T304 Stainless Steel Sheets: Reliable Supply for Construction

Project delays cost money. Unreliable material delivery creates chaos. A stable T304 sheet supply chain is the solution for keeping your construction projects on track and on budget.

**A reliable supply of T304 stainless steel sheets is crucial because it ensures project timelines are met, prevents costly delays, and guarantees material consistency. Its corrosion resistance and aesthetic versatility make it a strategic choice for modern construction, demanding a stable and responsive supply chain.**

As someone who has managed global supply chains for years, I've seen firsthand how the right material, delivered at the right time, can make or break a project. Choosing T304 stainless steel is not just a material selection; it's a commitment to quality and longevity. But that commitment is only as strong as the supply chain behind it. Let's dive deeper into why securing a reliable source is a critical strategic decision for any serious construction contractor or developer.

## What is the historical background of T304 stainless steel sheets in construction?

Wondering why T304 became a go-to material? Its journey from industrial novelty to architectural staple is fascinating. Understanding its past reveals its value for your future projects.

**T304 stainless steel, developed in the early 20th century, gained prominence in construction post-WWII. Its adoption surged with iconic structures like the Chrysler Building's spire, proving its long-term durability, corrosion resistance, and timeless aesthetic appeal, making it a modern architectural standard.**

The story of T304 in construction is a story of innovation meeting demand. When it was first developed, its primary appeal was for industrial applications where corrosion was a major problem. However, architects quickly saw its potential.

### The Dawn of an Architectural Icon

The real turning point came in the 1930s. Architects of the Art Deco movement needed a material that was modern, sleek, and could withstand the test of time. The gleaming spire of the Chrysler Building in New York, clad in a type of stainless steel very similar to T304, became a global symbol of this new era. It demonstrated to the world that stainless steel wasn't just functional; it was beautiful and incredibly durable. I often walk past older buildings in European cities and point out the T304 elements to my team. They still look incredible after decades of exposure to the elements. It's a testament to the material's longevity.

### From Niche to Mainstream

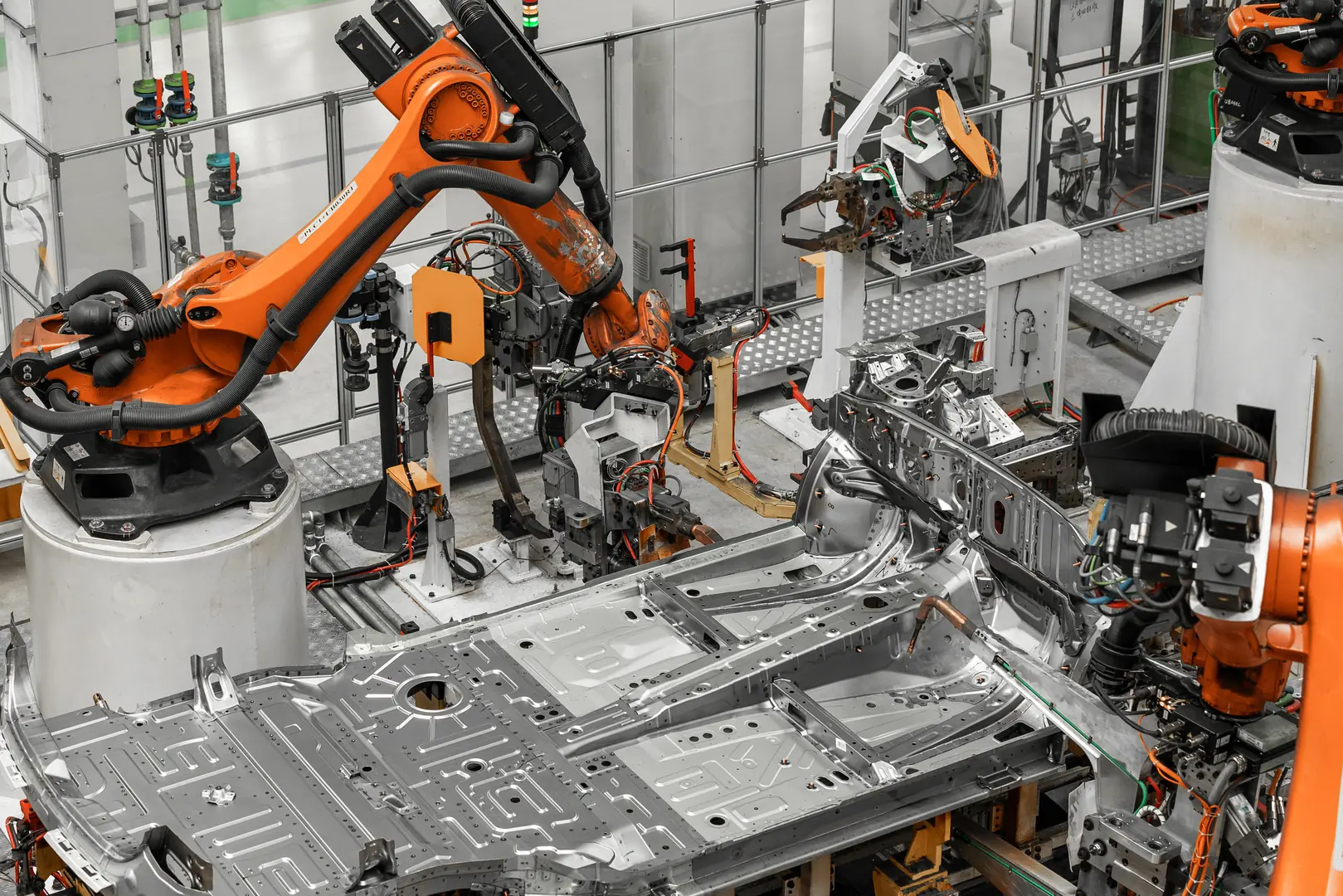

After World War II, construction boomed, and the demand for reliable, low-maintenance materials grew. T304 stainless steel, with its excellent formability and welding characteristics, became the standard for everything from curtain walls and roofing to interior fixtures and railings. Its advantages over traditional materials were clear.

| Feature | T304 Stainless Steel | Carbon Steel |

| :--- | :--- | :--- |

| **Corrosion Resistance** | Excellent | Poor (requires coating) |

| **Maintenance** | Low | High (frequent painting) |

| **Aesthetic** | Modern, clean finish | Industrial, prone to rust |

| **Longevity** | Very High | Moderate (depends on coating) |

This history is important because it establishes T304 not as a trend, but as a proven, reliable foundation for quality construction.

## How is the current supply chain of T304 stainless steel sheets structured?

The journey from raw ore to your job site is complex. This complexity can cause delays. Understanding the chain helps you find a reliable partner who can navigate it.

**The modern T304 supply chain starts with raw material mining (nickel, chromium), moves to steel mills for melting and rolling, then to service centers for processing (cutting, polishing). Finally, distributors and traders like MFY manage logistics to deliver finished sheets to construction sites.**

Navigating the T304 supply chain requires expertise because it has many moving parts. Each stage presents opportunities for both value creation and potential disruption. At MFY, we have built our business around mastering this entire process to deliver a seamless experience for our clients.

### From Mine to Mill

It all begins with raw materials. The price and availability of nickel and chromium are the foundation of T304 pricing. These materials are mined globally and then shipped to steel mills. At the mill, they are melted in an [electric arc furnace](https://jinsuncarbon.com/electric-arc-furnace/)[^1], refined, cast into slabs, and hot-rolled into coils. This is a capital-intensive, high-technology process that determines the fundamental quality of the steel. We maintain direct relationships with major mills, giving us visibility into production schedules and material availability.

### The Value-Added Chain

The large coils from the mill are then sent to service centers. This is where the material is transformed to meet specific project requirements. Processes include cold rolling for a smoother finish, slitting coils into narrower widths, and cutting sheets to precise lengths. This stage is critical for customization. An integrated supplier has these capabilities in-house or through trusted partners, ensuring quality control at every step.

| Supply Chain Stage | Key Activity | Key Player |

| :--- | :--- | :--- |

| **Upstream** | Raw Material Extraction | Mining Companies |

| **Midstream** | Melting, Casting, Rolling | Steel Mills |

| **Processing** | Cutting, Finishing, Polishing | Service Centers |

| **Downstream** | Logistics, Distribution | Traders, Distributors (MFY) |

| **End User** | Fabrication, Installation | Construction Contractors |

By managing these stages within a unified network, we reduce hand-offs, minimize delays, and provide our clients with a single point of accountability.

## What challenges affect the reliability of T304 stainless steel sheet supply?

Your project is on a tight deadline. Unexpected material shortages create massive stress. Knowing the risks is the first step to avoiding them and ensuring a smooth supply.

**Supply reliability is challenged by raw material price volatility, geopolitical tensions disrupting trade routes, production bottlenecks at mills, and logistical hurdles. These factors can lead to unpredictable lead times, price hikes, and potential project delays for construction companies if not managed properly.**

In today's globalized world, the supply chain is more interconnected—and more fragile—than ever. From my perspective as a business director, risk management is now a core part of our service. Simply providing a product is not enough; we must provide certainty.

### The Geopolitical Factor

Global economic shifts and geopolitical tensions are no longer abstract concepts; they have a direct impact on construction sites. Tariffs can suddenly increase material costs, trade disputes can close borders to certain products, and shipping lane disruptions can add weeks to delivery times. I recall a situation in 2022 where a sudden port closure in Asia delayed a shipment for a major contractor in the Middle East. Because we have a diversified logistics network at MFY, we were able to re-route a different shipment from another region to cover their immediate needs, but it highlights the fragility of the system for those who are unprepared. This is where having a partner with a global footprint and strong supply chain capabilities becomes a competitive advantage.

### Market Volatility and Production

The prices for nickel and chromium can swing wildly based on global demand and supply speculation. This makes project budgeting a serious challenge. Furthermore, steel mills operate on tight schedules and require periodic shutdowns for maintenance, which can create production bottlenecks. A supplier without strong inventory or deep mill relationships can leave their clients waiting.

| Challenge | Potential Impact on Construction Project |

| :--- | :--- |

| **Geopolitical Tensions** | Sudden material shortages, shipping delays |

| **Price Volatility** | Budget overruns, project unprofitability |

| **Logistical Hurdles** | Missed deadlines, idle workforce |

| **Production Bottlenecks** | Extended lead times, project timeline reset |

Understanding these challenges is why we built MFY on a foundation of agility and resilience. We actively monitor these risks to shield our partners from their impact.

## What strategies can be implemented to enhance the supply reliability of T304 sheets?

Worried about supply chain disruptions? These risks can derail your project. The solution is a proactive strategy built on strong partnerships and smart planning to secure your materials.

**To enhance reliability, focus on building strategic partnerships with integrated suppliers like MFY. Also, implement long-term forecasting, diversify your sourcing, and maintain clear communication. This proactive approach mitigates risks from market volatility and logistical challenges, ensuring a stable material flow.**

You cannot eliminate all risk, but you can manage it effectively. The most successful contractors I work with have shifted their thinking from transactional purchasing to strategic sourcing. They don't just buy steel; they secure a supply line.

### The Power of Strategic Partnerships

This is the most important strategy. A true partner does more than just take your order. They work with you to understand your project pipeline and anticipate your needs. An integrated supplier like MFY, with deep connections from the mill to the port, can provide the rapid response and flexible delivery that modern construction demands. This relationship transforms the supply chain from a source of risk into a source of competitive advantage. It's about building trust and transparency, so when challenges arise, we solve them together. This approach not only reduces risk but also enhances the overall quality of the project.

### Proactive Supply Chain Management

A strong partnership enables proactive management. I had a client in Germany working on a large public infrastructure project who shared their full 18-month timeline with us. This allowed us to lock in material prices and schedule production runs well in advance, protecting them from two major price hikes and ensuring every delivery was on time. This is what proactive management looks like in practice. It involves clear communication, forward-looking contracts, and a shared commitment to the project's success.

| Strategy | Key Benefit |

| :--- | :--- |

| **Strategic Partnership** | Access to expertise, flexibility, and risk mitigation |

| **Long-Term Forecasting** | Price stability and guaranteed material availability |

| **Transparent Communication** | Faster problem-solving and alignment with project goals |

| **Diversified Sourcing** | Resilience against regional disruptions |

Implementing these strategies ensures that the T304 sheets you need are on-site exactly when your schedule demands them.

## What technological advancements support the construction industry's use of T304 stainless steel sheets?

Old methods are slow and costly. New technology is changing how we build. Adopting these advancements with T304 sheets can boost your project's efficiency and quality.

**Technological advancements like Building Information Modeling (BIM) for precise planning, advanced laser cutting and forming for complex designs, and supply chain management software for real-time tracking are revolutionizing how T304 sheets are used, enhancing efficiency, accuracy, and aesthetic possibilities in construction.**

Technology is a powerful enabler, both in how T304 is used on-site and in how it gets there. At MFY, we are constantly investing in digital innovation because we see it as essential for serving the modern construction industry.

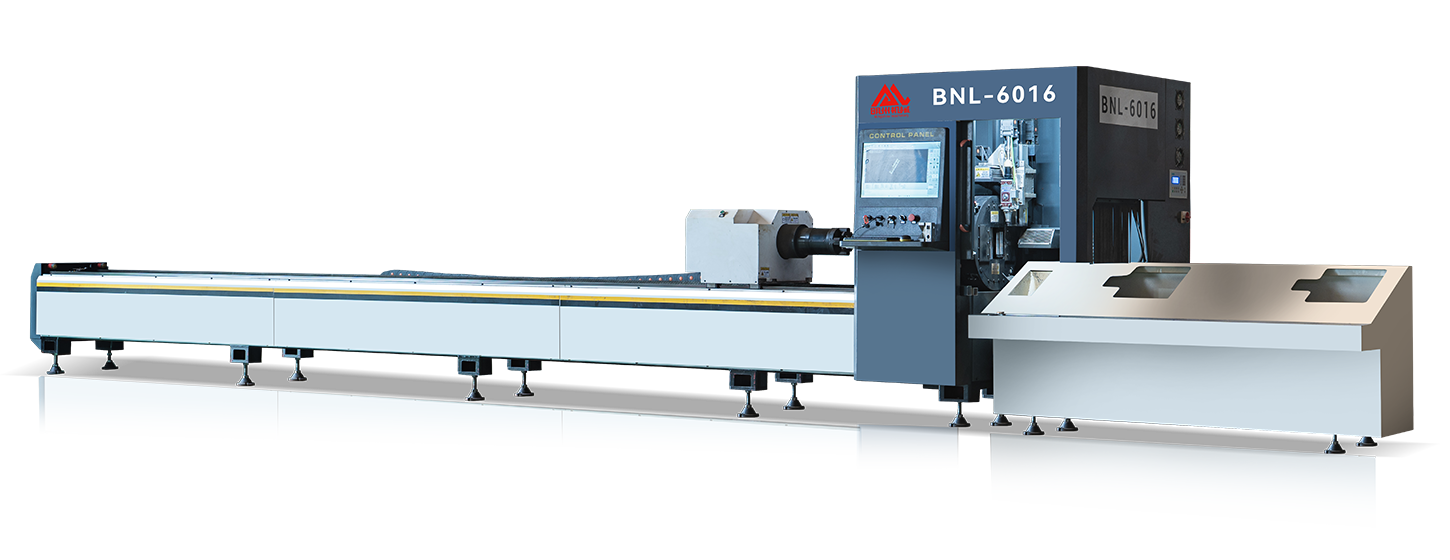

### Design and Fabrication

Building Information Modeling (BIM) has been a game-changer. Digital 3D models allow architects and engineers to plan every detail, including the exact size and quantity of T304 sheets needed. This minimizes waste and prevents costly on-site errors. In fabrication, technologies like [CNC laser cutting](https://steelwaylasercutting.com/the-role-of-laser-cutting-in-construction-building-techniques/)[^2] and waterjet cutting now allow for incredibly intricate and precise shapes. This has opened up new creative possibilities for architects using T304 for decorative facades, custom fixtures, and complex structural elements that were once impossible to produce economically.

### Supply Chain and Logistics

Technology is also transforming the supply chain itself. Digital platforms, like the ones we are developing at MFY, provide clients with real-time visibility into their orders. You can track your shipment from our warehouse to your site. This transparency eliminates uncertainty and allows for better on-site planning. We are also exploring [IoT sensors](https://www.infosysbpm.com/blogs/supply-chain/internet-of-things-supply-chain.html)[^3] that can monitor the condition of materials in transit, ensuring that the quality specified is the quality delivered.

| Technology | Benefit for T304 Construction |

| :--- | :--- |

| **BIM** | Reduced material waste, improved design accuracy |

| **Laser Cutting** | Enables complex architectural designs, high precision |

| **Digital Platforms** | Real-time order tracking, improved communication |

| **IoT Sensors** | Quality assurance during transit |

These tools are not just about convenience; they are about delivering a higher level of precision, efficiency, and reliability to our partners.

## Conclusion

Securing a reliable T304 stainless steel sheet supply is a strategic decision. It's about choosing a partner, not just a product. A proactive approach with an integrated supplier like MFY protects your project from risk, ensuring quality, and delivering success on time and on budget.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.