After 15 years in stainless steel manufacturing, I've seen countless customers confused about pipe grades. Understanding these grades is crucial - choosing the wrong one can lead to costly failures and compromised system integrity.

Stainless steel pipes are graded based on their chemical composition, mechanical properties1, and intended applications, with key elements like chromium, nickel, and molybdenum determining their performance characteristics and classification standards.

Let me share my expertise from working with thousands of customers worldwide. Whether you're in chemical processing, construction, or food manufacturing, understanding pipe grades is essential for making informed decisions that impact your project's success. I've seen projects succeed brilliantly and fail catastrophically - the difference often comes down to proper grade selection.

Through my experience managing a stainless steel manufacturing facility, I've learned that pipe grading is more than just numbers and letters - it's about matching the right material properties to your specific application needs. The complexity of modern industrial applications demands a thorough understanding of how these grades perform under various conditions. Let's explore the intricate world of stainless steel pipe grading together.

What Are the Key Factors That Determine Stainless Steel Pipe Grades?

In my daily interactions with quality control and through countless material tests, I've found that several critical factors consistently influence pipe grading decisions. Each factor plays a unique role in determining the final grade designation.

Stainless steel pipe grades are determined by chemical composition, mechanical properties, corrosion resistance, and manufacturing process, with each factor playing a crucial role in the final grade designation and performance capabilities.

Chemical Composition Requirements

| Element | Purpose | Typical Range | Impact on Properties |

|---|---|---|---|

| Chromium | Corrosion Resistance | 10.5-30% | Forms protective oxide layer |

| Nickel | Structure Stability | 0-35% | Enhances ductility |

| Molybdenum | Pitting Resistance | 0-7% | Improves chemical resistance |

| Carbon | Strength | 0.03-0.08% | Affects weldability |

Mechanical Properties Impact

Our testing facility regularly evaluates:

-

Strength Characteristics:

- Tensile strength (ranging from 515 to 1000 MPa)

- Yield strength (205 to 410 MPa)

- Elongation values (30% to 65%)

- Hardness measurements (150-200 HB)

-

Performance Metrics:

- Impact resistance at various temperatures

- Fatigue properties under cyclic loading

- Stress corrosion cracking resistance

- Creep resistance at elevated temperatures

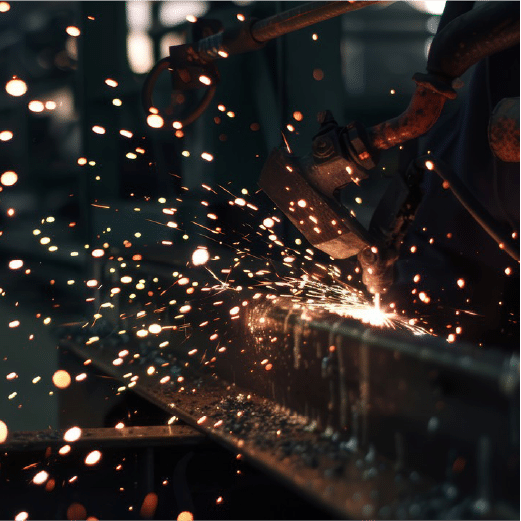

Manufacturing Process Considerations

Based on our extensive production experience:

-

Processing Methods:

- Hot-finished vs cold-finished processing impacts final properties

- Annealing temperature and time affect grain structure

- Surface finish requirements influence corrosion resistance

- Dimensional tolerances affect installation compatibility

-

Quality Control:

- Non-destructive testing requirements

- Material traceability systems

- Third-party certification needs

- Documentation and compliance standards

How Do ASTM, AISI, and EN Standards Classify Stainless Steel Pipes?

Through years of international trade and collaboration with global partners, I've worked extensively with various standards and their unique classification systems. Each standard brings its own perspective to grade classification.

Global standards organizations classify stainless steel pipes using standardized numbering systems, with ASTM, AISI, and EN standards2 providing detailed specifications for chemical composition, mechanical properties, and testing requirements to ensure consistent quality worldwide.

Standards Comparison Overview

| Standard | Format Example | Region | Key Focus | Testing Requirements |

|---|---|---|---|---|

| ASTM | A312 TP304L | Americas | Performance | Hydrostatic, NDT |

| AISI | 304L | Global | Composition | Chemical Analysis |

| EN | 1.4307 | Europe | Systematic | Mechanical Testing |

Comprehensive Classification Criteria

My experience with international certifications has shown that standards focus on:

-

Material Requirements:

- Precise chemical composition limits

- Specific mechanical property ranges

- Surface finish specifications

- Dimensional tolerances

-

Manufacturing Controls:

- Process control parameters

- Heat treatment requirements

- Testing frequency

- Quality assurance systems

-

Documentation Requirements:

- Material test certificates

- Production records

- Inspection reports

- Traceability documentation

What Is the Difference Between 304, 316, and 430 Stainless Steel Pipe Grades?

Having manufactured and tested these grades extensively in our facility, I can provide detailed insights into their characteristics and optimal applications. Each grade represents a specific balance of properties and cost-effectiveness.

The main differences lie in their chemical composition and resulting properties3: 304 offers excellent general-purpose performance, 316 provides superior corrosion resistance with added molybdenum, while 430 serves as a cost-effective ferritic option for less demanding applications.

Comprehensive Grade Analysis

| Property | Grade 304 | Grade 316 | Grade 430 |

|---|---|---|---|

| Chromium % | 18-20 | 16-18 | 16-18 |

| Nickel % | 8-10.5 | 10-14 | 0-0.75 |

| Molybdenum % | - | 2-3 | - |

| Corrosion Resistance | Good | Excellent | Moderate |

| Cost Factor | Medium | High | Low |

| Structure | Austenitic | Austenitic | Ferritic |

Detailed Performance Characteristics

-

Grade 304 Performance:

- Excellent resistance to ordinary corrosion

- Superior formability and weldability

- Temperature resistance up to 870°C

- Ideal for food processing equipment

- Cost-effective for general applications

-

Grade 316 Advantages:

- Enhanced pitting resistance

- Superior chloride resistance

- Better high-temperature strength

- Excellent marine environment performance

- Extended service life in aggressive conditions

-

Grade 430 Applications:

- Good oxidation resistance

- Moderate corrosion resistance

- Magnetic properties

- Cost-effective alternative

- Suitable for indoor applications

Real-World Application Examples

From our global project experience:

-

Food & Beverage Industry:

- 304: Dairy processing equipment, brewing tanks

- 316: High-acid food processing

- 430: Kitchen equipment, decorative elements

-

Chemical Processing:

- 304: General chemical handling

- 316: Aggressive chemical environments

- 430: Mild chemical exposure areas

-

Construction Applications:

- 304: Building facades, railings

- 316: Coastal architecture

- 430: Indoor architectural elements

How Does the Composition of Chromium, Nickel, and Molybdenum Affect Pipe Grading?

Through countless material analyses and performance tests in our laboratory, I've observed how these key elements create distinct property profiles that define each grade's capabilities.

The synergistic combination of chromium, nickel, and molybdenum4 determines not only the grade classification but also the performance boundaries and application suitability of stainless steel pipes.

Element Interaction Effects

-

Chromium's Role:

- Forms passive oxide layer

- Minimum 10.5% for stainless properties

- Increases oxidation resistance

- Enhances high-temperature performance

- Affects mechanical properties

-

Nickel's Contribution:

- Stabilizes austenitic structure

- Improves ductility and formability

- Enhances weldability

- Increases impact resistance

- Improves stress corrosion resistance

-

Molybdenum's Impact:

- Enhances pitting resistance

- Improves chloride resistance

- Strengthens passive layer

- Increases high-temperature strength

- Improves crevice corrosion resistance

Performance in Different Environments

Based on our extensive field testing:

-

Marine Environments:

- High chloride exposure requires Mo

- Ni content crucial for structure stability

- Cr provides basic corrosion protection

-

Chemical Processing:

- Mo content critical for acid resistance

- Higher Cr levels for oxidizing environments

- Ni content affects thermal stability

-

High-Temperature Applications:

- Cr content affects scaling resistance

- Ni stabilizes structure at high temperatures

- Mo improves strength retention

How to Choose the Right Stainless Steel Pipe Grade for Different Applications?

After helping countless customers select the optimal grade for their specific needs, I've developed a comprehensive approach to grade selection that considers all critical factors.

Selecting the appropriate stainless steel pipe grade requires careful consideration of the operating environment, temperature requirements, chemical exposure, and cost constraints while ensuring compliance with industry standards and long-term performance requirements.

Systematic Selection Process

-

Environmental Analysis:

- Operating temperature range

- Chemical exposure types and concentrations

- Mechanical stress levels

- Cleaning requirements

- Environmental regulations

-

Performance Requirements:

- Required service life

- Maintenance accessibility

- Safety factors

- Pressure ratings

- Temperature cycling

-

Economic Considerations:

- Initial material costs

- Installation expenses

- Maintenance requirements

- Expected service life

- Replacement costs

Industry-Specific Recommendations

Based on our extensive field experience:

-

Food & Beverage Industry:

- Primary Choice: 304/304L

- Alternative: 316L for high-acid products

- Considerations: Sanitary requirements, cleaning protocols

-

Chemical Processing:

- Primary Choice: 316/316L

- Alternative: 317L for severe conditions

- Considerations: Chemical compatibility, temperature resistance

-

Marine Applications:

- Primary Choice: 316L

- Alternative: 904L for extreme conditions

- Considerations: Chloride resistance, atmospheric exposure

Conclusion

Through my years of experience in stainless steel manufacturing and grade selection, I've learned that understanding pipe grades is fundamental to project success. The right grade choice ensures optimal performance, longevity, and cost-effectiveness, while wrong selections can lead to premature failure and significant expenses.

-

Learn about the elements influencing stainless steel pipe performance and classification ↩

-

Understand global standards for consistent stainless steel pipe quality ↩

-

Explore the distinct properties and applications of common stainless steel grades ↩

-

Discover how key elements influence stainless steel's performance and suitability ↩