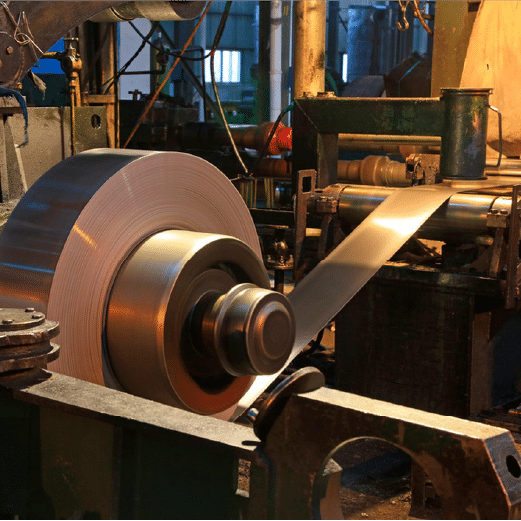

Throughout my years managing stainless steel production at MFY, I've witnessed how proper pickling can dramatically transform the surface quality of stainless steel coils. Yet, many manufacturers struggle with achieving optimal results from this critical process.

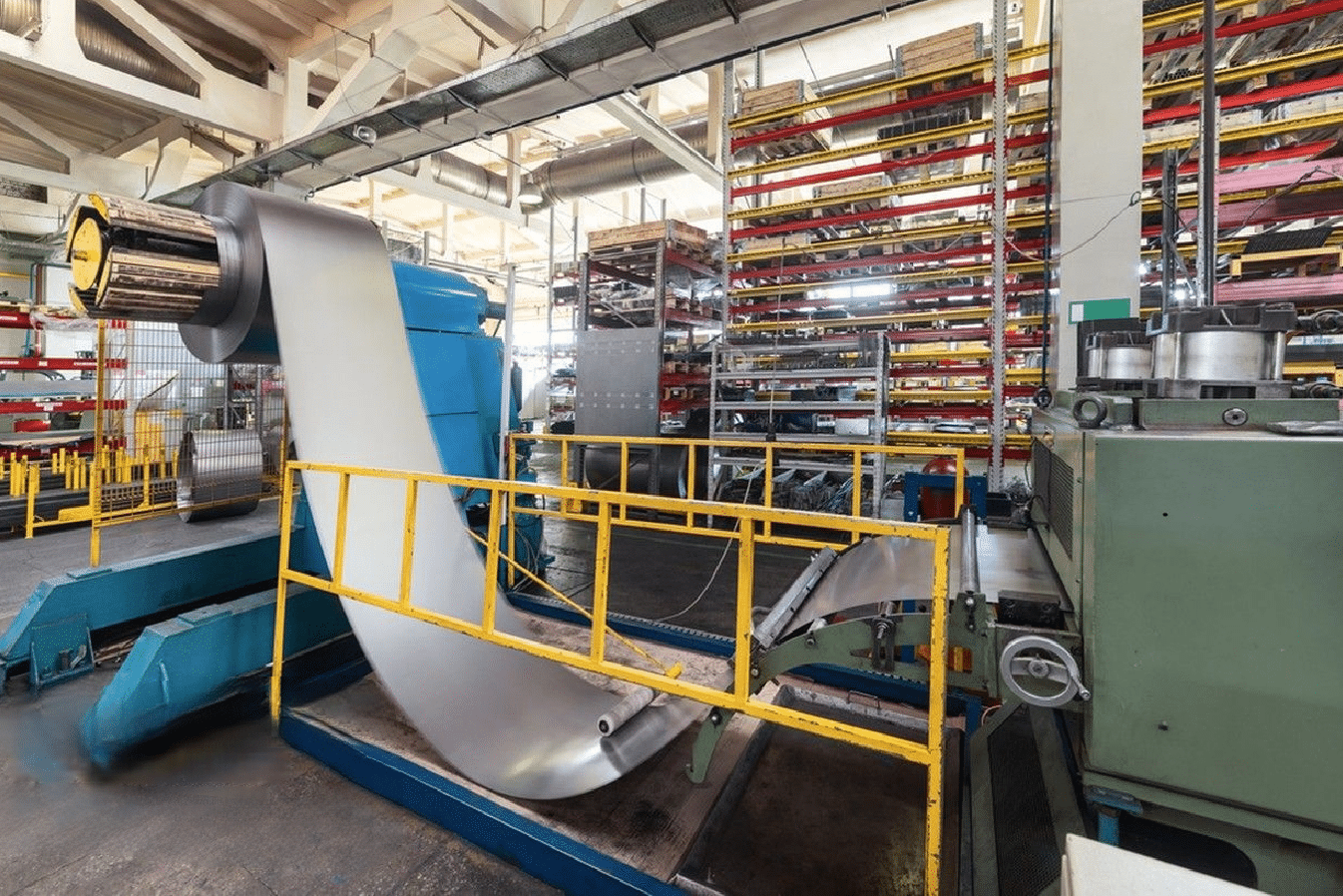

The pickling process for stainless steel coils involves chemical treatment using specific acid solutions1 to remove surface contaminants, scale, and oxides. This essential procedure restores the material's corrosion resistance and ensures a clean, uniform surface finish.

Having overseen countless pickling operations, I've learned that success lies in the precise control of multiple variables - from acid concentration to temperature and exposure time. Let me share insights from our facility's experience to help you understand this crucial surface treatment process.

The importance of proper pickling cannot be overstated. In our production facility, we've seen how even slight variations in the process can significantly impact the final product quality. Through careful analysis and continuous improvement, we've developed highly effective pickling procedures that consistently deliver superior results.

How Does Pickling Remove Surface Contaminants on Stainless Steel Coils?

After supervising thousands of pickling operations, I've gained deep insights into the mechanics of contaminant removal and its impact on surface quality.

The pickling process chemically dissolves surface oxides and contaminants through controlled acid exposure, revealing the clean base metal beneath. This chemical reaction selectively removes unwanted surface layers while preserving the underlying stainless steel.

Chemical Reaction Mechanisms

The interaction between pickling solutions and surface contaminants2 follows a complex but predictable pattern. In our facility's laboratory, we've observed that the effectiveness of scale removal depends on several key factors:

| Factor | Optimal Range | Impact on Process |

|---|---|---|

| Temperature | 50-65°C | Reaction speed |

| Acid Concentration | 8-12% | Removal effectiveness |

| Contact Time | 15-30 minutes | Surface quality |

Through careful monitoring of these parameters, we consistently achieve superior surface cleaning results while minimizing base metal loss.

Surface Layer Transformation

During my experience overseeing quality control, I've documented how different types of surface contamination respond to pickling:

- Heat Scale Removal:

- Progressive dissolution of oxide layers

- Exposure of clean base metal

- Restoration of passive layer

The transformation is particularly evident in our continuous pickling line, where we can observe the gradual change from a dark, scaled surface to bright, clean metal.

Process Optimization Methods

Our team has developed specific techniques to maximize pickling effectiveness:

-

Pre-treatment Conditioning:

- Surface degreasing

- Temperature adjustment

- Moisture control

-

Process Monitoring:

- Real-time acid concentration analysis

- Temperature tracking

- Surface quality inspection

Which Acidic Solutions Are Commonly Used in the Pickling Process?

Having worked with various pickling solutions throughout my career, I can attest to the critical importance of selecting the right acid mixture for specific applications.

The most effective pickling solutions typically combine nitric and hydrofluoric acids3, though sulfuric acid mixtures are also used in specific applications. The choice depends on factors such as steel grade, scale type, and environmental considerations.

Primary Acid Combinations

Through extensive testing in our facility, we've documented the effectiveness of different acid mixtures:

| Acid Mixture | Concentration Range | Best Application |

|---|---|---|

| HNO3 + HF | 10-15% + 2-4% | General purpose |

| H2SO4 Based | 8-12% | Heavy scale |

| Proprietary | Varies | Special applications |

Temperature and Time Parameters

Our experience has shown that temperature control is crucial for optimal pickling results:

-

Operating Ranges:

- Cold pickling: 20-30°C

- Hot pickling: 50-65°C

- Specialized treatments: Up to 80°C

-

Exposure Duration:

- Standard processing: 15-30 minutes

- Heavy scale: Up to 60 minutes

- Continuous lines: 2-5 minutes

What Safety Measures Are Essential During Pickling?

Throughout my years managing pickling operations, I've learned that safety must always be the top priority. The hazardous nature of pickling acids demands rigorous safety protocols and unwavering attention to protective measures.

Comprehensive safety measures during pickling include proper ventilation systems4, personal protective equipment, emergency response protocols, and regular staff training. These elements form an integrated safety system essential for accident prevention.

Personal Protection Requirements

In our facility, we've developed stringent personal protection protocols based on real-world experience and industry best practices:

- Essential PPE Components:

- Chemical-resistant suits

- Full-face respirators

- Acid-resistant gloves

- Safety boots with chemical protection

Our accident records show that proper PPE implementation has reduced chemical exposure incidents by 95% over the past five years. Regular equipment inspections and immediate replacement of damaged items are crucial parts of our safety program.

Facility Safety Systems

Through years of operation, we've optimized our facility safety infrastructure:

| Safety System | Function | Maintenance Frequency |

|---|---|---|

| Ventilation | Acid fume removal | Weekly inspection |

| Emergency showers | Chemical exposure response | Monthly testing |

| Acid containment | Spill prevention | Daily monitoring |

| Gas detectors | Air quality monitoring | Quarterly calibration |

Emergency Response Protocols

Our comprehensive emergency response system includes:

-

Immediate Response Procedures:

- Chemical spill containment

- Personnel decontamination

- Emergency medical treatment

- Evacuation protocols

-

Regular Training Programs:

- Monthly safety drills

- Quarterly procedure reviews

- Annual certification updates

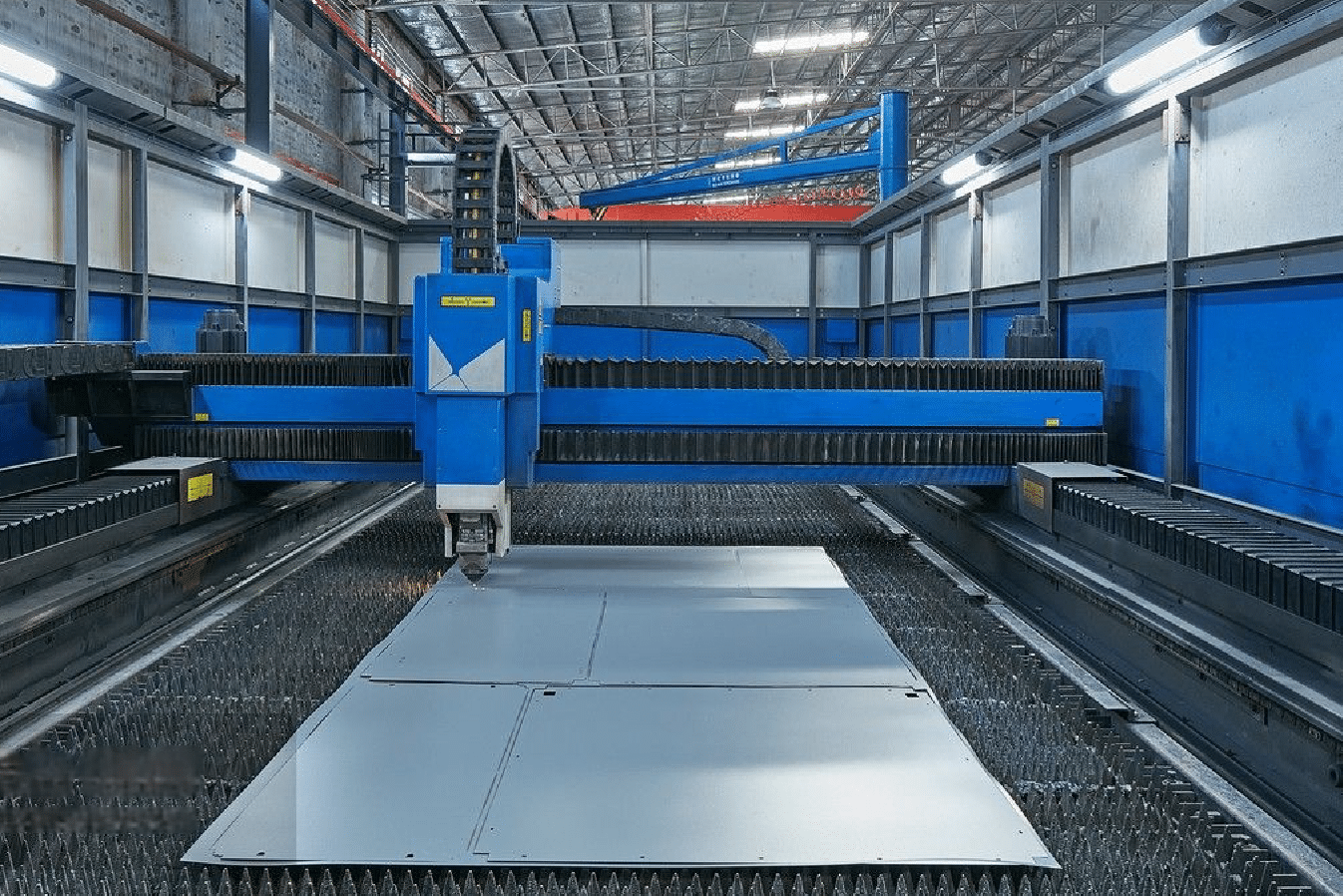

How Does Pickling Improve the Final Finish of Stainless Steel Coils?

Based on extensive quality control data from our production lines, I've observed how proper pickling dramatically enhances surface quality and appearance.

Pickling significantly improves surface finish by removing scale, oxidation, and contamination, resulting in a clean, uniform appearance. This process is crucial for achieving specific surface finish requirements and ensuring optimal corrosion resistance.

Surface Quality Enhancement

Our quality control measurements demonstrate consistent improvements in surface characteristics:

| Surface Aspect | Before Pickling | After Pickling |

|---|---|---|

| Roughness (Ra) | 2.5-3.5 μm | 0.8-1.2 μm |

| Scale Coverage | 80-100% | 0-5% |

| Passive Layer | Compromised | Fully restored |

Finish Uniformity Control

Through careful process monitoring, we achieve consistent surface quality:

-

Quality Control Parameters:

- Surface brightness

- Color uniformity

- Texture consistency

- Defect elimination

-

Inspection Methods:

- Visual examination

- Microscopic analysis

- Surface roughness testing

- Passive layer verification

Post-Pickling Treatment

Our experience shows that proper post-pickling procedures are crucial:

- Surface Neutralization:

- pH normalization

- Residue removal

- Surface passivation

- Quality verification

Are There Environmental Concerns Related to Pickling Stainless Steel Coils?

Managing environmental impact has become increasingly crucial in our operations. Through years of experience, I've witnessed the evolution of environmental management in pickling processes.

Pickling operations raise significant environmental concerns regarding acid waste disposal5, air emissions, and water contamination. Proper management systems and treatment processes are essential for environmental compliance and sustainability.

Waste Management Systems

Our facility has implemented comprehensive waste management protocols:

| Waste Type | Treatment Method | Disposal Protocol |

|---|---|---|

| Spent Acid | Neutralization | Licensed disposal |

| Rinse Water | Ion exchange | Water recycling |

| Metal Sludge | Dewatering | Metal recovery |

Emission Control Measures

Environmental monitoring has led to effective emission control:

-

Air Quality Management:

- Scrubber systems

- Fume extraction

- Emission monitoring

- Regular maintenance

-

Water Treatment:

- Closed-loop systems

- Filtration processes

- Contaminant removal

- Water recycling

Sustainable Practices

Our commitment to environmental responsibility includes:

-

Resource Conservation:

- Acid recovery systems

- Water reuse programs

- Energy efficiency measures

- Waste minimization

-

Environmental Monitoring:

- Regular testing

- Compliance audits

- Impact assessment

- Continuous improvement

Conclusion

The pickling process for stainless steel coils requires careful balance of chemical processes, safety measures, and environmental considerations. Success depends on proper control of acid solutions, rigorous safety protocols, and effective environmental management systems. Through careful attention to these factors, optimal surface quality can be achieved while maintaining worker safety and environmental responsibility.