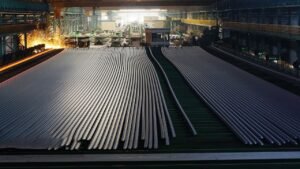

Schedule 10 Stainless Pipe Explained: Specs & Uses

Are you finding the world of pipe schedules, particularly Schedule 10 stainless steel, a bit perplexing? It can be frustrating when project success hinges on selecting the right materials, and uncertainty leads to costly errors or over-engineering. As Global Business Director at MFY, I understand that clarity is key, and this guide is designed to demystify Schedule 10 stainless pipe for you.

Schedule 10 (Sch 10) stainless steel pipe refers to a specific pipe wall thickness designation under ASME B36.19M for stainless steel pipes. It signifies a relatively thin wall, making it lighter and more cost-effective for suitable low-pressure applications compared to heavier schedules.

Choosing the right pipe schedule is more than just a technical detail; it’s a critical decision that impacts your project's safety, efficiency, and budget. If you've ever felt overwhelmed by the various specifications or unsure if Schedule 10 is the optimal choice for your application, you're not alone. We at MFY often guide clients through this selection process, ensuring they get the best value and performance.

Understanding pipe schedules, like Schedule 10, is fundamental in industries ranging from food processing to chemical manufacturing and construction. The designation "Schedule 10" directly correlates to the pipe's ability to withstand internal pressure, its weight, and consequently, its cost. For instance, according to ASME B36.19M1, which specifically covers stainless steel pipes, the wall thickness for a 2-inch NPS Schedule 10S pipe is 0.109 inches (2.77mm). This contrasts sharply with a Schedule 40S pipe of the same nominal size, which has a wall thickness of 0.154 inches (3.91mm). This difference, while seemingly small, has significant implications. In my experience at MFY, we’ve seen projects where selecting Sch 10 for a low-pressure water treatment system saved a client in India nearly 15% on material costs compared to their initial consideration of Sch 40, without compromising safety or performance for that specific application. This highlights how a nuanced understanding can lead to substantial efficiencies.

What are the specifications of Schedule 10 stainless pipe?

Feeling unsure about the precise dimensions, material grades, or applicable standards for Schedule 10 stainless pipe? This uncertainty can easily lead to incorrect orders, project delays, or compatibility issues. At MFY, we believe in empowering our clients with clear, concise information to navigate these specifications confidently.

Schedule 10 stainless pipe specifications primarily involve a defined wall thickness relative to the nominal pipe size (NPS), governed by ASME B36.19M. Common material grades include 304/304L and 316/316L, offering varying corrosion resistance suitable for low-pressure fluid conveyance.

Knowing these specifications isn't just an academic exercise; it's absolutely crucial for engineers designing systems and for procurement teams sourcing materials. Imagine, for example, a project manager at one of our client companies, a food and beverage manufacturer in Southeast Asia. They needed to expand their purified water distribution lines. Their primary concerns were maintaining product purity, ensuring easy clean-in-place (CIP) operations which involve low-pressure chemical solutions, and managing project costs. Understanding that Schedule 10S 316L stainless steel pipe offered the necessary corrosion resistance for both the purified water and the cleaning agents, along with a wall thickness suitable for their low operating pressures (typically below 150 psi), was vital. If they had mistakenly ordered a thicker schedule, like Sch 40S, they would have incurred unnecessary material costs and increased the weight of the piping system, potentially requiring more robust supports. Conversely, opting for a schedule too thin or an incorrect material grade could lead to premature failure or contamination risks. This is why a detailed grasp of specifications like Nominal Pipe Size (NPS), actual outer diameter (OD), specific wall thickness for Sch 10, and the properties of grades like 304L (excellent for general corrosive environments) versus 316L (superior for chloride-rich environments) is indispensable. We at MFY often walk our clients through these details, referencing standards like ASTM A3122 for seamless and welded austenitic stainless steel pipes, to ensure every order perfectly matches the application's demands.

Understanding the detailed specifications of Schedule 10 stainless steel pipe is the first step towards making an informed decision for your project. These specifications are not arbitrary; they are defined by industry standards to ensure consistency, safety, and interoperability. As a global supplier at MFY, we regularly work with these standards and help our clients navigate them. Let's break down the key aspects.

Understanding Pipe Nominal Size (NPS) and Outer Diameter (OD)

The Nominal Pipe Size (NPS) is a North American standard designation for pipe sizes. It's important to note that for NPS 1/8 inch to 12 inches, the NPS number is dimensionless and only loosely related to the actual inside diameter; it more closely identifies the "name" of the pipe size. The actual Outer Diameter (OD) is a fixed value for each NPS. For instance, a 2-inch NPS pipe always has an OD of 2.375 inches (60.3 mm), regardless of the schedule or wall thickness. This standardization is critical for ensuring that pipes, fittings, and valves from different manufacturers are compatible.

When you specify a "Schedule 10, 2-inch stainless steel pipe," the "2-inch" refers to the NPS. The OD remains constant for that NPS, and the "Schedule 10" then dictates the wall thickness. At MFY, our manufacturing processes for stainless steel pipes adhere strictly to these OD tolerances as specified in standards like ASTM A312. We had a client, an equipment integrator, who was developing a modular processing skid. The precise OD and its consistency were paramount for the automated welding processes they employed and for the fit-up with various pre-fabricated components. Any deviation could cause significant delays and rework.

The consistency of the OD for a given NPS is a cornerstone of piping system design. It allows engineers to select appropriate fittings (elbows, tees, flanges) and valves with confidence, knowing they will match the pipe. For Schedule 10 pipes, because the wall is thinner, the inner diameter (ID) will be larger than for a higher schedule pipe of the same NPS. This can sometimes be an advantage for flow characteristics, but the primary dimensional constant for system design is the OD.

Wall Thickness and its Relation to Schedule Number

The "Schedule number" is a dimensionless identifier that relates to the pipe's wall thickness. For stainless steel pipes, the relevant standard is typically ASME B36.19M, which uses an "S" suffix for stainless steel schedules (e.g., Sch 10S, Sch 40S). Schedule 10S specifically denotes a relatively thin wall, designed for low-pressure applications. The actual wall thickness for a Schedule 10S pipe varies depending on the NPS. For example:

- A 1-inch NPS Sch 10S pipe has a wall thickness of 0.109 inches (2.77 mm).

- A 4-inch NPS Sch 10S pipe has a wall thickness of 0.120 inches (3.05 mm).

- A 6-inch NPS Sch 10S pipe has a wall thickness of 0.134 inches (3.40 mm).

These values are significantly less than those for, say, Schedule 40S. For that same 4-inch NPS pipe, a Sch 40S wall thickness is 0.237 inches (6.02 mm) – almost double. This difference directly impacts the pressure rating, weight, and cost of the pipe. MFY produces a wide range of schedules, and we always emphasize to our clients that Sch 10S is an economical and efficient choice, but only when the application's pressure requirements are well within its limits. One of our customers, a contractor for commercial HVAC systems, frequently uses Sch 10S stainless steel pipes for chilled water lines where pressures are typically low, and the corrosion resistance of stainless steel is beneficial.

The schedule system, originating from the need to standardize pipe wall thicknesses for different pressure services, essentially provides a relative measure of a pipe's strength. While Barlow's formula (P = 2St/D) gives a more precise calculation for allowable pressure (where P is pressure, S is allowable stress, t is wall thickness, and D is outside diameter), the schedule number offers a quick, standardized way to classify pipes for various duty levels.

Common Stainless Steel Grades and Their Properties (e.g., 304/304L, 316/316L)

Schedule 10 pipes are commonly available in various stainless steel grades, with austenitic grades like 304/304L and 316/316L being the most prevalent. Grade 304 is the workhorse of the stainless steel family, offering good corrosion resistance in a wide range of atmospheric and mildly corrosive chemical environments. The "L" designation, as in 304L, indicates low carbon content (typically below 0.03%), which is crucial for preventing chromium carbide precipitation during welding, thereby maintaining corrosion resistance in the heat-affected zone. This makes 304L an excellent choice for welded Sch 10 pipe applications.

Grade 316/316L contains molybdenum (typically 2-3%), which significantly enhances its corrosion resistance, particularly against chlorides and other industrial solvents. This makes it ideal for more aggressive environments, such as coastal regions, chemical processing, or food and beverage applications where chloride-based cleaning agents are used. For instance, MFY supplied a significant quantity of Sch 10S 316L pipes to a desalination pre-treatment facility in the Middle East. The client specifically chose 316L due to the high salinity of the feed water and the surrounding environment, even though the operating pressures were low, making Sch 10S suitable from a mechanical standpoint. The cost premium for 316L over 304L was justified by the extended service life and reduced maintenance in that corrosive setting.

The choice between these grades often comes down to a balance of corrosion resistance requirements and budget. While 316L offers superior performance in harsher conditions, 304L is often perfectly adequate and more economical for many Sch 10 applications. We at MFY help our clients make this assessment, considering the specific fluid, operating temperature, and external environment.

| Feature | Grade 304/304L SS | Grade 316/316L SS | Typical Sch 10 Application Relevance |

|---|---|---|---|

| Corrosion Resist. | Good general corrosion resistance | Excellent, especially against chlorides & acids | 316L for coastal, chemical, or saline fluids |

| Стоимость | More economical | Higher cost due to Molybdenum content | 304L for cost-sensitive, less corrosive apps |

| Weldability | Good (304L preferred for welding) | Good (316L preferred for welding) | L-grades crucial for maintaining integrity |

| Typical Uses | Water treatment, food (non-saline), architectural | Chemical processing, marine, pharma, food (saline) | Match grade to fluid and environment |

| Strength | Similar to 316 | Similar to 304 (slightly higher at elevated temps) | Less critical for low-pressure Sch 10 design |

Schedule 10 has thinner walls than Schedule 40Правда

For the same NPS, Schedule 10 pipes have significantly thinner walls (e.g., 2.77mm vs 3.91mm for 2-inch pipe) making them lighter and more cost-effective for low-pressure applications.

316L is identical to 304LЛожь

316L contains molybdenum which 304L lacks, giving it superior corrosion resistance especially against chlorides - a crucial difference for applications like desalination plants.

How does the thickness impact the performance of Schedule 10 stainless pipe?

Are you wondering if the thinner walls of Schedule 10 stainless pipe might compromise its performance or longevity in your specific system? It's a valid concern, as misinterpreting the impact of wall thickness can lead to over-engineering with unnecessary costs, or worse, under-engineering resulting in premature system failures.

The reduced thickness of Schedule 10 stainless pipe directly results in a lower pressure rating and less structural rigidity compared to thicker schedules. However, it offers significant advantages in terms of lighter weight, improved flow characteristics (larger internal diameter), and lower material cost for suitable applications.

The thickness of a pipe wall is a primary determinant of its mechanical strength and pressure-containing capability. For Schedule 10 stainless pipe, its relatively thin wall profile means it's inherently designed for low-pressure environments. If you were to, for example, use Sch 10 pipe in an application where high pressures are expected, say above 200-300 psi depending on diameter and temperature (which is a general range, specific calculations are always needed), you would be risking deformation or rupture. I recall a situation where a new plant engineer, unfamiliar with stainless steel schedules, considered using Sch 10S for a medium-pressure steam condensate return line. Luckily, during our consultation at MFY, we identified this potential misapplication and guided them towards a more appropriate Sch 40S, preventing a likely operational hazard. Conversely, using Sch 40S where Sch 10S would suffice, such as in gravity-fed drainage systems or low-pressure chemical dosing lines common in the water treatment facilities we supply in India, means unnecessary expenditure on material and increased installation complexity due to heavier pipes. The key is to match the pipe's capabilities, dictated largely by its thickness, to the operational demands of the system. This balance ensures both safety and economic efficiency.

The wall thickness of a pipe is not just a dimensional attribute; it's a critical factor that dictates its behavior under various operational stresses. For Schedule 10 stainless pipe, its characteristically thinner wall compared to higher schedules like Sch 40 or Sch 80 has profound implications on its performance. At MFY, we always emphasize understanding these impacts to ensure our clients select the most appropriate and cost-effective solution.

Pressure Handling Capabilities

The most direct impact of wall thickness is on the pipe's ability to withstand internal pressure. Schedule 10 pipes, due to their thinner walls, are designed for low-pressure applications. The allowable internal working pressure for a pipe can be estimated using Barlow's formula3, where 'P' is pressure, 'S' is the allowable stress for the material at a given temperature, 't' is the nominal wall thickness, and 'D' is the outside diameter. Since 't' for Sch 10 is relatively small, the resulting 'P' will be lower compared to a thicker walled pipe of the same material and diameter.

For example, a 2-inch NPS 304L Sch 10S stainless steel pipe (OD 2.375", wall 0.109") at ambient temperature might have an approximate allowable working pressure in the range of 400-500 psi (this is illustrative; exact values depend on specific allowable stress from codes like ASME B31.3). In contrast, a 2-inch NPS 304L Sch 40S pipe (wall 0.154") would have a significantly higher pressure rating, often exceeding 700-800 psi under similar conditions. It's crucial for engineers to consult relevant piping codes and material specifications to determine accurate pressure ratings for their specific operating temperatures and conditions. MFY provides pipes manufactured to meet these stringent standards, but the system design responsibility lies with the user. We've assisted clients, like a beverage company in Southeast Asia, who needed piping for their carbonated drink lines. While some sections were low pressure and Sch 10S was suitable, sections closer to the carbonation units experienced higher pressures, necessitating Sch 40S.

This lower pressure rating makes Sch 10 unsuitable for applications involving high-pressure fluids, steam, or hydraulic systems. However, it is perfectly adequate and often preferred for numerous low-pressure services such as gravity flow lines, drainage, vent pipes, conduit, and low-pressure water or chemical transfer.

Weight, Cost, and Flow Characteristics

A thinner wall directly translates to less material used per unit length of pipe. This has a cascading effect on several important factors. Firstly, the pipe is lighter. A 2-inch NPS Sch 10S stainless steel pipe weighs approximately 2.64 lbs/ft, whereas a Sch 40S pipe of the same size weighs about 3.65 lbs/ft. This ~28% weight reduction for Sch 10S makes it easier to handle, transport, and install, potentially reducing labor costs and the need for heavy lifting equipment. The supporting structures (hangers, racks) can also be less robust, leading to further savings.

Secondly, less material means lower initial purchase cost. For projects where large quantities of piping are required, such as in extensive water distribution networks or architectural features, the cost savings from choosing Sch 10 over a heavier schedule (where appropriate) can be substantial. MFY's efficient production processes for stainless steel coils and pipes allow us to pass on these material efficiencies to our customers, making Sch 10 an attractive option for budget-conscious projects. I remember a contractor working on a large architectural project in Dubai who specifically chose MFY's polished Sch 10S 304 pipes for decorative handrailing; the lighter weight and lower cost were key decision factors, alongside the aesthetic appeal and corrosion resistance.

Thirdly, for a given Nominal Pipe Size (NPS), a thinner wall results in a larger internal diameter (ID). This larger bore can improve flow characteristics by reducing frictional losses and pressure drop, especially in systems where maintaining flow velocity or minimizing pumping energy is important. While the difference in ID might seem small, over long pipe runs or in complex systems, it can be a contributing factor to overall system efficiency. For instance, in low-pressure, high-volume air or fluid transfer, the slightly larger ID of Sch 10 can be beneficial.

Susceptibility to Mechanical Damage and Corrosion Allowance

The trade-off for the benefits of a thinner wall is a reduced resistance to mechanical damage. Schedule 10 pipes are more susceptible to denting, bending, or puncturing from external impacts compared to thicker-walled pipes like Sch 40. This means that in environments where there's a higher risk of mechanical abuse (e.g., high-traffic industrial areas, outdoor installations prone to impact), Sch 10 might not be the best choice, or it may require additional protective measures.

Furthermore, the corrosion allowance is inherently less with a thinner wall. While stainless steel offers excellent corrosion resistance, in very aggressive environments or over very long service lives, some material loss due to corrosion can occur. A thicker wall provides a greater margin before the pipe's integrity is compromised. Therefore, when selecting Sch 10, especially with grades like 304L, it's vital to ensure the fluid and environment are well within the material's resistance capabilities to prevent premature failure. For applications with more aggressive media, opting for a more corrosion-resistant grade like 316L within the Sch 10 specification, or even considering a thicker schedule if corrosion rates are predictably high, might be necessary. At MFY, we often advise clients on this balance. For instance, a chemical plant in India using Sch 10S 316L for mildly corrosive process lines found it to be a good balance, but for more aggressive chemicals, they opted for heavier schedules or more exotic alloys.

| Параметр | Sch 10S (e.g., 2" NPS 304L) | Sch 40S (e.g., 2" NPS 304L) | Implication |

|---|---|---|---|

| Толщина стенок | ~0.109 inches | ~0.154 inches | Sch 10 is thinner |

| Номинальное давление | Нижний | Выше | Sch 10 for low-pressure; Sch 40 for moderate/high |

| Weight/foot | ~2.64 lbs | ~3.65 lbs | Sch 10 is lighter, easier to install, less support |

| Material Cost | Нижний | Выше | Sch 10 more economical for suitable applications |

| Внутренний диаметр | Larger | Smaller | Sch 10 may offer slightly better flow |

| Mechanical Strength | Нижний | Выше | Sch 10 more prone to damage, less structural rigidity |

| Коррозионная надбавка | Less | More | Material selection critical for Sch 10 longevity |

Schedule 10 has lower pressure ratingПравда

Due to its thinner walls, Schedule 10 stainless pipe is designed for low-pressure applications and cannot handle the same pressures as thicker schedules like Sch 40.

Schedule 10 is heavier than Sch 40Ложь

Actually, Schedule 10 is lighter than Sch 40 due to its thinner walls, making it easier to handle and install while requiring less support structure.

What are the primary uses of Schedule 10 stainless pipe in various industries?

Are you unsure exactly where Schedule 10 stainless pipe fits into the industrial landscape? Using it inappropriately can lead to operational inefficiencies or safety concerns, while overlooking it for suitable applications means missing out on potential cost savings. As your partner at MFY, I want to illuminate its common and effective applications.

Schedule 10 stainless pipe is primarily utilized in low-pressure applications across various industries, including water treatment, food and beverage processing, chemical transfer (for compatible fluids), architectural elements, and automotive or industrial exhaust systems, leveraging its corrosion resistance and cost-effectiveness.

The versatility of Schedule 10 stainless pipe stems from its favorable balance of properties for specific conditions. Consider its use in the food and beverage industry, a key sector MFY serves. Many processing lines, such as those for milk, juices, or other non-carbonated liquids, operate at relatively low pressures. Here, Sch 10S pipes4, particularly in 304L or 316L grades, provide the necessary hygienic surfaces and corrosion resistance for both the product and the cleaning-in-place (CIP) solutions, without the added expense and weight of heavier schedules. We've supplied numerous dairy plants in India and Southeast Asia with MFY's Sch 10S pipes for precisely these applications. Similarly, in water treatment facilities, large volumes of water are moved at low pressures through various filtration and purification stages. The corrosion resistance of stainless steel is vital for longevity, and Sch 10S offers an economical solution for the extensive piping networks required. Its lighter weight also simplifies installation in these often sprawling plants. From architectural handrails that require a sleek look and durability against elements to low-pressure chemical dosing lines where material compatibility is key, Sch 10S finds its niche where high pressure is not a primary concern.

Schedule 10 stainless steel pipe, with its characteristic thin wall, has carved out a significant niche in various industries where its specific attributes offer the optimal balance of performance, cost, and ease of handling. At MFY, we've seen firsthand its successful implementation across a diverse range of applications, reflecting its versatility for low-pressure environments.

Fluid Conveyance in Low-Pressure Systems

This is arguably the most common application area for Schedule 10 stainless steel pipes. In many industrial processes, fluids need to be transported efficiently and hygienically, but without the demand of high pressures. Water treatment plants are a prime example. Whether it's for potable water distribution, wastewater handling, or desalination pre-treatment stages, vast networks of piping are required. Sch 10S, often in 304L or 316L stainless steel5 (especially for saline or more corrosive water), offers excellent corrosion resistance and longevity at a more economical price point than heavier schedules. MFY has supplied Sch 10S pipes to numerous municipal and industrial water projects across Asia, where its performance in low-pressure conveyance is well-proven.

The food and beverage industry heavily relies on stainless steel for its hygienic properties and resistance to corrosion from food products and cleaning agents. Many product transfer lines, Clean-In-Place (CIP) systems (which typically operate at low pressures), and utility lines (e.g., for low-pressure process water) effectively utilize Sch 10S pipes. We worked with a major beverage manufacturer in Vietnam who retrofitted their fruit juice processing lines with MFY's Sch 10S 316L pipes to ensure product integrity and facilitate efficient cleaning, all while managing project costs effectively.

In the chemical processing industry, while high-pressure applications demand thicker-walled pipes, there are numerous low-pressure transfer lines for less aggressive chemicals, solvents, or utility fluids where Sch 10S stainless steel (typically 316L for better chemical resistance) is a suitable and cost-effective choice. Careful consideration of chemical compatibility is, of course, paramount. A client of ours, a specialty chemical producer, uses our Sch 10S 316L pipes for transferring intermediate products between low-pressure holding tanks, benefiting from the material's resistance and the schedule's cost-efficiency.

Architectural and Structural Applications (Non-Load Bearing)

The aesthetic appeal, corrosion resistance, and relatively light weight of Schedule 10 stainless steel pipe6 make it a popular choice for various architectural applications. Polished Sch 10S pipes are frequently used for handrails, balustrades, decorative guardrails, and other ornamental features in both interior and exterior settings. Its resistance to atmospheric corrosion ensures a long-lasting, attractive finish with minimal maintenance, which is highly valued in commercial buildings, public spaces, and even high-end residential projects. MFY has supplied polished Sch 10S 304 pipes for several modern building facades and interior design elements in rapidly developing urban centers in Southeast Asia.

Beyond purely decorative uses, Sch 10S can also be employed for light structural supports where high load-bearing capacity is not the primary requirement, but corrosion resistance and appearance are. This could include framework for signage, supports for lightweight paneling, or custom-designed furniture elements. Its ease of fabrication (cutting, welding, polishing) compared to heavier sections also contributes to its suitability for such custom architectural work. However, it's crucial to emphasize that for any application involving structural loads, a qualified engineer must verify the suitability of Sch 10S based on structural calculations and relevant building codes.

The durability of stainless steel, even in the thinner Sch 10S profile, often surpasses that of carbon steel or aluminum in many outdoor or humid environments, reducing the need for protective coatings and frequent upkeep, making it a lifecycle-cost-effective choice for these visible architectural components.

Specialized Uses like Exhaust Systems and Conduit

Schedule 10 stainless steel pipe also finds application in more specialized areas. For instance, in automotive and industrial exhaust systems, particularly for aftermarket or performance applications, Sch 10S (often in grades like 304 or sometimes heat-resistant grades) can be used. Its ability to withstand moderate temperatures, resist corrosive exhaust gases, and its relatively light weight are advantageous. While very high-performance or high-temperature systems might require different materials or thicker walls, Sch 10S serves well in many general-duty exhaust applications.

Another specialized use is as a conduit for protecting electrical wiring or data cables in corrosive or harsh environments where standard galvanized or PVC conduit would degrade quickly. The inherent corrosion resistance of stainless steel makes Sch 10S a durable option for chemical plants, marine environments, or food processing facilities where washdowns are frequent. Its thinner wall makes it easier to install than heavier stainless steel conduit options while still providing robust protection. We've seen MFY's Sch 10S pipes used by equipment integrators to create durable and clean-looking conduit runs on machinery destined for such demanding environments.

| Промышленность | Primary Application of Sch 10 Stainless Pipe | Key Benefits Provided by Sch 10 | Common SS Grade(s) |

|---|---|---|---|

| Water Treatment | Potable water lines, wastewater, low-pressure filtration systems | Corrosion resistance, cost-effectiveness for large scale | 304L, 316L |

| Продукты питания и напитки | Product transfer lines (low pressure), CIP system piping, utility lines | Hygiene, corrosion resistance, cost | 304L, 316L |

| Химическая обработка | Low-pressure transfer of compatible chemicals, utility fluid lines | Chemical resistance (316L), cost | 316L, 304L |

| Architectural | Handrails, balustrades, decorative elements, light non-load bearing frames | Aesthetics, corrosion resistance, lighter weight | 304, 304L |

| Automotive/Industrial | Exhaust systems (moderate temp), vent pipes | Heat/corrosion resistance, weight | 304 |

| General Manufacturing | Low-pressure air/fluid lines, conduit in corrosive areas | Durability, protection, cost | 304L, 316L |

Sch 10S is ideal for food processingПравда

Its hygienic surface and corrosion resistance make it perfect for food/beverage applications where high pressure isn't required.

Sch 10S handles high-pressure steamЛожь

Schedule 10's thin walls make it unsuitable for high-pressure applications; thicker schedules would be required.

How does Schedule 10 stainless pipe compare to other schedules?

Feeling overwhelmed by the array of different pipe schedules and unsure how Schedule 10 truly stacks up against alternatives like Schedule 5, Schedule 40, or even Schedule 80? This confusion can lead to over-specifying and overspending, or under-specifying and risking system integrity. At MFY, we often help clients make these comparisons to find the perfect fit.

Schedule 10 stainless pipe is significantly thinner and lighter than Schedule 40 and 80, offering lower cost and easier handling for low-pressure applications. It's slightly thicker than Schedule 5, providing a bit more robustness while remaining a lightweight option.

Understanding these comparisons is crucial for optimal material selection. Imagine you're designing a low-pressure water system. Schedule 40 would be overkill – heavier, more expensive, and harder to install. Schedule 5 might be too thin if minor structural integrity or slight pressure variations are a concern. Schedule 10 often hits that sweet spot, providing adequate strength for low-pressure duties without the excess material and cost of heavier schedules. For instance, a manufacturing client in India recently consulted us at MFY for a new coolant distribution system. Their pressures were consistently below 100 psi. While they initially considered Sch 40S out of habit, we demonstrated that Sch 10S 304L would meet all their performance requirements, saving them nearly 20% on piping material costs and significantly reducing installation time due to the lighter weight. This kind of practical comparison ensures resources are used wisely, aligning with MFY’s commitment to providing efficient solutions.

Choosing the right pipe schedule is a critical engineering and procurement decision. Schedule 10 stainless steel pipe occupies a specific position within the spectrum of available wall thicknesses, and understanding its relative strengths and weaknesses compared to other common schedules is key to its effective application. As a manufacturer and supplier at MFY, we deal with these comparisons daily, guiding our clients to the most suitable options.

Comparison with Lighter Schedules (e.g., Schedule 5S)

Schedule 5S is even thinner-walled than Schedule 10S. This makes Sch 5S pipes exceptionally lightweight and offers the lowest material cost among the common stainless steel schedules. For a given NPS, Sch 5S will have a larger internal diameter than Sch 10S, potentially offering slight advantages in flow for very low-pressure, gravity-fed systems.

However, the extreme thinness of Sch 5S also means it has the lowest pressure rating and is the most susceptible to mechanical damage. Its structural rigidity is minimal, making it unsuitable for applications requiring any significant self-support or resistance to external forces. Welding thin Sch 5S material can also be more challenging, requiring greater skill to avoid burn-through or distortion. At MFY, while we can produce Sch 5S, we often find clients opt for Sch 10S if there's any uncertainty about handling stresses or minor pressure fluctuations. A typical application for Sch 5S might be for very low-pressure ducting or purely decorative uses where weight is absolutely paramount and mechanical loads are negligible. For instance, a client designing custom light fixtures once inquired about Sch 5S for its minimal weight, but ultimately chose Sch 10S for a bit more robustness during assembly and installation.

In summary, Sch 10S offers a step up in terms of mechanical strength and pressure handling capability compared to Sch 5S, making it a more versatile choice for many low-pressure fluid conveyance applications where Sch 5S might be considered too fragile. The cost difference is usually not substantial enough to justify Sch 5S if the added robustness of Sch 10S is beneficial.

Comparison with Heavier Schedules (e.g., Schedule 40S)

Schedule 40S is a very common, medium-duty pipe schedule and is significantly thicker and heavier than Schedule 10S. For any given NPS, a Sch 40S pipe7 will have a much higher pressure rating and greater structural strength. For example, for a 2-inch NPS 304L pipe, the wall thickness of Sch 10S is 0.109 inches, while for Sch 40S it's 0.154 inches. This ~41% increase in wall thickness results in a proportionally higher pressure capacity and much greater resistance to bending, denting, and other forms of mechanical damage.

This makes Sch 40S suitable for a broader range of applications, including moderate-pressure process lines, utility piping (e.g., compressed air, steam condensate), and structural uses where greater strength is needed. However, these benefits come at a cost: Sch 40S pipes are heavier, more expensive due to increased material content, and can be more cumbersome to install. The smaller internal diameter of Sch 40S (for the same NPS) also means slightly higher frictional losses for fluid flow. MFY supplies large volumes of both Sch 10S and Sch 40S. We often see Sch 40S specified by default in many engineering specifications, sometimes even when Sch 10S would be perfectly adequate and more economical. We had a construction contractor client working on a new food processing plant in Southeast Asia. Their initial drawings specified Sch 40S for all stainless steel piping. After a review with MFY, we identified several low-pressure utility water and drainage lines where Sch 10S 316L would meet all performance and hygiene requirements, resulting in considerable material and installation cost savings for the project.

The decision between Sch 10S and Sch 40S often hinges on a careful evaluation of the system's operating pressure, potential for mechanical abuse, and budget. If pressures are low (typically under 150-200 psi, though this varies by diameter and code) and the pipe is reasonably protected, Sch 10S is often the more economical and efficient choice.

Comparison with Very Heavy Schedules (e.g., Schedule 80S and above)

Schedule 80S and even heavier schedules (like Sch 160 or XXS) represent pipes with very thick walls, designed for high-pressure applications, severe service conditions, or significant structural loads. Compared to Sch 10S, the difference is stark. A 2-inch NPS 304L Sch 80S pipe8 has a wall thickness of 0.218 inches – double that of Sch 10S. Consequently, Sch 80S pipes have substantially higher pressure ratings, excellent mechanical strength, and a greater corrosion allowance.

These heavy-wall pipes are used in applications like high-pressure chemical processing, hydraulic systems, steam lines operating at high pressures, and critical process piping where safety margins must be very high. They are significantly more expensive, much heavier, and require more effort and expertise to weld and install. MFY's product range includes these heavier schedules for clients in demanding industries, but their application is far more specialized than Sch 10S. For instance, a petrochemical client in the Middle East uses MFY's Sch 80S and Sch 160S 316L pipes for specific high-pressure reactor feed lines.

For the vast majority of applications where Sch 10S is considered, Sch 80S would be gross over-engineering, leading to unnecessary expenditure on materials, support structures, and labor. The internal diameter of Sch 80S is also considerably smaller for a given NPS, which would significantly restrict flow compared to Sch 10S if used in a low-pressure system designed around Sch 10S flow rates. The comparison essentially highlights different tools for entirely different jobs: Sch 10S for lightweight, low-pressure duties, and Sch 80S for heavy-duty, high-pressure service.

| Feature | Sch 5S | Sch 10S | Sch 40S | Sch 80S |

|---|---|---|---|---|

| Толщина стенок | Thinnest | Thin | Средний | Thick |

| Относительная стоимость | Lowest | Низкий | Умеренный | Высокий |

| Weight | Lightest | Light | Heavier | Heaviest |

| Номинальное давление | Очень низкий | Низкий | Moderate to High | High to Very High |

| Mechanical Strength | Очень низкий | Низкий | Хорошо | Превосходно |

| Typical Use Case | Decorative, light ducting | Low-pressure fluid, architectural | General purpose, moderate P | High-pressure, severe service |

| Installation | Easiest (but delicate) | Easy | More demanding | Most demanding |

Schedule 10 is thinner than Schedule 40Правда

Schedule 10 stainless pipe has a thinner wall thickness compared to Schedule 40, making it lighter and more cost-effective for low-pressure applications.

Schedule 10 is suitable for high-pressure systemsЛожь

Schedule 10 is designed for low-pressure applications; heavier schedules like Schedule 40 or 80 are required for high-pressure systems.

When is Schedule 10 stainless pipe the best choice for your needs?

Are you at the point of decision, trying to determine if Schedule 10 stainless pipe is truly the optimal material for your specific project, worried about balancing cost, performance, and longevity? Making the wrong choice can be costly. As your advisor from MFY, let me help you pinpoint when Sch 10 shines.

Schedule 10 stainless pipe is the best choice when your application involves low internal pressures, requires good corrosion resistance, benefits from lighter weight for easier installation or reduced structural load, and where cost-effectiveness for materials is a significant consideration.

The "sweet spot" for Schedule 10 stainless pipe emerges when several conditions align. For example, if you are designing a potable water system9 for a new commercial building, the pressures are typically well within Sch 10's capabilities. The stainless steel (e.g., 304L) offers excellent hygiene and longevity against corrosion from treated water. The lighter weight of Sch 10 compared to Sch 40 makes it easier for plumbers to handle and install, especially in complex routes within walls and ceilings, potentially reducing labor time. Furthermore, the material cost savings across an entire building's plumbing can be substantial. One of MFY’s clients, an engineering contractor specializing in green buildings in Southeast Asia, consistently specifies Sch 10S 304L for their domestic water and chilled water lines. They've found it provides the necessary performance and contributes to their goals of material efficiency and reduced installation impact, without compromising safety or service life for these specific low-pressure applications. This is where Sch 10 isn't just an option; it's the smart, economical, and practical solution.

Selecting the ideal pipe schedule is a balancing act, weighing performance requirements against economic realities and installation practicalities. Schedule 10 stainless steel pipe emerges as the superior choice in a well-defined set of circumstances. At MFY, we believe that understanding these specific scenarios empowers our clients to make informed decisions that optimize both functionality and budget.

Applications with Low Operating Pressures

The foremost criterion for selecting Schedule 10 stainless pipe is the system's operating pressure. If your application consistently operates at low pressures – generally considered to be below 150-200 psi10 (approximately 10-14 bar), although this can vary with pipe diameter, temperature, and specific code requirements – then Sch 10S is often perfectly adequate. Examples abound: gravity-fed drainage systems, many water distribution networks (potable, chilled, or utility water), low-pressure chemical dosing lines, vent piping, and conduit systems. In these scenarios, opting for a heavier schedule like Sch 40S would mean paying for pressure-handling capability that isn't needed, leading to unnecessary material costs and increased weight.

MFY recently supplied a project for a large-scale aquaculture farm in Southeast Asia. The extensive network for distributing oxygenated water to the fish tanks operated at very low pressures, often just enough to ensure flow. Sch 10S 316L pipes were chosen for their excellent corrosion resistance in the brackish water environment and their cost-effectiveness for the sheer volume of piping required. The client confirmed that the pressure capacity of Sch 10S was more than sufficient, and the lighter weight significantly eased the installation process across the large farm. It is crucial, however, to always verify pressure ratings against applicable piping codes (e.g., ASME B31.3 for process piping, B31.9 for building services piping) for your specific design conditions.

Over-specifying pipe schedules for low-pressure systems is a common pitfall. While it might seem like a "safer" option, it directly impacts project economics without adding functional value. Careful hydraulic analysis to confirm low-pressure operation can unlock the cost benefits of Sch 10S.

Need for Corrosion Resistance and Hygienic Properties

Stainless steel, in grades like 304/304L or 316/316L, is inherently corrosion-resistant and offers a smooth, non-porous surface that is easy to clean and maintain, making it ideal for applications where hygiene is paramount or where the conveyed fluid/external environment is corrosive. Schedule 10 pipes, being made from these same high-quality stainless steel alloys, inherit these crucial properties.

In the food and beverage industry, pharmaceutical manufacturing, and biotechnology, Sch 10S (particularly 316L for enhanced corrosion resistance and cleanability) is widely used for product lines, CIP (Clean-In-Place) systems11, and utility piping where product integrity and prevention of contamination are critical. Similarly, in architectural applications, the corrosion resistance of Sch 10S 304 ensures longevity and aesthetic appeal for handrails, decorative elements, and facades, even in outdoor or humid environments. A distributor we work with in India regularly supplies MFY’s Sch 10S polished pipes to high-end residential and commercial developers for exactly these architectural uses, where the combination of sleek appearance and durability against urban pollution or coastal air is highly valued.

Even if a system is low pressure, if it handles mildly corrosive chemicals or requires frequent washdowns with sanitizing agents, Sch 10S stainless steel is often a far better long-term choice than carbon steel or plastic piping, justifying its selection even if those alternatives might seem cheaper initially. The lifecycle cost, considering maintenance and replacement, often favors stainless steel.

Projects Where Weight Reduction and Ease of Installation are Valued

The thinner wall of Schedule 10 pipe translates directly to a lower weight per unit length compared to heavier schedules. This can be a significant advantage in several scenarios. Lighter pipes are easier to handle, transport, and install, potentially reducing labor costs and installation time. This is especially beneficial for overhead piping runs, installations in confined spaces, or projects with limited access for heavy lifting equipment.

Furthermore, reduced pipe weight can lead to savings in support structures. Lighter pipes require less robust hangers, brackets, and supports, which can contribute to overall project cost reduction, especially in extensive piping networks. We had an interesting case with an equipment integrator building modular processing skids for export. They switched from Sch 40S to Sch 10S for many of the low-pressure utility connections on their skids. The primary driver was not just the pipe cost but the cumulative weight reduction of the fully assembled skid, which translated to lower shipping costs and easier handling during site installation. This highlights how the benefits of Sch 10S can extend beyond just the pipe material itself.

In retrofitting projects or upgrades to existing facilities, the lighter weight of Sch 10S can also simplify integration with existing structures that may not have been designed to support heavier piping.

| Consideration Factor | Favors Schedule 10S When... | Example MFY Client Scenario | Consequence of Not Choosing Sch 10S (if suitable) |

|---|---|---|---|

| Рабочее давление | Consistently low (e.g., <150-200 psi, verify with codes) | Water treatment plant's distribution lines (India) | Unnecessary cost and weight with Sch 40S/80S |

| Corrosion/Hygiene | High requirement for cleanliness, resistance to fluid/environment | Dairy processing CIP system (Southeast Asia) using 316L Sch 10S | Potential contamination or shorter lifespan with other materials |

| Weight & Installation | Easier handling, reduced support structure, or installation constraints | Architectural handrails on a multi-story building (Middle East) | Increased labor, heavier supports, higher installation costs |

| Material Cost | Budget is a key driver, and performance criteria for low-P are met | Large-scale, low-pressure irrigation system | Overspending on materials that are over-specified |

| Flow Efficiency | Larger bore for given NPS is slightly beneficial for low-P flow | Low-pressure air ducting in a manufacturing facility | Slightly higher friction losses with thicker schedules |

| Structural Integrity | Not a primary load-bearing element; minimal external mechanical stress | Conduit for electrical wiring in a food processing plant (protected environment) | Sch 5S might be too fragile; Sch 40S unnecessary weight/cost |

Schedule 10 is ideal for low-pressure systemsПравда

Schedule 10 stainless pipe is designed for applications with operating pressures typically below 150-200 psi, making it perfect for water distribution and drainage systems.

Schedule 10 is heavier than Schedule 40Ложь

Actually, Schedule 10 has thinner walls and is significantly lighter than Schedule 40, which makes installation easier and reduces structural load.

Заключение

Ultimately, Schedule 10 stainless pipe offers a cost-effective, lightweight, and corrosion-resistant solution ideal for low-pressure applications across diverse industries. Understanding its specifications, performance impacts, and comparing it to other schedules ensures you make the optimal choice for your specific project needs.

-

Understand the standard governing stainless steel pipe dimensions ↩

-

Understand seamless and welded stainless steel pipe specifications ↩

-

Learn how to apply Barlow’s formula in determining pipeline pressure ratings for safe design. ↩

-

Learn about the importance of Sch 10S pipes in food and beverage processing. ↩

-

Understand the advantages of 304L and 316L stainless steels in corrosive environments. ↩

-

Explore the aesthetic and structural applications of Sch 10 in architecture. ↩

-

Understand why Sch 40S is often specified in moderate-pressure systems. ↩

-

Learn about suitability and advantages of Sch 80S in severe service conditions. ↩

-

To understand the advantages of using 304L stainless steel in terms of hygiene and corrosion resistance. ↩

-

To gain insights on pressure limits suitable for Sch 10 use. ↩

-

Learn about CIP systems' importance in ensuring hygienic processes. ↩

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.