India/SE Asia Contractor's Guide to Stainless Steel Grades & Applications

Struggling with steel selection in the demanding climates of India or Southeast Asia? The wrong choice can inflate costs and compromise long-term durability. We provide the expert guidance you need.

Mastering stainless steel involves understanding the specific properties of common grades like 304 and 316, aligning them with regional climatic demands (coastal vs. inland), and leveraging expert supply chain partners to navigate complex specifications for optimal cost-performance and project longevity.

As the Global Business Director at MFY, I've worked directly with contractors across these vibrant markets. The rapid urbanization means projects are bigger, faster, and more ambitious than ever. But it also means the stakes for material selection are higher. Choosing the right stainless steel isn't just a technical detail; it's a strategic decision that impacts your budget, reputation, and the ultimate success of your project. Let's dive into the specifics to give you a clear advantage.

What are the common stainless steel grades used in India's construction industry?

Choosing the wrong grade in India's diverse climate is a costly risk. This can lead to premature corrosion and budget overruns. Let's clarify the most reliable and common options.

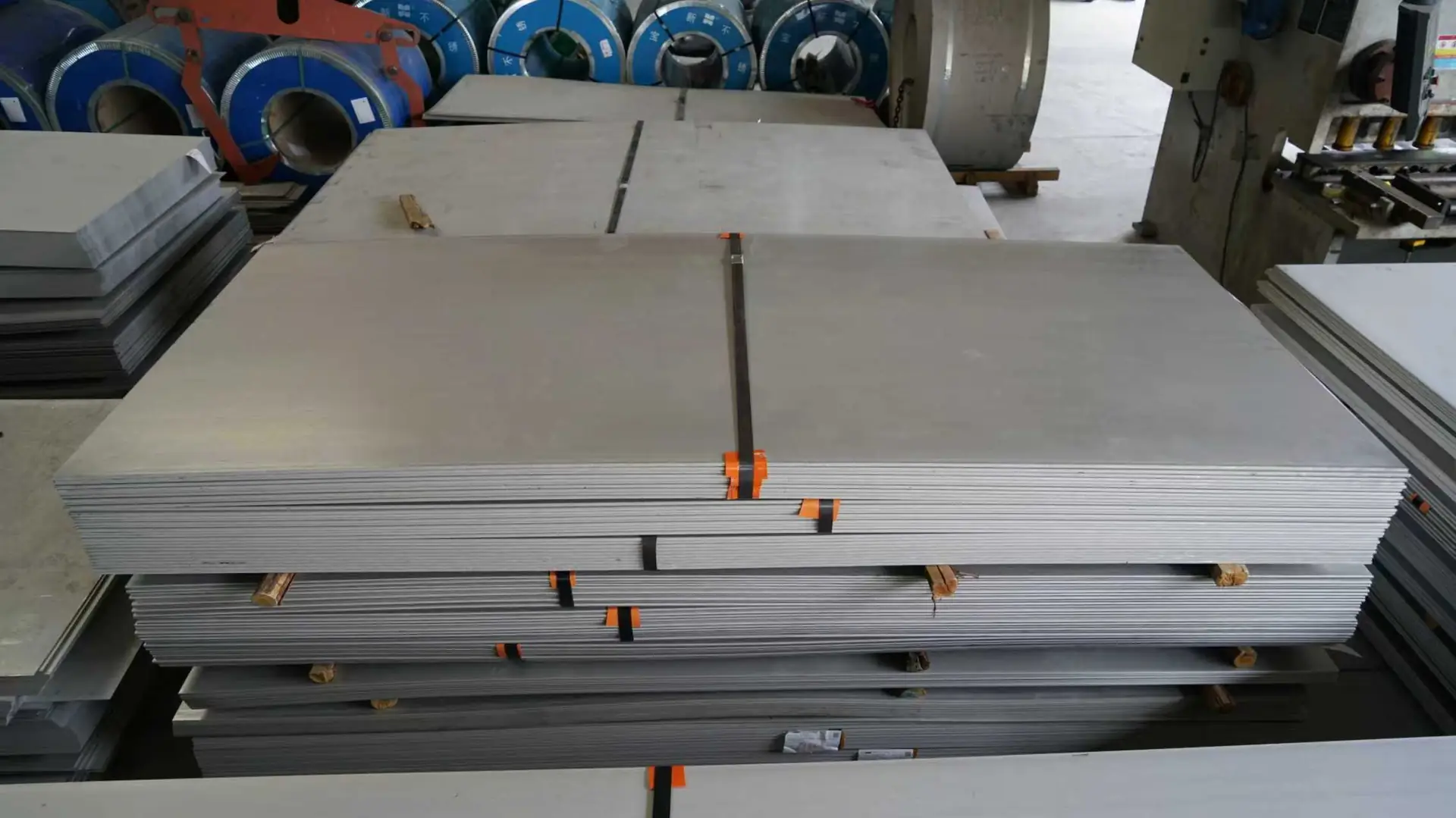

The most common grades are Austenitic 304 and 316. Grade 304 is a versatile, cost-effective choice for general structural and decorative applications, while 316 is essential for coastal and high-pollution areas due to its superior corrosion resistance.

In my experience, the conversation with Indian contractors almost always starts with a comparison between Grade 304 and Grade 316. This isn't surprising, as these two grades cover the vast majority of construction needs, but understanding their nuances is critical, especially given the country's vast and varied geography. From the humid, saline air of Mumbai to the dry heat of Delhi, the environmental demands change dramatically.

The Workhorse: Grade 304

Grade 304 is the go-to for a reason. It offers an excellent balance of corrosion resistance, formability, and cost. It's perfect for indoor applications like kitchen equipment, railings, and decorative panels. For exterior use, it performs well in low-pollution, non-coastal environments. However, I always caution clients against specifying 304 for projects near the sea. I remember a case with a developer in Chennai who used 304 for exterior balustrades to save on initial costs. Within two years, they were dealing with significant tea staining and rust, leading to expensive replacement work that far outweighed the initial savings.

The Coastal Protector: Grade 316

This is where Grade 316, with its added molybdenum content, becomes indispensable. That small addition provides a significant boost in resistance to chlorides, which are prevalent in coastal air and de-icing salts. For any project within 50 kilometers of the coastline, or in heavily industrialized zones with high pollution, we at MFY strongly recommend 316. It's the standard for facades, structural supports, and outdoor fixtures in cities like Mumbai, Kolkata, and Kochi. The slightly higher upfront cost is an investment in longevity and drastically reduced maintenance over the project's lifecycle.

| Grade | Key Elements | Primary Use Case in India | Cost Factor |

|---|---|---|---|

| 304 | 18% Cr, 8% Ni | Indoor fixtures, railings, non-coastal exteriors | Standard |

| 316 | 16% Cr, 10% Ni, 2% Mo | Coastal facades, marine hardware, polluted areas | Higher |

| 201 | 16% Cr, 3.5% Ni, 5.5% Mn | Low-cost indoor decorative, low-corrosion areas | Lower |

How is stainless steel being applied in Southeast Asia's building projects?

SE Asia's rapid growth demands modern materials. Using outdated options can limit design and durability. Stainless steel offers innovative, long-lasting solutions for this dynamic market.

In Southeast Asia, stainless steel is applied extensively in high-rise facades, structural components, roofing, and interior fixtures. Its use is driven by demand for durability in humid, tropical climates and for creating modern, sustainable architectural designs.

The architectural landscape in Southeast Asia is breathtaking. From Kuala Lumpur to Ho Chi Minh City, skylines are being transformed by ambitious designs that push the boundaries of engineering. Stainless steel is a key enabler of this transformation. The region's hot and humid climate is incredibly corrosive, making material resilience a top priority for developers and contractors. This is where stainless steel's inherent durability provides immense value, ensuring that these iconic buildings not only look stunning on day one but continue to perform for decades with minimal maintenance.

Architectural Statements: Facades and Cladding

One of the most visible applications is in building exteriors. Stainless steel cladding and curtain wall systems are popular because they offer a sleek, modern aesthetic while providing exceptional resistance to the elements. I've worked on projects in Singapore where Grade 316 with a specific surface finish was specified to combat both the saline coastal air and urban pollution. The material's strength-to-weight ratio also allows for more intricate and lightweight designs, which is a major advantage for architects.

Functional Durability: Structural and Interior Use

Beyond the facade, stainless steel is a workhorse inside and out. It's used for structural applications like reinforcement bars (rebar) in critical infrastructure, especially bridges and marine structures, where corrosion can compromise safety. We are seeing a significant uptick in demand for stainless steel rebar in coastal infrastructure projects across Vietnam and Indonesia. Internally, its hygienic properties and ease of cleaning make it the standard for handrails, elevators, and public area fittings in airports, malls, and hospitals. Its longevity ensures that high-traffic areas remain safe, functional, and aesthetically pleasing for years. This focus on lifecycle performance is a smart, sustainable approach that defines the region's best construction projects.

What challenges do contractors face when selecting stainless steel grades?

Material selection can feel like a minefield. One wrong step leads to project delays and unforeseen expenses. Understanding these common challenges is the first step to avoiding them.

Contractors face challenges balancing initial material cost against long-term performance, navigating complex technical specifications and standards, and ensuring consistent quality from suppliers. Misinformation about grade properties often leads to costly errors.

Every day, my team and I speak with contractors who are navigating a complex set of pressures. The root cause of most selection errors isn't a lack of diligence, but rather a difficult balancing act between tight budgets, aggressive timelines, and demanding technical requirements. The market is flooded with options and information—not all of it accurate—which can make a seemingly simple choice incredibly difficult. This is the core challenge we help our partners solve.

The Cost vs. Lifecycle Value Dilemma

The most immediate pressure is almost always the upfront cost. It's tempting to select a lower-cost grade, like a 200-series stainless steel, when the budget is tight. However, this often proves to be a classic case of "penny wise, pound foolish." I recall a contractor in Thailand who opted for a cheaper grade for a coastal resort's outdoor showers and fixtures. Within 18 months, severe corrosion had set in, forcing a complete and costly replacement. The initial savings were wiped out many times over by the repair costs and operational disruption. This highlights the critical need to evaluate materials based on their total lifecycle cost, not just the purchase price.

Navigating the Maze of Standards

Contractors must also deal with a complex web of international and local standards (ASTM, EN, JIS, etc.). Understanding which standard applies and ensuring a supplier's material genuinely conforms to it can be daunting. Without a reliable partner, you risk receiving material that doesn't meet the project's engineering specifications, leading to potential rejection on-site, project delays, and contractual penalties.

| Challenge | Immediate Impact | Long-Term Consequence |

|---|---|---|

| Cost Pressure | Temptation to use cheaper, non-compliant grades. | High maintenance, early failure, replacement costs. |

| Complex Standards | Confusion over specifications, risk of non-compliance. | Project delays, material rejection, structural risks. |

| Inconsistent Quality | Variation in material composition and finish. | Poor performance, aesthetic flaws, reputational damage. |

What strategies can contractors use to overcome material selection challenges?

Don't let material uncertainty derail your project. Guesswork leads to financial risk and potential failure. A strategic approach ensures you make the right choice every time.

Contractors can overcome challenges by focusing on Total Cost of Ownership (TCO) instead of just upfront price, partnering with technically proficient suppliers like MFY, and demanding clear Material Test Certificates (MTCs) to verify grade and quality.

Overcoming these challenges isn't about becoming a metallurgist overnight. It's about adopting a smarter, more strategic procurement process. The most successful contractors I work with have shifted their mindset from simply buying a commodity to making a long-term investment. They build resilience into their projects by building it into their supply chain first. At MFY, our goal is to be more than a supplier; we aim to be a strategic partner who provides the technical expertise and supply chain reliability our clients need to succeed.

Adopt a Total Cost of Ownership (TCO) Mindset

The first and most critical strategy is to shift the financial focus from the initial purchase price to the Total Cost of Ownership. TCO includes the upfront cost, installation, maintenance, and potential replacement costs over the asset's entire life. When you analyze it this way, specifying a slightly more expensive but far more durable grade like 316 for a coastal application becomes the obvious financial choice. We provide our clients with data-driven recommendations that model this out, making it easy to justify the right material choice to project stakeholders.

Forge Strategic Supplier Partnerships

You cannot navigate this complex landscape alone. A reliable, technically competent supplier is your greatest asset. A true partner does more than just provide a quote; they ask about the application, the environment, and the project's long-term goals. They can then recommend the most appropriate and cost-effective grade. This collaborative approach de-risks the procurement process and ensures you get the right material for the job, backed by expert advice.

Demand Transparency and Verification

Finally, always insist on complete and verifiable documentation. A Material Test Certificate (MTC) or Mill Test Report (MTR) is non-negotiable. This document provides the chemical composition and mechanical properties of the exact batch of steel you are buying, proving that it meets the required standards. Any reputable supplier will provide this without hesitation. It is your ultimate guarantee of quality and compliance.

What technical advice is available for optimizing stainless steel use in construction?

Even the right material can fail if used incorrectly. Improper fabrication or maintenance undermines your investment. Let's cover key technical points for optimal performance.

Key technical advice includes selecting the appropriate surface finish for the environment (e.g., 2B vs. No. 4), ensuring proper welding techniques to maintain corrosion resistance, and implementing a regular cleaning schedule to prevent contamination.

Getting the grade right is half the battle. The other half is ensuring the material is handled, fabricated, and maintained correctly. A few key technical considerations can make the difference between a stainless steel installation that lasts a lifetime and one that disappoints. We always provide post-sale technical support to our clients to ensure they maximize the value of their investment.

Choosing the Right Surface Finish

The finish of the stainless steel is not just about aesthetics; it plays a crucial role in corrosion resistance. Smoother, less porous finishes are easier to clean and less likely to trap corrosive particles. For exterior applications in coastal or industrial areas, a smoother finish is generally better.

| Finish | Description | Common Application |

|---|---|---|

| No. 2B | Smooth, moderately reflective cold-rolled finish. | General purpose, non-decorative structural parts. |

| No. 4 | Brushed finish with visible parallel polishing lines. | Decorative panels, elevators, kitchen equipment. |

| No. 8 | Highly reflective, mirror-like finish. | High-end architectural features, column covers. |

Best Practices in Fabrication and Welding

During fabrication, it's critical to avoid cross-contamination[^1] with carbon steel. Using tools that have been used on regular steel can embed iron particles into the stainless surface, leading to rust spots. Welding also requires specific techniques and filler materials to preserve the integrity of the protective chromium oxide layer. Post-weld cleaning and passivation[^2] are essential steps to restore full corrosion resistance at the weld site.

Proactive Maintenance for Longevity

Finally, while stainless steel is low-maintenance, it is not "no-maintenance." In exterior applications, especially in areas with high salt or pollution, regular cleaning is vital. A simple wash-down with soap and water can remove the salt deposits and pollutants that can eventually compromise the surface, ensuring the steel continues to look and perform its best for decades.

Conclusion

Selecting the right stainless steel in India and Southeast Asia is a strategic decision, not just a purchase. By focusing on lifecycle value, demanding quality verification, and partnering with technical experts, you can ensure your projects are durable, cost-effective, and built to last in demanding regional environments.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.