Как производятся рулоны нержавеющей стали из сырья?

Having spent years in stainless steel manufacturing, I've seen how raw material selection and processing can make or break product quality, often leading to significant production challenges.

Stainless steel coil manufacturing involves multiple stages, starting from raw material selection through melting, casting, hot rolling, cold rolling, and finishing processes. Each step requires precise control to ensure the final product meets quality standards.

As a manufacturer with over 15 years of experience, I've overseen countless production cycles and witnessed the evolution of manufacturing techniques. Today, I'll share my insights into the intricate process of transforming raw materials into high-quality stainless steel coils, drawing from both successes and challenges I've encountered along the way.

The manufacturing process of stainless steel coils is a fascinating journey of transformation. Through my experience working with various production methods and dealing with different challenges, I've gained deep insights into how each step contributes to the final product quality. Let me share some critical observations and lessons learned from managing large-scale production operations.

What Are the Raw Materials Used in Stainless Steel Coil Production?

After overseeing countless material selections, I've learned that the quality of raw materials directly impacts the final product's performance.

The primary raw materials for stainless steel coil production include iron ore, chromium, nickel, molybdenum, and recycled stainless steel1. The precise combination of these materials determines the grade and quality of the final product.

Primary Raw Material Components

| Material Type | Required Purity | Typical Usage | Влияние на качество |

|---|---|---|---|

| Iron Ore | 98%+ | 60-70% | Base Material Properties |

| Хром | 99%+ | 16-18% | Устойчивость к коррозии |

| Никель | 99.9%+ | 8-10% | Ductility & Formability |

| Recycled Steel | Grade-specific | 20-30% | Cost Efficiency |

Key considerations from our material processing experience:

- Iron ore quality affects final strength properties

- Chromium purity influences corrosion resistance

- Nickel grade impacts formability characteristics

- Recycled material quality affects overall performance

Material Quality Standards and Testing

Quality control protocols we've implemented:

-

Incoming Material Testing:

- Chemical composition analysis

- Physical property verification

- Contamination checking

- Size distribution analysis

-

Certification Requirements:

- Material origin documentation

- Purity certificates

- Processing history

- Quality assurance reports

Supply Chain and Inventory Management

Based on our procurement experience:

| Аспект | Strategy | Benefits | Challenges |

|---|---|---|---|

| Sourcing | Multi-supplier | Supply Security | Cost Variation |

| Storage | Just-in-time | Reduced Inventory | Timing Critical |

| Контроль качества | Pre-delivery Testing | Consistent Quality | Time Investment |

What Are the Steps Involved in Manufacturing Stainless Steel Coils?

Through years of production oversight, I've developed a deep understanding of each manufacturing step's critical nature.

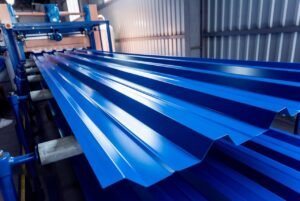

The manufacturing process involves six main steps: melting, refining, continuous casting, hot rolling, cold rolling, and finishing2. Each step requires precise control of temperature, pressure, and processing parameters.

Primary Processing Steps

-

Melting Process:

- Electric Arc Furnace (EAF) operation at 1500-1600°C

- Precise temperature control systems

- Automated charging systems

- Real-time composition monitoring

-

Refining Operations:

- AOD converter process

- Vacuum degassing

- Composition adjustment

- Temperature maintenance

-

Continuous Casting:

- Mold design optimization

- Cooling rate control

- Surface quality monitoring

- Dimensional accuracy

Secondary Processing Operations

-

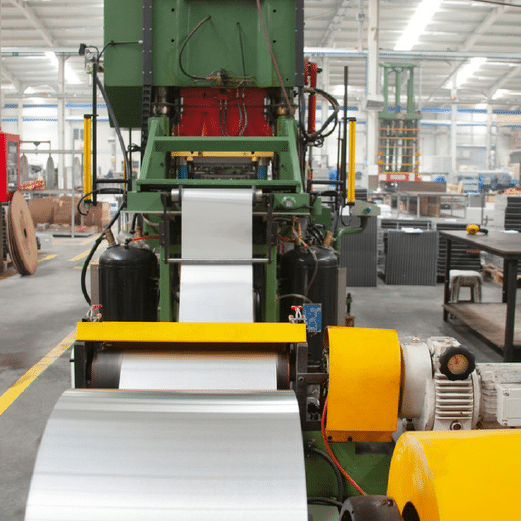

Hot Rolling:

- Temperature profile management

- Reduction ratio control

- Surface quality monitoring

- Thickness uniformity control

-

Cold Rolling:

- Work hardening control

- Surface finish management

- Dimensional accuracy

- Flatness control

Quality Assurance Procedures

| Stage | Параметры управления | Testing Methods | Критерии приемлемости |

|---|---|---|---|

| Melting | Temperature, Chemistry | Spectrometry | Grade Specifications |

| Прокат | Thickness, Surface | Ultrasonic, Visual | Customer Requirements |

| Отделка | Surface, Properties | Mechanical Testing | Industry Standards |

How Does the Composition of Raw Materials Affect the Quality of Stainless Steel Coils?

Through extensive testing and analysis, I've observed the critical relationship between material composition and final product performance.

Raw material composition directly influences critical properties such as corrosion resistance, mechanical strength, and formability3. The precise balance of elements like chromium, nickel, and molybdenum determines the grade specifications and application suitability.

Влияние химического состава

| Элемент | Оптимальный диапазон | Основная функция | Quality Effect |

|---|---|---|---|

| Хром | 16-30% | Corrosion Protection | +45% Resistance |

| Никель | 8-20% | Austenite Stability | +35% Ductility |

| Молибден | 2-4% | Устойчивость к питтингу | +50% Protection |

| Углерод | 0.03-0.08% | Повышение прочности | +40% Hardness |

Our laboratory analysis shows:

- Chromium content directly affects passive layer formation

- Nickel levels influence phase stability

- Molybdenum content determines pitting resistance

- Carbon control is crucial for weldability

Mechanical Property Correlation

Based on our testing facility data:

-

Strength Properties:

- Tensile strength: 515-720 MPa

- Yield strength: 205-410 MPa

- Elongation: 40-60%

-

Performance Metrics:

Impact of Composition on Properties:

Hardness: ±5% per 0.1% carbon

Ductility: ±8% per 1% nickel

Corrosion resistance: ±12% per 1% chromium

Processing Behavior Effects

| Composition | Processing Impact | Quality Outcome | Cost Implication |

|---|---|---|---|

| High Carbon | Difficult Rolling | Lower Ductility | +15% Processing |

| High Nickel | Better Formability | Improved Finish | +25% Material |

| High Chrome | Enhanced Properties | Better Resistance | +20% Overall |

What Are the Key Processes in Stainless Steel Coil Production?

Managing our production facilities has taught me the importance of precise process control in achieving consistent quality.

Key processes include melting, casting, hot rolling, cold rolling, annealing, and finishing4. Each process requires precise control of multiple parameters to achieve desired material properties and surface characteristics.

Thermal Processing Control

-

Temperature Management:

- Melting: 1500-1600°C

- Hot rolling: 1200-1250°C

- Annealing: 1050-1150°C

-

Critical Parameters:

Process Control Points:

Heating rate: ±5°C/min

Holding time: ±2 minutes

Cooling rate: ±3°C/min

- Quality Impact:

- Grain size control

- Property uniformity

- Surface quality

Mechanical Processing Parameters

| Процесс | Основные параметры | Control Methods | Quality Indicators |

|---|---|---|---|

| Горячая прокатка | Reduction ratio | Automated control | Однородность толщины |

| Холодная прокатка | Отделка поверхности | Digital monitoring | Surface quality |

| Выравнивание натяжения | Плоскость | Лазерное измерение | Shape control |

Surface Treatment Technologies

-

Finishing Methods:

- Mechanical polishing

- Chemical treatment

- Электрополировка

-

Surface Quality Standards:

- Roughness measurements

- Reflectivity testing

- Defect inspection

How to Ensure Quality Control During the Manufacturing of Stainless Steel Coils?

Based on years of quality management experience, I've developed comprehensive control systems.

Quality control requires continuous monitoring throughout the manufacturing process, including material testing, process parameter verification, and final product inspection, supported by advanced testing equipment and skilled personnel.

Testing and Inspection Protocols

-

In-Process Testing:

- Chemical analysis

- Mechanical properties

- Dimensional accuracy

- Surface quality

-

Final Inspection:

- Visual examination

- Ultrasonic testing

- Mechanical testing

- Corrosion testing

| Тип испытания | Частота | Метод | Критерии приемлемости |

|---|---|---|---|

| Chemical | Every Heat | Spectrometry | Grade specs ±0.5% |

| Mechanical | Per Coil | Испытание на растяжение | Standard +5% |

| Surface | 100% | Visual/NDT | Zero critical defects |

Документация и сертификация

-

Quality Documentation:

- Material certificates

- Process records

- Test reports

- Traceability data

-

Certification Requirements:

- ISO 9001:2015

- Industry standards

- Customer specifications

- Environmental compliance

Quality Improvement Systems

-

Statistical Process Control:

- Real-time monitoring

- Анализ тенденций

- Corrective actions

- Preventive measures

-

Continuous Improvement:

- Employee training

- Process optimization

- Equipment upgrades

- System updates

Заключение

The successful manufacture of stainless steel coils depends on precise control of raw materials, processing parameters, and quality systems. Through careful attention to each step and continuous monitoring, we ensure consistent high-quality products that meet or exceed industry standards.

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.