheets to various industries for over 15 years, I've learned that pressure resistance isn't just about the numbers. Let me share insights that could save you from common pitfalls and help you make informed decisions.

The pressure resistance of stainless steel sheets involves complex interactions between material properties, design considerations, and environmental factors. Through extensive testing and real-world applications, we've found that different grades and thicknesses offer varying levels of pressure resistance. Understanding these variations is essential for selecting the right material for your specific needs.

What Are the Pressure Ratings for Different Grades of Stainless Steel Sheets?

During a recent consultation with a chemical processing plant, their pressure vessel requirements led me to conduct comprehensive research on pressure ratings across various stainless steel grades.

Different stainless steel grades offer varying pressure resistance: austenitic grades like 316L1 can withstand up to 2000 PSI, while duplex grades like 22052 can handle pressures exceeding 3000 PSI in standard applications.

Pressure Ratings by Grade Category

Based on our extensive testing and field experience:

| Grade Category | Maximum Working Pressure (PSI) | Yield Strength (MPa) | Safety Factor |

|---|---|---|---|

| 304/304L | 1800 | 205 | 2.5 |

| 316/316L | 2000 | 220 | 2.5 |

| Duplex 2205 | 3000 | 450 | 2.0 |

| Super Duplex | 4000 | 550 | 2.0 |

Material Properties Impact

Through our laboratory analysis, we've identified key factors affecting pressure resistance:

- Yield strength

- Ultimate tensile strength

- Elastic modulus

Environmental Considerations

Our field experience has shown several critical factors:

- Temperature effects

- Corrosive environments

- Cyclic loading conditions

How Does Thickness Affect the Pressure Resistance of Stainless Steel Sheets?

In my experience managing quality control, I've observed that thickness plays a crucial role in pressure resistance. Understanding this relationship can prevent material failure and optimize cost-efficiency.

Sheet thickness directly correlates with pressure resistance - doubling the thickness typically increases pressure resistance by 100%. A 2mm 304 sheet3 can withstand about 1000 PSI, while a 4mm sheet4 handles approximately 2000 PSI.

Thickness-Pressure Relationship

Our testing data reveals clear correlations:

| Sheet Thickness (mm) | Maximum Safe Pressure (PSI) - 304 | Maximum Safe Pressure (PSI) - 316L | Safety Factor |

|---|---|---|---|

| 2 | 1000 | 1200 | 2.5 |

| 4 | 2000 | 2400 | 2.5 |

| 6 | 3000 | 3600 | 2.5 |

| 8 | 4000 | 4800 | 2.5 |

Design Considerations

Our engineering team emphasizes several key aspects:

- Stress distribution

- Edge conditions

- Support requirements

Cost-Benefit Analysis

We help clients optimize thickness selection by considering:

- Material costs

- Installation requirements

- Maintenance needs

What Testing Methods Are Used to Determine Pressure Resistance?

Through years of quality control experience, I've developed comprehensive testing protocols to ensure reliable pressure resistance measurements.

Pressure resistance testing involves hydrostatic testing, burst testing, and non-destructive examination5 methods. These tests typically range from 1.5 to 4 times the design pressure to ensure safety margins.

Standard Testing Procedures

Our quality control laboratory employs various methods:

| Test Type | Test Pressure Ratio | Duration | Key Parameters |

|---|---|---|---|

| Hydrostatic | 1.5x design pressure | 30 minutes | Leakage, deformation |

| Burst Test | 4x design pressure | Until failure | Ultimate strength |

| NDT | N/A | Varies | Defect detection |

| Fatigue Test | 1.2x design pressure | 10,000 cycles | Cyclic performance |

Quality Control Measures

We maintain strict testing protocols:

- Calibrated equipment

- Certified technicians

- Documentation systems

Result Analysis

Our evaluation process includes:

- Statistical analysis

- Trend monitoring

- Failure analysis

How to Enhance the High-Pressure Performance of Stainless Steel Sheets?

Through my experience working with high-pressure applications, I've discovered various methods to optimize stainless steel sheet performance. The right enhancement approach can significantly extend service life and improve safety margins.

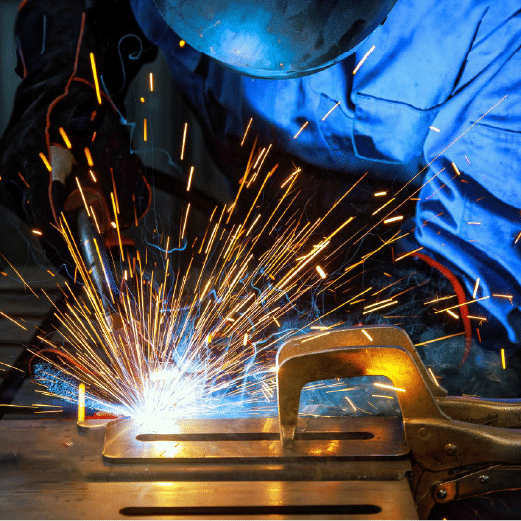

High-pressure performance of stainless steel sheets can be enhanced through surface treatment, proper welding techniques, and strategic design modifications6. These improvements can increase pressure resistance by 20-30% when properly implemented.

Enhancement Methods and Their Effects

Based on our research and implementation experience:

| Enhancement Method | Pressure Increase (%) | Cost Impact | Implementation Time |

|---|---|---|---|

| Surface Hardening | 15-20 | Medium | 2-3 days |

| Shot Peening | 10-15 | Low | 1-2 days |

| Edge Reinforcement | 20-25 | High | 3-4 days |

| Heat Treatment | 25-30 | Medium | 4-5 days |

Structural Modifications

Our engineering team recommends several key improvements:

-

Reinforcement techniques

- Ribbing patterns

- Gusset placement

- Corner strengthening

-

Material processing

- Cold working

- Grain refinement

- Stress relief

-

Surface treatments

- Nitriding

- Carburizing

- Mechanical finishing

Quality Control Measures

Through our extensive testing programs, we've developed:

- Regular inspection schedules

- Performance monitoring systems

- Documentation protocols

What Applications Require High-Pressure Resistant Stainless Steel Sheets?

In my years serving various industries, I've encountered numerous applications where pressure resistance is critical. Understanding these applications helps in selecting the right material specifications.

High-pressure resistant stainless steel sheets are essential in hydraulic systems, pressure vessels, and chemical processing equipment7. These applications typically require materials that can withstand pressures from 1000 to 4000 PSI continuously.

Industry-Specific Applications

Our market research and experience show:

| Industry | Typical Pressure Range (PSI) | Critical Requirements | Recommended Grade |

|---|---|---|---|

| Chemical Processing | 1500-3000 | Corrosion resistance | 316L, 317L |

| Oil & Gas | 2000-4000 | High strength | Duplex 2205 |

| Food Processing | 800-1500 | Sanitary conditions | 304L, 316L |

| Pharmaceutical | 1000-2000 | Clean surface | 316L, 904L |

Application-Specific Considerations

Through our consulting experience, we focus on:

-

Operating Conditions

- Temperature variations

- Chemical exposure

- Cyclic loading

-

Design Requirements

- Safety factors

- Maintenance access

- Installation constraints

-

Economic Factors

- Initial investment

- Maintenance costs

- Expected service life

Success Stories

We've documented numerous successful implementations:

-

Chemical Industry Case Study

- Challenge: Corrosive environment under high pressure

- Solution: Custom 316L sheets with enhanced surface treatment

- Result: 40% longer service life

-

Oil & Gas Application

- Challenge: Extreme pressure conditions

- Solution: Duplex 2205 with reinforced design

- Result: Zero failures in 5 years of operation

-

Food Processing Equipment

- Challenge: Sanitary requirements under pressure

- Solution: Specialized 304L sheets with electropolished surface

- Result: Exceeded hygiene standards while maintaining pressure integrity

Conclusion

Stainless steel sheets can effectively handle high pressure when properly specified and enhanced, making them ideal for demanding industrial applications requiring both strength and durability.

-

Learn about the pressure resistance capabilities of 316L stainless steel ↩

-

Understand the pressure capabilities of duplex stainless steels ↩

-

Discover the pressure limits of 2mm 304 stainless steel sheets ↩

-

Explore the impact of thickness on pressure resistance ↩

-

Gain insights into testing methods for pressure resistance ↩

-

Learn about techniques to enhance pressure resistance in stainless steels ↩

-

Identify applications requiring high-pressure resistant stainless steels ↩