Reputable Stainless Steel Coil Suppliers: Services, Products, & Tips

Finding a reliable supplier is daunting. A poor choice costs you valuable time, money, and project integrity. At MFY, we believe a strong partnership starts with shared knowledge and transparency.

A reputable stainless steel coil supplier is defined by their consistent product quality, on-time delivery, and comprehensive support. They excel by integrating digital solutions for supply chain transparency, providing robust quality assurance, and acting as a strategic partner rather than just a vendor for their clients.

Stacked industrial stainless steel coils ready for shipping in outdoor warehouse](https://mfysteel.com/wp-content/uploads/2025/08/industrial-stainless-steel-coils-1.webp)

Selecting the right partner for your stainless steel coil needs is one of the most critical decisions you can make for your business's operational health. It goes far beyond just securing a good price; it's about building a resilient supply chain that can withstand market volatility and support your growth. In my years as Global Business Director at MFY, I've seen firsthand how the right supplier relationship can transform a business. Let's explore how you can identify and build these essential partnerships.

What Does the Stainless Steel Coil Industry Landscape Look Like?

The stainless steel industry can seem overwhelmingly complex. Misunderstanding its structure leads to poor purchasing decisions and missed opportunities. Let's demystify the key players and processes for you.

The stainless steel coil industry is a dynamic global network of producers, specialized processors, and distributors. It connects raw material sourcing to final manufacturing applications, driven by strong demand from key sectors like construction, automotive, and consumer goods, making it a critical part of the global economy.

As an integrated group company, we at MFY operate across multiple stages of this landscape, and I can tell you it's a fascinating and fast-paced environment. At its core, the industry is built on a supply chain that begins with raw materials like nickel, chromium, and iron ore. These are melted and processed by large steel mills into massive slabs, which are then hot-rolled and cold-rolled into coils of varying thicknesses and finishes. This is where companies like ours step in. We take these master coils and provide value-added services—from precision slitting and cutting to length, to manufacturing finished products like pipes and sheets.

Key Players in the Value Chain

The industry isn't monolithic. It’s composed of several distinct players, each serving a vital function:

- Mills: The massive producers who create the raw stainless steel.

- Service Centers/Processors: Companies like MFY that purchase large coils from mills and process them to customer specifications. We are the bridge between mass production and custom requirements.

- Traders and Distributors: These entities focus on the logistics and sales of stainless steel products, connecting processors with end-users across the globe. Our export trade division fulfills this role, ensuring our products reach markets in India, Southeast Asia, and beyond.

The final products serve a vast array of applications, highlighting the material's versatility.

| Industry Sector | Common Stainless Steel Coil Applications |

|---|---|

| Construction | Structural components, roofing, cladding, handrails |

| Automotive | Exhaust systems, trim, structural parts |

| Appliances | Refrigerators, washing machines, kitchen sinks |

| Industrial | Chemical processing tanks, food-grade equipment |

Understanding this structure helps you identify where your potential supplier fits and what capabilities they should possess to meet your specific needs effectively.

What Are the Key Market Trends Shaping Stainless Steel Coil Supply Today?

The market is constantly in motion. If you fall behind on key trends, you risk losing your competitive edge and supply chain stability. Here are the critical shifts we're watching.

Key trends include the rapid digitalization of supply chains for enhanced transparency, a growing emphasis on sustainable production ("green steel"), and persistent raw material price volatility. Consequently, buyers are prioritizing suppliers who demonstrate agility, technological adoption, and the ability to offer stable, long-term partnerships.

In my role, I spend a lot of time analyzing market dynamics to position MFY for the future. The trends we see today are not just passing phases; they are fundamentally reshaping what it means to be a "reputable" supplier. The biggest shift I've observed is the move from a purely transactional relationship to a digitally integrated partnership.

The Rise of Digital Integration

This is the non-obvious insight that separates market leaders from the rest. Suppliers who integrate digital solutions into their logistics and customer engagement are winning. At MFY, we have invested heavily in our software development to provide clients with real-time tracking of their orders, transparent inventory management, and seamless communication. This digital backbone builds trust and provides the operational efficiency our clients need. It’s no longer enough to just promise a delivery date; you must provide the visibility to back it up.

Sustainability and Price Volatility

Two other major forces are at play:

- Sustainability: There is increasing pressure from end-users and regulators for "green steel"—products made with a lower carbon footprint. Suppliers who are proactive in this area are becoming more attractive partners.

- Price Volatility: The prices of raw materials like nickel fluctuate daily on the London Metal Exchange (LME). This creates uncertainty for buyers. A reputable supplier helps manage this risk through transparent pricing models and, in some cases, strategic purchasing advice.

Here’s how these trends impact you as a buyer:

| Market Trend | Impact on Buyers | What to Look For in a Supplier |

|---|---|---|

| Digitalization | Need for real-time information and efficiency. | A supplier with a modern digital platform for orders, tracking, and communication. |

| Sustainability | Growing demand for eco-friendly materials. | Suppliers with clear sustainability policies and certifications. |

| Price Volatility | Difficulty in budgeting and cost forecasting. | Partners who offer transparent pricing and risk management strategies. |

Navigating these trends requires a supplier who is not just a producer but a forward-thinking partner.

What Are the Biggest Challenges When Selecting a Stainless Steel Coil Supplier?

Choosing a new supplier is filled with risk. The wrong partner can trigger production delays, quality failures, and budget overruns. Let's identify the common pitfalls so you can avoid them.

Buyers often struggle with verifying quality claims, ensuring supply consistency, and navigating complex or non-transparent pricing. The primary challenge is distinguishing genuinely reliable partners from those who overpromise and underdeliver, a task made harder in a crowded and competitive global marketplace.

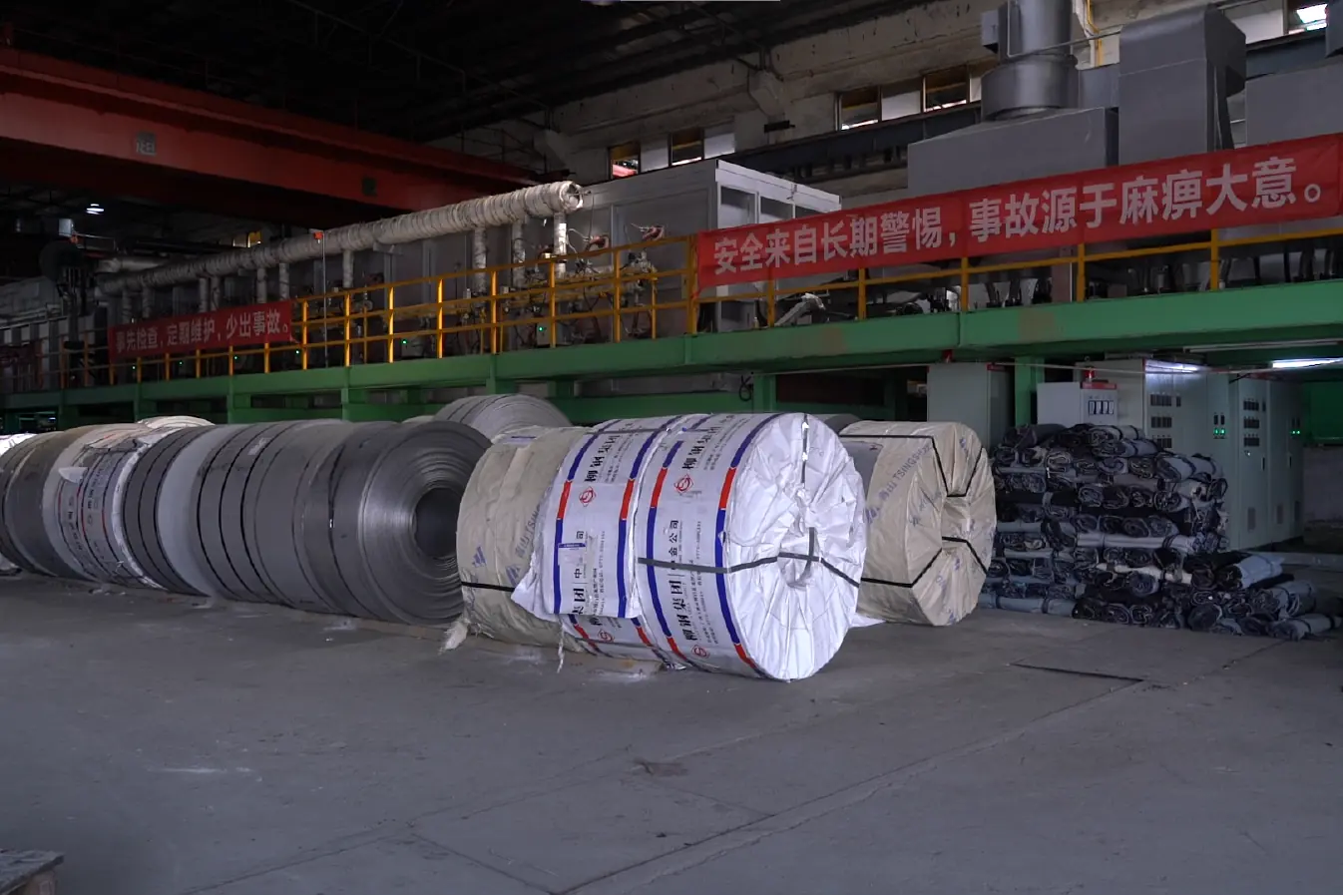

Large stainless steel coils in a modern industrial facility with a crane](https://mfysteel.com/wp-content/uploads/2025/08/industrial-stainless-steel-coils.webp)

I've spoken with countless businesses that have been burned by a poor supplier choice. I recall one client, a major equipment integrator, who came to us after their previous supplier delivered an entire batch of 316L coils that failed to meet corrosion resistance standards. The discovery was made late in their production cycle, causing a catastrophic delay and financial loss. Their story is a powerful reminder of the real-world consequences of the challenges buyers face. The issues almost always fall into three categories.

Quality Assurance vs. Reality

The single biggest fear for any buyer is receiving material that doesn't meet specifications. A supplier’s website might promise top-tier quality, but the coils that arrive on your factory floor tell a different story. Inconsistent thickness, poor surface finish, or incorrect chemical composition can derail your entire production process. This is why demanding and verifying a Mill Test Certificate (MTC) for every coil is non-negotiable.

Supply Chain Reliability and Communication

A great price is meaningless if the product doesn't arrive on time. The global supply chain is fraught with potential disruptions, from shipping delays to port congestion. A supplier without a robust logistics network and proactive communication strategy leaves you in the dark. You need a partner who alerts you to potential delays and works with you to find solutions, not one who goes silent when problems arise. This is where an integrated supply chain like ours at MFY becomes a major competitive advantage for our clients.

Hidden Costs and Complex Pricing

Finally, the price you are quoted is not always the price you pay. Some suppliers lure customers with low unit costs, only to add exorbitant fees for shipping, insurance, special packaging, or documentation. A reputable supplier provides a clear, all-inclusive quotation that outlines every cost, allowing you to budget accurately and avoid unpleasant surprises.

How Can You Effectively Identify a Trustworthy Stainless Steel Coil Supplier?

You need a reliable, long-term partner. But with so many options, how do you effectively sort the good from the bad? Follow this proven checklist for vetting potential suppliers.

Identify trustworthy suppliers by rigorously evaluating their certifications (like ISO 9001), production capabilities, and industry track record. Always request client references, review their quality control documentation, and assess their communication for transparency. A strong digital presence is another key indicator of a modern, reliable operation.

Finding a trustworthy supplier is an exercise in due diligence. It requires a methodical approach that goes beyond a simple price comparison. At MFY, we welcome this scrutiny because we are confident in our processes and believe transparency is the foundation of a good partnership. When we are evaluating a new partner or a client is evaluating us, I always recommend focusing on a few key areas that provide a clear picture of the supplier's reliability and capabilities.

Your Due Diligence Checklist

Think of this as your investigation process. A supplier who is hesitant to provide any of this information should be a major red flag.

- Verify Certifications: Ask for copies of their quality management certifications, such as ISO 9001. This demonstrates a commitment to standardized processes and continuous improvement.

- Request Samples and MTCs: Before placing a large order, request a sample of the product and its corresponding Mill Test Certificate (MTC). This allows you to verify the quality firsthand.

- Assess Production and Inventory: A supplier with significant production capacity and a robust inventory is better equipped to handle large orders and respond quickly to your needs. Ask about their coil processing lines and stock levels.

- Check References: Ask for contact information for a few current clients in a similar industry. Speaking with them can provide invaluable, unbiased insight into the supplier's performance.

The Importance of Communication and Digital Presence

In today's market, how a company communicates is as important as what it produces. A responsive, knowledgeable sales team is a good sign. Furthermore, as I've mentioned, their digital footprint matters. A professional website, clear product information, and digital tools for managing orders show that they are invested in the customer experience. This is a core part of our philosophy at MFY—we use technology to make our clients' lives easier.

What Are the Best Tips for Negotiating with Stainless Steel Coil Suppliers?

You want to secure the best possible deal. But aggressive or uninformed negotiation can damage the relationship and the final outcome. Use these expert tips for a productive, win-win discussion.

For successful negotiations, first understand the market pricing drivers, such as LME nickel prices. Clearly define and communicate your technical specifications and volume needs. Most importantly, focus on the total value proposition—including logistics, payment terms, and support—not just the lowest per-unit price.

I believe negotiation should be the start of a collaborative partnership, not an adversarial battle. The goal is to arrive at an agreement that is sustainable and beneficial for both parties. A supplier who feels squeezed on price may be forced to cut corners elsewhere, which ultimately hurts you. Instead, approach the negotiation as a strategic discussion aimed at maximizing value.

Come Prepared with Clear Requirements

The most effective negotiations begin long before you speak with the supplier. You must have a complete understanding of your own needs. This includes not just the grade of stainless steel but all the technical details.

- Grade: (e.g., 304, 316L, 430)

- Finish: (e.g., 2B, BA, No. 4)

- Thickness and Tolerances: Be precise.

- Width: Specify your exact requirements.

- Coil Weight and ID/OD: Important for your machinery.

Presenting this information clearly allows the supplier to provide an accurate and competitive quote from the start.

Negotiate the Entire Package, Not Just the Price

While price is important, it's only one part of the equation. A slightly higher unit price might be well worth it if the supplier offers more favorable terms elsewhere.

| Negotiable Point | Potential Value for You |

|---|---|

| Payment Terms | Better terms (e.g., Net 60 instead of Net 30) can improve your cash flow. |

| Incoterms (Shipping) | Favorable shipping terms (e.g., DDP vs. EXW) can reduce your logistics burden and risk. |

| Inventory Management | A supplier might agree to hold dedicated stock for you, ensuring availability. |

| Packaging | Custom packaging can protect your material better and streamline your receiving process. |

By discussing the total value, you show that you are a serious, long-term partner, which often leads to a much better overall deal.

Conclusion

Choosing the right supplier is a strategic decision. Focus on reliability, transparency, and total value—especially with partners embracing digital innovation—to secure your supply chain and drive your business forward.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.