How are Stainless Steel Pipes Manufactured?

Struggling to understand the complex journey from raw steel to a finished pipe? This knowledge gap can lead to costly procurement mistakes. Let’s demystify the manufacturing process together.

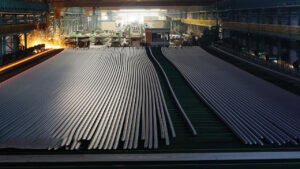

Stainless steel pipe manufacturing is a multi-stage process that transforms raw steel into a finished product. Key stages include raw material selection and preparation, forming (either welded or seamless), welding, heat treatment, rigorous quality testing and inspection, and finally, finishing and packaging to meet specific standards.

As someone who has spent years navigating the global stainless steel supply chain, I've seen firsthand how crucial it is for our partners—engineers, contractors, and distributors—to understand what goes into the products they rely on. The journey of a stainless steel pipe is a fascinating blend of raw power and precision engineering. It’s not just about bending metal; it’s about ensuring every single piece meets the stringent demands of modern industry. Let's walk through this process step-by-step, from the initial steel coil to the final, polished pipe ready for your project.

What is the initial preparation process for manufacturing stainless steel pipes?

The quality of the final pipe is determined at the very beginning. Poor initial preparation can lead to downstream defects and eventual failures. It all starts with selecting and preparing the right steel.

The initial preparation involves selecting the correct grade of stainless steel, typically in coil or billet form. This material is then precisely slit into required widths for welded pipes or prepared for piercing for seamless pipes, ensuring it has the exact dimensions and quality for forming.

Everything we do at MFY is built on a foundation of quality, and that foundation is laid long before a pipe takes shape. The first step is arguably the most critical: selecting the right raw material for the job. This isn't just about grabbing any stainless steel; it's about a meticulous selection process based on the pipe's intended application.

Material Selection and Verification

The process begins with large coils or solid billets of stainless steel. We work with various grades, and the choice depends entirely on the end-use. For general-purpose applications, we might use Grade 304. For environments with high corrosion risk, like marine or chemical processing, Grade 316L is the standard. At our facilities, every incoming batch of raw material undergoes rigorous verification to confirm its chemical composition and mechanical properties. Modern digital inventory systems allow us to trace each coil back to its source, ensuring complete transparency and accountability.

Slitting and Preparation

Once a grade is selected, the preparation begins. For welded pipes, the large steel coils are uncoiled and fed into a slitting machine. This machine cuts the wide coil into narrower strips, with the width precisely calculated to correspond to the desired circumference of the final pipe. For seamless pipes, the process starts with a solid cylindrical billet, which is cut to length and inspected for any imperfections before being sent to the furnace for heating. This initial precision is non-negotiable because any deviation here will be magnified in the later stages.

| Grade | Primary Elements | Key Application |

|---|---|---|

| 304 | 18% Chromium, 8% Nickel | General-purpose, food processing, architectural |

| 316L | 16% Cr, 10% Ni, 2% Molybdenum | Chemical, marine, medical implants |

| 201 | 16% Cr, 3.5% Ni, 5.5% Manganese | Decorative, light structural use |

How does the formation of stainless steel pipes occur during production?

You have a flat strip or a solid billet of steel; how does it become a tube? The forming method is critical, as it directly dictates the pipe's structural properties and cost-effectiveness.

Pipe formation happens via two primary methods. For welded pipes, a continuous steel strip is passed through rollers that gradually form it into a cylinder. For seamless pipes, a heated solid billet is pierced and then elongated over a mandrel to create a hollow tube.

The transformation from a two-dimensional strip or a solid bar into a three-dimensional pipe is where the real magic happens. The choice between the two main forming methods—welded versus seamless—is one of the most fundamental decisions in pipe manufacturing, each with distinct advantages tailored to different industrial needs. I remember a client in the oil and gas sector who absolutely required seamless pipes for a high-pressure application, while another in architectural design found welded pipes perfectly suitable and more economical.

Welded Pipe Formation

This is the most common and cost-effective method. The process starts with the prepared steel strip being fed into a series of rollers. Each successive set of rollers, or "stands," progressively bends the strip's edges upwards until they meet, forming a round, open-seam tube. This is a continuous process, allowing for high-speed production. The precision of these rollers is paramount to ensure the pipe has a uniform diameter and wall thickness before it moves to the welding station.

Seamless Pipe Formation

Seamless pipe manufacturing is a more intensive process, reserved for applications demanding the highest integrity and pressure ratings. It begins by heating a solid steel billet to extreme temperatures (over 1200°C). This glowing-hot billet is then pierced through its center with a mandrel. The resulting hollow "shell" is then rolled and stretched to achieve the desired wall thickness and diameter. Because there is no weld seam, the finished pipe has uniform strength all around its circumference, making it ideal for critical high-pressure environments.

| Feature | Welded Pipe | Seamless Pipe |

|---|---|---|

| Process | Roll-formed from a flat strip | Pierced from a solid billet |

| Cost | More economical | More expensive |

| Strength | Seam can be a weak point | Uniform strength |

| Best For | Structural, low-pressure, decorative | High-pressure, high-temp, critical |

What techniques are used for welding and joining in stainless steel pipe manufacturing?

For welded pipes, the seam is a potential point of failure. A weak or inconsistent weld can compromise the integrity of the entire pipeline. Advanced welding techniques are therefore essential to ensure a strong, durable bond.

Common techniques include Tungsten Inert Gas (TIG) for high-quality, precise welds and high-frequency induction (HFI) for faster production. Laser beam welding is also emerging for its speed and minimal heat-affected zone, ensuring a strong and durable seam.

Once the flat strip has been formed into an open-seam cylinder, the next crucial step is to permanently join the edges. The quality of this weld is what defines the performance and reliability of the finished pipe. Over the years, I’ve seen welding technology evolve dramatically. What was once a manual art is now a highly automated science, which is great news for our customers who depend on consistency.

High-Frequency (HFI) Welding

For most standard stainless steel pipes, High-Frequency Induction (HFI)[^1] welding is the go-to method. In this process, a high-frequency electric current is passed through the edges of the formed tube. This heats the metal to a forging temperature, and then pressure rollers squeeze the edges together, creating a solid-state forged weld. No filler material is used. It's an incredibly fast and efficient process, perfect for high-volume production.

TIG and Laser Welding

For applications requiring a finer, more aesthetically pleasing, or higher-purity weld, we turn to other methods. Tungsten Inert Gas (TIG) welding uses a non-consumable tungsten electrode to create the arc, resulting in a very clean and precise weld. It's slower than HFI but offers superior control. More recently, laser beam welding has become a game-changer. It uses a highly concentrated laser beam to melt and fuse the material. This method is extremely fast, has a very small heat-affected zone (which preserves the metal's properties), and produces a beautiful, narrow weld bead. At MFY, we leverage automated welding systems guided by sensors to ensure every inch of the seam is perfect, a technological leap that significantly enhances reliability.

How is the quality of stainless steel pipes ensured through testing and inspection?

You need to have absolute trust that the pipe will perform as expected under pressure. Unseen defects can lead to catastrophic failures, costly downtime, and safety hazards. This is why rigorous, multi-stage testing is non-negotiable.

Quality is ensured through a battery of non-destructive tests (NDT), such as hydrostatic testing for leaks, eddy current testing for surface defects, and ultrasonic testing for internal flaws. Mechanical tests also verify tensile strength and hardness, ensuring compliance with international standards.

A pipe is only as good as its proven integrity. At MFY, we consider the quality control stage to be just as important as the manufacturing process itself. We can't just assume a pipe is strong; we have to prove it. This is done through a comprehensive suite of tests that leave no stone unturned, combining proven methods with cutting-edge technology to guarantee performance.

Non-Destructive Testing (NDT)

The core of our quality assurance program is Non-Destructive Testing, which allows us to inspect the pipe without damaging it.

- Hydrostatic Testing: We fill the pipe with water and pressurize it to a level far beyond its normal operating pressure. This is a simple but effective test to confirm its strength and find any potential leaks.

- Eddy Current Testing: This test uses electromagnetic induction to detect tiny surface and near-surface flaws, such as cracks or weld defects, that might be invisible to the naked eye.

- Ultrasonic Testing: High-frequency sound waves are sent through the pipe material. By analyzing the returning echoes, we can detect internal flaws like voids or inclusions deep within the pipe wall or weld.

The Rise of Smart QC

This is an area where technology is making a huge impact. Beyond traditional NDT, we are integrating AI-driven quality control. For instance, AI-powered visual inspection systems can scan the surface of a pipe and identify microscopic imperfections with a speed and accuracy no human operator can match. This digital oversight ensures that our quality standards are not just met but consistently exceeded, giving our clients the peace of mind they need for their critical projects.

| Test Type | Purpose |

|---|---|

| Hydrostatic Test | Checks for leaks and pressure strength |

| Eddy Current Test | Detects surface and near-surface flaws |

| Ultrasonic Test | Finds internal defects in the material/weld |

| Tensile Test | Measures material strength and ductility |

What finishing processes are applied to stainless steel pipes before they are ready for use?

A pipe isn't quite ready for shipment right after testing. The wrong surface finish or residual internal stress can affect its corrosion resistance, appearance, and performance. Finishing processes are the final step in preparing the pipe for its specific application.

Finishing includes processes like annealing (heat treatment to relieve stress), pickling and passivation (to restore the corrosion-resistant layer), and polishing. Pipes are then cut to length, marked for traceability, and packaged for shipment.

The final leg of the manufacturing journey is all about refinement. These finishing steps are crucial for locking in the pipe's desired mechanical properties and ensuring its long-term performance, especially its resistance to corrosion. It's the difference between a good pipe and a great one.

Heat Treatment (Annealing)

After welding, the area around the seam has been subjected to intense heat, which can alter the grain structure of the steel and create internal stresses. To fix this, the pipes are passed through an annealing furnace. This controlled heating and cooling process relieves stress, refines the grain structure, and restores ductility and corrosion resistance to the weld zone, making it uniform with the rest of the pipe body. This step is absolutely essential for ensuring the long-term reliability of the pipe.

Surface Treatment and Final Touches

Next comes surface treatment. The pipes are submerged in a pickling bath (a mixture of acids) to remove any scale or heat tint left over from welding and annealing. This is immediately followed by passivation, which is a chemical process that re-forms the passive, chromium-oxide layer that gives stainless steel its signature corrosion resistance. Depending on the customer's requirements, pipes can then be polished to various finishes, from a standard brushed look to a mirror-like shine for architectural or sanitary applications. Finally, the pipes are cut to precise lengths, marked with grade, size, and heat number for full traceability, and carefully packaged to protect them during transit to our clients around the world.

Conclusion

The journey from a raw steel coil to a finished pipe combines proven metallurgical principles with digital innovation. This ensures every pipe we deliver from MFY offers the superior quality, reliability, and performance that our partners depend on for their most critical projects worldwide.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.