Precision Stainless Steel Coil Slitting Services

Standard coils don't fit your custom specs, causing waste and delays. This inefficiency hurts your bottom line. Precision slitting provides the exact widths you need, right when you need them.

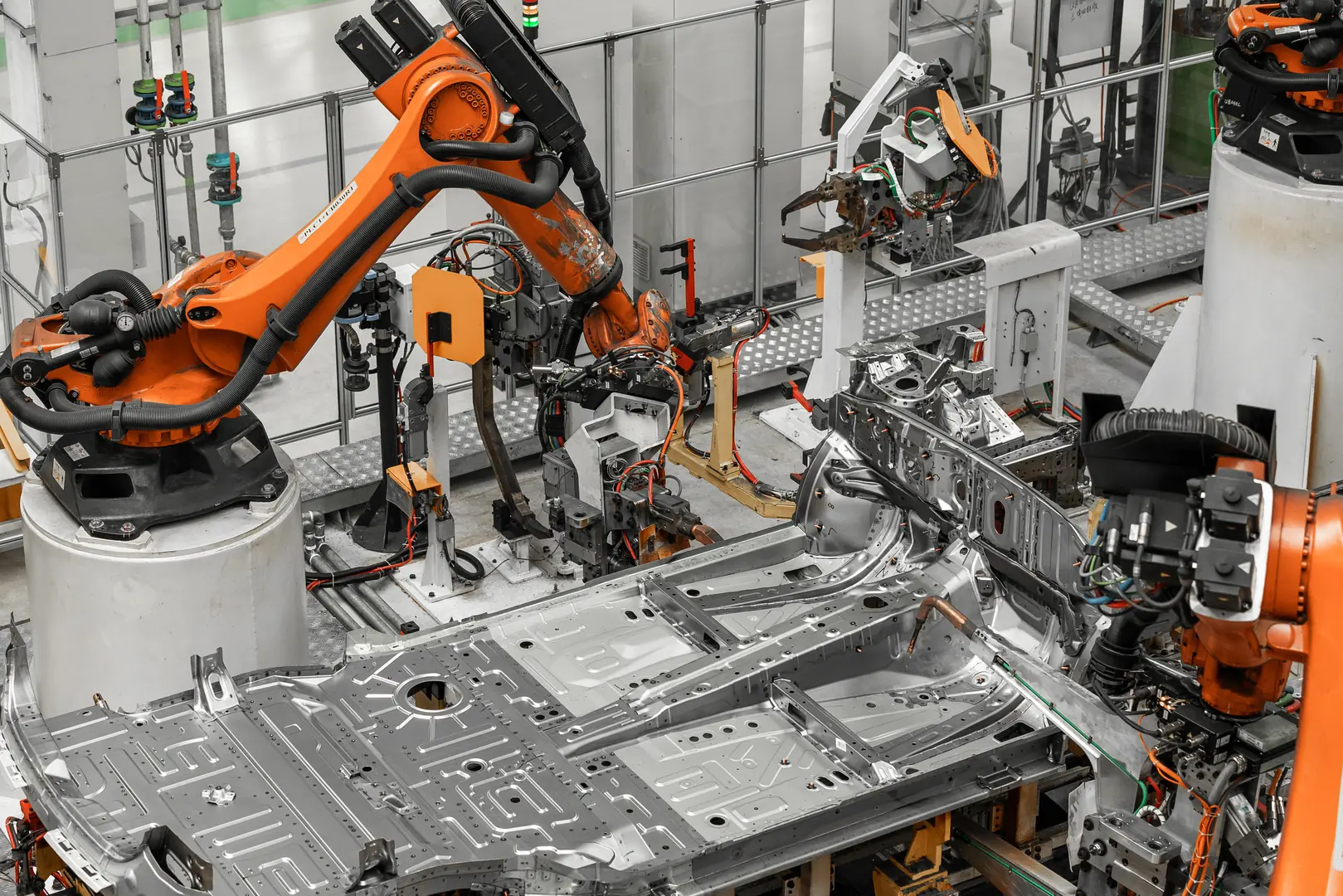

Precision stainless steel coil slitting is a crucial service that transforms wide master coils into narrower strips with exact dimensions. It enables just-in-time manufacturing, reduces material waste, and provides customized materials essential for high-tech industries like automotive, aerospace, and electronics, boosting efficiency and resilience.

As the Global Business Director at MFY, I've seen firsthand how the manufacturing landscape is evolving. Companies are no longer just buying raw materials; they are seeking strategic partners who can provide tailored solutions that integrate seamlessly into their production lines. This is where precision slitting[^1] becomes not just a service, but a competitive advantage. It’s the critical link that transforms a standard commodity into a high-value, customized component. Let's break down the process and explore why getting it right is so important for your business.

What is the initial assessment process in stainless steel coil slitting?

A wrong initial assessment leads to costly errors and material waste. This risk can disrupt your entire production schedule. A thorough assessment ensures perfect results from the start.

The initial assessment involves a detailed analysis of the master coil's properties—grade, thickness, hardness, and surface finish. We also confirm the client's final specifications, including required width, tolerance, and edge condition, to create a precise slitting plan.

The initial assessment is far more than a simple check of the paperwork. It is the foundation upon which the entire success of the slitting operation rests. At MFY, we treat this stage as a critical risk mitigation step. I remember a client in the electronics sector who came to us after another supplier provided slit coils that failed in their stamping process. The issue wasn't the slitting itself, but a failure to properly assess the master coil's temper and grain direction beforehand. This is why our process is so rigorous. We don’t just look at the coil; we analyze its entire story to predict how it will behave under the pressure of the slitting knives.

Material Verification

Before a single cut is made, we verify the material certificate against the physical properties of the coil. This includes using specialized tools to measure thickness at multiple points and testing hardness. We check for any inconsistencies that could affect the final product. A slight variation in thickness, for example, can lead to tolerance issues in high-precision applications like automotive components.

Specification Alignment

This step is a deep conversation with our client. We go beyond the numbers on a spec sheet to understand the end-use application. This allows us to recommend the ideal edge condition and coil set to optimize their manufacturing process.

| Assessment Parameter | MFY Standard Check | Importance for Client |

|---|---|---|

| Material Grade | Spectrometer Analysis | Ensures correct corrosion resistance & strength. |

| Thickness & Tolerance | Digital Micrometer | Guarantees fit and function in final assembly. |

| Hardness (Temper) | Rockwell Hardness Test | Affects formability and tool wear. |

| Surface Finish | Visual & Profilometer Check | Critical for aesthetic and functional applications. |

| Edge Condition | Client Consultation | Determines safety and suitability for processes. |

How to prepare stainless steel coils for precision slitting?

Improper coil handling can cause surface damage or tension issues. These defects lead to poor slitting quality. Proper preparation is key to protecting material integrity and ensuring a flawless cut.

Preparation involves carefully uncoiling the master coil and feeding it into the slitting line. We check for any surface defects, ensure proper tension is applied, and clean the material if necessary to prevent contamination or damage during the slitting process.

Once the assessment is complete, the physical preparation of the coil begins. Think of this as setting the stage for a perfect performance. Any mistake here, like a scratch from poor handling or incorrect tension during uncoiling, will be magnified in the final slit strips. In our facilities, this process is highly automated to minimize human error and protect the material. Our goal is to feed a perfectly flat, clean, and stable strip of steel into the slitting head. This meticulous preparation is fundamental to reducing material wastage and ensuring the reliability that our partners in demanding industries, like aerospace, count on.

Tension Control

The uncoiler and recoiler must work in perfect harmony. We use sophisticated tension control systems[^2] that apply consistent back-tension as the coil is fed into the slitter. Too little tension and the strip can wander; too much and you can introduce stress or even stretch the material, altering its mechanical properties. This precision is what allows us to hold tight tolerances, which is a non-negotiable requirement for many of our clients.

Surface Integrity

For applications where the surface finish is critical, such as in architectural panels or high-end appliances, we take extra precautions. The coil may pass through cleaning stations to remove any oils or debris from the mill. We also conduct a final visual inspection under specialized lighting as it uncoils to catch any surface imperfections that were not visible when the coil was tightly wound. This attention to detail ensures that the final product is not just dimensionally accurate but also aesthetically flawless.

What are the critical steps involved in the actual slitting process?

The slitting process itself is complex and demands precision. A small error can ruin an entire coil. Our process uses advanced tooling and expert oversight to guarantee accuracy every time.

The critical steps are setting the rotary knives to the exact width, applying precise tension as the coil passes through, and making the cut. The newly slit strips, or 'mults', are then carefully recoiled onto a new mandrel with consistent tension.

This is where the magic happens. The heart of the slitting line is the slitter head, which houses two parallel arbors fitted with ultra-hard rotary knives. The precision of this setup is measured in microns. Getting it right requires a combination of advanced technology and the experienced hand of a skilled operator. It’s a process we have refined over many years at MFY to serve industries that demand perfection. The quality of the cut, especially the condition of the edge, directly impacts the performance and safety of the final product, whether it's a tiny electronic component or a structural part in a vehicle.

Tooling and Arbor Setup

The setup is everything. The knives, made from high-strength tool steel, must be perfectly ground and free of any nicks. The horizontal clearance between the top and bottom knives is precisely calculated based on the material's thickness and tensile strength. This clearance is what determines the quality of the edge and the amount of burr—the slight, sharp ridge left on the edge after cutting. Our technicians use computer-controlled systems to ensure this setup is flawless for every single job.

Recoiling and Separation

As the master coil is slit into narrower strips, they must be recoiled with uniform tension to prevent damage. We use separator arms[^3] to ensure the strips don't rub against each other, which could scratch the surface. The recoiling tension is just as important as the uncoiling tension. Inconsistent tension here can lead to loose or telescoped coils that are difficult and dangerous to handle in a customer's facility.

| Edge Type | Description | Common Application |

|---|---|---|

| Standard Slit Edge | A standard, sharp edge with minimal burr. | General manufacturing, further processing. |

| Deburred Edge | The burr is mechanically removed for safety. | Exposed parts, manual handling applications. |

| Skived Edge | A rounded, smooth edge. | Safety-critical parts, decorative trim. |

How to ensure quality control during and after slitting?

How can you be sure every slit coil meets your standards? Inconsistent quality can halt your production line. We implement rigorous QC at every stage to ensure total compliance.

Quality control involves continuous monitoring of width, camber, and burr using laser micrometers and visual inspections during the process. After slitting, we conduct final checks on dimensional accuracy, edge quality, and surface finish to guarantee the product meets all specifications.

For our clients, reliability is not a feature; it's a prerequisite. A shipment of out-of-spec material can bring a multi-million dollar production line to a grinding halt. That's why our quality control is not just a final step—it's a continuous process woven into every stage of the slitting operation. We believe in catching potential issues before they become problems. I recall a situation with an automotive client where our in-process laser scanner detected a width deviation of just a few microns on a single coil. We were able to stop the line, correct the setup, and isolate the small amount of affected material. That proactive measure saved our client what would have been days of downtime and significant costs.

In-Process Monitoring

Our slitting lines are equipped with modern technology to provide real-time feedback. Non-contact laser micrometers continuously measure the width of the slit strips as they exit the slitter head. Any deviation outside the set tolerance immediately alerts the operator. We also use high-speed cameras to monitor for surface defects and ensure the edge quality remains consistent throughout the entire run of the coil. This data-driven approach removes guesswork and ensures uniformity from the first meter to the last.

Final Product Verification

Once a coil is fully slit and recoiled, a sample is taken for final verification. Our QC technicians use calibrated instruments, including digital calipers and profilometers, to perform a full dimensional and surface analysis. They check the width, burr height, camber (the deviation from a straight line), and overall appearance against the customer's specifications. Only after a coil passes this final, rigorous inspection is it approved for packaging and shipment.

What are the post-slitting handling and packaging best practices?

A perfectly slit coil can be damaged by poor handling. This negates all the precision work. Our best practices in packaging protect your investment until it reaches your facility.

Best practices include using separators between slit coils to prevent contact and damage, securely strapping the coils to prevent unwinding, and using weather-resistant packaging like VCI paper and plastic wrap. Proper labeling ensures easy identification and inventory management.

The job isn't finished when the cutting stops. The final, and arguably one of the most critical, stages is ensuring that the perfectly slit coils arrive at our client's facility in the same pristine condition they left ours. This is where MFY’s expertise in global trade and logistics truly shines. We understand that these materials often travel thousands of miles by sea and land, facing temperature fluctuations and rough handling. Our packaging is designed not just to protect, but to fortify our clients' supply chains against disruption. It’s the final handshake, our promise that the quality we crafted is delivered intact.

Protecting Material Integrity

We never allow slit coils to have metal-to-metal contact. We use plastic or paperboard separators on the recoiler to create a gap between each strip. Once off the line, each coil is wrapped in VCI (Vapor Corrosion Inhibitor) paper, which actively prevents rust and corrosion, especially during long sea voyages. The coils are then securely strapped to a pallet, or "skid," often with protective eye-to-the-sky orientation to prevent coil collapse. The final layer is a heavy-duty plastic wrap that shields the product from moisture and dirt.

Logistical Efficiency

Proper packaging is also about making the material easy for our clients to receive, store, and use. Every coil and every pallet is clearly labeled with all the essential information: customer name, PO number, material grade, dimensions, weight, and a unique coil number. This detailed labeling allows for quick identification and seamless integration into a client's inventory management or just-in-time production system. It’s a simple step that saves valuable time and prevents costly mix-ups on the factory floor.

Conclusion

Precision slitting is more than just cutting steel; it's a strategic service that boosts manufacturing efficiency, reduces waste, and strengthens your supply chain. At MFY, we deliver this precision to help your business thrive in a competitive global market.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.