Stainless steel sheets can be a source of confusion regarding their magnetic properties. Understanding this can help in selecting the right materials for your projects.

Snippet paragraph: The magnetic properties of stainless steel sheets depend on their composition and structure. While some grades are magnetic, others, like 304 stainless steel1, are not. This article explores the factors influencing magnetism in stainless steel.

Transition paragraph: As a manufacturer, I often encounter questions about the magnetic properties of stainless steel sheets. This understanding is crucial for applications in various industries, from construction to manufacturing. In this article, I will delve into the factors that determine whether stainless steel sheets exhibit magnetism, providing insights that can help you make informed decisions for your projects.

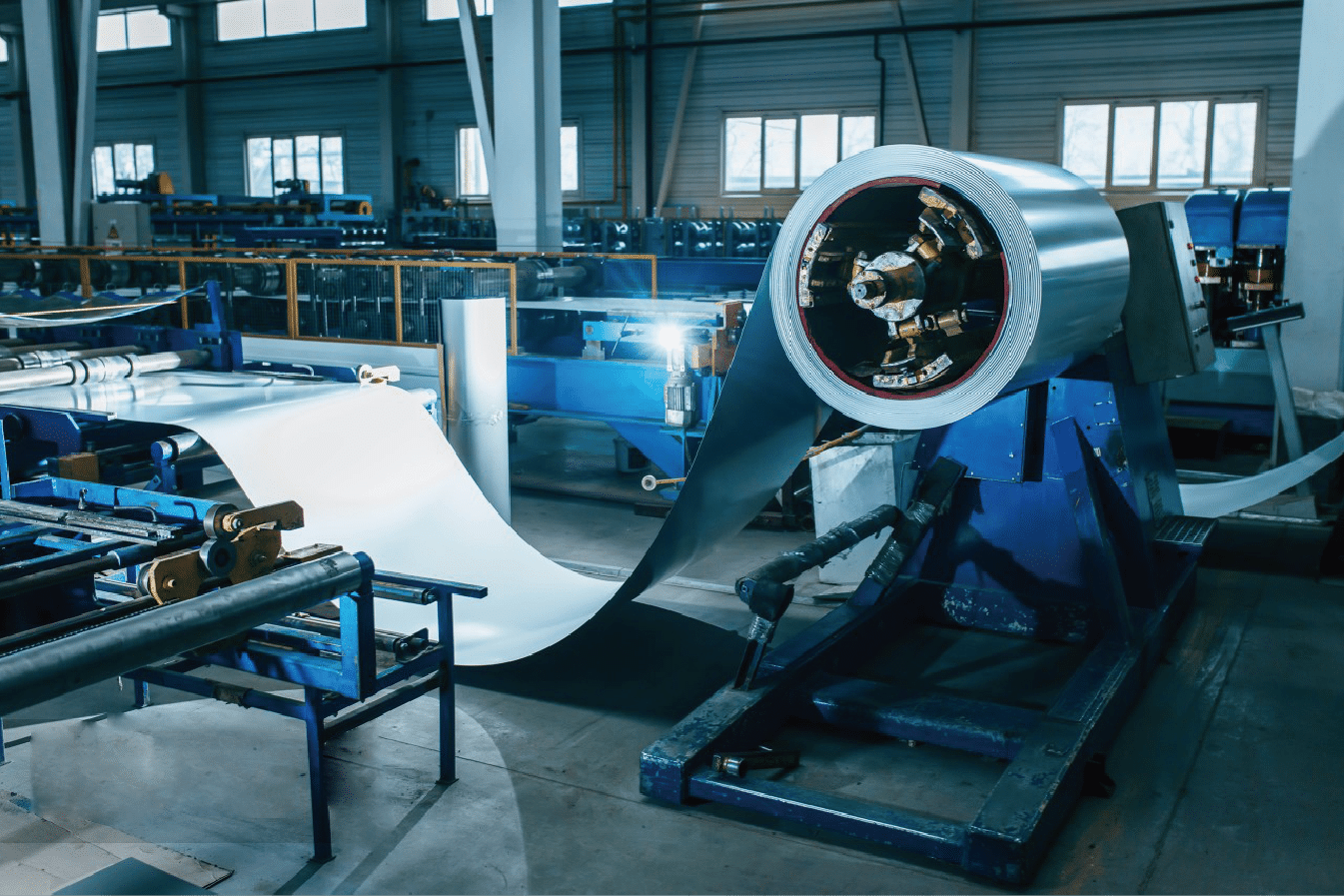

Dive-Deeper paragraph: The magnetism of stainless steel is primarily influenced by its composition and crystal structure. Stainless steel is an alloy primarily made of iron, chromium, and nickel. The presence of these elements can significantly affect its magnetic properties. For instance, austenitic stainless steels, such as 304, are generally non-magnetic due to their face-centered cubic (FCC) structure, which does not allow for magnetic ordering. In contrast, ferritic stainless steels, like 430 stainless steel2, have a body-centered cubic (BCC) structure, which can exhibit magnetic properties. Understanding these differences is essential for industries that require specific material characteristics, such as automotive and aerospace sectors.

Which Grades of Stainless Steel Sheets Exhibit Magnetic Properties?

Stainless steel grades vary widely in their magnetic properties, which can be a critical factor in material selection. Ferritic stainless steels, such as 430 and 446, are known for their magnetic characteristics due to their high iron content and BCC structure. These grades are often used in applications where magnetism is beneficial, such as in magnetic sensors or components that require magnetic attraction.

Snippet paragraph: Ferritic stainless steels, like 430, exhibit magnetic properties due to their crystal structure and composition. In contrast, austenitic grades, such as 304 stainless steel3, are typically non-magnetic, making them suitable for applications where magnetism is undesirable.

Transition paragraph: Understanding the differences in magnetic properties among stainless steel grades is crucial for manufacturers and engineers. For example, when selecting materials for a project, knowing whether a grade is magnetic can influence design choices and functionality. In my experience, clients often overlook these details, leading to challenges in their applications. By exploring the grades that exhibit magnetism, we can better understand how to choose the right materials for specific needs.

Dive-Deeper paragraph: The magnetic properties of stainless steel sheets are primarily determined by their microstructure and alloying elements. Ferritic stainless steels, which contain higher levels of chromium and lower levels of nickel, tend to be magnetic. For instance, grade 430 stainless steel4 is commonly used in kitchen appliances and automotive applications due to its magnetic properties, which allow for easy attachment to magnetic fixtures.

The Role of Crystal Structure in Magnetism

The crystal structure of stainless steel plays a significant role in its magnetic behavior. Ferritic stainless steels have a BCC structure, which allows for the alignment of magnetic domains, resulting in magnetism. In contrast, austenitic stainless steels, such as 304 stainless steel5, have an FCC structure that does not support magnetic ordering. This fundamental difference explains why 304 is often chosen for applications requiring non-magnetic materials, such as in medical devices or food processing equipment.

The Impact of Manufacturing Processes

Manufacturing processes can also influence the magnetic characteristics of stainless steel sheets. For example, cold working can induce some magnetism in austenitic grades, which are typically non-magnetic in their annealed state. This phenomenon occurs due to the deformation of the crystal structure, leading to the alignment of magnetic domains. Understanding how different manufacturing techniques affect magnetism is essential for ensuring the desired properties in the final product.

Case Study: 430 vs. 304 Stainless Steel

In my experience working with clients, the choice between 430 and 304 stainless steel often comes down to their specific application needs. For instance, a client in the automotive industry required a material that could withstand magnetic forces for a component. We opted for 430 stainless steel due to its magnetic properties, which provided the necessary functionality. Conversely, another client in the food processing sector preferred 304 stainless steel for its non-magnetic nature, ensuring no interference with sensitive equipment. These real-world applications highlight the importance of understanding the magnetic properties of stainless steel grades.

Ferritic steels are magneticTrue

Ferritic stainless steels, such as 430, exhibit magnetic properties due to their iron content and BCC structure.

Austenitic steels are magneticFalse

Austenitic grades, like 304, are typically non-magnetic and used where magnetism is undesirable.

How Does Crystal Structure Impact Magnetism in Stainless Steel?

The relationship between crystal structure and magnetism in stainless steel is a fascinating aspect that directly impacts material selection and performance. Having worked with numerous manufacturers, I've observed how understanding this relationship can prevent costly mistakes in material specification.

Snippet paragraph: Crystal structure determines magnetic properties in stainless steel through atomic arrangement patterns. Body-centered cubic (BCC) structures promote magnetism, while face-centered cubic (FCC) structures typically resist magnetic properties.

Transition paragraph: Throughout my years in stainless steel manufacturing, I've witnessed countless examples where crystal structure knowledge has proven crucial for project success. Recently, I worked with a manufacturing client who needed to ensure their production line equipment wouldn't interfere with sensitive magnetic sensors. Understanding crystal structure helped us select the perfect grade for their application.

Atomic Arrangement and Magnetic Properties

The crystal structure of stainless steel fundamentally determines its magnetic behavior through the arrangement of atoms within the material. In my experience working with various grades, I've observed how this microscopic arrangement creates macroscopic effects that impact real-world applications.

For example, when working with a client in the medical equipment industry, we needed to ensure absolute non-magnetic properties for MRI-compatible equipment. The FCC structure of grade 316L stainless steel6 provided the perfect solution, as its atomic arrangement naturally resists magnetic ordering. This arrangement creates a stable, non-magnetic environment essential for sensitive medical applications.

Phase Transformations and Their Effects

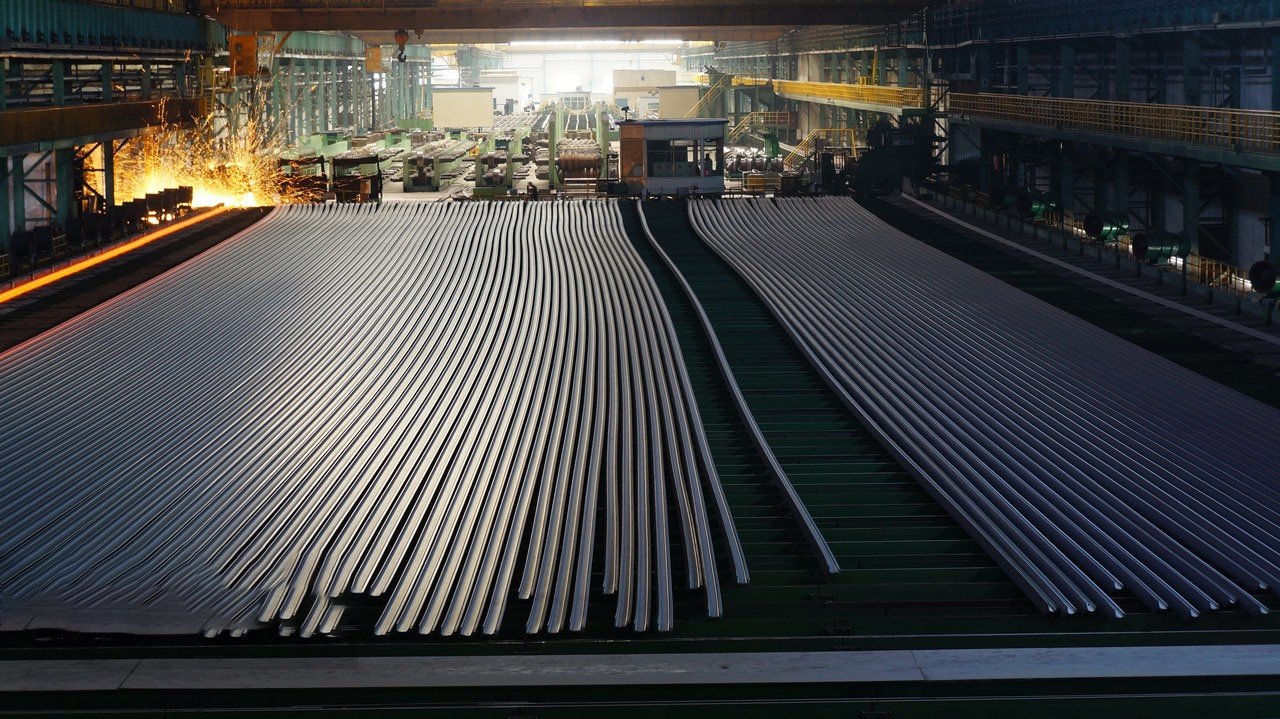

Phase transformations can significantly alter the magnetic properties of stainless steel. During manufacturing processes, temperature changes and mechanical stress can trigger these transformations, leading to unexpected magnetic behavior.

| Crystal Structure | Common Grades | Magnetic Properties | Typical Applications |

|---|---|---|---|

| BCC (Ferritic) | 430, 446 | Strongly Magnetic | Kitchen appliances, Automotive parts |

| FCC (Austenitic) | 304, 316L | Non-magnetic | Medical equipment, Food processing |

| BCT (Martensitic) | 410, 420 | Magnetic | Cutlery, Surgical instruments |

Impact of Alloying Elements on Crystal Structure

The addition of specific alloying elements can stabilize certain crystal structures, thereby influencing magnetic properties. Through extensive testing in our facilities, we've documented how elements like nickel promote the formation of austenitic structures, while chromium tends to stabilize ferritic structures. This knowledge has proven invaluable when developing custom solutions for clients with specific magnetic requirements.

BCC structures promote magnetismTrue

Body-centered cubic (BCC) structures in stainless steel promote magnetic properties.

FCC structures are magneticFalse

Face-centered cubic (FCC) structures, like those in 304 and 316L, resist magnetic properties.

Do Manufacturing Processes Affect Magnetic Characteristics?

In my 15 years of experience in stainless steel manufacturing, I've observed how various processing methods can significantly alter the magnetic properties of stainless steel sheets. This understanding has helped us optimize our production processes to meet specific client requirements.

Snippet paragraph: Manufacturing processes like cold working, heat treatment, and welding can significantly alter the magnetic properties of stainless steel by changing its crystal structure and internal stress distribution.

Transition paragraph: The relationship between manufacturing processes and magnetic properties is complex and often misunderstood. Through countless production cycles and client consultations, I've gathered valuable insights into how different manufacturing techniques can either enhance or reduce magnetic properties in stainless steel sheets. This knowledge has proven invaluable in helping clients achieve their desired material characteristics.

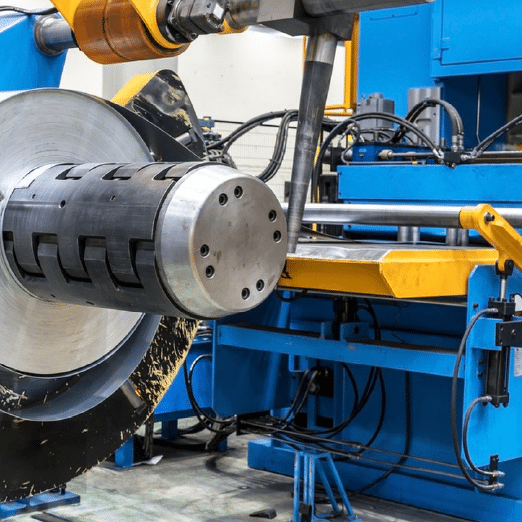

Cold Working Effects on Magnetism

Cold working can induce significant changes in the magnetic properties of stainless steel. Through our extensive testing and quality control processes, we've documented how various degrees of cold working affect different grades. For instance, when working with 304 stainless steel7, we've observed that severe cold working can induce partial transformation to martensite, creating magnetic properties in traditionally non-magnetic material.

In a recent project with an automotive components manufacturer, we carefully controlled the cold working process to maintain specific magnetic properties required for their sensor housings. This involved precise monitoring of deformation rates and regular testing to ensure consistency.

Heat Treatment Impact

Heat treatment processes play a crucial role in determining the final magnetic properties of stainless steel sheets. Through careful temperature control and cooling rates, we can manipulate the crystal structure to achieve desired magnetic characteristics.

| Process Type | Effect on Magnetism | Application Example |

|---|---|---|

| Annealing | Reduces magnetism | Medical equipment |

| Cold Working | Can increase magnetism | Automotive parts |

| Welding | Local magnetic changes | Construction joints |

Surface Finishing and Magnetic Properties

The surface finishing process can also affect magnetic properties, particularly in thin sheets. Our quality control data shows that certain finishing methods can create surface stress that influences magnetic behavior. This knowledge has been particularly valuable when working with clients in the electronics industry, where surface properties are critical.

Cold working increases magnetismTrue

Cold working can induce magnetic properties by altering the crystal structure of stainless steel.

Annealing increases magnetismFalse

Annealing typically reduces magnetism by relieving internal stresses and stabilizing crystal structures.

Why Does 430 Stainless Steel Sheet Show Magnetism While 304 May Not?

Understanding why certain stainless steel grades exhibit magnetism while others do not is essential for making informed material choices. My experience in the industry has shown that this knowledge can significantly impact project outcomes.

Snippet paragraph: The difference in magnetic properties between 430 and 304 stainless steel8 sheets stems from their crystal structures and alloy compositions. While 430 is ferritic and magnetic, 304 is austenitic and typically non-magnetic.

Transition paragraph: In my work with various clients, I've often encountered confusion regarding the magnetic properties of different stainless steel grades. For instance, a client once asked why they should choose 430 over 304 for a project requiring magnetic properties. By explaining the underlying reasons for these differences, I was able to guide them toward the best material choice for their specific application.

The Role of Alloy Composition

The alloy composition of stainless steel plays a crucial role in determining its magnetic properties. Ferritic stainless steels, such as 430, contain higher levels of chromium and lower levels of nickel, which contribute to their magnetic characteristics. In contrast, austenitic grades like 304 have a higher nickel content, which stabilizes the FCC structure and inhibits magnetic ordering.

In a recent project, a client in the construction industry required materials that could withstand magnetic forces for structural components. We recommended 430 stainless steel due to its magnetic properties, which provided the necessary functionality for their application.

Crystal Structure and Magnetism

The crystal structure of stainless steel is another critical factor influencing its magnetic behavior. Ferritic stainless steels have a BCC structure that allows for the alignment of magnetic domains, resulting in magnetism. On the other hand, austenitic stainless steels, such as 304, have an FCC structure that does not support magnetic ordering, making them non-magnetic.

This distinction is vital for industries that require specific material characteristics. For example, in the medical field, non-magnetic materials are essential for MRI-compatible equipment. Understanding these differences can help manufacturers select the right materials for their applications.

Practical Applications and Considerations

When selecting between 430 and 304 stainless steel, it's essential to consider the specific requirements of your application. For instance, if magnetic properties are necessary for a project, 430 stainless steel is the better choice. However, if non-magnetic properties are required, 304 stainless steel is the preferred option.

In my experience, clients often overlook these details, leading to challenges in their applications. By understanding the differences between these grades, manufacturers can make informed decisions that enhance their project outcomes.

430 is ferritic and magneticTrue

Grade 430 stainless steel is ferritic and exhibits magnetic properties due to its BCC structure.

304 is ferritic and magneticFalse

Grade 304 stainless steel is austenitic and typically non-magnetic due to its FCC structure.

How to Test for Magnetism in Stainless Steel Sheets?

Testing for magnetism in stainless steel sheets is a straightforward process that can provide valuable insights into material properties. My experience in the industry has shown that understanding how to conduct these tests can help ensure the right material is selected for specific applications.

Snippet paragraph: Testing for magnetism in stainless steel sheets can be done using simple methods such as a magnet test or more advanced techniques like magnetic permeability measurements. These tests help determine the magnetic properties of the material.

Transition paragraph: Throughout my career, I've encountered various methods for testing the magnetic properties of stainless steel. Recently, a client asked how to verify the magnetism of a batch of stainless steel sheets before using them in their production line. By sharing effective testing methods, I was able to help them ensure they were using the right materials for their application.

Simple Magnet Test

One of the easiest ways to test for magnetism in stainless steel sheets is to use a standard magnet. This method involves bringing a magnet close to the surface of the stainless steel sheet and observing whether it is attracted. If the magnet sticks, the material is likely magnetic, indicating it may be a ferritic grade like 430. If there is no attraction, the material is likely austenitic, such as 304.

In my experience, this simple test can quickly help manufacturers determine the magnetic properties of their materials. However, it is essential to note that this method may not provide a complete picture of the material's magnetic characteristics.

Magnetic Permeability Measurements

For more precise testing, magnetic permeability measurements can be conducted using specialized equipment. This method involves measuring how easily a magnetic field can pass through the material, providing a quantitative assessment of its magnetic properties.

| Test Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| Magnet Test | Simple attraction test | Quick and easy | Limited accuracy |

| Magnetic Permeability | Measures field penetration | Accurate and quantitative | Requires specialized equipment |

Importance of Testing in Material Selection

Testing for magnetism is crucial for ensuring that the selected stainless steel sheets meet the specific requirements of a project. For example, in the automotive industry, components may need to exhibit certain magnetic properties for functionality. By conducting tests, manufacturers can avoid costly mistakes and ensure they are using the right materials for their applications.

In my experience, clients who invest time in testing their materials often achieve better project outcomes. By understanding the magnetic properties of stainless steel sheets, manufacturers can make informed decisions that enhance their production processes.

Simple magnet test is effectiveTrue

Using a standard magnet to test for attraction can quickly determine if a stainless steel sheet is magnetic.

Magnetic permeability is uselessFalse

Magnetic permeability measurements provide accurate, quantitative data on the magnetic properties of stainless steel.

Conclusion

In conclusion, understanding the magnetic properties of stainless steel sheets is essential for making informed material choices. The differences between grades like 430 and 304 stem from their composition and structure, influencing their applications across various industries.

-

Learn why 304 stainless steel is preferred for non-magnetic applications. ↩

-

Discover the reasons behind the magnetic properties of 430 stainless steel. ↩

-

Understand the differences in magnetism between 430 and 304 stainless steel. ↩

-

Explore common uses of 430 stainless steel in industries requiring magnetic materials. ↩

-

Learn how the FCC structure affects the magnetic properties of 304 stainless steel. ↩

-

Understand why 316L stainless steel is chosen for non-magnetic medical equipment. ↩

-

Find out how cold working can change the magnetic properties of 304 stainless steel. ↩

-

Get a detailed comparison of the magnetic properties of 430 and 304 stainless steel. ↩