Understanding Stainless Steel Coil: Grades, Cost-Effectiveness, and Sourcing Strategies

Choosing the right stainless steel coil is complex. A wrong move can lead to budget overruns and project delays. Strategic alignment of sourcing with material performance is the solution.

Mastering stainless steel coil involves a holistic approach: correctly matching grades like 304 or 316 to application needs, understanding volatile market trends, and implementing agile global sourcing strategies. This alignment is crucial for optimizing costs, ensuring quality, and building a resilient supply chain.

As the Global Business Director at MFY, I've spent years helping partners navigate the complexities of the stainless steel market. It's not just about buying steel; it's about making a strategic investment that impacts your entire operation. The difference between a thriving project and a struggling one often comes down to the decisions made before the first coil is even unrolled. Let's break down how you can gain a competitive edge by mastering these critical elements.

What Exactly is Stainless Steel Coil and Where is it Used?

The term 'coil' is common but often vague. Misunderstanding its fundamental role and properties can lead to inefficient processing and poor material choices for your specific project.

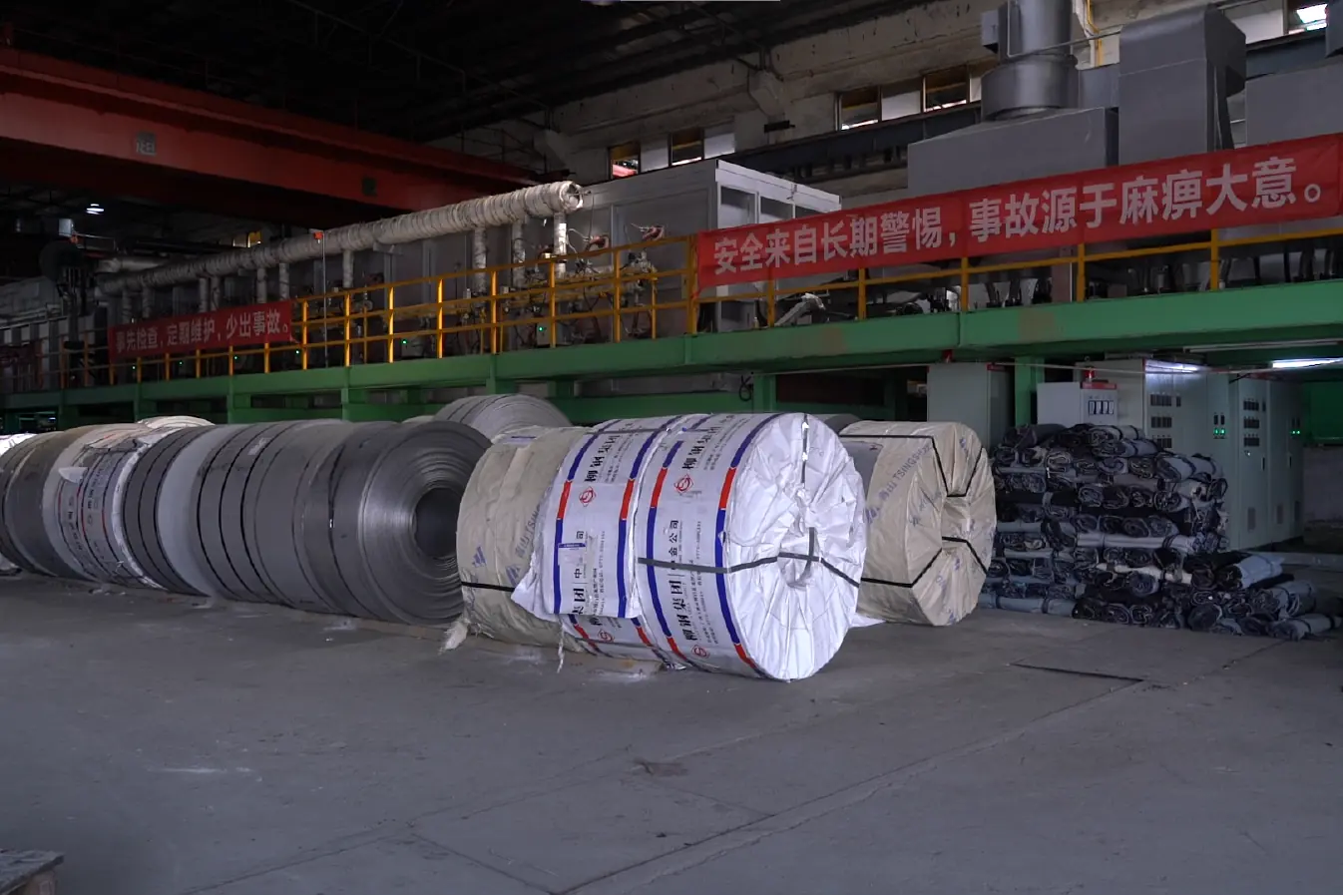

A stainless steel coil is a long, continuous strip of steel, processed to a specific thickness and width, and then wound into a roll. It is a primary form used in manufacturing for applications ranging from automotive parts and construction panels to kitchen appliances and medical equipment.

A stainless steel coil is the workhorse of modern industry. It’s the starting point for countless products we use every day. By supplying the material in a large, continuous roll, we enable manufacturers to achieve incredible efficiency. Automated production lines can feed directly from the coil, minimizing waste and maximizing throughput. This is a significant advantage over using pre-cut sheets, especially in high-volume production environments. I remember working with a client in the automotive sector who switched from sheets to coils for their stamping process; their production efficiency increased by over 20% almost overnight. It's this kind of practical impact that makes understanding the material form so important.

Key Characteristics

The primary benefit of a coil is its suitability for continuous, automated manufacturing. This form allows for long production runs without the need to constantly load new material, which is ideal for processes like stamping, roll forming, and tube making. Furthermore, coils can be slit into narrower strips or cut to specific lengths with high precision, giving manufacturers immense flexibility while drastically reducing scrap material compared to working with standard sheet sizes.

Common Applications

The versatility of stainless steel coil means it's used across a vast number of industries. Here’s a quick look at some of the most common applications and the typical grades we at MFY supply for them.

| Industry Sector | Common Applications | Typical Stainless Steel Grades |

|---|---|---|

| Construction | Roofing, cladding, structural components | 304, 316, 430 |

| Automotive | Exhaust systems, trim, structural parts | 409, 439, 304 |

| Appliances | Refrigerators, ovens, washing machines | 430, 304 |

| Industrial | Tanks, pipes, processing equipment | 304L, 316L, Duplex |

What Are the Current Market Trends for Stainless Steel Coil Grades?

The stainless steel market is constantly in motion. If you ignore the shifting trends, you risk missing cost-saving opportunities or getting caught off guard by supply chain disruptions.

Current market trends show a rising demand for high-performance and sustainable grades, such as duplex stainless steels and those with high recycled content. Meanwhile, price volatility, driven primarily by fluctuating nickel and chromium costs, remains a dominant factor requiring agile procurement strategies.

In today’s market, we are seeing a clear divergence. On one hand, the standard austenitic grades like 304 remain the backbone of the industry due to their excellent balance of cost, workability, and corrosion resistance. However, there's a growing appetite for more specialized materials. The push for sustainability and the development of new technologies, especially in green energy sectors like LNG and hydrogen, are driving demand for grades with superior strength and corrosion resistance. This is where duplex grades are gaining significant traction. At the same time, geopolitical factors and mining outputs create constant fluctuations in the prices of raw materials, especially nickel. A few years ago, a sudden spike in nickel prices caught many unprepared. We worked closely with our partners to suggest temporary shifts to lower-nickel or nickel-free ferritic grades for non-critical applications, helping them weather the storm. This kind of market agility is no longer a "nice-to-have"—it's essential for survival.

The Rise of Duplex and High-Performance Grades

As projects become more demanding, particularly in harsh marine or chemical environments, the limitations of standard 300-series grades become apparent. Duplex stainless steels, with their mixed austenitic-ferritic microstructure, offer nearly double the strength of their austenitic counterparts and superior resistance to stress corrosion cracking. This allows for thinner, lighter designs, which can lead to significant overall cost savings despite the higher initial material price.

Price Volatility and Raw Materials

The London Metal Exchange (LME) price for nickel is the single biggest factor influencing the cost of 300-series stainless steel. Any procurement manager in this industry has to watch it like a hawk. This volatility makes long-term budget forecasting a challenge and underscores the need for sourcing partners who can offer flexible pricing mechanisms or help you lock in prices when the market is favorable.

What are the Biggest Challenges in Achieving Cost-Effectiveness?

Every business wants to reduce procurement costs. But focusing only on the per-ton price can blind you to hidden factors that ultimately inflate your total cost of ownership.

The greatest challenges to cost-effectiveness are navigating raw material price volatility, managing complex global logistics, mitigating quality control risks from unvetted suppliers, and avoiding the common mistake of over-specifying a grade, which leads to paying for performance you don't need.

True cost-effectiveness is about total value, not just the initial price tag. I've seen companies get burned by choosing a supplier based on a slightly lower quote, only to face devastating costs from production delays due to poor quality, inconsistent material thickness, or logistical nightmares. A client in South America once shared a story about a "bargain" coil shipment that arrived with surface defects, forcing them to scrap nearly 15% of the material. The initial savings were wiped out many times over. This is why a holistic view is critical. You must factor in material yield, processing efficiency, reliability of supply, and the technical support your partner provides. The cheapest price is rarely the best value.

The Myth of the 'Cheapest' Price

The allure of a low upfront cost is strong, but it often masks underlying issues. Inconsistent chemical composition can lead to welding problems. Variations in thickness can damage expensive tooling and dies. A reliable partner like MFY, with a fully integrated supply chain, ensures that the material you receive is exactly what you ordered, every single time. Our quality control isn't an afterthought; it's embedded from the raw material stage all the way to final delivery.

Aligning Grade with Application

One of the most common ways money is wasted is by using an over-qualified material. For example, using Grade 316, with its costly molybdenum content, for an indoor decorative application where Grade 304 or even 430 would perform perfectly well is a significant and unnecessary expense. A deep understanding of the service environment is crucial to selecting the most cost-effective grade that meets all technical requirements without overpaying.

What Are the Most Effective Sourcing Strategies for Stainless Steel Coil?

Finding a reliable stainless steel supplier can feel overwhelming. A weak sourcing strategy can introduce massive risk and instability into your supply chain, disrupting your entire operation.

Effective sourcing strategies include diversifying suppliers globally to mitigate regional risks, building long-term, transparent partnerships with integrated producers, and leveraging a partner's deep market knowledge to make opportunistic purchases. This creates a resilient and cost-effective supply chain.

Your sourcing strategy should be as robust as the steel you're buying. Relying on a single supplier or region is a high-risk game in today's world. At MFY, we advocate for a balanced approach. We leverage our position as a major Chinese producer to offer competitive pricing and massive capacity, but we also operate as a global trade partner. This means we help our clients build a supply chain that isn't dependent on a single point of failure. I often advise our key accounts to think of their supply chain like an investment portfolio—diversification is key. By having established relationships with producers in different regions, you can pivot quickly if one area is affected by tariffs, logistical bottlenecks, or production issues. This agility is what separates market leaders from the rest.

The Power of an Integrated Partner

Working directly with a fully integrated company like MFY offers advantages that a simple trader cannot. Because we control the process from raw materials to final export, we can guarantee quality, provide full traceability, and offer more stable pricing. We aren't just selling a product; we're providing a service. We become an extension of your procurement team, offering insights and support that help you make smarter decisions.

Comparing Sourcing Models

Choosing the right type of supplier is a critical decision. Each model has its own set of advantages and disadvantages that you must weigh against your company's specific needs for volume, customization, and risk tolerance.

| Sourcing Model | Pros | Cons | Best For |

|---|---|---|---|

| Direct from Mill (MFY) | Best pricing, high volume, quality control | Large minimum order quantities (MOQs) | High-volume manufacturers |

| Distributor/Service Center | Low MOQs, quick delivery, processing | Higher per-unit cost | Small to medium businesses, JIT needs |

| Trader | Access to multiple sources, market flexibility | Less control over quality, less stability | Opportunistic buyers, spot purchases |

What Technical Recommendations Can Optimize Stainless Steel Coil Use?

You've sourced the perfect coil at a great price. But if it's not handled and processed efficiently in your facility, you're still leaving money on the table through waste and inefficiency.

To optimize coil use, start with a thorough needs analysis to perfectly match the grade to the service environment. Then, focus on optimizing your processing—like nesting patterns for cutting—to maximize material yield and minimize scrap. Always consult with material experts.

This is where engineering meets economics. The most successful companies I work with are obsessed with optimization. They understand that every bit of scrap material represents lost profit. The first and most critical step is grade selection. It requires a detailed analysis of the end product's environment. Will it be exposed to saltwater? High temperatures? Abrasive chemicals? Answering these questions determines whether you need the superior corrosion resistance of a grade like 316L or if the general-purpose durability of 304 is sufficient. I recall a client manufacturing marine hardware who was struggling with rust on their 304-grade products. We conducted a joint analysis and recommended a switch to 316L. Their warranty claims dropped to nearly zero, saving them far more in the long run than the modest increase in material cost. That's the power of technical alignment.

Grade Selection: A Practical Guide

Choosing between the most common grades can be simplified by understanding their key differences. Molybdenum is the key ingredient that gives Grade 316 its enhanced resistance to chlorides (like salt), making it the standard for marine and coastal applications.

| Feature | Grade 304 / 304L | Grade 316 / 316L |

|---|---|---|

| Key Alloying Elements | 18% Chromium, 8% Nickel | 16% Chromium, 10% Nickel, 2% Molybdenum |

| Corrosion Resistance | Excellent for general atmospheric conditions | Superior, especially against chlorides/salt |

| Cost | Lower | Higher (due to Molybdenum) |

| Typical Use Case | Kitchen sinks, food processing, indoor architecture | Marine hardware, chemical tanks, coastal structures |

Minimizing Waste in Processing

Once you have the right material, the focus shifts to your production floor. For companies doing a lot of stamping or laser cutting, using nesting software[^1] to optimize how parts are laid out on the coil can dramatically reduce the amount of scrap generated. Small changes in layout can add up to huge savings over thousands of meters of coil.

Conclusion

Mastering stainless steel coil is not about a single action, but a continuous strategy. Aligning grade selection with real-world needs, adopting agile sourcing, and optimizing technical use are the pillars of a successful, cost-effective, and resilient supply chain that will give your business a lasting competitive advantage.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.