Stainless Steel Slitting Services and Processing (Best Prices)

Finding affordable, high-quality stainless steel slitting is a challenge. This can delay projects and inflate budgets, hurting your bottom line. We provide precision processing at the best prices.

Getting the best prices for stainless steel slitting and processing involves partnering with a provider who integrates their supply chain, leverages technology for efficiency, and offers transparent pricing. This combination ensures you receive high-quality, custom-cut materials without overpaying, directly boosting your project's profitability.

As Global Business Director at MFY, I talk with partners every day who are looking for an edge. They need more than just raw materials; they need a processing partner who understands that value is about more than the price per ton. It’s about precision, reliability, and efficiency that impacts the entire production cycle. Let's explore how to achieve this and secure the best possible value for your business.

What is the importance of stainless steel slitting services in the industry?

Using standard-sized coils is wasteful and inefficient. This leads to higher material costs and production bottlenecks. Slitting provides custom widths, minimizing scrap and optimizing your manufacturing processes.

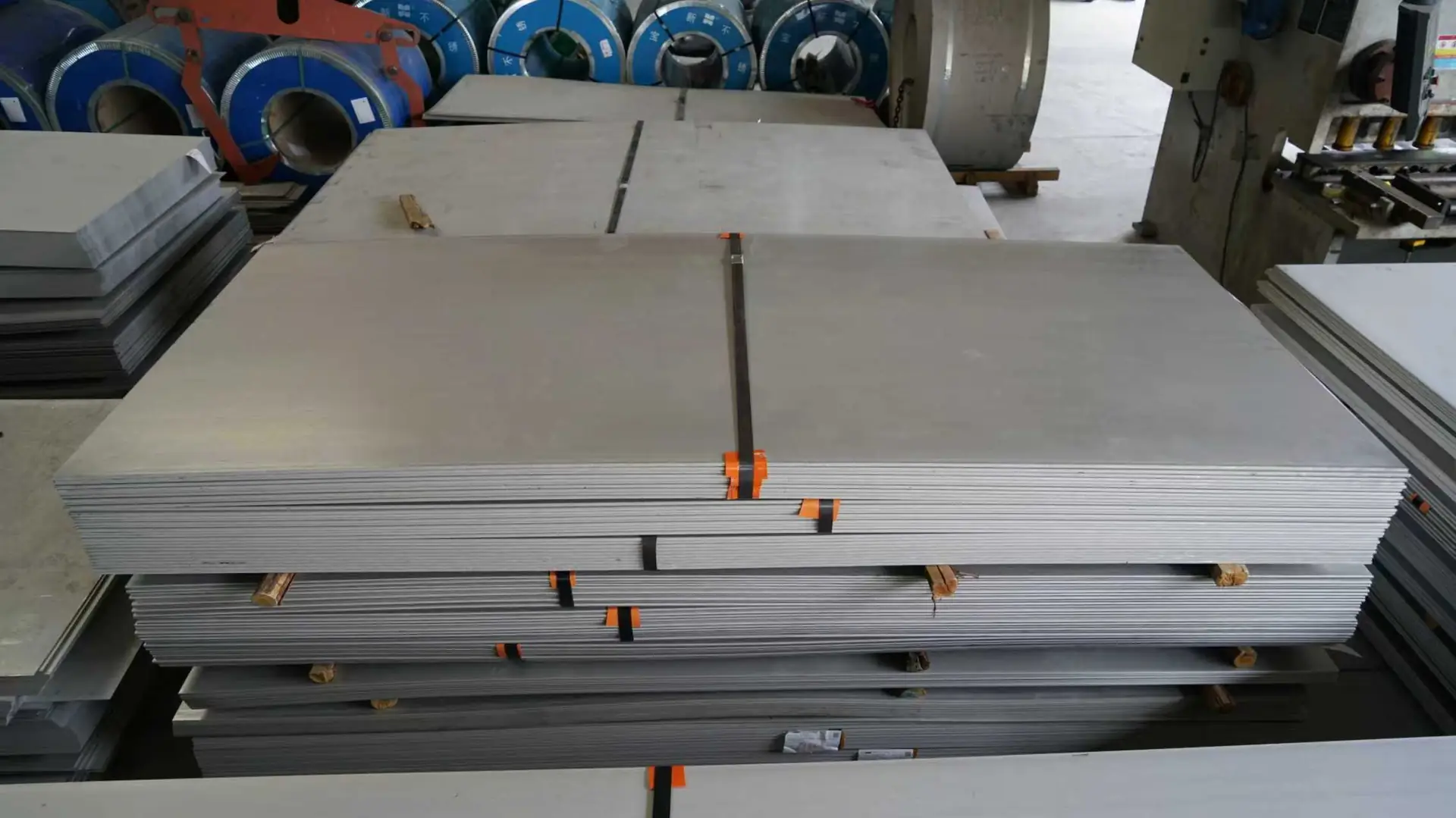

Stainless steel slitting is crucial because it transforms large master coils into custom, narrow strips tailored for specific applications. This precision service minimizes material waste, enhances manufacturing efficiency, and ensures components fit perfectly, directly impacting project costs and quality for industries like automotive and construction.

The true value of slitting lies in its ability to bridge the gap between the steel mill and the end-user's specific needs. Mills produce wide, heavy master coils for efficiency, but very few manufacturers can use them directly. This is where precision slitting[^1] becomes an indispensable part of the supply chain. I remember a client in the automotive sector in Germany who was struggling with high scrap rates. Their stamping process required a very specific width, and they were trimming down wider sheets, which was incredibly wasteful. By providing them with coils slit to their exact tolerance, we not only reduced their material waste by over 15% but also increased their production line's throughput because they no longer needed that extra trimming step. This is a perfect example of how slitting delivers value far beyond the simple act of cutting steel.

Reducing Material Waste

The most immediate benefit of slitting is the optimization of material usage. By cutting a master coil into strips that perfectly match the required dimensions for a stamping, roll-forming, or tube-making process, you drastically reduce the amount of scrap generated. This has a direct and significant impact on the total cost of a project.

Enhancing Production Efficiency

When manufacturers receive materials that are ready for their production lines, it eliminates time-consuming and costly in-house preparation steps. This "just-in-time" and "ready-to-use" approach allows for smoother, faster, and more predictable manufacturing cycles.

| Аспект | Standard Coil Usage | Precision Slit Coil Usage |

|---|---|---|

| Scrap Rate | High (5-20%) | Minimal (<2%) |

| Setup Time | Longer (requires in-house cutting) | Shorter (ready for production) |

| Инвентаризация | Requires more space for various sizes | Optimized for specific jobs |

| Overall Cost | Higher due to waste and labor | Lower due to efficiency |

How are current market trends affecting stainless steel processing?

The market is demanding more than just steel. Ignoring trends like sustainability and digitalization can leave you behind. We're embracing these shifts to offer smarter, more efficient processing solutions.

Current market trends, including the push for sustainability, supply chain digitalization, and demand for just-in-time delivery, are heavily influencing stainless steel processing. Providers must now offer greater transparency, faster turnarounds, and eco-friendly options to remain competitive in a rapidly evolving global market.

The industry is moving at a pace I haven't seen before. It's no longer enough to simply deliver a quality product. Our clients now expect a seamless digital experience and a commitment to sustainable practices. They want to know where their material is at every stage of the process, from our warehouse to their factory floor. This demand for transparency is a major driver of change. At MFY, we've invested heavily in digital integration because we see it as a core part of our service, not just an add-on. By providing real-time tracking and digital inventory management, we give our partners the data they need to plan their production schedules with confidence. This isn't just about convenience; it's about building trust and creating a resilient, predictable supply chain that can withstand market volatility.

Рост цифровизации

Clients are demanding greater visibility into their supply chains. They want to track their orders in real time, manage inventory digitally, and receive instant updates. This requires processing centers to adopt smart factory technologies, integrating their systems with their clients' for a seamless flow of information. This move towards Industry 4.0[^2] enhances efficiency, reduces errors, and provides the transparency the modern market demands.

The Demand for Sustainability

There is a growing emphasis on the environmental impact of industrial processes. Clients are increasingly asking about the recycled content of the stainless steel, the energy efficiency of our processing lines, and our overall carbon footprint. Offering sustainable options and demonstrating a commitment to green practices is becoming a significant competitive advantage.

What challenges do providers face in delivering efficient slitting services?

Delivering perfect cuts on time is complex. Equipment failure, material variations, and logistical hurdles can cause costly delays. Overcoming these requires expertise, technology, and robust process control.

Providers face significant challenges, including maintaining equipment precision to prevent defects like burrs and camber, managing material variability from different mills, and navigating complex supply chain logistics. Ensuring consistent quality, tight tolerances, and on-time delivery while managing costs are the primary hurdles in efficient slitting services.

Every slitting provider knows the pressure of maintaining quality under tight deadlines. The challenges are both technical and logistical. On the technical side, even the slightest deviation in knife clearance or tension control can result in a coil that is unusable for the customer, leading to costly rejections. I recall an urgent order for a construction project in the Middle East where the material had to be perfect. Our quality control team detected a minor camber issue early in the run, a slight sideways curve in the slit strip. We immediately stopped the line, recalibrated the tensioner, and restarted the job. While it caused a small internal delay, it prevented a much bigger problem for our client on-site. This highlights the absolute necessity of rigorous process control. Logistically, coordinating raw material intake, production scheduling, and final delivery across continents is a daily puzzle that requires a robust and agile system to solve effectively.

Maintaining Technical Precision

The core of the challenge is technical. Stainless steel is a tough material, and slitting it to tolerances measured in micrometers requires state-of-the-art machinery and highly skilled operators.

- Burr Control: A sharp edge or burr left after cutting can damage downstream equipment and compromise the final product's quality.

- Camber Control: Ensuring the slit strips are perfectly straight is critical for automated manufacturing processes.

- Width Tolerance: Consistently hitting the exact width specified by the client is non-negotiable.

Navigating Supply Chain Volatility

Beyond the factory floor, providers must manage a volatile global supply chain. Fluctuations in raw material prices, shipping delays, and geopolitical events can disrupt the flow of materials. A resilient slitting service needs a strong sourcing network and sophisticated logistics management to buffer against these external shocks and ensure reliable delivery to clients.

What strategies can improve the efficiency of stainless steel slitting?

Inefficient slitting wastes time and money. Slow setups and poor planning can halt your entire production line. Strategic planning and modern technology are key to maximizing output.

Improving efficiency involves a multi-faceted strategy: investing in high-speed, automated slitting lines, implementing predictive maintenance for equipment, optimizing scheduling to minimize downtime between jobs, and integrating digital tools for better inventory management. These steps collectively boost throughput and reduce operational costs.

At MFY, we see efficiency as our core competitive advantage. It's how we deliver both quality and the best prices. The biggest leap forward for us came from integrating automation with smart scheduling. Instead of treating each order as a separate task, our system analyzes a full week's worth of orders to group jobs by material grade, thickness, and width. This dramatically reduces the number of time-consuming tooling changes our operators have to make. For example, by running all the 1.5mm 304-grade stainless steel jobs back-to-back, even for different clients, we can slash setup times by up to 70%. This isn't just about working faster; it's about working smarter. This optimized workflow allows us to increase our overall capacity, which translates into quicker lead times and more competitive pricing for our partners.

Leveraging Automation and Technology

Modern slitting lines are marvels of engineering. Automated coil loading, computerized knife positioning, and robotic packaging systems all work to reduce manual intervention, minimize errors, and increase the speed of the entire process. Furthermore, implementing a predictive maintenance schedule using sensors to monitor equipment health can prevent unexpected breakdowns, which are a major source of inefficiency.

Optimizing Workflow and Scheduling

Smart scheduling software can be a game-changer. By analyzing orders and grouping similar jobs together, a processing center can minimize the downtime required for re-tooling. This ensures the machinery is running for a higher percentage of the time, maximizing output.

| Характеристика | Traditional Slitting | Modern, Efficient Slitting |

|---|---|---|

| Setup Time | 45-60 minutes | 15-20 minutes (automated) |

| Running Speed | 100-200 m/min | 300-500 m/min |

| Контроль качества | Manual spot checks | In-line laser sensors |

| Scheduling | Manual, reactive | AI-optimized, proactive |

How to ensure cost-effective stainless steel processing while maintaining quality?

Cutting costs can often mean cutting quality. Poor quality materials lead to rework and reputational damage. True cost-effectiveness comes from efficiency, not just a low price tag.

To ensure cost-effective processing without sacrificing quality, partner with a vertically integrated supplier like MFY. This minimizes middlemen, optimizes material sourcing, and leverages economies of scale. Combining this with efficient, high-yield slitting processes guarantees the best overall value and consistent material integrity.

This is the most important question for any purchasing manager or business owner, and the answer is simpler than you might think. The "best price" is rarely the lowest number on a quote sheet. It's found in the total cost of ownership. I’ve seen companies choose a cheaper supplier only to face costly production delays due to poor quality or late deliveries. True cost-effectiveness comes from a partner who controls the entire value chain. At MFY, our integration—from sourcing raw materials to our advanced processing centers and global logistics network—gives us a unique ability to manage costs without ever compromising on quality. We aren't just a processor; we are a strategic part of the supply chain. This structure eliminates unnecessary markups from middlemen and allows us to pass those savings directly to our clients, providing premier quality at a price that reflects true efficiency.

The Power of Vertical Integration

When a company is involved in multiple stages of the supply chain—from raw material procurement to final processing and delivery—it can control costs and quality at every step. This vertical integration[^3] eliminates the markups added by intermediaries and ensures a consistent, reliable supply of high-quality feedstock for the slitting lines. This is a core part of MFY’s strategy and a direct benefit we offer our partners.

Focusing on Total Cost of Ownership

Smart buyers look beyond the per-kilogram price. They consider the total cost, which includes:

- Material Yield: How much of the coil is usable versus how much is scrap?

- Reliability: Will the material arrive on time, every time?

- Quality: Does the material meet specifications, or will it cause issues in production?

A slightly higher initial price from a reliable, high-efficiency provider often results in a lower total cost when you factor in reduced waste, zero production downtime, and superior end-product quality.

Заключение

In conclusion, achieving the best price for stainless steel slitting requires a partner who combines precision technology, efficient processes, and an integrated supply chain. At MFY, we deliver this value, ensuring you receive top-quality, custom-cut materials that optimize your projects and boost your bottom line.

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.