Hot Rolled vs Cold Rolled Stainless: Which to Buy?

Are you struggling to choose between hot rolled and cold rolled stainless steel1 for your project? Making the wrong choice can lead to unexpected costs, production delays, or even product failure. At MFY, we guide our partners through this critical decision to ensure their supply chain is both efficient and resilient.

Hot rolled stainless steel is processed above its recrystallization temperature, resulting in a rougher finish and looser tolerances. In contrast, cold rolled stainless steel is further processed at room temperature, creating a smoother surface, tighter tolerances, and increased strength. This distinction is crucial for your application's success.

Choosing the right steel is more than a technical detail; it's a strategic business decision that impacts your bottom line and product quality. I've seen firsthand how this choice can make or break a project's budget and timeline. This guide will walk you through everything you need to know, moving beyond simple definitions to explore the practical implications for your specific industry.

In my years as Global Business Director at MFY, I’ve learned that the "best" material is always relative to the application. A choice that’s perfect for a construction contractor in the Middle East might be completely wrong for a precision equipment manufacturer in India. The global steel market is complex, and the pressure to optimize costs without sacrificing quality is immense. This decision isn’t just about comparing spec sheets; it’s about understanding the entire lifecycle of your product, from fabrication to end-use. It requires a dialectical approach, balancing the material's inherent properties with your manufacturing capabilities and the final performance expectations. We'll explore this by looking at industry data, real-world case studies, and the critical trade-offs that experienced professionals consider.

What is the difference between hot rolled and cold rolled stainless steel?

The terms "hot rolled" and "cold rolled" sound similar, which can easily cause confusion when specifying materials for a project. This confusion can lead to ordering the wrong type of steel, causing costly delays and compatibility issues. Let's clearly define the fundamental difference to prevent these mistakes.

The primary difference is the temperature during processing. Hot rolled steel is formed at temperatures over 1,700°F (926°C), above its recrystallization point. Cold rolled steel begins as hot rolled steel that is then further processed and refined at room temperature, altering its final properties.

Understanding this core processing difference is the first step, but it’s not the whole story. The real value comes from comprehending how this single variable—temperature—creates a domino effect, influencing everything from the steel's surface appearance and dimensional accuracy to its mechanical strength and formability. These aren't just minor variations; they are distinct characteristics that make each type suitable for very different applications. A client of ours manufacturing agricultural machinery, for example, relies on the properties of one, while another client producing high-end kitchen appliances absolutely requires the other. Throughout my career, I've seen that a deep appreciation for this initial processing stage is what separates successful project planning from frustrating and expensive trial and error. We'll break down precisely how the journey from a heated slab to a finished coil dictates the material you ultimately receive and why it matters so much for your operations.

The distinction between these two processes is fundamental to everything we do at MFY, from sourcing raw materials to delivering finished products to markets in Southeast Asia and Russia. The journey of the steel determines its destiny, and understanding this journey is key to making an informed purchasing decision. It's not just about what happens in the mill; it's about how those events translate into performance in your hands. Let's delve deeper into what each process truly entails and how they set the stage for the material's final characteristics, which will ultimately impact your own production processes and the quality of your finished goods. This knowledge is the foundation of a resilient and cost-effective supply chain.

The Hot Rolling Process: Foundation and Function

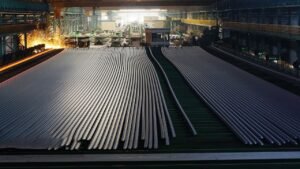

The hot rolling process is the foundational method for producing steel. It begins with a large rectangular billet or slab of steel that is heated to a malleable temperature, typically exceeding 1,700°F (926°C) for stainless steel. Once heated, it's passed between large rollers that compress and stretch it into a longer, thinner piece. This process is repeated through multiple stands of rollers until the desired thickness is achieved. Because the steel is shaped at such a high temperature, it's relatively easy to form into various shapes and large dimensions.

As the hot-rolled steel cools, it shrinks slightly and in a less-than-perfectly-uniform manner. This leads to its defining characteristics: looser dimensional tolerances and slightly distorted shapes, such as less-than-perfectly-square corners. The high-temperature process also creates a scaly, rough surface finish, often referred to as a "pickled and annealed" (No. 1 Finish) surface after the scale is removed with acid. I remember a client in India working on a large-scale infrastructure project who needed thousands of tons of structural steel. For them, the precise finish was irrelevant as the beams would be hidden. The cost savings and immediate availability of hot-rolled material from our inventory were the decisive factors, allowing their project to stay on schedule and under budget.

This process is highly efficient for producing large quantities of steel, making it a more economical choice. The key takeaway is that hot rolling prioritizes manufacturability and cost-effectiveness over precision and surface aesthetics. For applications where raw strength and function are paramount and a pristine finish is unnecessary—such as structural I-beams, railway tracks, or machine frames—hot rolled steel is often the ideal and most logical choice. Our ability at MFY to source and process high-quality hot-rolled coils forms the very beginning of our integrated supply chain, providing the essential raw material for both our clients and our own cold-rolling operations.

The Cold Rolling Process: Precision and Polish

The cold rolling process is a secondary step that refines hot rolled steel into a product with fundamentally different properties. It begins with a sheet of hot-rolled steel that has been pickled to remove the surface scale. This sheet is then passed through pairs of rollers at room temperature. Unlike hot rolling, this process does not involve reheating the metal. Because the steel is not malleable at this temperature, significantly more pressure is required to reduce its thickness, a process known as cold reduction.

This intense pressure at a low temperature causes a phenomenon called "strain hardening" or "work hardening." The crystal structure of the steel is changed, making it significantly harder and stronger—often increasing its yield and tensile strength by up to 20% or more. This increase in strength comes with a trade-off: the steel becomes less ductile, meaning it's more difficult to bend or form without cracking. However, the most visible benefits are the superior surface finish and tight dimensional tolerances. The cold rolling process can produce a smooth, often reflective surface (like the common 2B or bright annealed BA finishes) and hold thickness tolerances that are far more precise than what hot rolling can achieve.

A few years ago, we worked with an automotive parts manufacturer in Southeast Asia. They were producing exterior trim pieces that required both a flawless, paint-ready surface and exact dimensions to ensure a perfect fit during assembly. For them, cold-rolled stainless steel was the only option. The increased cost was easily justified by the reduction in their own surface preparation work and the elimination of rejection rates due to poor fitment. This illustrates the core value of cold rolling: it delivers precision, strength, and aesthetics for applications where these attributes are non-negotiable.

From Raw Material to Finished Product: An Integrated View

Understanding the two processes in isolation is useful, but seeing them as part of an integrated manufacturing ecosystem provides a much clearer picture of their value. At MFY, our business model is built on managing this entire journey. We don't just trade steel; we control the process from sourcing hot-rolled raw materials to our advanced cold-rolling processing facilities, and finally to manufacturing finished tubes and delivering them to clients worldwide. This integration gives us, and by extension our clients, a powerful advantage.

Consider a large-scale engineering and construction contractor in the Middle East building a new processing plant. For the structural framework of the buildings, they need cost-effective, high-strength hot-rolled beams and plates. For the miles of piping and the sensitive equipment housings within the plant, they require the clean, corrosion-resistant, and precise finish of cold-rolled stainless steel sheets and pipes. An integrated supplier like MFY can source, process, and deliver both types of material in a coordinated shipment, simplifying logistics and ensuring consistent quality across the board.

This holistic view is critical for building resilient supply chains. By understanding the nuances of both hot and cold rolling, we can help our partners optimize their material selection. Sometimes, a client might assume they need the higher-spec cold-rolled product when a more economical hot-rolled solution with minor secondary processing would suffice. Conversely, we can steer a client away from using hot-rolled in an application where its loose tolerances would cause downstream production nightmares. The table below provides a simplified comparison, but the real expertise lies in applying this knowledge to specific, real-world scenarios.

| Feature | Hot Rolled Stainless Steel | Cold Rolled Stainless Steel |

|---|---|---|

| Processing Temp. | Above 1,700°F (926°C) | Room Temperature |

| Surface Finish | Scaly, rough (e.g., No. 1) | Smooth, refined (e.g., 2B, BA) |

| Dimensional Tolerance | Looser, less precise | Tighter, more precise |

| Hardness & Strength | Lower | Higher (due to work hardening) |

| Ductility (Formability) | Higher | Lower |

| Cost | Lower | Higher |

This integrated perspective, moving from the heat of the hot-rolling mill to the precision of the cold-rolling stands, is what empowers us to be more than just a supplier. We act as strategic partners, helping our clients navigate the complexities of stainless steel to build a competitive edge.

Hot rolled steel has looser tolerancesTrue

Hot rolling's high-temperature process causes uneven cooling, resulting in less precise dimensions compared to cold rolled steel.

Cold rolling increases ductilityFalse

Cold rolling actually decreases ductility through work hardening, making the steel stronger but less flexible.

How do the processing methods affect the properties of stainless steel?

You know the "how," but are you clear on the "what"? Understanding the process is academic, but knowing how it concretely affects the steel's properties is where money is made or lost. Choosing based on process alone, without grasping its impact on performance, can lead to catastrophic material failure or over-engineering.

The differences between hot rolling and cold rolling produce a more ductile, formable steel with lower strength, a rough surface, and imprecise dimensions. Conversely, the cold rolling process imparts higher strength and hardness, a smooth finish, and tight dimensional control, but at the cost of reduced ductility.

These properties are not just abstract terms on a material data sheet; they have profound, real-world consequences for your fabrication processes, your product's long-term durability, and your project's overall budget. I've personally consulted with clients who faced significant setbacks because they underestimated these differences. For instance, a manufacturer of industrial tanks once selected a cold-rolled grade for its perceived superior quality, only to find their forming equipment couldn't handle the material's reduced ductility, leading to cracking and wasted inventory. Another client in the construction sector almost rejected a hot-rolled product based on its appearance, not realizing its superior formability was exactly what they needed for on-site adjustments. These experiences underscore the need to move beyond the surface-level understanding and analyze the deep-seated mechanical and physical changes induced by each rolling method. Let’s dive into how mechanical properties, dimensional tolerances, and surface finish2 directly influence strength, precision, and aesthetics, which are the three pillars that should guide your purchasing decision.

At MFY, we believe that an educated customer is our best partner. When you understand the intricate relationship between processing and properties, you can specify your needs with confidence and clarity. This knowledge empowers you to ask the right questions and challenge assumptions, whether you're sourcing from us or any other supplier. It transforms the conversation from one about price per ton to one about value and performance over the product's entire lifecycle. The following analysis will provide the detailed, practical insights you need, drawing from industry data and our extensive experience across diverse global markets, to ensure you make the most informed and strategic choice for your application.

Mechanical Properties: The Trade-Off Between Strength and Ductility

The most significant impact of the rolling process is on the mechanical properties of the stainless steel, specifically the balance between strength and ductility. Hot rolling vs Cold rolling3, occurring above the recrystallization temperature, results in a material with a uniform, stress-free grain structure. This makes it highly ductile and malleable, meaning it can be easily bent, stretched, and formed into complex shapes without fracturing. This is a critical advantage for manufacturers producing items like large-diameter pipes, automotive chassis components, or agricultural implements that require significant deformation during fabrication.

Cold rolling, on the other hand, fundamentally alters this balance. The intense pressure applied at room temperature deforms and elongates the grain structure of the steel, a process known as work hardening. This makes the material significantly stronger and harder. For example, a standard 304 stainless steel sheet might see its tensile strength increase from approximately 515 MPa in its annealed (hot-rolled) state to over 620 MPa after cold rolling. However, this gain in strength comes at a direct cost to ductility. The same material will see its elongation percentage (a measure of how much it can stretch before breaking) drop dramatically, making it more brittle and prone to cracking during aggressive forming operations.

I recall a case with an equipment integrator building custom food processing machinery. They initially specified cold-rolled 316L for all components due to its smooth finish and perceived higher quality. However, their design involved several tight-radius bends in the support structure. During prototyping, they experienced consistent fracturing at the bend points. After consulting with our technical team at MFY, we recommended switching to a hot-rolled 316L plate for the structural frame. This provided the necessary ductility for their fabrication process while still offering the corrosion resistance they required. They kept the cold-rolled material for the product-contact surfaces, creating an optimized solution that balanced performance, manufacturability, and cost.

Dimensional Tolerances and the Quest for Precision

Beyond strength, the most critical differentiator for many applications is Dimensional tolerances and precision in steel4 - The permissible limit of variation in a physical dimension. Hot rolling is, by its nature, a less precise process. The extreme heat and subsequent non-uniform cooling cause the steel to shrink and warp in ways that are difficult to control perfectly. This results in wider tolerances for thickness, width, length, and straightness. For a large structural I-beam, a few millimeters of variation in thickness is often perfectly acceptable and has no impact on its performance.

Cold rolling is the solution when precision is paramount. Because the process is performed at room temperature, there is no heat-related shrinking or warping. The powerful, computer-controlled rollers can maintain incredibly consistent pressure, resulting in a product with uniform thickness and exceptional dimensional accuracy. For a distributor in Russia we partner with, this is a make-or-break attribute. They supply stainless steel sheets to manufacturers of precision electronics enclosures and medical devices. Their clients' automated assembly lines require sheets with a thickness tolerance of just a few hundredths of a millimeter. Any deviation would cause machinery to jam and production to halt.

This level of precision is why cold-rolled steel is the default choice for any application involving intricate assembly, CNC machining, or where tight fit-up between parts is required. The higher upfront cost of cold-rolled material is often recouped through faster assembly, reduced scrap rates, and the elimination of secondary machining operations that would be needed to bring a hot-rolled product into tolerance. The table below illustrates the typical difference in thickness tolerance for a 3mm sheet, highlighting the precision gained through cold rolling.

| Feature | Hot Rolled (No. 1 Finish) | Cold Rolled (2B Finish) |

|---|---|---|

| Typical Thickness | 3.0 mm | 3.0 mm |

| Typical Tolerance | ±0.25 mm | ±0.09 mm |

| Application Example | Industrial Walkway Grating | Medical Instrument Tray |

| Key Driver | Cost and Function | Precision and Fit |

Surface Finish, Aesthetics, and Application

The final major property affected by the rolling process is the surface finish. The appearance of the steel is a direct result of the manufacturing method and is often a primary factor in the selection process, especially for consumer-facing or architectural products. Hot rolled stainless steel has a characteristic rough, slightly uneven, and scaled surface caused by cooling from extreme temperatures. Even after this scale is removed through pickling and passivation, the surface remains dull and non-reflective (a No. 1 finish). This is perfectly suitable for industrial applications where the steel is painted over or hidden from view.

Cold rolling, in contrast, produces a vastly superior surface. The pressure from the smooth, highly polished rollers imparts their own finish onto the steel. The most common cold-rolled finish is the "2B," which is smooth, greyish, and moderately reflective. For an even more mirror-like appearance, a "Bright Annealed" (BA) finish can be produced by annealing the steel in a controlled atmosphere to prevent any surface oxidation. These smooth surfaces are not just aesthetically pleasing; they are also easier to clean and less prone to bacterial growth, making them essential for food processing, pharmaceutical, and sanitary applications.

I often share the story of a client in the hospitality industry in Dubai who was developing a new luxury hotel. They needed to source stainless steel for thousands of items, from kitchen backsplashes and appliances (requiring a cleanable 2B finish) to decorative elevator panels and lobby fixtures (requiring a flawless BA finish). For them, the surface was not just a property; it was an integral part of their brand identity. We worked closely with them to supply the exact finishes required, ensuring consistency across their entire project. The higher investment in premium cold-rolled finishes was a strategic decision to create a specific guest experience, demonstrating that for many applications, the "look" of the steel is just as important as its strength or precision.

Cold rolling increases strength but reduces ductilityTrue

Cold rolling work-hardens the steel, making it stronger but more brittle compared to hot-rolled steel.

Hot rolling produces tighter dimensional tolerancesFalse

Hot rolling actually results in wider tolerances due to heat-related shrinking and warping, while cold rolling achieves precise dimensions.

What are the benefits and drawbacks of hot rolled stainless steel?

You're facing a choice for a structural part, and the lower cost of hot rolled steel is tempting, but you're worried about its quality. Choosing a material based solely on price without understanding its inherent limitations can lead to costly rework, project delays, or a final product that fails to meet expectations.

The primary benefits of hot rolled stainless steel are its significantly lower cost and superior formability, making it ideal for large structural components. Its main drawbacks are a rough, inconsistent surface finish and less precise dimensional tolerances compared to cold rolled steel.

These trade-offs are not abstract concepts; they are daily realities in the world of manufacturing and construction. The key is to see them not as "good" or "bad," but as characteristics that make the material suitable for some jobs and unsuitable for others. For instance, I recall a project with a major engineering contractor in Southeast Asia that perfectly illustrates when hot rolled is the undisputed champion. They were constructing a massive new warehouse facility, and by using hot rolled sections for the internal steel frame, they saved over 20% on their material budget without compromising an ounce of structural integrity. This saving was then reallocated to higher-spec materials for the building's exterior. This kind of strategic decision-making is only possible when you have a clear, balanced view of the material's pros and cons.

At MFY, our role as a partner in your supply chain is to provide this balanced view. We don't just sell steel; we provide solutions that are optimized for your specific context. The decision to use hot rolled steel should be a conscious, strategic choice based on a full understanding of its profile. It's about leveraging its strengths—cost-effectiveness and workability—while ensuring its weaknesses—surface quality and precision—are not critical to your application's success. Let's dig deeper into these aspects to arm you with the knowledge to make that choice confidently and effectively, ensuring you get the most value for your investment.

The Decisive Advantage: Cost-Effectiveness

The most compelling benefit of hot rolled stainless steel is its lower price point. This cost advantage stems directly from its simpler and less energy-intensive manufacturing process. Since it involves fewer production steps—it is essentially rolled to its final thickness in a single production line without the need for reheating or high-pressure cold reduction—the associated labor, energy, and equipment costs are significantly lower. This can translate into a material cost that is anywhere from 20% to 40% lower than its cold-rolled counterpart, depending on the grade and market conditions.

This cost differential becomes a powerful strategic advantage in large-scale projects where material volume is high. Consider a client of ours in India who was awarded a contract to build a new series of railway bridges. The project required thousands of tons of high-strength stainless steel plate. The aesthetic finish5 was completely irrelevant, as the plates would be used for internal support structures and eventually coated. By opting for hot rolled plates, the contractor was able to submit a more competitive bid for the project, ultimately winning the contract. The savings on the raw material, facilitated by MFY's efficient sourcing and delivery, were substantial and directly contributed to the project's profitability.

It's a common story we see with our partners in construction, heavy manufacturing, and infrastructure. For applications like structural supports, underground tanks, or industrial platforms, where the material's primary role is to provide strength and corrosion resistance without any aesthetic requirements, hot rolled steel is the intelligent economic choice. Its cost-effectiveness allows for more competitive project quoting and can free up capital to be invested in other critical areas of the project.

The Fabricator's Friend: Superior Formability and Weldability

Beyond cost, a key mechanical benefit of hot rolled stainless steel is its excellent formability and weldability. Because the material is processed at high temperatures and allowed to cool slowly, its crystalline grain structure is uniform and free from internal stresses. This metallurgical state makes the steel more ductile, meaning it can be bent, pressed, and drawn into various shapes with less effort and a lower risk of cracking compared to the harder, less forgiving nature of cold-rolled steel6.

This property is invaluable for fabricators. I worked with a company that manufactures large, heavy-duty dump truck bodies. Their design involved creating curved side panels from thick stainless steel plate. They needed a material that could withstand the aggressive forming process without compromising its integrity. Hot rolled plate was the perfect solution. Its inherent ductility allowed them to achieve the desired shapes consistently, reducing their scrap rate and improving production throughput. Had they attempted to use a cold-rolled material, they would have required more powerful machinery and faced a much higher risk of material failure during production.

Furthermore, the characteristics of hot rolled steel often make it easier to weld. The absence of internal stresses and the material's composition can lead to more predictable and robust welds, which is a critical consideration in any structural application. For welders on a construction site or in a fabrication shop, this ease of use translates into faster completion times and more reliable joints, contributing to both the safety and efficiency of the overall project.

Navigating the Limitations: Surface Imperfections and Tolerances

Of course, the decision to use hot rolled steel requires a clear-eyed acceptance of its drawbacks: surface finish and dimensional precision. The high-temperature rolling process leaves a rough, scaly oxide layer on the surface. While this scale is typically removed through an acid bath (a process called pickling), the resulting surface is still matte and slightly uneven, a stark contrast to the smooth finish of cold-rolled products. For any application where the final appearance is important—from consumer appliances to architectural cladding—this finish is generally unacceptable without extensive secondary processing like grinding or polishing, which would negate the initial cost savings.

Similarly, the less controlled cooling process leads to looser dimensional tolerances. The thickness, width, and straightness of a hot-rolled sheet or plate can vary more from one end to the other. For a manufacturer of precision machinery where parts must fit together with micrometer accuracy, this level of variation is a non-starter. Using hot-rolled steel in such a context would lead to assembly problems, inconsistent performance, and high rejection rates.

However, it's crucial to frame these "drawbacks" within the context of the application. For the vast majority of its intended uses, these limitations are entirely irrelevant. The table below highlights this context-driven reality. The loose tolerance of a structural beam is a non-issue, and its rough surface will be covered by concrete or paint. By understanding and accepting these limitations, you can confidently leverage the significant cost and formability benefits of hot rolled steel in the right situations.

| Application Category | Is Hot Rolled Suitable? | Rationale |

|---|---|---|

| Architectural Facades | No | Poor surface finish and aesthetics. |

| Structural I-Beams | Yes | Cost-effective, high strength, finish is not visible. |

| Kitchen Sinks | No | Requires a smooth, cleanable, aesthetic surface. |

| Heavy Machinery Frames | Yes | Excellent formability, low cost, finish is secondary. |

Hot rolled steel is cheaper than cold rolledTrue

Hot rolled steel's simpler manufacturing process makes it 20-40% less expensive than cold rolled steel.

Hot rolled has better surface finishFalse

Hot rolled steel has a rough, scaly surface that requires additional processing for smooth finishes.

What are the benefits and drawbacks of cold rolled stainless steel?

Your product demands a flawless finish and tight precision, but you're operating under strict budget constraints. You might be tempted to over-specify and pay for properties you don't fully need, or worse, compromise on the material's strength and workability just to meet aesthetic goals. It's a difficult balance to strike.

Cold rolled stainless steel offers superior benefits in its smooth surface finish, tight dimensional tolerances, and increased strength. Its primary drawbacks are a significantly higher cost and reduced ductility, which can make fabrication more challenging and expensive.

These characteristics position cold rolled steel as a premium material for applications where precision and appearance are paramount. However, I always caution my clients to consider the total picture. I remember a consultation with a manufacturer of high-end consumer appliances. They were drawn to the beautiful, reflective finish of a bright annealed (BA) cold-rolled sheet7. What they hadn't fully accounted for was how the material's increased hardness and lower ductility would impact their existing stamping and forming equipment. It's a classic example of how the benefits you see on the surface must be weighed against the potential challenges in production. Understanding this complete profile is key to avoiding costly mistakes and making a truly optimal choice.

As your partner at MFY, our goal is to empower you with this complete, nuanced understanding. The appeal of a perfect surface and precise dimensions is strong, but it must be balanced against the realities of your budget and manufacturing processes. The decision to invest in cold-rolled steel should be a strategic one, where the added cost is justified by tangible benefits like reduced finishing work, improved product performance, or enhanced market appeal. Let's explore these benefits and drawbacks in detail, using real-world data and case studies to illustrate how you can leverage the strengths of cold-rolled steel while skillfully managing its challenges.

The Pursuit of Perfection: Unmatched Finish and Aesthetics

The most immediate and obvious benefit of cold-rolled stainless steel is its superior surface finish. The process of rolling the material at room temperature using highly polished rollers imparts a smooth, dense, and often reflective surface that is simply unattainable through hot rolling8. This aesthetic quality is not just for looks; it's a critical functional requirement in a vast range of industries. The standard "2B" finish is smooth and suitable for most applications, while premium finishes like "Bright Annealed" (BA) offer a near-mirror-like quality.

This high-quality surface is a huge advantage for manufacturers because it often eliminates the need for costly and time-consuming secondary finishing processes like grinding and polishing. A client of ours in the Middle East's thriving hospitality sector sources our BA finish cold-rolled sheets for exactly this reason. They fabricate everything from decorative panels in hotel lobbies to elevator interiors and high-end bathroom fixtures. For them, the steel's surface is the final product finish. Using our BA sheets allows them to go directly from fabrication to installation, saving them enormous amounts of labor and ensuring a consistently flawless appearance across their projects. The premium paid for the material is easily offset by the savings in downstream processing.

Furthermore, the smooth, non-porous surface of cold-rolled steel is easier to clean and more hygienic, which is a non-negotiable requirement in the food and beverage, pharmaceutical, and medical industries. The reduced surface roughness, often measured in micrometers (μm), provides fewer microscopic crevices for bacteria to harbor, ensuring compliance with strict sanitary standards. This functional benefit is a perfect example of how the "look" of the steel directly translates to performance and safety.

The Engineer's Choice: Precision Tolerances and Enhanced Strength

For engineers and designers, the true beauty of cold-rolled steel lies in its mechanical properties: tight dimensional control and increased strength. As we've discussed, the cold-reduction process allows for incredibly precise control over the final thickness of the material, which is critical for automated manufacturing and complex assemblies. This precision ensures consistency from part to part, which is essential for industries like automotive and electronics where components must fit together perfectly every time.

The work-hardening effect during cold rolling also provides a significant boost in strength. This allows engineers to design parts that are thinner and lighter without sacrificing structural integrity, a concept known as "down-gauging." I worked with a manufacturer of commercial drones who needed to create a lightweight yet incredibly strong frame9. By using a specific temper of cold-rolled stainless steel, they were able to reduce the material thickness by 15% compared to a hot-rolled alternative, leading to a lighter drone with longer flight times and better payload capacity. The enhanced strength of the cold-rolled material was the key enabler for this innovation.

The table below shows a typical comparison of yield strength (the point at which the material begins to permanently deform) for a common stainless steel grade, illustrating the significant mechanical advantage gained through cold rolling. This enhanced strength, combined with precision, is why cold-rolled steel is the default choice for high-performance applications where reliability and tight specifications are critical.

| Property (for Type 304) | Hot Rolled (Annealed) | Cold Rolled (Half Hard) |

|---|---|---|

| Typical Yield Strength | ~290 MPa (42 ksi) | ~760 MPa (110 ksi) |

| Typical Tensile Strength | ~600 MPa (87 ksi) | ~1035 MPa (150 ksi) |

| Result | More Formable | Significantly Stronger |

Balancing the Books: The Trade-Offs of Cost and Formability

With such clear advantages, why isn't cold-rolled steel used for everything? The answer lies in its two significant drawbacks: higher cost and reduced formability. The additional processing steps—pickling, cold reduction, and annealing—require more energy, time, and specialized equipment, making cold-rolled steel inherently more expensive than its hot-rolled counterpart. This cost premium must be justified by the application's requirements. For a hidden structural bracket, paying extra for a beautiful finish and tight tolerance makes no economic sense.

The second challenge is its reduced ductility. The same work-hardening process that increases strength makes the steel more resistant to bending and forming. Fabricators may require more powerful machinery to shape cold-rolled steel, and aggressive designs with tight bend radii run a higher risk of "orange peeling" (surface texturing) or even cracking. This can lead to higher scrap rates and more complex production planning if not managed properly.

This is where expert guidance from a supplier like MFY becomes crucial. We don't just supply a product; we help our clients navigate these trade-offs. We recently advised a company manufacturing metal enclosures. They needed the smooth finish of cold-rolled steel but were struggling with cracking during the bending process. After analyzing their design, we recommended a specific temper of cold-rolled steel—one that was work-hardened enough to provide the needed strength but retained enough ductility for their 90-degree bends. This nuanced solution saved their project, highlighting that even within the "cold rolled" category, there is a spectrum of properties to choose from. The key is to balance the need for aesthetics and precision against the practicalities of fabrication and budget.

Cold-rolled steel has superior surface finishTrue

Cold rolling at room temperature with polished rollers creates a smoother, denser surface than hot rolling, often eliminating secondary finishing processes.

Cold-rolled steel is cheaper than hot-rolledFalse

The additional processing steps (pickling, cold reduction, annealing) make cold-rolled steel significantly more expensive than hot-rolled alternatives.

How to decide whether to buy hot rolled or cold rolled stainless steel?

You've learned the technical differences, the pros, and the cons. Yet, when it comes to your specific purchase order, making that final call can still feel daunting. A single wrong choice at this stage can ripple through your production line, inflate your budget, and compromise your final product.

Your decision should be guided by a clear evaluation of three factors: the aesthetic and surface requirements of your application, the necessity for tight dimensional precision, and the constraints of your project budget. Prioritize cold rolled stainless steel for visible, precise parts and hot rolled stainless steel for structural, cost-sensitive applications.

Making this choice is a strategic exercise, not just a technical one. As a partner, my role at MFY goes beyond simply taking an order for a specific tonnage of steel. I see it as my responsibility to ensure you're making the most resilient, efficient, and profitable choice for your business. To help you formalize this process, let's walk through the final decision-making framework that I personally use when advising my clients, ensuring that every key variable is considered before a single coil is shipped.

This final step is about synthesis—bringing together everything we've discussed into a practical, actionable decision matrix. It's about asking the right questions and prioritizing what truly matters for your project's success. Whether you're a distributor balancing inventory costs, a construction contractor bidding on a massive project, or a manufacturer creating a new product line, this structured approach will provide clarity. It will help you move from a state of uncertainty to a position of confidence, knowing that your material choice is backed by a sound, logical, and strategic rationale that aligns with your business goals.

Factor 1: Aesthetics and Surface Finish—The Visibility Test

The first and often most straightforward question to ask is: Will the final surface of the stainless steel be visible and integral to the product's function or appeal? This is the visibility test. If the answer is yes, your choice will heavily lean towards cold-rolled steel. Applications like architectural elements, consumer appliances, commercial kitchen equipment, and automotive trim rely on a smooth, clean, and consistent finish. The rough, matte surface of hot-rolled steel is simply not suitable for these aesthetic-driven products.

I often work with distributors whose clients span this entire spectrum. For instance, one of our partners in Southeast Asia supplies stainless steel to both architectural facade fabricators and industrial tank manufacturers. For the facade contracts, they exclusively order our BA and No. 4 finish cold-rolled sheets. For the tank builders, they order large volumes of cost-effective No. 1 finish hot-rolled plates. The distributor understands that trying to sell a hot-rolled product to an architect is a non-starter, just as proposing a premium-priced cold-rolled product for a hidden storage tank would be uncompetitive.

So, your first step is to categorize your application. Is it primarily functional and hidden, or is it aesthetic and visible? If it's the former, hot-rolled is a strong contender. If it's the latter, cold-rolled is almost certainly the correct path. If it's somewhere in between—for example, a painted industrial machine housing—you then weigh the cost of the raw material against the cost of secondary surface preparation (e.g., grinding and painting a hot-rolled sheet vs. just painting a cold-rolled sheet).

Factor 2: Tolerance and Mechanical Properties—The Precision Mandate

The second critical question is: How important are tight dimensional tolerances and specific mechanical properties to my manufacturing process and final product performance? This is the precision mandate. If your product involves automated assembly, CNC machining, or intricate part fit-up, or if it requires the enhanced strength that comes from work hardening, then cold-rolled steel is your answer. The consistency and precision of cold-rolled material prevent downstream production issues and ensure the reliability of the final assembly.

A client of ours, an equipment integrator for the semiconductor industry, provides a perfect case study. They build complex machines where components must align with microscopic accuracy. They exclusively use our cold-rolled sheets and precision-cut plates because the dimensional stability is non-negotiable. The slightest variation in material thickness from a hot-rolled product would throw off their entire calibration. For them, the higher material cost is insignificant compared to the cost of a single machine failure.

Use the following checklist, which I've turned into a simple table, to guide your thinking. Be honest about what is a "must-have" versus a "nice-to-have" for your project. This will clarify whether the premium for precision is a necessary investment or an unnecessary expense.

| Decision Question | If YES, lean towards... | If NO, lean towards... |

|---|---|---|

| Is the part visible in the final product? | Cold Rolled | Hot Rolled |

| Does the part require tight dimensional tolerance? | Cold Rolled | Hot Rolled |

| Does the design require significant forming/bending? | Hot Rolled | Cold Rolled |

| Is the part's strength-to-weight ratio critical? | Cold Rolled | Hot Rolled |

| Is minimizing the initial material cost the top priority? | Hot Rolled | Cold Rolled |

Factor 3: Budget and Total Cost of Ownership—The Economic Reality

Finally, you must ask: What is my budget, and what is the true total cost of ownership? This is the economic reality check. While hot-rolled steel has a lower upfront purchase price, the total cost can sometimes be higher if it requires significant secondary processing. If you have to spend extensive labor hours grinding a hot-rolled surface to make it acceptable, you may have been better off starting with a more expensive but ready-to-use cold-rolled sheet.

This is where a partnership with an experienced supplier like MFY provides immense value. We help our clients look beyond the price per ton. I recently consulted with a contractor who was defaulting to hot-rolled for some semi-exposed brackets to save money. We ran a cost analysis that showed the labor cost to prepare and paint the rough hot-rolled surface was actually 15% higher than the cost of using a pre-finished cold-rolled product that required only a light cleaning before installation. By presenting this total cost analysis, we helped them make a more profitable long-term decision.

Ultimately, the decision rests on a balanced assessment of these three factors. There is no single "best" type of steel, only the "right" type of steel for your specific job. By systematically working through the questions of aesthetics, precision, and total cost, you move from a simple commodity purchase to a strategic sourcing decision. At MFY, with our fully integrated supply chain and deep market knowledge, we stand ready to be your partner in this process, ensuring you procure the optimal material that enhances your product and strengthens your competitive position in the market.

Cold-rolled steel has better surface finishTrue

Cold rolling produces a smoother, more polished surface compared to hot rolling, making it ideal for visible applications.

Hot-rolled steel is always cheaperFalse

While hot-rolled steel typically has a lower upfront cost, secondary processing needs may make cold-rolled steel more cost-effective in some cases.

Conclusion

Choosing between hot and cold rolled stainless steel depends on your application's unique demands for aesthetics, precision, and budget. By evaluating these factors, you can make a strategic choice that enhances product quality and optimizes cost, ensuring a resilient and competitive supply chain.

-

Learn how application differences affect material choice in stainless steel projects. ↩

-

Understand key factors to consider for optimal stainless steel choices based on specific applications. ↩

-

Explore detailed effects of rolling methods on grain structure and mechanical strength. ↩

-

Gain insights into tolerance levels and their critical role in stainless steel fabrication. ↩

-

Learn why surface appearance matters less in internal support structures ↩

-

Compare the mechanical benefits of cold rolled steel against hot rolled for different uses ↩

-

Learn about the reflective finish and its impact on ductility and hardness ↩

-

Discover differences in process effects on surface finish and mechanical properties ↩

-

Understand structural advantages in drone manufacturing using cold-rolled steel ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.