Stainless Steel Coil in Automotive: Key Applications & Benefits

Struggling with material choices for modern vehicles? The demand for lighter, stronger, and more sustainable materials is intense. Stainless steel coil offers the perfect solution for next-generation performance and durability.

Stainless steel coil is essential in the automotive industry for its superior strength-to-weight ratio, excellent corrosion resistance, and premium aesthetic finish. It is used in exhaust systems, structural components, and trim, enhancing vehicle longevity, safety, and efficiency while supporting sustainability goals.

As the Global Business Director at MFY, I've seen firsthand how the right material choice can define a project's success. The automotive industry is undergoing a massive transformation, driven by efficiency standards and the electric vehicle revolution. Stainless steel isn't just a component; it's a strategic enabler of this change. Let’s explore why this material has become so indispensable for car manufacturers around the globe.

What is the role of stainless steel coil in the auto industry?

Choosing the right material is a constant battle. You need strength without adding weight, and durability without inflating costs. Stainless steel coil solves these core problems for critical automotive applications.

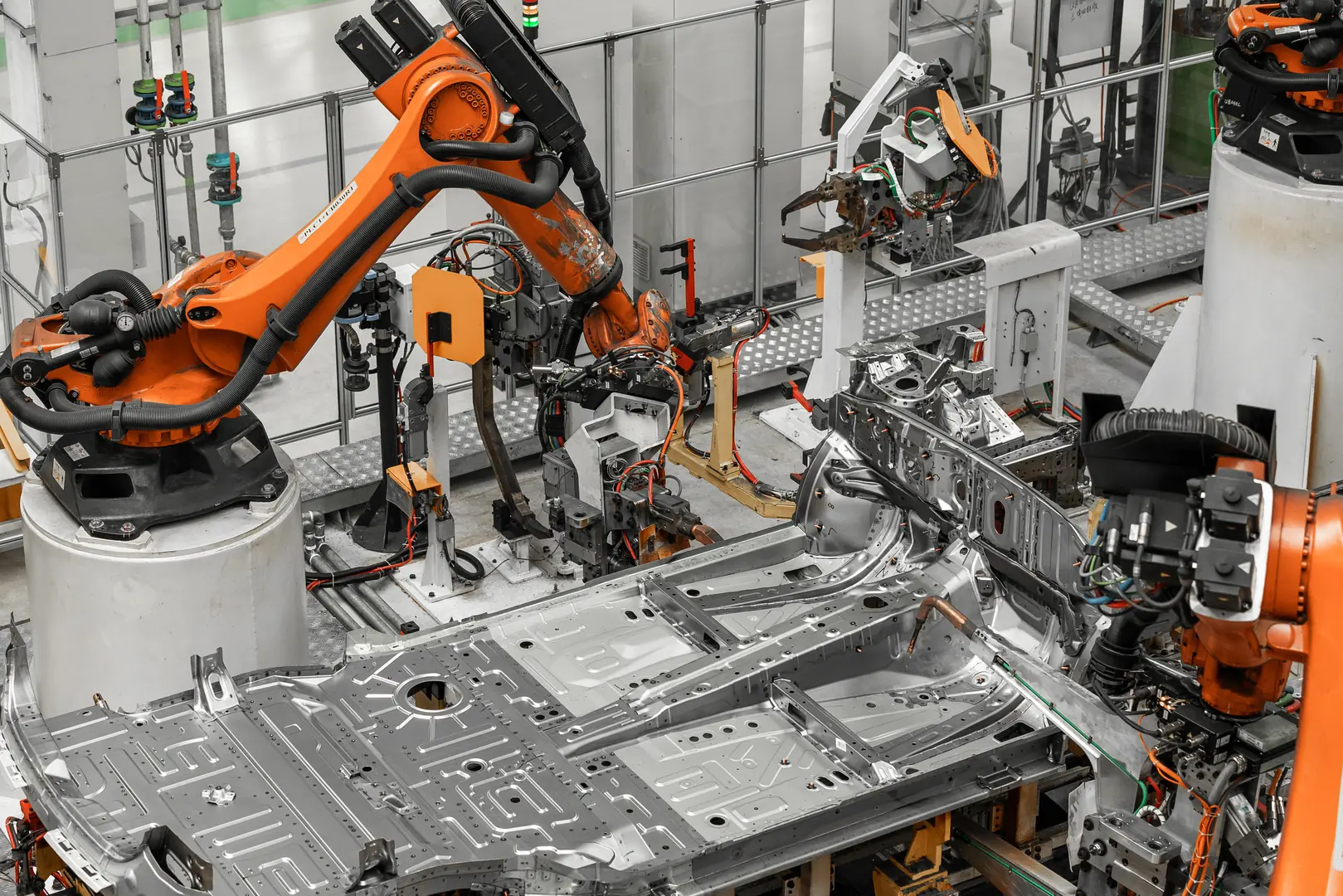

Stainless steel coil is primarily used for manufacturing exhaust systems, structural components like chassis frames, and aesthetic trim. Its inherent resistance to corrosion, heat, and physical impact makes it ideal for parts that demand long-term reliability and performance under harsh conditions.

At MFY, we supply coils for a wide range of automotive parts, and the reasons for its selection are always rooted in performance and longevity. The material's value isn't just in its raw properties but in how it performs over the entire life of the vehicle. For engineers and procurement managers, this means fewer warranty claims, higher customer satisfaction, and a stronger brand reputation. The application of stainless steel is a direct investment in the quality of the final product. I remember a client in Germany who was hesitant about the upfront cost for their exhaust systems. After a year, they reported a significant drop in corrosion-related warranty issues, which more than justified the initial investment. This is a common story. The benefits are tangible and directly impact the bottom line.

Key Application Areas

The versatility of stainless steel allows it to serve multiple functions within a single vehicle, from performance-critical systems to visual enhancements.

| Application Area | Key Benefit | Common Stainless Steel Grade |

|---|---|---|

| Exhaust Systems | High-temperature strength & corrosion resistance | 409, 439, 304 |

| Structural Components | High strength-to-weight ratio for safety | Advanced High-Strength Steels (AHSS) |

| Fuel Tanks & Lines | Corrosion resistance to alternative fuels | 304L, 316L |

| Decorative Trim | Aesthetic appeal & durability | 304, 430 |

The Value Proposition

Ultimately, stainless steel provides a superior total cost of ownership. While the initial material cost might be higher than traditional carbon steel, its durability, lack of need for protective coatings, and full recyclability create long-term value. It allows manufacturers to build lighter, safer, and more fuel-efficient vehicles that last longer and look better.

What are the latest trends in automotive stainless steel?

The industry is evolving at an incredible pace. Staying ahead means anticipating the next big shift in material science. The trend is clear: we need smarter, more sustainable materials.

Current trends are focused on lightweighting for fuel efficiency, using advanced high-strength stainless steels for improved crash safety, and its growing role in electric vehicles (EVs) for battery enclosures and thermal management systems due to its durability and fire resistance.

The most exciting development I'm seeing is the surge in demand for stainless steel in the EV sector. This isn't a coincidence. As we move away from internal combustion engines, new challenges arise, particularly around battery safety and thermal management. Stainless steel is proving to be a game-changer here. Its structural integrity provides excellent protection for sensitive battery modules in the event of a crash. Furthermore, its thermal properties are crucial for designing efficient cooling and heating systems that maintain optimal battery performance and longevity. We're working with several EV startups who are designing their battery enclosures entirely around stainless steel grades for this very reason. They see it not just as a container, but as a multi-functional safety and performance system.

The EV Revolution

The shift to electric mobility is redefining material requirements. Stainless steel is at the forefront of this change.

- Battery Enclosures: Providing robust physical protection and corrosion resistance is paramount. Stainless steel offers a strong, durable, and fire-resistant solution to safeguard the heart of the EV.

- Thermal Management: Coolant tubes and plates made from stainless steel are essential for regulating battery temperatures, ensuring both safety and optimal performance.

- Lightweighting for Range: Every kilogram saved extends an EV's range. Advanced high-strength stainless steel grades allow for thinner, lighter structural components without compromising safety, directly addressing range anxiety.

Sustainability and Circular Economy

Another major trend is the focus on sustainability. With its high recycled content and 100% recyclability at the end of a vehicle's life, stainless steel is a perfect fit for the circular economy. Manufacturers are increasingly highlighting the environmental credentials of their vehicles, and using stainless steel is a powerful part of that story.

What challenges do manufacturers face when using stainless steel coil?

Adopting a superior material isn't always simple. Manufacturers face real-world hurdles in cost and production. Understanding these challenges is the first step to overcoming them.

The primary challenges include the higher initial material cost compared to carbon steel and the complexities in forming and welding. Stainless steel's higher strength and work-hardening properties require more robust tooling, specialized techniques, and process adjustments in manufacturing lines.

It's a conversation I have almost every week with engineering teams. They love the properties of stainless steel, but the production manager is worried about cycle times and tool wear, while the finance department is looking at the upfront cost per ton. These are valid concerns that need to be addressed strategically. The key is to shift the perspective from cost to value. For instance, while the material itself is more expensive, its corrosion resistance can eliminate the need for costly and environmentally-unfriendly coating processes like galvanizing. Similarly, while it may be harder to form, its high strength means you can often use less material (thinner gauges) to achieve the same or better performance, a concept known as downgauging.

Cost vs. Performance Breakdown

It's not just about the price per kilogram; it's about what you get for that price.

| Factor | Mild Carbon Steel | Stainless Steel | Implication for Manufacturers |

|---|---|---|---|

| Initial Cost | Lower | Higher | Requires a Total Cost of Ownership (TCO) analysis. |

| Strength | Good | Excellent | Allows for lightweighting and downgauging. |

| Corrosion Resistance | Poor (requires coating) | Excellent (inherent) | Eliminates coating steps, saving time and money. |

| Formability | Easier | More challenging | May require investment in stronger tooling/updated processes. |

| Weldability | Simpler | Requires specific techniques | Needs skilled labor or automated systems optimized for stainless. |

Addressing these challenges requires a holistic approach. It’s about understanding the full lifecycle of the part and recognizing that a higher initial investment can lead to significant savings and a superior final product.

How can these integration challenges be overcome?

Problems in manufacturing are just puzzles waiting for a solution. The key is collaboration and expertise. By working together, we can turn integration challenges into competitive advantages.

Challenges are overcome by adopting a Total Cost of Ownership (TCO) model, collaborating with expert material suppliers for grade selection and processing advice, investing in modern manufacturing technologies like laser welding, and optimizing component design specifically for stainless steel's properties.

The most successful integrations I've witnessed happen when there's a true partnership between the manufacturer and the material supplier. At MFY, we don't just sell steel coils; we provide solutions. We work with our clients' design and production teams from the very beginning. For example, we might suggest a specific ferritic grade that offers a great balance of corrosion resistance, formability, and cost for an exhaust component, rather than a more expensive austenitic grade. We can also provide data on the optimal settings for stamping or welding that grade, reducing the client's trial-and-error phase. This collaborative approach de-risks the transition and ensures the material's full potential is realized.

Strategic Solutions

Here are the key strategies to smooth the integration of stainless steel:

- Early Supplier Involvement (ESI): Engage with material experts like MFY during the design phase. We can help you select the perfect grade for your application, balancing performance, manufacturability, and cost. This avoids costly redesigns later on.

- Focus on Lifecycle Value: Champion a TCO mindset within your organization. Build a business case that includes savings from eliminated coating processes, reduced warranty claims due to higher durability, and the benefits of lightweighting on fuel efficiency or EV range.

- Invest in Technology and Training: Modern manufacturing requires modern tools. Advanced technologies like hydroforming[^1], hot stamping, and laser welding are particularly well-suited for working with high-strength stainless steels. Investing in training for your welding and forming teams is equally critical.

- Design for the Material: Don't simply substitute stainless steel into a design made for carbon steel. Redesign the part to take advantage of stainless steel's higher strength. This often means creating more complex geometries that are thinner and lighter but just as strong.

By taking these steps, manufacturers can turn the perceived challenges of stainless steel into a powerful competitive edge.

What innovations are maximizing the benefits of stainless steel in vehicles?

Innovation is what drives our industry forward. New alloys and processes are constantly pushing the boundaries. These advancements are making stainless steel an even more compelling choice for automakers.

Key innovations include the development of new Advanced High-Strength Steel (AHSS) grades that offer unprecedented strength-to-weight ratios, advanced forming techniques like hydroforming for complex shapes, and the use of stainless steel in additive manufacturing (3D printing) for prototyping and specialized components.

The pace of material science innovation is truly remarkable. We are seeing the development of new duplex and lean duplex stainless steel[^2] grades that offer incredible strength and corrosion resistance at a more competitive price point. These materials are perfect for structural safety components like A-pillars and B-pillars, where they can absorb massive amounts of crash energy while keeping the passenger cabin intact. Another area is surface engineering. New texturing and finishing techniques are allowing designers to use stainless steel in more visible interior and exterior trim applications, providing a premium look that lasts the lifetime of the vehicle without peeling or fading like chrome plating.

Breakthroughs in Materials and Manufacturing

These innovations are unlocking new possibilities for automotive design.

- Advanced Alloys:

- High-Strength Ferritics: Offering better performance in exhaust systems to meet stricter emissions standards.

- Austenitic AHSS: Providing extreme strength for critical safety cage components, enabling significant weight reduction.

- Next-Generation Manufacturing:

- Hydroforming: Using high-pressure fluid to form complex, single-piece components like exhaust manifolds or frame rails. This reduces the need for welding, creating stronger and lighter parts.

- Laser Blanking & Welding: Allowing for the precise cutting and joining of different thicknesses and grades of stainless steel into a single "tailored blank[^3]," optimizing material use where it's needed most.

These advancements are not just theoretical; they are being implemented on production lines today. They allow us to build cars that are safer, more efficient, and more sustainable than ever before, with stainless steel playing a central role in that progress.

Conclusion

From exhaust systems to EV battery enclosures, stainless steel coil has proven its value. It is more than just a raw material; it is a strategic asset for building the safer, more efficient, and more sustainable vehicles of the future. Its role will only grow.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.