As a stainless steel manufacturer with 15 years of experience, I've witnessed how corrosion and pressure resistance challenges in oil and gas pipelines have driven the demand for high-quality stainless steel solutions1.

Stainless steel pipes are extensively used in oil and gas pipelines due to their superior corrosion resistance, high strength-to-weight ratio, and durability. They can withstand extreme temperatures, high pressures, and aggressive chemicals while maintaining structural integrity throughout their service life.

Having supplied stainless steel pipes to major oil and gas projects across India and the Middle East, I've seen firsthand how crucial material selection is for ensuring pipeline safety and longevity. Let me share insights from our successful installations and the evolving industry standards.

The oil and gas industry's pipeline infrastructure represents a critical investment, where material choice can mean the difference between decades of reliable service and catastrophic failure. Through my experience working with clients like David Zhang2, who manages large-scale petrochemical operations in India, I've learned that understanding the complete lifecycle of stainless steel pipes in oil and gas applications is essential for making informed decisions.

What is the historical background of using stainless steel pipes in oil and gas pipelines?

The journey of implementing stainless steel in oil and gas pipelines began with devastating corrosion failures that plagued early carbon steel installations, leading to environmental disasters and significant financial losses.

The adoption of stainless steel pipes in oil and gas pipelines evolved from the 1950s, driven by increasing demands for corrosion resistance and safety. This transition marked a significant shift from traditional carbon steel, offering superior performance in aggressive environments and longer service life.

Working closely with industry veterans, I've gathered fascinating insights about how material selection in pipeline construction has evolved. Through my conversations with clients who've been in the industry for decades, I've learned about the remarkable transformation from basic carbon steel to sophisticated stainless steel grades. The evolution wasn't just about material changes; it represented a fundamental shift in how the industry approached safety, efficiency, and environmental protection.

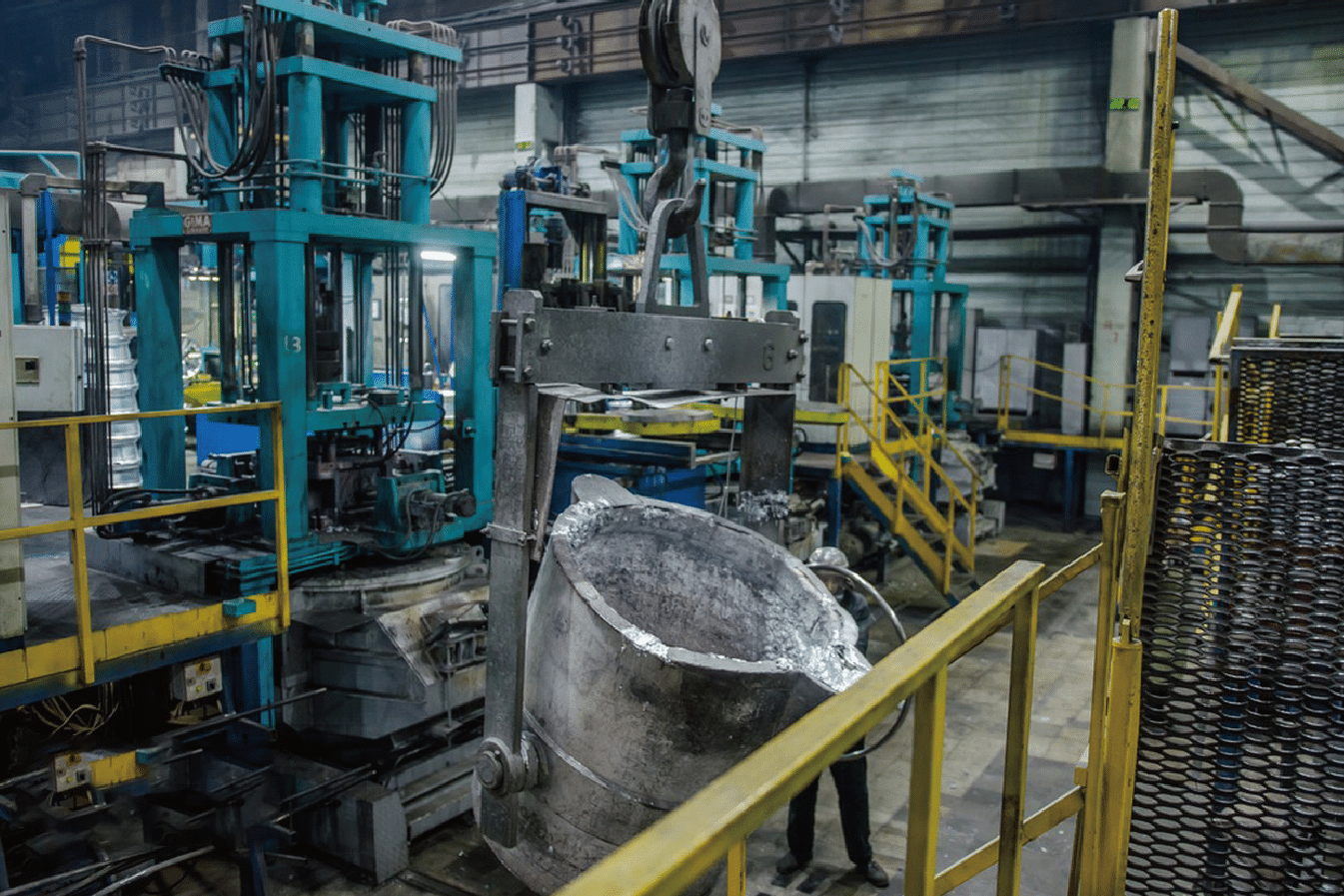

Early Adoption and Development

The early days of oil and gas pipeline construction were marked by significant challenges and frequent failures. Carbon steel pipelines often succumbed to corrosion within just a few years, leading to costly replacements and environmental concerns. The introduction of stainless steel grades in the 1950s revolutionized the industry. Through my experience working with various grades of stainless steel, I've seen how different compositions can dramatically affect performance in specific environments.

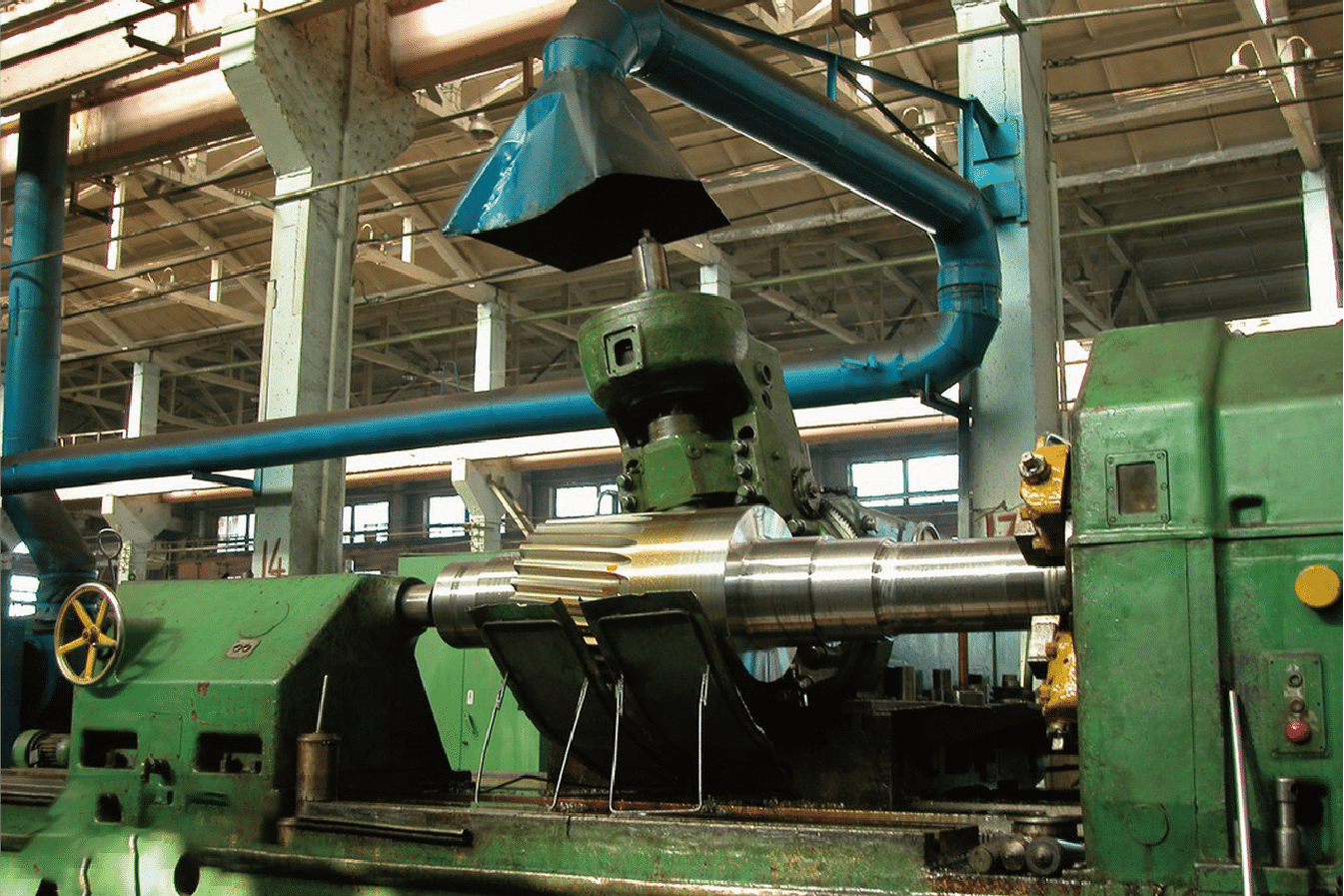

Technical Evolution

The development of specialized stainless steel grades has been a game-changer. From basic austenitic grades to advanced duplex varieties, each innovation addressed specific challenges in the oil and gas sector. Working with companies like National Oil Corporation3, I've witnessed the transition from standard 304/316 grades to more sophisticated super duplex grades for critical applications.

Impact on Industry Standards

The implementation of stainless steel has fundamentally transformed industry standards and safety protocols. Here's a comparison of key performance metrics between traditional carbon steel and modern stainless steel pipes:

| Characteristic | Carbon Steel | Stainless Steel | Impact on Operations |

|---|---|---|---|

| Corrosion Resistance | Low | High | Reduced maintenance costs |

| Service Life | 10-15 years | 30+ years | Lower lifecycle costs |

| Initial Cost | Lower | Higher | Higher upfront investment |

| Maintenance Requirements | High | Low | Reduced downtime |

| Environmental Risk | Higher | Lower | Better safety profile |

Stainless steel replaced carbon steel in the 1950sTrue

The shift was driven by the need for better corrosion resistance and safety.

Carbon steel has higher corrosion resistanceFalse

Stainless steel offers significantly better corrosion resistance than carbon steel.

What is the current usage of stainless steel pipes in the oil and gas industry?

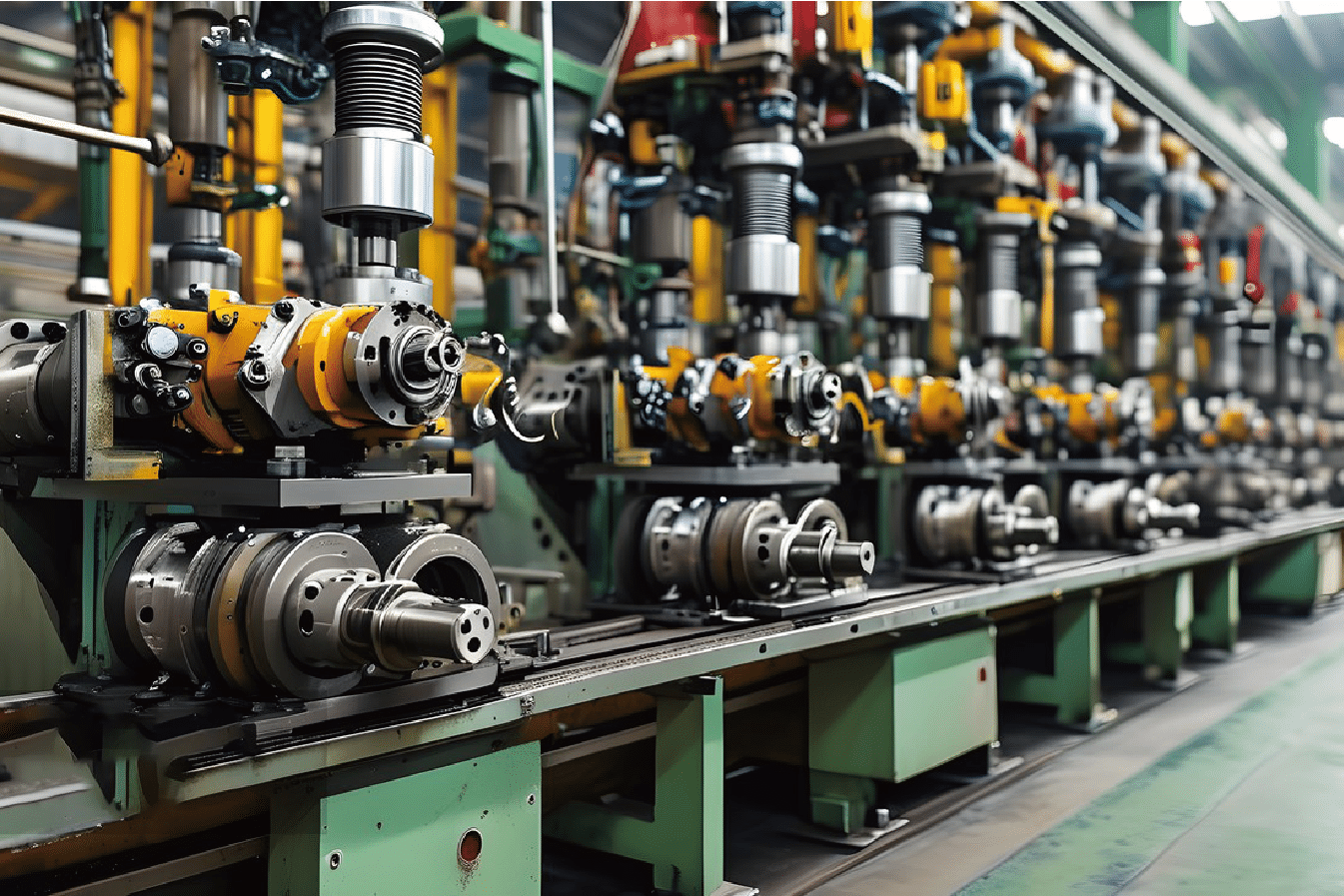

In my role as a supplier to major oil and gas projects, I've observed the increasing sophistication in how stainless steel pipes are deployed across different segments of the industry, from upstream exploration to downstream processing.

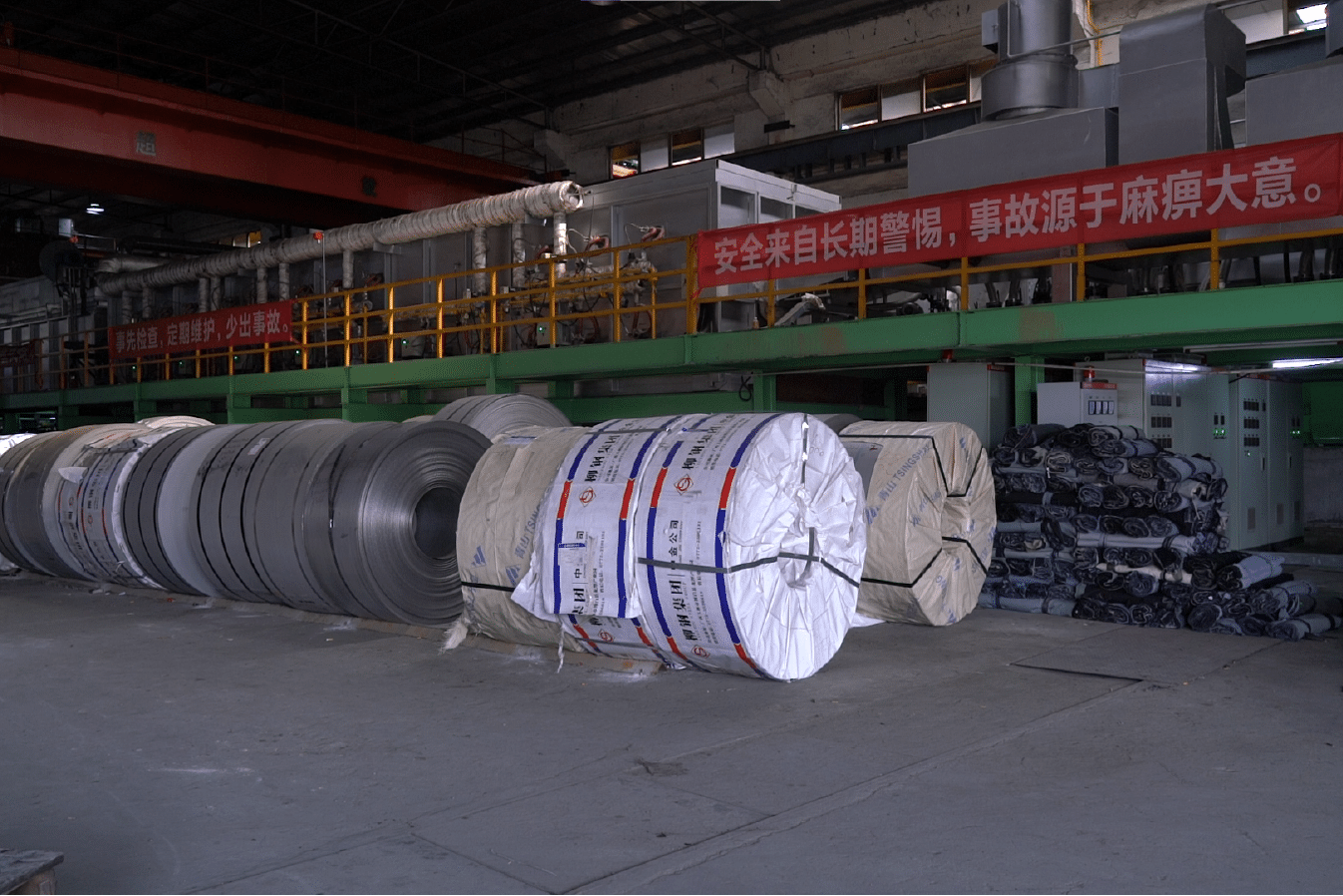

Modern oil and gas operations utilize stainless steel pipes extensively in critical applications, including subsea pipelines, processing facilities, and transportation networks. These pipes handle everything from corrosive crude oil to high-pressure natural gas, ensuring safe and efficient operations.

Through my recent collaboration with a major Indian refinery expansion project4, I gained valuable insights into the diverse applications of stainless steel pipes. The project required various grades of stainless steel for different sections of the facility, each chosen based on specific operating conditions. This experience highlighted the complexity of material selection in modern oil and gas facilities and the critical role that proper material choice plays in ensuring operational success.

Upstream Applications

In upstream operations, where extraction and initial processing occur, stainless steel pipes face some of their toughest challenges. Working with offshore platforms in the Arabian Gulf, I've seen how our super duplex stainless steel pipes withstand the combined effects of high pressure, corrosive fluids, and marine environments. These installations require pipes that can handle:

- Pressures exceeding 10,000 psi

- Temperatures ranging from -50°C to 150°C

- Highly corrosive hydrogen sulfide (H2S) content

- Constant exposure to seawater and marine organisms

Midstream Transportation

The midstream sector presents unique challenges that I've helped clients address through careful material selection. When working with a major pipeline project in Southeast Asia, we implemented a comprehensive solution using various stainless steel grades to handle different sections of the transportation network.

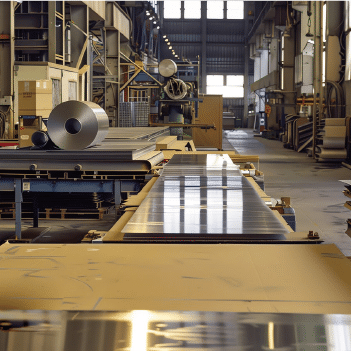

Downstream Processing

In downstream operations, where refineries and processing plants operate, the demands on stainless steel pipes are especially diverse. Here's a detailed breakdown of common applications:

| Process Area | Stainless Steel Grade | Key Requirements | Typical Service Life |

|---|---|---|---|

| Distillation Units | 316L | High temperature resistance | 25-30 years |

| Cooling Systems | 304L | Corrosion resistance | 20-25 years |

| Chemical Processing | Duplex 2205 | Combined strength and corrosion resistance | 30+ years |

| Storage Facilities | 316 | Moderate corrosion resistance | 25-30 years |

Stainless steel is used in upstream applicationsTrue

Stainless steel handles high pressure and corrosive fluids in upstream operations.

Stainless steel is cheaper than carbon steelFalse

Stainless steel has a higher upfront cost compared to carbon steel.

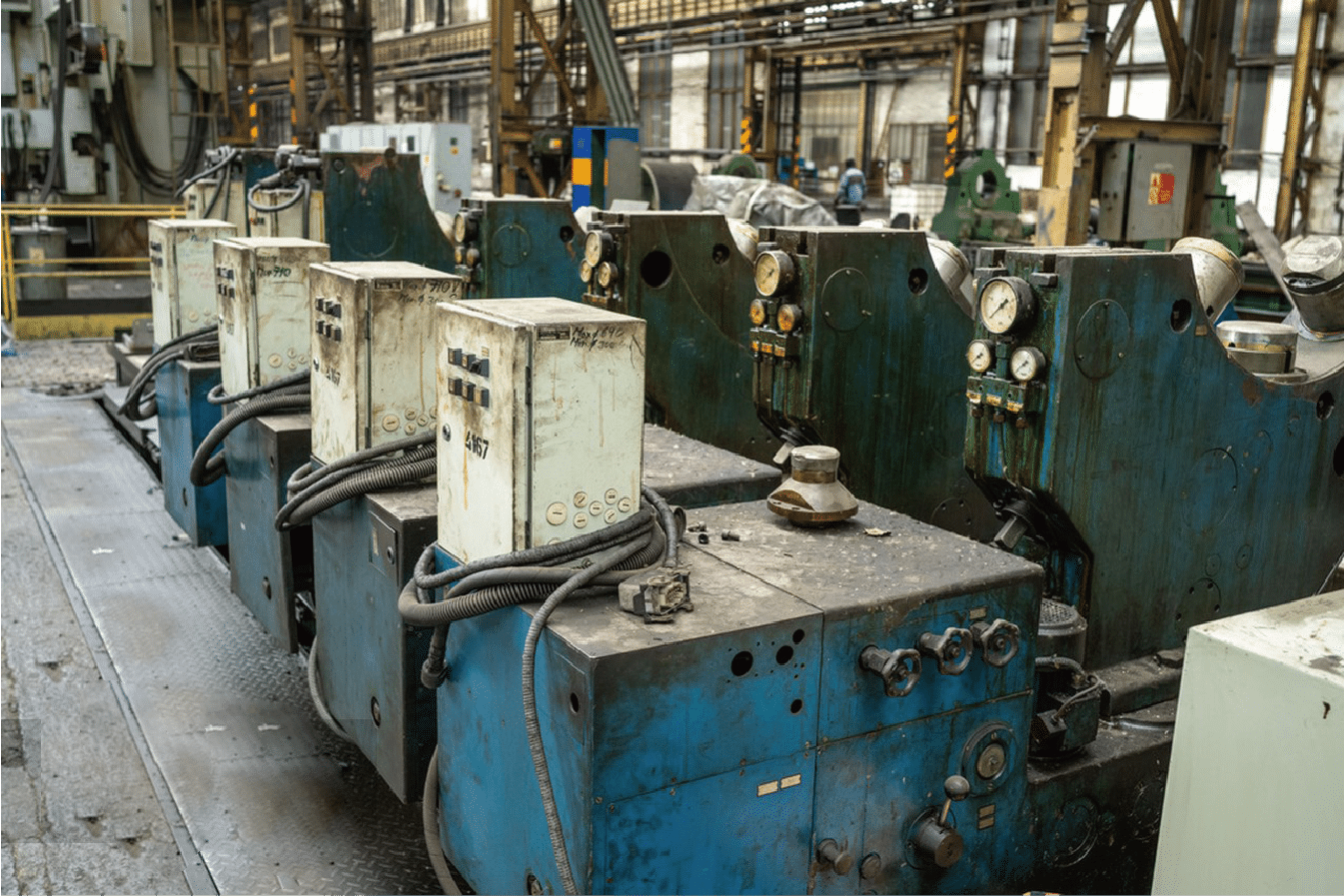

What challenges are faced when using stainless steel pipes in oil and gas pipelines?

Having worked with numerous oil and gas clients across Asia and the Middle East, I've encountered various challenges that impact the performance and longevity of stainless steel pipe installations.

The primary challenges in using stainless steel pipes for oil and gas applications include stress corrosion cracking, hydrogen embrittlement, high material costs, and complex installation requirements. These issues require careful consideration during design, installation, and maintenance phases.

During a recent project consultation with an Indian petrochemical plant5, we faced multiple technical challenges that highlighted the importance of proper material selection and installation procedures. Let me share our approach to addressing these challenges and the lessons learned from implementing solutions in real-world scenarios.

Material Integrity Issues

In my experience working with major oil and gas facilities, material integrity poses one of the most significant challenges. Last year, while assisting a client in the Middle East, we encountered severe stress corrosion cracking in their existing pipeline system. The investigation revealed several critical factors:

The combination of high chloride content in the transported medium and elevated temperatures had accelerated the corrosion process. This led us to develop a comprehensive material selection framework that considers multiple environmental and operational factors. Through extensive testing and field validation, we determined that super duplex stainless steel grades offered the best resistance to these specific conditions.

Environmental Impact Concerns

Environmental challenges vary significantly across different regions. Working with installations in both coastal and desert environments has taught me the importance of considering location-specific factors:

| Environmental Factor | Impact on Pipes | Mitigation Strategy | Cost Implication |

|---|---|---|---|

| Marine Atmosphere | Chloride-induced corrosion | Special coating systems | +15-20% initial cost |

| Desert Climate | Thermal cycling stress | Enhanced pipe design | +10-15% material cost |

| Subsea Conditions | External pressure damage | Higher grade selection | +25-30% investment |

| Chemical Exposure | Internal corrosion | Specialized linings | +20-25% total cost |

Installation and Maintenance Complexities

The installation phase presents unique challenges that I've helped clients navigate. During a recent pipeline expansion project in Southeast Asia, we encountered several critical issues:

- Welding difficulties due to material properties

- Alignment challenges in complex terrain

- Quality control requirements for high-pressure systems

- Access limitations in remote locations

Through my experience working with clients like David Zhang, I've learned that cost management is a crucial aspect of any pipeline project. The initial investment in stainless steel pipes can be 2-3 times higher than traditional materials, requiring careful financial planning and ROI analysis.

Stainless steel can face stress corrosion crackingTrue

Stress corrosion cracking is a significant challenge for stainless steel in certain environments.

Stainless steel has low material costsFalse

Stainless steel is more expensive than many other materials used in pipelines.

How can these challenges be addressed to ensure reliable performance?

From my years of supplying stainless steel solutions to the oil and gas sector, I've developed comprehensive strategies to address the common challenges faced by our clients.

Reliable performance of stainless steel pipes in oil and gas applications can be achieved through proper material selection, advanced coating technologies, systematic monitoring systems, and comprehensive maintenance programs. These measures significantly extend service life and reduce operational risks.

Drawing from my recent experience with a major pipeline upgrade project in India6, I want to share some proven strategies that have helped our clients overcome common challenges and achieve optimal performance from their stainless steel pipe installations.

Advanced Material Selection Strategies

Working closely with engineering teams across various projects, I've developed a systematic approach to material selection that has proven successful in challenging environments:

The key is to consider not just the immediate operating conditions but also potential future changes in the pipeline's service requirements. For instance, when working with a refinery in the Middle East, we implemented a comprehensive material evaluation system that considered:

- Chemical composition of transported materials

- Operating temperature ranges

- Pressure requirements

- Environmental exposure

- Cost-effectiveness over the entire lifecycle

Innovative Installation Techniques

Through years of collaboration with installation contractors, I've identified several best practices that significantly improve project outcomes:

| Installation Aspect | Traditional Method | Improved Technique | Performance Gain |

|---|---|---|---|

| Welding Process | Manual TIG | Automated orbital welding | 40% faster completion |

| Joint Design | Basic butt joints | Advanced weld prep | 30% stronger joints |

| Quality Control | Visual inspection | Advanced NDT methods | 80% defect detection |

| Surface Treatment | Basic cleaning | Specialized passivation | 50% longer life |

Monitoring and Maintenance Solutions

Modern technology has revolutionized how we monitor and maintain stainless steel pipelines. Based on our experience with multiple installations:

Implementing real-time monitoring systems has helped our clients detect potential issues before they become critical. For example, we recently helped a client implement an IoT-based monitoring system that tracks:

- Wall thickness changes

- Corrosion rates

- Temperature variations

- Pressure fluctuations

- Strain measurements

Proper material selection enhances performanceTrue

Selecting the right material based on operating conditions is crucial for optimal performance.

Manual TIG welding is the fastest methodFalse

Automated orbital welding is faster and more efficient than manual TIG welding.

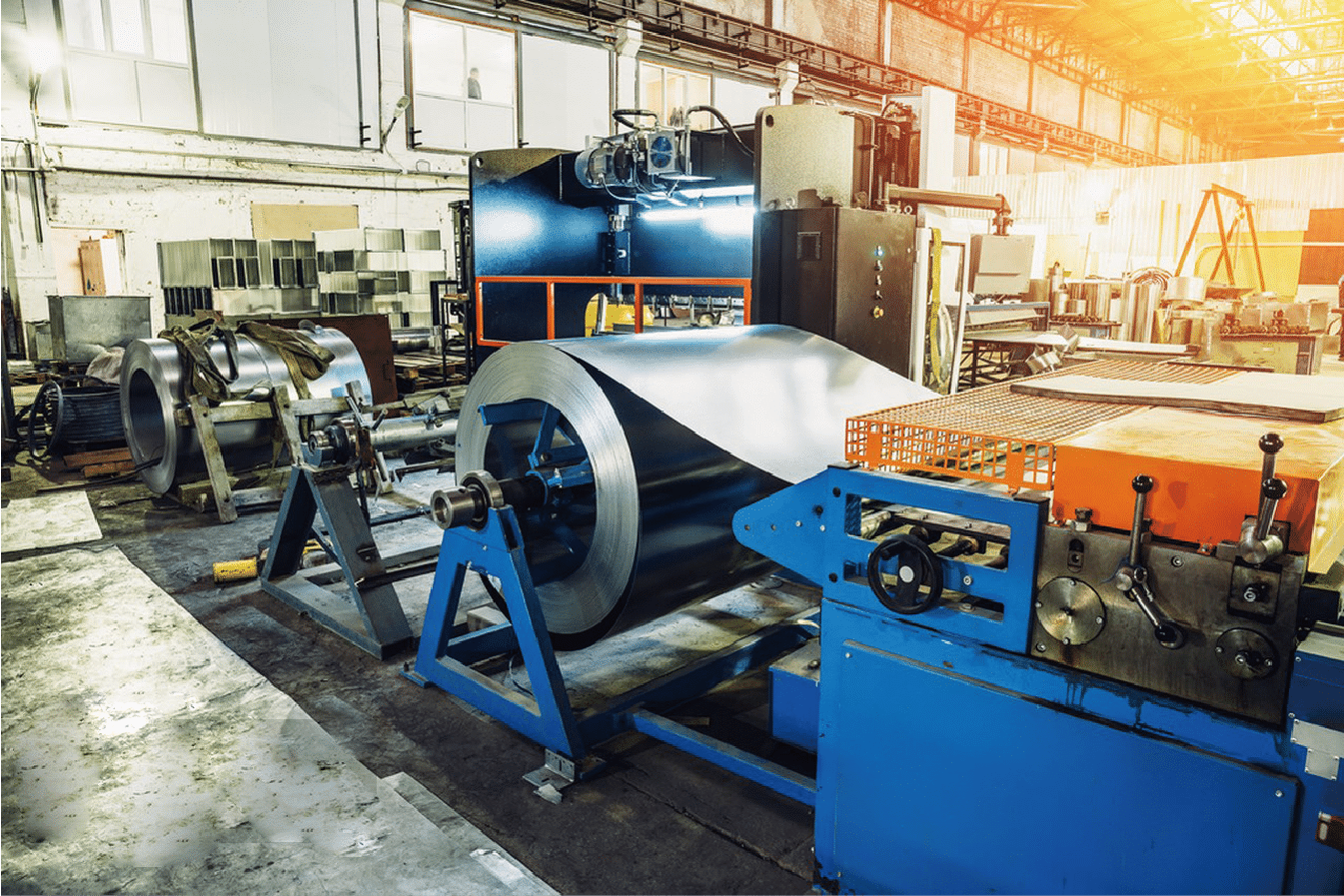

What are the best practices for selecting and maintaining stainless steel pipes in oil and gas pipelines?

As someone who has guided numerous clients through the selection and maintenance of stainless steel pipes, I've learned that success lies in following a comprehensive, systematic approach that considers both immediate needs and long-term performance.

The best practices for stainless steel pipe selection and maintenance include detailed material analysis, comprehensive testing protocols, regular inspection schedules, and preventive maintenance programs. This systematic approach ensures optimal performance and extends the service life of oil and gas pipeline systems.

Throughout my career supplying stainless steel to major oil and gas projects, I've developed a deep understanding of what works and what doesn't. Let me share insights gained from working with clients like David Zhang, whose successful pipeline installations have stood the test of time.

Material Selection Criteria

In my experience working with major petrochemical facilities, proper material selection is the foundation of a successful pipeline installation. Recently, we helped a client in India upgrade their processing facility, implementing a comprehensive selection framework:

The selection process must consider multiple factors simultaneously. We developed a systematic approach that evaluates:

- Operating conditions (temperature, pressure, flow rates)

- Chemical composition of transported materials

- Environmental exposure

- Cost-effectiveness over the entire lifecycle

- Maintenance requirements and accessibility

| Selection Factor | Assessment Criteria | Impact on Performance | Risk Level |

|---|---|---|---|

| Chemical Resistance | Composition analysis | Corrosion prevention | High |

| Mechanical Properties | Strength requirements | Structural integrity | Critical |

| Temperature Rating | Operating range | Material stability | Medium |

| Cost Effectiveness | Lifecycle analysis | Financial viability | High |

Installation Best Practices

Based on our experience with numerous successful installations across Asia and the Middle East, proper installation procedures are crucial for long-term performance:

Careful attention to installation details can prevent up to 80% of early-life failures. Our recommended installation protocol includes:

- Comprehensive pre-installation material verification

- Advanced welding techniques with certified welders

- Strict quality control measures during assembly

- Post-installation testing and validation

Maintenance Protocols

Through years of supporting clients' maintenance programs, I've identified key elements that ensure optimal performance:

Regular maintenance isn't just about preventing failures; it's about optimizing performance and extending service life. Our recommended maintenance framework includes:

- Scheduled inspection intervals based on operating conditions

- Non-destructive testing protocols

- Corrosion monitoring systems

- Documentation and trending analysis

- Preventive maintenance scheduling

Stainless steel is used in upstream applicationsTrue

Stainless steel handles high pressure and corrosive fluids in upstream operations.

Stainless steel is cheaper than carbon steelFalse

Stainless steel has a higher upfront cost compared to carbon steel.

Conclusion

Based on my extensive experience in the stainless steel industry, successful implementation of stainless steel pipes in oil and gas pipelines requires careful material selection, proper installation techniques, and comprehensive maintenance programs, supported by advanced monitoring systems and regular inspections.

-

Understand the advantages of stainless steel solutions in challenging pipeline environments ↩

-

Learn about David Zhang's experience and expertise in managing large-scale petrochemical operations ↩

-

Discover how the National Oil Corporation has influenced stainless steel usage in pipelines ↩

-

Gain insights into the specific applications and challenges of using stainless steel in refinery projects ↩

-

Explore the common technical issues and solutions for stainless steel pipelines in Indian petrochemical plants ↩

-

Learn about the strategies and outcomes of using stainless steel in the Indian pipeline upgrade project ↩