Нержавеющая труба Schedule 10: Характеристики и применение

Are you finding the world of pipe specifications, particularly Schedule 10 stainless steel, a bit overwhelming? Choosing the wrong pipe can lead to costly project failures or inefficiencies. This guide will demystify Schedule 10 pipes, empowering you to make informed decisions for your applications.

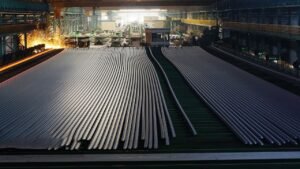

Schedule 10 stainless steel pipe refers to a specific pipe wall thickness designation, indicating a relatively thin wall compared to higher schedule numbers. It's designed for low-pressure applications where its lighter weight and larger internal diameter offer advantages in flow and cost-effectiveness.

I know that navigating the technicalities of stainless steel piping can be challenging. As Global Business Director at MFY, a company deeply rooted in the stainless steel industry, I've seen firsthand how crucial the right pipe selection is. This article aims to break down everything you need to know about Schedule 10 stainless pipes, making your next project smoother and more successful.

Understanding pipe schedules is more than just an academic exercise; it's fundamental to engineering integrity, operational efficiency, and cost management. At MFY, we often encounter clients, from manufacturing companies to engineering contractors, who are looking for clarity on which pipe schedule best suits their needs. Schedule 10, with its unique characteristics, often comes up in these discussions. It's not a one-size-fits-all solution, and its suitability hinges on a nuanced understanding of its capabilities versus the demands of the application. The choice involves balancing factors like pressure requirements, corrosion resistance, installation ease, and overall project budget. A misstep here can lead to premature system failure, safety hazards, or unnecessary expenditure on over-specified materials. My goal here is to share insights gleaned from years in the industry, helping you see beyond the numbers and appreciate the practical implications of selecting Schedule 10.

What are the specifications of Schedule 10 stainless pipes?

Feeling lost in a sea of technical jargon when trying to understand pipe specifications? This confusion can lead to incorrect material choices, potentially derailing your project timelines and budgets. Let's clearly define the key specifications of Schedule 10 stainless pipes for you.

Schedule 10 stainless pipes are primarily defined by their nominal pipe size (NPS), a specific wall thickness dictated by the "Schedule 10" designation, and the material grade (e.g., 304L, 316L). These specifications are governed by standards like ASTM A312.

Understanding these specifications is the first step towards leveraging Schedule 10 pipes effectively. The nominal pipe size, or NPS, is a North American standard for designating pipe diameters. It's important to note that for NPS ⅛ to 12 inches, the NPS and the outside diameter (OD) are different. Above 12 inches, the NPS and OD are the same. For Schedule 10, the "10" signifies a particular wall thickness relative to the NPS. This wall thickness is thinner than, say, Schedule 40 or Schedule 80 pipes of the same NPS. This directly impacts the pipe's internal diameter, pressure rating, weight, and ultimately, its cost. At MFY, we often emphasize to our clients, especially those in manufacturing and engineering, that these subtle differences in specification can have significant implications for system design and performance. For instance, a client involved in a food processing plant upgrade in Southeast Asia needed a piping solution that offered good flow characteristics for low-pressure lines while maintaining hygiene. Schedule 10 in 316L stainless steel was an ideal candidate due to its thinner wall (allowing for a larger internal bore) and excellent corrosion resistance. The material grade, such as 304/304L or 316/316L, is another critical specification, determining the pipe's corrosion resistance, temperature limits, and mechanical properties. ASTM A312 is a common standard covering seamless, straight-seam welded, and heavily cold-worked welded austenitic stainless steel pipe intended for high-temperature and general corrosive service – precisely where many Schedule 10 applications lie.

The specifications of Schedule 10 stainless pipes are not arbitrary numbers; they are carefully defined parameters that dictate the pipe's suitability for various applications. A deep dive into these specifications reveals how each element contributes to the overall functionality and reliability of the piping system. At MFY, we deal with these specifications daily, ensuring our clients receive products like stainless steel coils, sheets, and pipes that precisely meet their project requirements, whether they are in India, the Middle East, or Russia.

Understanding Nominal Pipe Size (NPS) and Outer Diameter (OD)

The Nominal Pipe Size (NPS) is a dimensional standard for pipes used in high or low pressure and temperature applications. It's crucial to understand that NPS refers to the pipe's nominal, not exact, internal diameter, especially for sizes NPS ⅛ to NPS 12. For example, an NPS 2 pipe does not have an actual 2-inch outer or inner diameter. The actual Outer Diameter (OD) for an NPS 2 pipe is standardized at 2.375 inches (60.3 mm) across all schedules. What changes with different schedules for the same NPS is the wall thickness, and consequently, the inner diameter (ID). This distinction is vital for engineers and designers when calculating flow rates, pressure drops, and compatibility with fittings.

For Schedule 10 pipes, the OD remains constant for a given NPS, consistent with other schedules. However, its thinner wall means the ID will be larger compared to a Schedule 40 or Schedule 80 pipe of the same NPS. This larger bore can be advantageous for applications where maximizing flow capacity with minimal pressure drop is important, provided the pressure ratings are not exceeded. For instance, in a recent project with an equipment integrator, we supplied Schedule 10 304L pipes for a low-pressure fluid transfer system. The choice was driven by the need for good flow characteristics and the cost savings associated with a lighter pipe, as the system's operating pressures were well within Schedule 10's limits.

Understanding this relationship between NPS, OD, and schedule number is fundamental. When we, at MFY, consult with distributors or manufacturing companies, we often use charts and technical data sheets to illustrate these differences. For instance, an NPS 4 Schedule 10 pipe has an OD of 4.500 inches (114.3 mm) and a wall thickness of 0.120 inches (3.05 mm), resulting in an approximate ID of 4.260 inches. An NPS 4 Schedule 40 pipe, with the same OD, has a thicker wall of 0.237 inches (6.02 mm), leading to a smaller ID of approximately 4.026 inches. This difference significantly impacts flow volume.

The Significance of Wall Thickness in Schedule 10

The wall thickness is the defining characteristic that differentiates pipe schedules. For Schedule 10, this thickness is relatively small, making it a "light-wall" pipe. According to ASME B36.19M, which covers stainless steel pipes, the wall thicknesses for Schedule 10S (the 'S' often denotes stainless steel, though Schedule 10 is also used) are clearly specified for each NPS. For example, an NPS 1 Schedule 10S pipe has a wall thickness of 0.109 inches (2.77 mm), while an NPS 6 Schedule 10S pipe has a wall thickness of 0.134 inches (3.40 mm). These dimensions directly influence the pipe's pressure rating, weight, and cost.

The primary implication of a thinner wall is a lower pressure-retaining capability compared to higher schedules like Schedule 40 or 80. Therefore, Schedule 10 pipes are typically used in low-pressure applications, such as gravity flow systems, drainage, vent lines, and low-pressure fluid or gas transport. The reduced material usage also translates to a lighter pipe, which offers several advantages: easier handling and installation (potentially reducing labor costs), lower shipping costs, and less structural support required for overhead piping runs. I recall a project with a construction contractor in Southeast Asia where the ease of installing lighter Schedule 10 316L pipes for a large-scale water feature was a significant factor in meeting tight deadlines.

However, the thinner wall also means Schedule 10 pipes are more susceptible to mechanical damage if not handled or installed correctly. They also offer less structural rigidity compared to heavier-walled pipes. Therefore, system designers must carefully consider the operating pressures, potential for external loads or impacts, and the overall system environment before specifying Schedule 10. At MFY, our integrated supply chain allows us to provide various schedules, ensuring clients get the optimal balance of performance and cost.

Material Grades and Standards (e.g., ASTM A312 for 304/316L)

While the schedule number defines the wall thickness, the material grade determines the pipe's chemical composition and, consequently, its mechanical properties and corrosion resistance. For stainless steel Schedule 10 pipes, common grades include austenitic stainless steels like Type 304/304L and Type 316/316L. Type 304 is a versatile, general-purpose stainless steel with good corrosion resistance in many environments. Type 304L, its low-carbon variant, is preferred for welded applications to prevent carbide precipitation and subsequent intergranular corrosion. Type 316 contains molybdenum, which significantly enhances its corrosion resistance, particularly against chlorides and other industrial solvents, making it suitable for more aggressive environments like marine applications or chemical processing. Type 316L is its low-carbon version for welding.

These material grades for Schedule 10 pipes are typically manufactured according to standards such as ASTM A312 / A312M, "Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes." This standard covers pipes intended for high-temperature and general corrosive service. Adherence to such standards ensures consistent quality, dimensional tolerances, and material properties. For example, ASTM A312 specifies requirements for chemical composition, tensile properties (like tensile strength and yield strength), and testing procedures (e.g., hydrostatic or non-destructive electric tests).

At MFY, we emphasize the importance of selecting the correct grade in conjunction with the schedule. A manufacturing client in India required Schedule 10 pipes for a food processing line. While Schedule 10 was suitable for the low-pressure transfer, the choice between 304L and 316L depended on the specific food products being handled and the cleaning agents used. We guided them towards 316L due to slightly more acidic products and chloride-based sanitizers, ensuring longevity and compliance with food safety standards. Our ability to supply a range of grades, backed by our strong production capacity, means we can cater to these specific needs.

| Параметр | NPS 2" Sch 10S (304L) | NPS 4" Sch 10S (316L) | NPS 6" Sch 10S (304L) |

|---|---|---|---|

| OD (inch / mm) | 2.375 / 60.3 | 4.500 / 114.3 | 6.625 / 168.3 |

| Wall (inch / mm) | 0.109 / 2.77 | 0.120 / 3.05 | 0.134 / 3.40 |

| Approx. ID (in/mm) | 2.157 / 54.78 | 4.260 / 108.2 | 6.357 / 161.47 |

| Approx. Wt (lb/ft) | 2.64 | 5.53 | 9.17 |

| Material Standard | ASTM A312 | ASTM A312 | ASTM A312 |

Note: Weights are approximate and can vary.

Schedule 10 has thinner walls than Schedule 40Правда

Schedule 10 pipes have a thinner wall thickness compared to Schedule 40 pipes of the same nominal size, resulting in a larger internal diameter.

NPS equals exact outer diameterЛожь

Nominal Pipe Size (NPS) doesn't equal the exact outer diameter, especially for sizes NPS ⅛ to NPS 12, where the OD is standardized differently.

How do the properties of Schedule 10 stainless pipes affect their performance?

Are you concerned that selecting Schedule 10 pipes might compromise your system's performance or longevity? Misunderstanding how its properties translate to real-world performance can lead to unexpected issues. Let's explore the key performance characteristics influenced by Schedule 10's unique properties.

The thinner wall of Schedule 10 stainless pipes results in lower pressure ratings and reduced mechanical strength compared to higher schedules. However, it offers better flow capacity, lighter weight for easier installation, and retains the excellent corrosion resistance of stainless steel.

The inherent properties of Schedule 10 stainless steel pipes—stemming largely from their relatively thin walls and the intrinsic qualities of stainless steel—play a pivotal role in dictating their performance envelope. When I discuss options with MFY clients, from rapidly growing manufacturing firms to established engineering contractors, the conversation often centers on matching these properties to specific application demands. The most apparent characteristic is the lower pressure handling capability. This isn't a flaw, but a design feature making it suitable and cost-effective for systems where high pressures are not a concern. Think of gravity-fed systems, low-pressure chemical dosing lines, or certain types of exhaust and ventilation ducting. The lighter weight, a direct consequence of the thinner wall, is another significant property. This translates into easier manual handling, faster installation, reduced need for heavy lifting equipment, and potentially lower structural support requirements for the piping runs. For a recent project supplying a distributor in Southeast Asia who serves many small to medium-sized installation contractors, the ease of handling Schedule 10 pipes was a key selling point for their customers working on architectural and light industrial applications. Furthermore, the stainless steel itself, whether 304L or 316L, brings its renowned corrosion resistance, crucial for longevity and maintaining product purity in industries like food and beverage or pharmaceuticals.

The interplay between these properties – wall thickness, material composition, and resulting mechanical characteristics – defines the sweet spot for Schedule 10 stainless pipe applications. It's not just about what the pipe этоНо что это делает under specific operational stresses. At MFY, our extensive experience across diverse markets like India, the Middle East, and Russia has shown us that a thorough understanding of these performance nuances is critical for our clients to gain a competitive edge.

Corrosion Resistance: The Stainless Steel Advantage in Sch 10

One of the primary reasons for choosing stainless steel, regardless of schedule, is its excellent corrosion resistance. Schedule 10 pipes1, typically made from austenitic stainless steels like 304L or 316L, fully inherit this crucial property. The chromium content in stainless steel (minimum 10.5%) forms a passive, self-repairing chromium oxide layer on the surface, protecting the underlying metal from corrosive attack. This makes Schedule 10 stainless pipes highly suitable for conveying a wide variety of fluids and gases that would quickly degrade carbon steel or other materials. For instance, in the food and beverage industry, where MFY has supplied numerous clients, Schedule 10 304L or 316L pipes are standard for product lines, cleaning-in-place (CIP) systems, and utility lines due to their resistance to food acids, cleaning chemicals, and their hygienic, non-contaminating surface.

The choice between grades like 304L and 316L within Schedule 10 further refines this corrosion resistance. While 304L offers good general corrosion resistance, 316L, with its molybdenum addition, provides superior resistance to pitting and crevice corrosion, especially in chloride-rich environments or when handling more aggressive chemicals. I recall advising an engineering contractor working on a coastal water treatment facility in the Middle East. While the pressures were low, making Schedule 10 viable, the saline atmosphere and treated water necessitated the use of 316L Schedule 10 pipes to ensure long-term performance and avoid premature failure due to chloride-induced corrosion. The thinner wall of Schedule 10 does not inherently reduce its corrosion resistance rate compared to a thicker wall of the same material grade, assuming the corrosive environment doesn't involve significant erosive wear that could mechanically thin the pipe wall over time.

It's important to note, however, that even stainless steel is not immune to all forms of corrosion under all conditions. Factors like chemical concentration, temperature, pH, presence of specific ions (e.g., chlorides), and flow velocity can all influence corrosion rates. Therefore, proper material selection, considering the specific service environment, remains paramount even when using robust materials like stainless steel. At MFY, our technical team often assists clients in this selection process, leveraging our deep understanding of material science and application requirements.

Pressure Handling Capabilities and Limitations

The most significant performance aspect directly affected by the Schedule 10 designation is its pressure handling capability. Due to its thinner wall compared to higher schedules like Schedule 40 or Schedule 80 for the same Nominal Pipe Size (NPS), Schedule 10 pipes have a lower allowable internal working pressure. This pressure rating is calculated based on Barlow's formula or similar equations found in piping codes like ASME B31.3 (Process Piping) or ASME B31.1 (Power Piping), which consider the material's allowable stress at a given temperature, the pipe's outer diameter, and its wall thickness. For example, an NPS 2, 304L Schedule 10S stainless steel pipe at ambient temperature might have an allowable pressure of around 538 psi according to ASME B31.3 calculations, whereas an NPS 2, 304L Schedule 40S pipe could handle approximately 1025 psi.

This lower pressure rating makes Schedule 10 pipes unsuitable for high-pressure systems. However, they are perfectly adequate and often more economical for a wide range of low-pressure applications. These include gravity flow systems, drainage and vent lines, low-pressure water lines, chilled water systems, condensate lines, and various process lines where operating pressures are well below a few hundred psi. For example, many of MFY's manufacturing clients use Schedule 10 304L pipes for internal utility air or water distribution where pressures are typically around 100-150 psi. The key is to accurately determine the maximum operating pressure (including any potential surges) of the system and ensure it remains comfortably below the allowable pressure rating of the selected Schedule 10 pipe, with an appropriate safety factor.

It's also crucial to consider the effect of temperature on the allowable stress of the stainless steel. As temperature increases, the allowable stress of the material decreases, which in turn reduces the pipe's pressure rating. Piping codes provide tables for allowable stress values at different temperatures for various materials. Therefore, when evaluating Schedule 10 for an application, both the maximum operating pressure and temperature must be considered. Our team at MFY always advises clients to consult the relevant piping codes and perform necessary calculations or consult with qualified engineers to ensure system safety and integrity.

Impact of Weight and Malleability on Installation and System Design

The thinner wall of Schedule 10 pipes translates directly to a lower weight per unit length compared to heavier schedule pipes of the same NPS and material. For instance, an NPS 4 Schedule 10S stainless steel pipe weighs approximately 5.53 lb/ft (8.23 kg/m), while an NPS 4 Schedule 40S pipe weighs about 10.79 lb/ft (16.07 kg/m). This nearly 50% weight reduction has several positive implications for installation and system design. Lighter pipes are easier to handle manually, reducing worker fatigue and potentially speeding up the installation process. They may also require less heavy lifting equipment, which can be a significant advantage on congested sites or for smaller projects. I've seen this benefit firsthand with contractors we supply in rapidly developing urban areas in Southeast Asia, where site access and crane availability can be challenging.

The reduced weight also means that Schedule 10 piping systems generally require less substantial structural support. Hanger spacing can sometimes be wider (though always check code requirements), and the load on supporting structures, buildings, or equipment skids is reduced. This can lead to cost savings in both support materials and installation labor. Furthermore, stainless steel, particularly austenitic grades like 304 and 316, is inherently quite ductile and malleable. While Schedule 10's thinner wall doesn't drastically alter this inherent malleability compared to Schedule 40 of the same material, it does mean that bending the pipe (where permissible and done correctly with appropriate tooling) might require less force. This can be advantageous in creating custom routing and reducing the number of fittings in some installations.

However, the lighter weight and thinner wall also mean Schedule 10 pipes are more susceptible to mechanical damage from impact or improper handling. Care must be taken during transportation, storage, and installation to avoid dents, gouges, or deformation, which could compromise the pipe's integrity. The system design must also account for potential vibrations or external loads to ensure the thinner-walled pipe is not overstressed. At MFY, we ensure our stainless steel pipes, including Schedule 10, are packaged and handled carefully to maintain their quality up to delivery, and we always advise clients on best practices for site handling.

| Недвижимость | Schedule 10 (e.g., NPS 3, 304L) | Schedule 40 (e.g., NPS 3, 304L) | Implication for Sch 10 Performance |

|---|---|---|---|

| Толщина стенок | Thinner (e.g., 0.120 in) | Thicker (e.g., 0.216 in) | Lower pressure rating, lighter weight |

| Approx. Pressure Rating (ambient) | Lower (e.g., ~500 psi) | Higher (e.g., ~900 psi) | Suitable for low-pressure systems |

| Weight per foot | Lighter (e.g., ~3.9 lb/ft) | Heavier (e.g., ~7.6 lb/ft) | Easier installation, less support needed |

| Внутренний диаметр | Larger | Smaller | Potentially better flow for same NPS |

| Устойчивость к коррозии | Excellent (material dependent) | Excellent (material dependent) | Maintained despite thinner wall |

| Cost (Material) | Нижний | Выше | More economical for suitable apps |

Note: Specific values are illustrative and vary with exact NPS, material, and temperature.

Schedule 10 has lower pressure ratingПравда

The thinner wall of Schedule 10 pipes results in lower pressure handling capability compared to higher schedules like Schedule 40.

Schedule 10 is heavier than Schedule 40Ложь

Schedule 10 pipes are actually lighter than Schedule 40 pipes of the same size due to their thinner walls.

What industries commonly use Schedule 10 stainless pipes and why?

Are you wondering if Schedule 10 stainless steel pipe is a common or suitable choice for your specific industry? Using an ill-suited pipe material can lead to operational inefficiencies or premature failures. Let's delve into the industries that frequently rely on Schedule 10 and the reasons behind their choice.

Industries such as food and beverage, pharmaceuticals, chemical processing (for low-pressure lines), water treatment, and architectural applications commonly use Schedule 10 stainless pipes. They choose it for its optimal balance of corrosion resistance, adequate strength for low pressures, and cost-effectiveness.

The adoption of Schedule 10 stainless steel pipes across various industries is driven by a pragmatic assessment of its benefits versus the operational demands. At MFY, we've seen a consistent demand for these pipes from sectors where the high-pressure capabilities of thicker-walled pipes are simply unnecessary, making Schedule 10 a more economical and efficient choice. The food and beverage industry, for example, is a prime user. They require materials that are hygienic, non-reactive with food products, and resistant to corrosive cleaning agents. Schedule 10, often in 304L or 316L grades2, meets these needs perfectly for many low-pressure transfer lines, CIP systems, and utility piping. Similarly, the pharmaceutical industry, with its stringent purity and cleanliness standards, utilizes Schedule 10 stainless steel for similar reasons, particularly where product integrity and system cleanability are paramount. I recall working with an equipment integrator building modular processing skids for a pharmaceutical client; Schedule 10 316L was specified for its smooth internal finish and resistance to sterilization processes, while its lighter weight also contributed to the portability of the skids. These are just a couple of examples highlighting how the specific attributes of Schedule 10 align with industry-specific requirements.

The decision to use Schedule 10 is rarely arbitrary; it's a calculated choice based on a combination of performance needs, regulatory compliance, and economic considerations. As a supplier with a broad reach into markets like India, Southeast Asia, and the Middle East, MFY has observed distinct patterns of use that underscore the versatility of these pipes when applied correctly.

Food & Beverage and Pharmaceutical: Hygiene and Flow

The food & beverage and pharmaceutical industries are significant consumers of Schedule 10 stainless steel pipes, primarily due to the material's hygienic properties and the suitability of Schedule 10 for low-pressure fluid handling. In these sectors, preventing contamination and ensuring product purity are non-negotiable. Austenitic stainless steels like 304L and 316L, commonly used for Schedule 10 pipes, offer a smooth, non-porous surface that is easy to clean and sanitize, minimizing bacterial harborage. This is critical for compliance with regulations like those from the FDA or GMP (Good Manufacturing Practices). I've personally worked with numerous beverage manufacturers in Southeast Asia through MFY, where Schedule 10 304L pipes are extensively used for transporting water, syrups, and finished beverages, where pressures are typically low.

The larger internal diameter of Schedule 10 pipes (for a given NPS compared to Schedule 40) can also be beneficial for optimizing flow rates and reducing pumping energy in low-pressure systems. This is particularly relevant for viscous fluids or where gentle handling of the product is required to maintain its quality. For instance, in dairies, Schedule 10 316L pipes are often preferred for milk and cream lines because 316L offers slightly better resistance to chloride-containing cleaning solutions, and the flow characteristics are favorable. The cost-effectiveness of Schedule 10 compared to heavier schedules, when high pressure is not a factor, also makes it an attractive option for these often large-scale processing facilities.

Furthermore, the weldability of 304L and 316L grades allows for smooth, crevice-free joints when properly executed, which is essential for maintaining hygiene. At MFY, we ensure our stainless steel pipes meet the stringent surface finish requirements often demanded by these industries. A typical scenario involves a food processing plant expansion where new product lines are being installed. The engineering contractor will specify Schedule 10 316L for product contact surfaces and potentially Schedule 10 304L for some utility lines, balancing performance with budget. Our role is to provide high-quality pipes that meet these exact specifications, ensuring rapid export delivery to keep their project on track.

Architectural and Decorative Applications: Aesthetics and Formability

Beyond industrial processing, Schedule 10 stainless steel pipes find a niche in architectural and decorative applications. Here, the aesthetic appeal of stainless steel – its clean, modern look and resistance to tarnishing – is a primary driver. Schedule 10 pipes, being lighter and often more cost-effective than thicker alternatives, are frequently used for handrails, balustrades, support structures for canopies, decorative framing, and even furniture. The relatively thinner wall can sometimes make them easier to bend and shape into custom designs, although this must be done with appropriate tooling to avoid kinking or excessive ovality. I remember a project MFY supplied for a commercial building in the Middle East, where polished Schedule 10 304 pipes were used extensively for interior railings and design features, contributing to a sleek and contemporary aesthetic.

In these applications, the pressure-retaining capability is usually not a concern. Instead, factors like surface finish (e.g., brushed, polished), visual consistency, and the ability to be fabricated into desired forms take precedence. Schedule 10 provides sufficient structural integrity for many such non-load-bearing or lightly loaded decorative elements. For exterior applications, 316 grade might be chosen for its superior corrosion resistance, especially in coastal or polluted urban environments, to maintain the aesthetic appeal over time.

The cost savings associated with Schedule 10, due to less material usage, can be significant when large quantities are required for architectural projects. This allows designers to incorporate the desirable look and durability of stainless steel without an excessive budget impact. MFY has worked with distributors who cater specifically to architectural metal fabricators, providing them with Schedule 10 pipes that meet their quality and finish requirements. The key here is the combination of visual appeal, adequate strength for the application, and relative ease of fabrication.

Water Treatment and Low-Pressure Chemical Lines: Balancing Cost and Performance

In water treatment plants and for various low-pressure chemical lines, Schedule 10 stainless steel pipes offer a compelling balance of performance and cost. Water treatment processes often involve various chemicals and water qualities that can be corrosive to carbon steel. Stainless steel, particularly 316L for more aggressive water or chemical compositions (e.g., reverse osmosis permeate, brine, or certain dosing chemicals), provides the necessary corrosion resistance for long service life. Schedule 10 is often sufficient for the pressures encountered in many parts of a water treatment facility, such as interconnecting piping between tanks, filter banks, or for distributing treated water. For example, MFY has supplied Schedule 10 316L pipes to engineering contractors building desalination pre-treatment facilities in India, where resistance to saline water at low pressures is critical.

Similarly, in general industrial plants, many utility lines or low-concentration chemical transfer lines operate at pressures well within the capabilities of Schedule 10. Using a heavier schedule pipe in these situations would represent over-specification and unnecessary cost. Industries like pulp and paper, textiles, and light manufacturing often have numerous such applications where Schedule 10 304L or 316L pipes are a practical choice. The decision often comes down to a careful evaluation of the fluid's corrosivity, operating temperature and pressure, and the overall life-cycle cost.

The rapid export delivery that MFY offers is particularly beneficial for these projects, which often have tight construction schedules. By providing a reliable supply of quality-assured Schedule 10 pipes, we help these industries optimize their capital expenditure without compromising on the necessary performance for their low-pressure systems. The key is understanding that "low pressure" doesn't mean low importance; reliability and corrosion resistance are still paramount, and Schedule 10 stainless steel delivers this effectively in the right context.

| Industry Sector | Primary Reasons for Using Schedule 10 Stainless Pipe | Общие оценки | Typical MFY Client Example |

|---|---|---|---|

| Продукты питания и напитки | Hygiene, corrosion resistance, flow, cost-effectiveness | 304L, 316L | Beverage producer in Southeast Asia needing piping for new syrup lines. |

| Фармацевтика | Purity, cleanability, corrosion resistance, light weight | 316L, 304L | Equipment integrator building modular skids for a pharma company. |

| Architectural/Decorative | Aesthetic appeal, formability, cost, corrosion resistance | 304, 316 | Contractor for commercial building interiors in the Middle East (railings). |

| Water Treatment | Corrosion resistance (various water qualities), cost | 316L, 304L | Engineering contractor for desalination plant in India. |

| Low-Pressure Chemical | Corrosion resistance, cost-effectiveness for utilities | 304L, 316L | Manufacturing company for internal low-pressure chemical dosing lines. |

Schedule 10 is cost-effective for low-pressureПравда

Schedule 10 stainless pipes provide adequate strength for low-pressure applications while being more economical than thicker-walled alternatives.

Schedule 10 is used in high-pressure systemsЛожь

Schedule 10 is specifically designed for low-pressure applications; high-pressure systems require thicker-walled pipes like Schedule 40 or 80.

How does Schedule 10 compare to other pipe schedules in terms of efficiency and application?

Feeling uncertain about whether Schedule 103 is truly the most efficient choice compared to other available pipe schedules like Schedule 40 or even thinner-walled tubing? Making a suboptimal choice can lead to overspending or, conversely, inadequate performance. Let's compare Schedule 10 to put its efficiency and applications into perspective.

Schedule 10 pipes are more cost-efficient and offer better flow characteristics for low-pressure applications compared to heavier schedules like 40 or 80. However, higher schedules provide superior mechanical strength and pressure ratings essential for more demanding conditions.

When I sit down with clients at MFY4, ranging from large manufacturing enterprises to specialized engineering contractors, a frequent point of discussion is the comparative advantages of different pipe schedules. Schedule 10 is often in the spotlight for applications where high pressure isn't the primary concern. Its main efficiency comes from material savings: less steel means lower initial cost and lighter weight. This weight reduction translates into logistical efficiencies—easier transport, handling, and installation, potentially reducing labor costs and the need for heavy-duty support structures. For instance, a distributor we work with in India specifically requests Schedule 10 for their clients in light fabrication and food processing, citing these cost and handling benefits as key differentiators. Furthermore, for a given Nominal Pipe Size (NPS), Schedule 10 has a larger internal diameter than Schedule 40 or 80. This means lower flow resistance and potentially reduced pumping energy for fluid transfer systems, an operational efficiency that can add up over time. However, this efficiency is bounded by its pressure limitations. It's crucial not to see Schedule 10 as universally "more efficient" but rather as "more efficient for the справа application."

The comparison isn't just about Schedule 10 versus heavier pipes; it's also about understanding its place relative to even thinner-walled options like stainless steel tubing. Each has its domain where it performs optimally. At MFY, with our integrated supply chain and diverse product offerings including stainless steel coils, sheets, and pipes, we aim to equip our clients with the knowledge to make these nuanced distinctions, ensuring they achieve the best balance of performance, cost, and long-term reliability for their projects across global markets.

Schedule 10 vs. Schedule 40: The Most Common Comparison

The comparison between Schedule 10 (often Sch 10S for stainless) and Schedule 40 (Sch 40S) is perhaps the most frequent one encountered in piping system design, especially for stainless steel. For any given Nominal Pipe Size (NPS), a Schedule 40S pipe will have a significantly thicker wall than a Schedule 10S pipe. For example, for an NPS 2 pipe, Sch 10S has a wall thickness of 0.109 inches (2.77mm), while Sch 40S has a wall of 0.154 inches (3.91mm). This difference might seem small, but it has major implications. The primary advantage of Sch 40S is its higher pressure rating and greater mechanical strength. This makes it suitable for a broader range of applications, including moderate to high-pressure services and situations where greater structural integrity or resistance to external loads is required.

However, this increased strength comes at a cost: Sch 40S pipes use more material, making them heavier and more expensive than Sch 10S pipes of the same NPS and material grade. The increased weight also translates to higher installation costs (more robust supports, potentially more labor-intensive handling). From an efficiency standpoint, if the application operates at low pressures where Sch 10S is perfectly adequate, choosing Sch 40S would be an over-specification, leading to unnecessary material and installation expenses. I recall a client, a manufacturing company in Southeast Asia, who initially specified Sch 40S for all their new utility water lines out of habit. After reviewing their system's actual operating pressures with our MFY team, they realized Sch 10S was sufficient for many sections, resulting in considerable cost savings on their project without compromising safety or performance.

Furthermore, the thicker wall of Sch 40S results in a smaller internal diameter compared to Sch 10S for the same NPS. This means Sch 10S offers better flow characteristics (lower friction loss) for the same flow rate, or higher flow capacity for the same pressure drop, in low-pressure systems. This can be an important efficiency consideration in systems where pumping costs are a factor or where maximizing flow is critical. The choice, therefore, hinges on a careful analysis of the system's pressure requirements, mechanical loading, flow needs, and budget.

Schedule 10 vs. Thinner Walled Tubing: When to Choose Which

While Schedule 10 is considered a "light-wall" pipe, there are even thinner-walled options available in the form of stainless steel tubing. Tubing is generally specified by its exact Outer Diameter (OD) and a specific wall thickness (often in Birmingham Wire Gauge - BWG, or inches/mm), rather than an NPS and schedule number. Stainless steel tubing is widely used in applications like heat exchangers, instrumentation lines, sanitary applications (especially polished tubing), and some decorative uses. Tubing often offers tighter dimensional tolerances and sometimes smoother surface finishes (especially if specified as "sanitary tubing") compared to standard schedule pipes.

The decision between Schedule 10 pipe and thinner-walled tubing depends heavily on the application's specific requirements. If the primary need is for precise OD dimensions, very thin walls for heat transfer efficiency (as in heat exchanger tubes), or highly polished sanitary surfaces, then tubing is often the preferred choice. For example, equipment integrators building compact heat exchangers or pharmaceutical processing equipment often rely on stainless steel tubing. However, Schedule 10 pipe generally offers greater structural robustness than very thin-walled tubing of a comparable OD due to its relatively thicker wall (even though it's "light-wall" in pipe terms). Pipe systems are also often designed for more robust connection methods (e.g., butt-welding, socket welding, threaded connections for some schedules though less common for Sch 10 stainless) that are standard in industrial piping.

From a cost perspective, very thin-walled tubing can sometimes be less expensive per foot than Schedule 10 pipe due to less material, but this is not always the case, especially if specialized finishes or very tight tolerances are required for the tubing. Installation methods can also differ; tubing often utilizes compression fittings or orbital welding for high-purity applications, while Sch 10 pipe more commonly uses butt-welding. At MFY, while our core is pipes, sheets, and coils, we understand the broader landscape. We guide clients; if their need points towards the characteristics of tubing (e.g., an OEM needing precise components for an instrument), we acknowledge that, but for general low-pressure fluid conveyance where standard pipe fittings and installation practices are preferred, Schedule 10 often strikes a better balance of robustness and cost-effectiveness than very light gauge tubing.

Cost-Benefit Analysis Across Different Schedules (MFY can give insights on cost savings for clients)

A crucial aspect of selecting any pipe schedule is the cost-benefit analysis. For Schedule 10 stainless steel pipe, the primary "benefit" in suitable low-pressure applications is its lower upfront material cost compared to heavier schedules like Sch 40S or Sch 80S. This cost saving stems directly from the reduced amount of stainless steel required to manufacture the thinner-walled pipe. For example, an NPS 6 Sch 10S 304L pipe might be 40-50% lighter than its Sch 40S counterpart, leading to a proportional reduction in material cost, assuming similar per-unit-weight pricing for the raw material (our stainless steel coils). This initial cost saving can be substantial for large projects involving extensive piping networks.

Beyond the material cost, other "cost" benefits of Schedule 10 include lower shipping and handling expenses due to its lighter weight. Installation can also be faster and less labor-intensive, potentially reducing overall project costs. As I've mentioned, less substantial structural supports might be needed. On the "cost" side of the equation (in terms of limitations or potential downsides if misapplied), Schedule 10's lower pressure rating and reduced mechanical strength mean it cannot be used in applications exceeding its design limits. Attempting to use it in higher-pressure systems to save money would lead to system failure, safety hazards, and far greater costs in the long run from damage, downtime, and potential liabilities.

At MFY, we often help our clients perform this cost-benefit analysis. For instance, a distributor in Russia was evaluating piping for a new agricultural irrigation system. While some main lines required higher pressure ratings, many lateral and distribution lines operated at very low pressures. We demonstrated how using Schedule 10S 304L for these low-pressure sections, instead of a blanket Sch 40S specification, could yield significant savings without compromising the system's integrity. The "benefit" here was not just cost, but also ease of installation in remote field locations. The key is a holistic view: the cost of the pipe itself, installation costs, long-term operational costs (like pumping energy, where Sch 10's larger bore can help), and the cost of potential failure if misapplied. Our strong production capacity and inventory at MFY allow us to offer competitive pricing on various schedules, facilitating these tailored solutions.

| Характеристика | Schedule 10S | Schedule 40S | Thin-Walled Tubing (Generic) |

|---|---|---|---|

| Толщина стенок | Thinner (vs. Sch 40) | Thicker (vs. Sch 10) | Thinnest (often) |

| Номинальное давление | Нижний | Выше | Variable, often very low |

| Weight | Lighter | Heavier | Lightest |

| Стоимость материала | Нижний | Выше | Variable, can be high for spec. |

| Internal Diameter (for same NPS/OD) | Larger | Smaller | N/A (OD specified) |

| Flow Efficiency (Low Pressure) | Выше | Нижний | Good, depends on ID |

| Mechanical Strength | Умеренный | Выше | Нижний |

| Установка | Easier, less support needed | More demanding, robust support | Specialized (e.g., compression, orbital weld) |

| Typical Use | Low-pressure fluid, architectural | Moderate/high pressure, structural | Instrumentation, sanitary, heat ex. |

| MFY Client Focus | Cost-effective for low-pressure; food/bev, water treatment clients | General industrial, higher pressure needs | (Advise when pipe is not optimal) |

Schedule 10 has better flow efficiencyПравда

Due to its larger internal diameter compared to Schedule 40 for the same NPS, Schedule 10 offers lower flow resistance and better flow characteristics in low-pressure systems.

Schedule 10 is always cheaperЛожь

While Schedule 10 is generally more cost-efficient for low-pressure applications, very thin-walled tubing can sometimes be less expensive per foot due to using even less material.

What are the recommended best practices for using Schedule 10 stainless pipes effectively?

Want to ensure your Schedule 10 stainless steel pipe installation is both effective and durable? Simply choosing the right schedule isn't enough; improper handling or installation can negate its benefits. Let's outline the best practices for maximizing the utility of Schedule 10 pipes.

Effective use of Schedule 10 stainless pipes involves meticulous system design confirming pressure/temperature suitability, employing proper joining techniques like TIG welding, careful handling to prevent damage, and ensuring material compatibility with the conveyed media for optimal lifespan.

At MFY, our commitment extends beyond simply supplying stainless steel products; we aim to empower our clients with the knowledge to use them effectively. For Schedule 10 pipes, this means adopting a set of best practices that begin long before the first pipe is laid and continue through to system operation and maintenance. The first step, always, is rigorous design verification. This involves not just checking maximum operating pressures5 but also considering potential surge pressures, thermal expansion and contraction, and the need for appropriate support systems, especially given the pipe's lighter wall. I've seen projects where cost savings from choosing Schedule 10 were compromised by inadequate support leading to sagging or vibration issues. Proper material grade selection (e.g., 304L vs. 316L) based on a thorough analysis of the fluid's corrosive properties and operating temperature is another cornerstone. A typical MFY client, an engineering contractor, working on a chemical plant expansion for low-pressure lines, would consult with us not just on schedule but also on the specific grade to resist nuanced chemical attack, ensuring long-term integrity. These initial steps are fundamental to leveraging Schedule 10's advantages safely and efficiently.

The journey to an effective Schedule 10 stainless steel piping system is paved with attention to detail at every stage. From the drawing board to final commissioning, each best practice contributes to a reliable, long-lasting, and cost-effective solution. As a global business director at MFY, I've seen firsthand how adherence to these principles helps our clients, whether they are manufacturing companies or equipment integrators, achieve superior outcomes in markets from India to the Middle East.

Proper Selection and System Design Considerations

The foundation of any successful Schedule 10 stainless steel piping system lies in meticulous upfront selection and design. This goes beyond simply noting that the application is "low pressure." Engineers must accurately calculate the Maximum Allowable Working Pressure (MAWP) for the chosen Schedule 10 pipe (e.g., 304L or 316L) at the highest anticipated operating temperature, referencing established piping codes like ASME B31.36. It's crucial to incorporate a suitable safety factor and account for any potential system upsets, such as surge pressures from pump starts/stops or rapid valve closures, which could momentarily exceed normal operating pressures. At MFY, we often advise clients to consider not just static pressure but also dynamic loads. For example, a food processing client in Southeast Asia needed to route Schedule 10 lines near vibrating equipment; the design had to incorporate measures to dampen vibration and prevent fatigue at connection points.

Another critical design consideration is thermal expansion and contraction. Stainless steel has a relatively high coefficient of thermal expansion. For long runs of Schedule 10 pipe, or systems experiencing significant temperature fluctuations, adequate provision for expansion (e.g., expansion loops, bellows, or flexible connectors) is essential to prevent overstressing the pipe or connected equipment. The support system design is also vital. While Schedule 10 is lighter, it still requires proper support to prevent sagging, maintain alignment, and manage loads from the pipe's weight, the fluid it contains, and any insulation. Support spacing should be determined based on engineering calculations, considering the pipe diameter, wall thickness, and operating conditions. Under-supporting can lead to stress concentrations and potential failure points.

Finally, material compatibility is paramount. The selected grade of stainless steel (304L, 316L, etc.) must be fully compatible with all fluids it will contact, including process fluids, cleaning agents, and any atmospheric contaminants. A common pitfall I've observed is focusing only on the process fluid and overlooking the corrosivity of CIP (Clean-In-Place) chemicals, which can sometimes be more aggressive. A thorough chemical compatibility review, considering concentrations and temperatures, will prevent premature corrosion and ensure the longevity of the Schedule 10 system. Our role at MFY often involves providing clients with detailed material data to support these critical design decisions.

Installation Techniques: Welding, Bending, and Joining

Proper installation techniques are critical to realizing the full potential of Schedule 10 stainless steel pipes and ensuring a leak-tight, durable system. Given the thinner wall of Schedule 10, welding requires particular care and skill. Gas Tungsten Arc Welding (GTAW or TIG welding) is the most commonly recommended method for Schedule 10 stainless steel, as it provides excellent control over the weld pool, resulting in high-quality, smooth weld beads with good penetration and minimal internal spatter. Using a proper inert gas purge (typically argon) on the inside of the pipe during welding is essential to prevent oxidation ("sugaring") of the root pass, which can compromise corrosion resistance and create sites for contamination. I recall a project with an equipment integrator where meticulous TIG welding with back-purging was specified for all Schedule 10 316L joints on a high-purity water system to maintain system integrity.

When bending Schedule 10 pipes (if permitted by the design and applicable codes), it's crucial to use appropriate bending equipment with the correct die sets to avoid kinking, excessive ovality, or wall thinning beyond acceptable limits. Cold bending is common, but the minimum bend radius and any requirements for post-bend heat treatment (though rare for austenitic stainless Schedule 10 in typical applications) should be considered. Careful handling during all installation phases is also paramount. The thinner wall makes Schedule 10 more susceptible to dents, scratches, or gouges than heavier schedule pipes. Such damage can become stress concentration points or compromise the passive layer, leading to localized corrosion. At MFY, we emphasize careful material handling from our warehouse to the client's site, and we advise our clients, especially distributors and contractors, to maintain these practices.

For joining, while welding is common, other methods like flanged connections or specialized mechanical fittings (e.g., grooved couplings designed for stainless steel pipe) can also be used, depending on the application, pressure, and maintenance requirements. If using threaded connections (less common and generally not recommended for thin-walled Schedule 10 stainless due to the risk of insufficient thread engagement and leakage), extreme care must be taken. Regardless of the joining method, ensuring proper alignment before making the connection is vital to avoid built-in stresses.

Maintenance and Inspection for Longevity

Once a Schedule 10 stainless steel piping system is installed and commissioned, a program of regular maintenance and inspection is key to ensuring its continued safe operation and longevity. The frequency and type of inspection will depend on the criticality of the system, the nature of the fluid being conveyed, operating conditions, and any regulatory requirements. Visual inspection is often the first line of defense, looking for any signs of leaks, external corrosion, mechanical damage, or issues with supports and hangers. For insulated lines, periodic removal of insulation at critical points (e.g., low points, connections) may be necessary to inspect for corrosion under insulation (CUI), although stainless steel is less susceptible than carbon steel.

For critical systems, or where there's a higher risk of corrosion or erosion, non-destructive testing (NDT) methods like ultrasonic thickness testing (UTT) can be employed to monitor wall thickness over time. This is particularly important if there's any concern about erosion-corrosion due to high flow velocities or particulate matter in the fluid, or if unexpected corrosion is suspected. Any findings from inspections should be documented, and a plan for corrective action implemented if necessary. For instance, MFY supplied Schedule 10 pipes for a mild chemical service to a manufacturing client in India; their internal maintenance plan included annual spot checks of wall thickness at known turbulence points like elbows.

Preventative maintenance might include regular cleaning, especially in food, beverage, or pharmaceutical applications, to maintain hygiene and prevent product buildup that could lead to under-deposit corrosion. Ensuring that operating parameters (pressure, temperature, fluid composition) remain within the original design envelope is also crucial. Any proposed changes to the process conditions should trigger a review of the piping system's suitability. At MFY, our commitment to quality extends to providing materials that, when properly installed and maintained, deliver reliable long-term service. Our integrated supply chain ensures consistent material properties, which is a foundational element for predictable performance and effective maintenance planning.

| Best Practice Aspect | Key Considerations for Schedule 10 Stainless Pipe | Example of MFY Client Scenario / Advice |

|---|---|---|

| System Design & Selection | Verify MAWP at temp, thermal expansion, support spacing, material/fluid compatibility. | Advising an engineering contractor on 316L vs 304L for a water treatment plant based on chloride levels. |

| Сварка | Prefer TIG (GTAW), ensure proper back-purge (argon), skilled welders, avoid weld defects. | Guiding an equipment integrator on best welding practices for high-purity Schedule 10 316L lines. |

| Handling & Bending | Avoid dents/scratches, use correct bending tools/radii, prevent kinking/ovality. | Emphasizing careful site handling to a distributor to prevent damage to lighter Schedule 10 pipes. |

| Joining (Non-Welded) | Ensure proper flange alignment, appropriate gasket selection, correct torque for bolts. | Discussing grooved coupling suitability with a contractor for a rapid-install fire protection system. |

| Inspection & Testing | Regular visual checks, NDT (e.g., UTT) for critical lines, CUI checks if insulated. | Recommending periodic wall thickness checks for a chemical client using Sch 10 in a mildly erosive service. |

| Maintenance | Regular cleaning (if needed), ensure operating conditions within design, review process changes. | Advising a food & beverage client on CIP compatibility with their Schedule 10 304L piping. |

TIG welding is preferred for Schedule 10Правда

TIG welding provides better control for thin-walled Schedule 10 pipes, preventing oxidation and ensuring quality welds.

Threaded connections are ideal for Schedule 10Ложь

Threaded connections are generally not recommended for Schedule 10 due to insufficient thread engagement and leakage risks.

Заключение

Schedule 10 stainless steel pipe offers a cost-effective, lightweight solution for low-pressure applications, excelling in corrosion resistance and flow efficiency. Proper specification, installation, and understanding its limitations are key to leveraging its benefits across various industries, ensuring reliable and efficient system performance.

-

Ensure quality and standard compliance in stainless steel pipe manufacturing ↩

-

Learn about the corrosion resistance and non-reactivity advantages of 304L and 316L grades ↩

-

Know the efficiency of Schedule 10 in different applications ↩

-

Learn about MFY's role in stainless steel solutions globally ↩

-

Understand how to check operating pressures for safety and efficiency in pipe systems ↩

-

Familiarize with ASME B31.3 standards for stainless steel pipe usage and safety ↩

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.