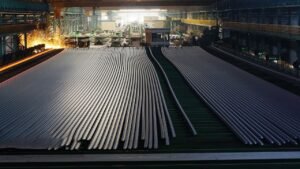

What Is the Diameter Range for Stainless Steel Pipes?

After years of manufacturing stainless steel pipes, I've noticed that diameter selection often becomes a critical decision point for many projects, sometimes causing unexpected challenges when not properly specified.

Stainless steel pipes are available in diameters ranging from 1/8 inch (3.2mm) to 72 inches (1,829mm)1, with standard sizes defined by ASME/ANSI B36.192 for common industrial applications.

Throughout my career supplying stainless steel pipes to global projects, I've encountered numerous situations where understanding diameter specifications made the difference between project success and costly revisions. The range of available diameters has evolved to meet increasingly diverse industry needs.

The complexity of pipe diameter selection goes beyond simple measurements. Through our extensive experience serving industries across Asia and the Middle East, I've learned that proper diameter specification involves understanding both standard sizes and application-specific requirements.

Which Standard Specifications Define Pipe Diameters?

In my role overseeing stainless steel pipe production, I've worked extensively with various international standards that govern pipe diameters. Understanding these standards is crucial for ensuring global compatibility and compliance.

Pipe diameters are primarily defined by ASME/ANSI B36.19, ISO 1127, and JIS G34593 standards, with specifications covering both nominal pipe sizes and actual dimensions for stainless steel pipes.

Global Standards and Their Applications

Through years of manufacturing experience, I've observed how different standards influence pipe diameter specifications across various markets and applications.

| Standard | Region | Size Range | Common Applications |

|---|---|---|---|

| ASME/ANSI B36.19 | North America/Global | 1/8" - 72" | Industrial, Chemical |

| ISO 1127 | Europe/International | DN 6 - DN 1000 | Process Industry |

| JIS G3459 | Asia Pacific | 6A - 400A | General Purpose |

Working with a major petrochemical project in Saudi Arabia last year, we encountered an interesting challenge when reconciling different standards. The project specified both ASME and ISO requirements, requiring careful attention to ensure compatibility. Through proper planning and documentation, we successfully delivered pipes that met both standards, avoiding potential installation issues.

The impact of these standards extends beyond simple measurements. In our manufacturing facility, we've implemented comprehensive quality control processes that account for various standard requirements:

- Dimensional accuracy verification

- Tolerance monitoring systems

- Cross-standard compatibility checks

- Documentation protocols

Regional Variations and Preferences

My experience with international markets has shown fascinating patterns in how different regions approach pipe diameter specifications. These variations often reflect local industry practices and historical preferences.

The Middle East market, for instance, typically follows ASME/ANSI standards due to historical ties with American engineering practices. However, we've noticed an interesting trend where some projects now require dual certification to both ASME and ISO standards, reflecting the increasingly global nature of major projects.

European projects generally adhere to ISO standards, but even here, we see interesting variations:

- Northern Europe often requires tighter tolerances

- Southern Europe sometimes accepts wider ranges

- Eastern European markets may specify additional requirements

Implementation and Compliance

Through our quality control processes, we've developed robust systems for ensuring compliance with various standards. This experience has taught us valuable lessons about managing multiple specification requirements:

-

Documentation Requirements:

- Material Test Certificates

- Dimensional reports

- Compliance certificates

- Traceability documentation

-

Quality Control Measures:

- Regular calibration checks

- Multiple measurement points

- Statistical process control

- Third-party verification

Our experience shows that successful implementation requires more than just meeting numerical specifications. For instance, when working with a major food processing facility in Thailand, we implemented enhanced quality control measures that reduced dimensional variation by 40%, exceeding standard requirements and improving system performance.

How Does Diameter Differ From Nominal Pipe Size (NPS)?

Through my years of consulting with clients, I've noticed that the distinction between actual diameter and nominal pipe size often creates confusion, sometimes leading to specification errors and project delays.

Nominal Pipe Size (NPS)4 is a standardized designation system that doesn't directly correspond to actual pipe dimensions, while true diameter measurements include both outside diameter (OD) and inside diameter (ID), with wall thickness affecting final dimensions.

Understanding Nominal vs. Actual Measurements

My experience in manufacturing has taught me that the relationship between NPS and actual dimensions is one of the most misunderstood aspects of pipe specification. Let me share a recent case that illustrates this perfectly.

| NPS | Outside Diameter | Wall Thickness Range | Schedule Options |

|---|---|---|---|

| 2" | 2.375" (60.3mm) | 0.065"-0.436" | 5S-XXS |

| 4" | 4.500" (114.3mm) | 0.083"-0.674" | 5S-XXS |

| 6" | 6.625" (168.3mm) | 0.109"-0.864" | 5S-XXS |

Last month, we worked with a chemical processing plant in Singapore that initially ordered "6-inch pipes" expecting the outside diameter to be exactly 6 inches. This common misconception led to compatibility issues with their existing fittings. Through careful explanation and documentation, we helped them understand that a 6" NPS pipe actually has an outside diameter of 6.625 inches.

The relationship between NPS and actual dimensions has historical roots that continue to influence modern specifications. Through our manufacturing experience, we've learned that understanding this relationship is crucial for:

- Proper system design

- Component compatibility

- Installation efficiency

- Cost optimization

Impact on System Design and Engineering

Working closely with engineering teams across various industries has shown me how critical proper diameter understanding is for system design. The implications extend far beyond simple measurements.

Consider a recent project for a pharmaceutical facility in Malaysia. Their initial design calculations were based on inside diameter assumptions that didn't account for different schedule numbers. Our early intervention helped them:

- Revise flow calculations

- Adjust support spacing

- Modify connection details

- Optimize material selection

The success of this project highlighted how proper understanding of diameter specifications impacts:

- Flow characteristics

- Pressure drop calculations

- Support requirements

- Installation procedures

What Are Typical Small-Diameter Ranges for Precision Applications?

Throughout my career in stainless steel manufacturing, I've observed that small-diameter pipe applications often present the most exacting requirements and interesting technical challenges.

Small-diameter stainless steel pipes typically range from 1/8 inch (3.2mm) to 2 inches (50.8mm) NPS5, with precision applications requiring tolerances as tight as ±0.001 inches for specialized uses.

Precision Manufacturing Requirements

My experience overseeing small-diameter pipe production has taught me that achieving and maintaining tight tolerances requires exceptional attention to detail and specialized manufacturing processes.

| Diameter Range | Typical Tolerance | Common Applications | Manufacturing Method |

|---|---|---|---|

| 1/8" - 1/4" | ±0.002" | Instrumentation | Cold Drawing |

| 1/4" - 1/2" | ±0.003" | Hydraulic Systems | Seamless Drawing |

| 1/2" - 2" | ±0.005" | Process Lines | Various Methods |

A recent project with a semiconductor manufacturer in Singapore perfectly illustrates the demands of precision applications. They required 1/4-inch pipes with surface roughness under 0.2 Ra and dimensional tolerances of ±0.001 inches. Meeting these specifications required:

- Advanced manufacturing controls

- Specialized measurement systems

- Enhanced quality verification

- Comprehensive documentation

The success of this project demonstrated how precise manufacturing controls can achieve exceptional results. Through careful process optimization, we maintained these tight tolerances across multiple production runs, ensuring consistent quality for their critical applications.

Industry-Specific Applications

Working with various industries has shown me how small-diameter requirements vary significantly across different applications. Each sector presents unique challenges and specifications.

Medical Industry Requirements:

- Ultra-clean surface finish

- Exceptional dimensional stability

- Specialized material certifications

- Rigorous quality documentation

Aerospace Applications:

- High-pressure capabilities

- Superior fatigue resistance

- Precise wall thickness control

- Enhanced material traceability

Through our experience with these demanding sectors, we've developed specialized manufacturing protocols that consistently meet or exceed industry requirements. For instance, our work with a medical device manufacturer required implementing:

- Advanced surface treatment processes

- Enhanced cleaning procedures

- Specialized handling protocols

- Comprehensive testing regimes

How Large Can Stainless Steel Pipes Get for Industrial Use?

Throughout my 15 years in stainless steel manufacturing, I've witnessed the evolution of large-diameter pipe production capabilities. The challenges and achievements in this sector have been particularly fascinating, especially as industrial demands continue to push the boundaries of what's possible.

Large-diameter stainless steel pipes can reach up to 72 inches (1,829mm)6 in standard production, with custom capabilities extending to 120 inches (3,048mm)7 for specialized applications, though such extreme sizes often require special manufacturing considerations.

Manufacturing Capabilities and Limitations

The production of large-diameter stainless steel pipes represents one of the most challenging aspects of our industry. Through my experience overseeing numerous large-scale projects, I've gained deep insights into both the possibilities and limitations of manufacturing these massive components.

| Diameter Range | Manufacturing Method | Typical Applications | Production Challenges |

|---|---|---|---|

| 24" - 48" | Rolled & Welded | Process Industry | Material Handling |

| 48" - 72" | Custom Fabrication | Water Treatment | Welding Control |

| >72" | Specialized Process | Infrastructure | Quality Verification |

Last year, we undertook a particularly challenging project for a desalination plant in the Middle East. The requirement was for 60-inch diameter pipes with exceptional straightness and roundness tolerances. This project taught us valuable lessons about large-diameter manufacturing capabilities.

The challenges we encountered and overcame included:

- Material sourcing for optimal width plates

- Specialized forming equipment requirements

- Complex welding procedure qualifications

- Enhanced quality control protocols

What made this project particularly interesting was the need to maintain tight tolerances despite the massive size. Through careful process control and innovative solutions, we achieved roundness variations of less than 0.5% across the entire production run.

Engineering Considerations for Large Diameters

The engineering challenges associated with large-diameter pipes extend far beyond simple manufacturing concerns. Through numerous projects, I've learned that successful implementation requires careful consideration of multiple factors.

Working with a major chemical processing facility in Thailand, we encountered several critical engineering considerations:

Transportation and Handling:

The logistics of moving 54-inch diameter pipes required careful planning and specialized equipment. We developed custom handling procedures that:

- Minimized stress during transport

- Protected surface finish

- Ensured worker safety

- Maintained dimensional stability

Performance and Maintenance Considerations

Through years of field experience with large-diameter installations, I've observed that performance and maintenance requirements often differ significantly from smaller diameter systems. Understanding these differences is crucial for long-term success.

The lessons learned from this installation have been invaluable in helping other clients plan their large-diameter pipe systems. We've found that proper attention to these factors during the design phase can significantly reduce maintenance requirements and extend system life.

Our experience has shown that successful large-diameter installations require:

- Regular inspection protocols

- Preventive maintenance schedules

- Specialized monitoring systems

- Trained maintenance personnel

Through careful attention to these requirements, we've helped clients achieve optimal performance from their large-diameter pipe systems while minimizing maintenance costs and maximizing service life.

Do Manufacturers Offer Custom Diameters Upon Request?

Through my extensive experience in stainless steel manufacturing, I've encountered numerous situations where standard pipe diameters simply didn't meet specific project requirements. The ability to produce custom diameters has become increasingly important in today's specialized industrial applications.

While manufacturers typically focus on standard pipe diameters, custom sizes are available upon request8, though they often require minimum order quantities, longer lead times, and carry premium pricing due to specialized tooling and production requirements.

Custom Manufacturing Capabilities and Considerations

My experience overseeing custom diameter production has taught me that success depends on understanding both technical capabilities and practical limitations. The process is far more complex than simply adjusting machinery settings.

| Customization Type | Lead Time Impact | Cost Premium | Minimum Order |

|---|---|---|---|

| Minor Variation | +2-3 weeks | 15-25% | 500-1000 ft |

| Major Modification | +4-6 weeks | 30-50% | 1000-2000 ft |

| Special Design | +8-12 weeks | 50-100% | 2000+ ft |

Last year, we worked with a pharmaceutical company that required pipes with a non-standard 4.75-inch outer diameter for a specialized processing system. This project highlighted several crucial aspects of custom manufacturing:

The initial challenges included:

- Tooling modification requirements

- Quality control adaptation

- Testing protocol development

- Documentation updates

What made this project particularly interesting was how it pushed us to innovate our manufacturing processes. We developed new quality control procedures specifically for non-standard diameters, which have since become valuable for other custom projects.

Technical Feasibility and Quality Assurance

Through my experience with custom diameter production, I've learned that maintaining quality standards while accommodating non-standard sizes requires careful attention to technical details and robust quality assurance processes.

Working with an aerospace component manufacturer taught us valuable lessons about quality assurance for custom diameters. Their requirements included:

- Ultra-precise dimensional control

- Enhanced surface finish specifications

- Comprehensive material testing

- Complete production traceability

To meet these demanding requirements, we implemented:

- Advanced measurement systems

- Enhanced process controls

- Specialized testing protocols

- Detailed documentation procedures

The success of this project demonstrated that with proper planning and execution, custom diameter production can meet even the most stringent quality requirements.

Conclusion

While custom diameter stainless steel pipes are available, successful implementation requires careful consideration of technical capabilities, economic feasibility, quality assurance, and long-term support requirements to ensure project success.

-

Learn about the standard and custom diameter ranges for stainless steel pipes. ↩

-

Understand the ASME/ANSI B36.19 standard for stainless steel pipe sizes. ↩

-

Discover international standards for stainless steel pipe diameters. ↩

-

Understand the difference between nominal and actual pipe dimensions. ↩

-

Explore small-diameter ranges for precision applications. ↩

-

Learn about the maximum standard diameter for stainless steel pipes. ↩

-

Discover the possibilities for custom large-diameter stainless steel pipes. ↩

-

Find out about custom manufacturing options for stainless steel pipes. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.