Are you struggling to find the perfect material for your decorative project? The versatility and aesthetic appeal of stainless steel sheets might be the solution you've been searching for.

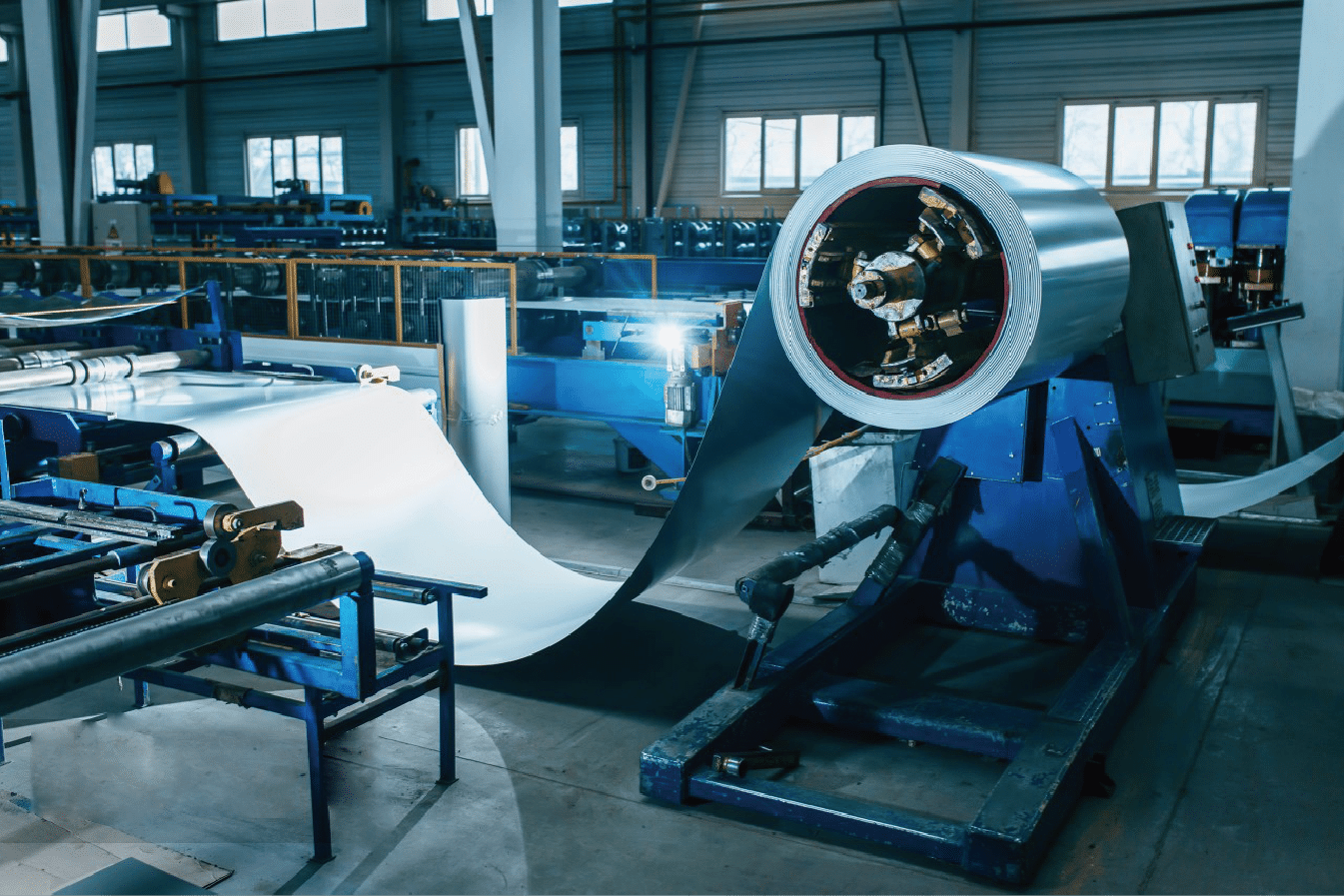

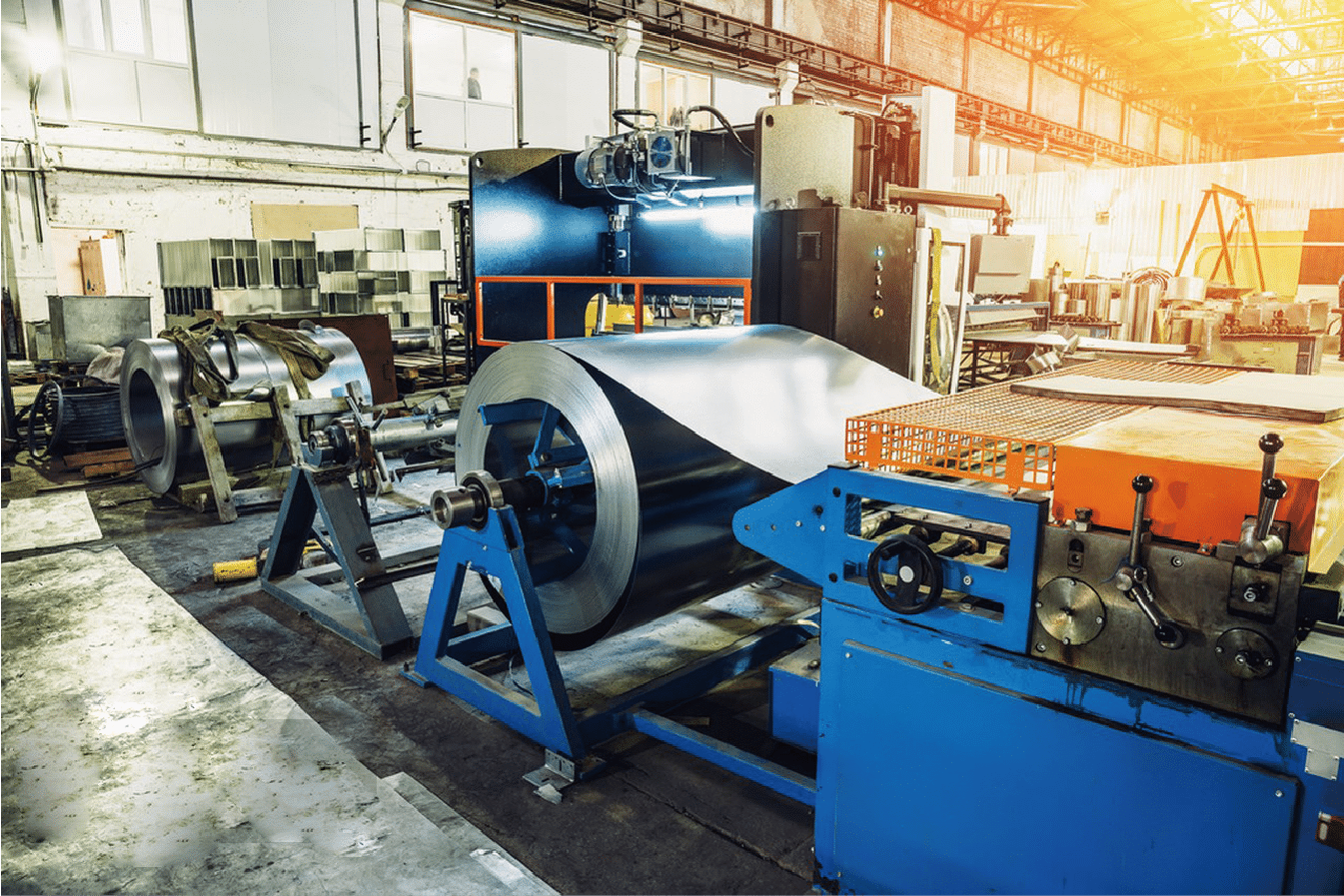

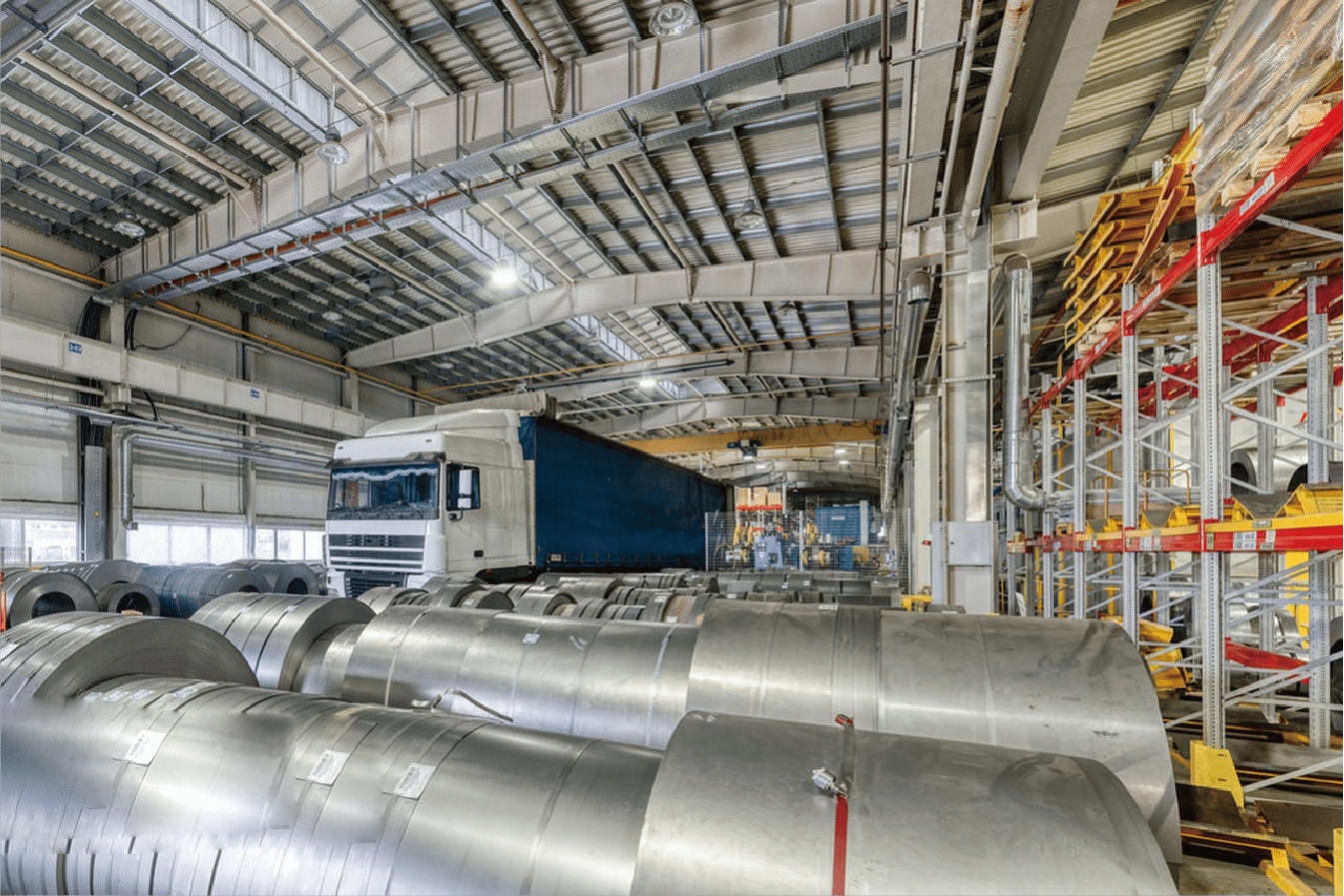

Stainless steel sheets are widely used in decorative projects due to their durability, aesthetic versatility, and low maintenance requirements. These materials can be finished in various ways, including brushed, mirror-polished, or patterned surfaces, making them ideal for both interior and exterior decorative applications.

As a stainless steel manufacturer with over 15 years of experience, I've witnessed countless innovative applications of stainless steel sheets in decorative projects. The material's ability to blend modern aesthetics with practical functionality continues to inspire architects and designers worldwide.

The evolution of stainless steel1 in decorative applications represents a fascinating journey from industrial utility to artistic expression. From the iconic Chrysler Building's art deco spire to contemporary architectural masterpieces, stainless steel has transformed our approach to aesthetic design. Today, we're seeing an unprecedented fusion of functionality and beauty, where stainless steel sheets serve not just as structural elements but as canvas for creative expression.

What is the background of using stainless steel sheets in decorative projects?

The journey of incorporating stainless steel sheets into decorative projects began with a simple problem: traditional materials weren't meeting the demands of modern architecture's need for durability and aesthetic appeal.

The use of stainless steel sheets in decorative projects dates back to the 1920s, when architects first recognized its potential beyond industrial applications. Its corrosion resistance, sleek appearance, and ability to maintain its finish made it an ideal choice for both interior and exterior decorative elements.

Working with various clients across India and Southeast Asia, I've observed a fascinating evolution in how stainless steel sheets are perceived and utilized in decorative projects. One particularly memorable project involved collaborating with a luxury hotel chain in Mumbai, where we supplied specialized finish stainless steel sheets2 for their lobby renovation. The project perfectly exemplifies how this material has transcended its industrial origins to become a cornerstone of contemporary aesthetic design.

The Historical Evolution of Decorative Stainless Steel

The integration of stainless steel into decorative applications marks a significant shift in architectural and design thinking. In the early 20th century, when stainless steel was primarily viewed as an industrial material, visionary architects began to recognize its aesthetic potential. The Chrysler Building3 in New York, completed in 1930, stands as a testament to this revolutionary thinking, featuring stainless steel spires that have maintained their brilliance for nearly a century.

Impact on Modern Architecture

Contemporary architecture has embraced stainless steel sheets in ways that would have been unimaginable to early pioneers. Through my work with MFY, I've witnessed the material's application in projects ranging from modest retail spaces to grand public buildings. For instance, we recently supplied specialized finish stainless steel sheets to a major commercial project in Delhi, where the architect used our materials to create an intricate facade that changes appearance throughout the day as light conditions vary.

Environmental and Economic Considerations

The sustainability aspect of stainless steel has become increasingly important in recent years. Based on our research and client feedback, here's a comparative analysis of different decorative materials:

| Material | Lifespan (Years) | Recyclability | Maintenance Cost/Year | Initial Cost |

|---|---|---|---|---|

| Stainless Steel | 50+ | 100% | Low ($0.5-1/sq ft) | High |

| Aluminum | 20-30 | 100% | Medium ($1-2/sq ft) | Medium |

| Copper | 40+ | 100% | High ($2-3/sq ft) | Very High |

| Glass | 20-30 | 90% | Medium ($1-2/sq ft) | Medium |

One of our clients, a sustainable building developer in Singapore, chose stainless steel sheets specifically for their LEED certification project4. The material's longevity and recyclability contributed significantly to their sustainability goals while providing the modern aesthetic they desired.

Stainless steel used since the 1920sTrue

Stainless steel's properties were first recognized for decorative use in the 1920s.

Stainless steel only for industrial useFalse

While initially industrial, its aesthetic potential was soon realized.

How are stainless steel sheets currently applied in decorative projects?

In my extensive experience working with architects and designers, I've noticed a dramatic shift in how stainless steel sheets are being utilized in contemporary decorative projects, pushing the boundaries of traditional applications.

Modern applications of stainless steel sheets in decorative projects encompass wall cladding, ceiling features, sculptural elements, and architectural accents. Designers utilize various finishes and patterns to create stunning visual effects, from mirror-polished surfaces that reflect light to textured patterns that add depth and character.

Through my role at MFY, I've had the privilege of witnessing countless innovative applications of stainless steel sheets in decorative projects. Recently, we worked with a prominent architect in Dubai who used our mirror-finished sheets5 to create an stunning lobby installation that plays with light and reflection in unexpected ways. This project exemplifies how modern designers are pushing the boundaries of what's possible with this versatile material.

Interior Applications

The versatility of stainless steel sheets in interior design continues to amaze me. Working with a luxury hotel chain in Mumbai, we supplied specialized finish sheets for their grand entrance hall. The architect created a stunning wall installation that combines different surface treatments – mirror-polished, brushed, and patterned sections – to create a dynamic visual experience that changes as guests move through the space.

Exterior Applications

Exterior applications present unique challenges and opportunities. A recent project with a commercial building in Singapore demonstrated how stainless steel sheets can be used to create a building envelope that's both functional and aesthetically pleasing. The architect specified our grade 316L sheets with a custom pattern finish that not only provides weather resistance6 but also creates an ever-changing play of light throughout the day.

Innovative Design Techniques

Modern fabrication technologies have revolutionized what's possible with stainless steel sheets. Here's a comparison of popular finishing techniques and their applications:

| Finish Type | Visual Effect | Best Application | Maintenance Level |

|---|---|---|---|

| Mirror Polish | High reflectivity | Interior features | High |

| Brushed | Subtle, directional | Wall panels | Medium |

| Patterned | Textured, unique | Accent walls | Low |

| Colored | Decorative | Feature elements | Medium |

Modern uses include wall claddingTrue

Wall cladding is a popular application of stainless steel sheets.

Stainless steel not used in ceilingsFalse

Stainless steel sheets are also used in ceiling features.

What challenges are faced when using stainless steel sheets in decorative projects?

Throughout my years in the stainless steel industry, I've encountered numerous challenges that architects and designers face when incorporating stainless steel sheets into their decorative projects.

Common challenges include maintaining consistent surface finish across large areas, preventing fingerprints and smudges on high-touch surfaces, managing installation costs, and ensuring proper maintenance. Environmental factors like coastal air exposure and chemical pollutants can also affect the material's appearance and longevity.

Last month, I consulted with a major hotel renovation project in Mumbai where the design team was struggling with these exact issues. Through careful material selection and proper installation techniques, we were able to overcome these challenges and create a stunning result that met both aesthetic and practical requirements.

Technical Installation Challenges

In my experience working with various installation teams, proper handling and installation of stainless steel sheets requires specific expertise. During a recent project with a commercial building in Delhi, we encountered several technical challenges that required innovative solutions:

The first challenge was maintaining perfect flatness across large wall panels. We developed a specialized backing system that prevented oil-canning effects while allowing for thermal expansion. This solution has since become our standard recommendation for similar projects.

Maintenance and Longevity Concerns

Maintenance challenges vary significantly based on the environment and application. Here's a comprehensive analysis of common issues and solutions:

| Challenge | Impact | Solution | Cost Implication |

|---|---|---|---|

| Fingerprints | Visual appearance | Anti-fingerprint coating | +15-20% |

| Coastal exposure | Corrosion risk | Grade 316L selection | +25-30% |

| Urban pollution | Surface staining | Regular cleaning protocol | +$2-3/sq ft/year |

| Scratches | Aesthetic damage | Protective films | +10-15% |

Environmental Factors

Working with clients across different regions has taught me that environmental considerations are crucial. A recent project in Dubai required special attention to sand abrasion and intense UV exposure. We recommended a specially treated surface finish that has shown excellent resistance to these conditions after two years of installation.

Fingerprint prevention is a challengeTrue

Preventing fingerprints on high-touch surfaces is a common challenge.

Stainless steel unaffected by coastal airFalse

Coastal air exposure can affect stainless steel's appearance and longevity.

How do stainless steel sheets' properties overcome these challenges in decorative projects?

In my 15 years of experience at MFY, I've witnessed countless examples of how stainless steel's unique properties provide elegant solutions to complex decorative challenges.

Stainless steel sheets overcome decorative project challenges through their inherent corrosion resistance, structural stability, and adaptable finishing options. The material's self-healing chromium oxide layer, combined with various surface treatments, provides long-lasting aesthetic appeal while minimizing maintenance requirements.

During a recent consultation with a luxury hotel developer in Mumbai, we demonstrated how our specialized surface treatments could maintain pristine appearance even in their humid coastal environment. This project perfectly illustrates how understanding material properties leads to successful long-term installations.

Material Properties and Performance

My experience working with diverse architectural projects has shown that stainless steel's success in decorative applications stems from its fundamental properties. Recently, we collaborated with a major commercial development in Singapore where the architect needed a material that could withstand tropical conditions while maintaining its aesthetic appeal. Our grade 316L sheets with specialized surface treatment proved perfect for this challenging environment.

The chromium oxide layer's self-healing properties particularly impressed our client when we demonstrated its effectiveness. Even after intentional surface scratching, the material showed remarkable recovery capabilities, maintaining its protective properties and appearance.

Environmental Adaptability

Through numerous projects across different climate zones, I've compiled extensive data on performance in various environments. Here's a comprehensive analysis of material behavior:

| Environment | Grade Selection | Surface Treatment | Expected Longevity | Maintenance Requirements |

|---|---|---|---|---|

| Coastal | 316L | Electropolished | 30+ years | Quarterly cleaning |

| Urban | 304 | Brushed | 25+ years | Bi-annual cleaning |

| Industrial | 316Ti | Chemical passivated | 20+ years | Monthly cleaning |

| Indoor | 304 | Mirror polished | 50+ years | Annual cleaning |

Innovative Solutions

Working closely with architects and designers has led to discovering innovative applications of stainless steel's properties. For instance, we recently developed a new surface treatment technique that enhances the material's natural corrosion resistance while providing unique aesthetic effects. This innovation came from a challenging project in Dubai where traditional finishes weren't meeting the client's expectations for durability in desert conditions.

Self-healing chromium oxide layerTrue

This layer allows stainless steel to maintain its aesthetic appeal.

Stainless steel not suitable for humid areasFalse

Specialized surface treatments can maintain stainless steel's appearance in humid environments.

What are the best practices for incorporating stainless steel sheets in decorative projects?

After supplying materials to hundreds of successful decorative projects, I've developed a deep understanding of what makes these installations truly exceptional.

The key best practices for incorporating stainless steel sheets include careful grade selection based on environment, proper surface finish choice for the intended application, professional installation techniques, and implementation of appropriate maintenance protocols. Success requires a holistic approach considering both technical and aesthetic factors.

Last month, I consulted on a high-profile project in Chennai where we implemented these best practices to create a stunning architectural feature that perfectly balanced visual impact with practical durability. The project's success reinforced the importance of following established guidelines while remaining open to innovative approaches.

Design and Planning Phase

Through my experience working with leading architects and designers, I've learned that successful projects start with thorough planning. Recently, while working with a commercial developer in Bangkok, we developed a comprehensive pre-installation checklist that has become our standard:

Material Selection and Specification

Based on extensive field testing and real-world applications, I've developed detailed guidelines for material selection. Here's a comparative analysis of different specifications and their optimal applications:

| Application Type | Recommended Grade | Finish Type | Installation Method | Special Considerations |

|---|---|---|---|---|

| Interior Walls | 304 | Brushed | Mechanical fixing | Thermal expansion |

| External Facades | 316L | Mirror polished | Curtain wall system | Weather exposure |

| Decorative Features | 316 | Patterned | Custom mounting | Lighting effects |

| High-traffic Areas | 304L | Anti-fingerprint | Panel system | Impact resistance |

Installation and Maintenance Guidelines

Working with installation teams across Asia has taught me the critical importance of proper installation techniques. During a recent project in Dubai, we documented every step of the installation process, creating a comprehensive guide that addresses common challenges:

Our maintenance protocols have been refined through years of post-installation monitoring. A recent project in Mumbai demonstrated the importance of proper maintenance when the client reported perfect condition of their installation after three years of following our recommended procedures.

Through careful attention to these practices, we've consistently achieved outstanding results in decorative applications. For example, a luxury hotel in Singapore that implemented our complete set of recommendations has maintained its stunning appearance for over five years, despite challenging tropical conditions.

Proper grade selection is essentialTrue

Selecting the right grade based on the environment is crucial for success.

Installation techniques are not importantFalse

Professional installation techniques are critical to ensure durability and aesthetic quality.

Conclusion

Stainless steel sheets have revolutionized decorative projects by offering unparalleled durability, versatility, and aesthetic appeal. Through proper selection, installation, and maintenance, these materials continue to push the boundaries of architectural design while providing sustainable, long-lasting solutions.

-

Learn about the historical development and modern uses of stainless steel in architecture and design ↩

-

Explore the various finishing options for stainless steel sheets and their applications ↩

-

Understand the iconic use of stainless steel in the Chrysler Building's architecture ↩

-

Discover the sustainability benefits of stainless steel in green building projects ↩

-

Explore the uses of mirror-polished stainless steel in creating reflective and dynamic designs ↩

-

Learn about the weather-resistant properties of stainless steel and its use in outdoor projects ↩