In my 15 years of manufacturing stainless steel products, I've overseen countless sheet and tube production runs. Understanding the forming process is crucial for achieving quality products and optimal performance.

Stainless steel is formed into sheets through hot and cold rolling processes1, while tubes are created through various forming and welding methods. The specific process depends on the grade, size requirements, and final application.

Through my experience managing production facilities, I've gained deep insights into forming processes. Let me share how different techniques and equipment work together to create high-quality stainless steel products.

The complexity of forming processes requires precise control and expertise. Having supervised numerous production lines, I understand how each step affects final product quality.

What Processes Are Involved in Rolling Stainless Steel into Sheets?

Drawing from extensive rolling mill experience, I can explain the detailed process steps.

Sheet production involves multiple rolling stages, including hot rolling at high temperatures2 followed by cold rolling for final thickness and surface finish.

Hot Rolling Process

-

Initial Preparation:

- Slab heating

- Scale removal

- Temperature control

- Surface preparation

-

Rolling Operations:

- Roughing passes

- Intermediate rolling

- Finish rolling

- Thickness control

| Process Stage | Temperature Range | Thickness Reduction |

|---|---|---|

| Roughing | 1200-1100°C | 50-70% |

| Intermediate | 1100-1000°C | 30-50% |

| Finishing | 1000-900°C | 10-30% |

Cold Rolling Operations

-

Surface Preparation:

- Pickling

- Cleaning

- Surface inspection

- Lubrication

-

Rolling Parameters:

- Roll pressure

- Speed control

- Tension settings

- Pass scheduling

How Does Welding Transform Flat Stainless Steel into Tubes?

My experience with tube production has taught me the intricacies of forming and welding.

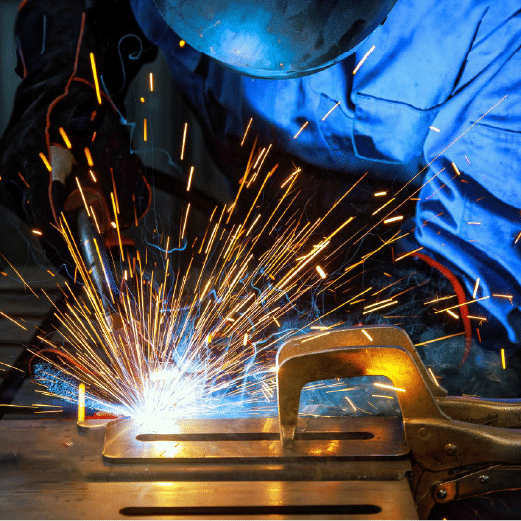

Tube production involves forming flat strip into a round shape and welding the seam3, followed by sizing and finishing operations to achieve final specifications.

Forming Process

-

Strip Preparation:

- Edge milling

- Surface cleaning

- Width control

- Edge inspection

-

Forming Steps:

- Gradual forming

- Shape control

- Alignment

- Seam positioning

-

Welding Operations:

- TIG welding

- Laser welding

- Seam preparation

- Weld inspection

Post-Weld Processing

-

Sizing Operations:

- Diameter control

- Roundness

- Straightness

- Length cutting

-

Surface Treatment:

- Weld cleaning

- Surface finishing

- Heat treatment

- Final inspection

Which Equipment Is Essential for Manufacturing Stainless Steel Sheets and Tubes?

Through years of equipment specification and operation, I understand critical machinery requirements.

Essential equipment includes rolling mills, forming machines, welding systems4, and various finishing equipment, all requiring precise control and maintenance.

Sheet Production Equipment

-

Rolling Mills:

- Hot rolling stands

- Cold rolling mills

- Tension levelers

- Surface finishing

-

Support Equipment:

- Furnaces

- Pickling lines

- Inspection systems

- Material handling

-

Control Systems:

- Thickness control

- Width control

- Surface monitoring

- Quality verification

Tube Manufacturing Equipment

-

Forming Equipment:

- Roll formers

- Tube mills

- Sizing stands

- Cutting systems

-

Welding Systems:

- TIG welders

- Laser welders

- Seam annealers

- Testing equipment

What Quality Control Measures Are Taken During Stainless Steel Fabrication?

Quality control has been central to my manufacturing experience.

Comprehensive quality control includes dimensional measurements, surface inspection, mechanical testing5, and non-destructive examination throughout the production process.

Inspection Methods

-

Dimensional Control:

- Thickness measurement

- Width verification

- Length control

- Profile checking

-

Surface Inspection:

- Visual examination

- Surface roughness

- Defect detection

- Finish verification

-

Material Testing:

- Mechanical properties

- Chemical analysis

- Corrosion testing

- Metallographic examination

Quality Documentation

-

Process Records:

- Production parameters

- Test results

- Inspection data

- Certification requirements

-

Quality Verification:

- Material certification

- Process validation

- Testing documentation

- Compliance verification

Are There Differences in Forming Methods for Various Stainless Steel Grades?

Different grades require specific forming approaches based on my production experience.

Forming methods vary significantly between austenitic, ferritic, and duplex grades6 due to their different mechanical properties and work hardening characteristics.

Grade-Specific Requirements

-

Austenitic Grades:

- Higher forming forces

- Work hardening control

- Temperature sensitivity

- Surface protection

-

Ferritic Grades:

- Limited formability

- Edge cracking prevention

- Grain size control

- Surface quality

-

Duplex Grades:

- Special forming techniques

- Higher power requirements

- Temperature control

- Tool wear management

Process Adaptations

-

Equipment Settings:

- Force adjustment

- Speed control

- Temperature management

- Tool selection

-

Process Parameters:

- Reduction ratios

- Pass schedules

- Annealing requirements

- Surface treatment

-

Quality Controls:

- Grade-specific testing

- Property verification

- Surface inspection

- Dimensional control

Conclusion

Successful forming of stainless steel sheets and tubes requires understanding of material properties, proper equipment selection, and precise process control. Different grades demand specific approaches to achieve optimal results.

-

Learn about how hot and cold rolling affect stainless steel properties ↩

-

Understand the impact of hot rolling on steel's microstructure and quality ↩

-

Explore different welding techniques and their applications in tube manufacturing ↩

-

Discover essential equipment for efficient stainless steel manufacturing ↩

-

Learn about critical quality checks in stainless steel production ↩

-

Compare forming techniques for different stainless steel grades ↩