Choosing the Right Hot-Rolled vs. Cold-Rolled Stainless Steel Coil

Choosing the wrong steel coil leads to project delays and budget overruns. The subtle differences can be confusing. We make the choice clear, aligning material with your specific project goals.

Choosing between hot-rolled and cold-rolled stainless steel depends on your project's needs. Hot-rolled is cost-effective for structural applications, while cold-rolled offers a superior finish and tighter tolerances for precision-focused products. Your budget and end-use are the deciding factors.

This decision is more than just a technical choice; it's a strategic one that directly impacts your bottom line and your product's final quality. As the Global Business Director at MFY, I’ve guided countless partners through this exact decision. The key is to move beyond a simple price comparison and look at the total value each option brings to your specific application. Let's break down the factors you need to consider to make an informed, confident choice.

What Are the Core Differences Between Hot-Rolled and Cold-Rolled Stainless Steel?

Confusing hot-rolled and cold-rolled can compromise your product's quality. This uncertainty costs money. Understanding their distinct manufacturing processes and properties is the solution to making the right choice.

The main difference lies in the processing temperature. Hot-rolled steel is processed above its recrystallization temperature, making it more malleable. Cold-rolled steel is processed further at room temperature, increasing its strength and improving its surface finish.

The distinction between hot-rolling and cold-rolling is fundamental, and it all starts at the mill. I remember a client in the architectural design space who initially specified hot-rolled coil for an exterior decorative panel to save on costs. When the first batch arrived, the rougher, scaled surface was not what they envisioned for a high-end building facade. They had to reorder with a cold-rolled finish, which delayed their project by weeks and eroded their profit margin. This experience highlights why understanding the "why" behind each process is so critical. Hot-rolling happens at extreme temperatures—over 930°C (1700°F). At this heat, steel is almost like dough, easy to shape and form into large coils. This process is efficient and less expensive, but as the steel cools, it shrinks slightly and unpredictably, resulting in a less precise shape and a rougher surface. Cold-rolling takes a hot-rolled coil and processes it further. At room temperature, the steel is passed through rollers under immense pressure. This refines the grain structure, making the steel stronger and harder. It also allows for much tighter dimensional tolerances and creates a smooth, clean, and often oily surface that is ready for painting or coating.

Property Comparison at a Glance

To make it simple, here’s a direct comparison of the key properties you should care about:

| Property | Hot-Rolled Stainless Steel Coil | Cold-Rolled Stainless Steel Coil |

|---|---|---|

| Surface Finish | Scaly, rougher texture | Smooth, refined, often oily |

| Dimensional Tolerance | Less precise, some distortion | Very precise and uniform |

| Mechanical Properties | More formable, lower strength | Higher strength, less ductile |

| Cost | Lower | Higher |

Ultimately, hot-rolled is the workhorse for structural components, pipes, and industrial applications where aesthetics and precision are secondary. Cold-rolled is the artist's choice for automotive bodies, home appliances, and any product where a flawless finish and exact dimensions are non-negotiable.

What Are the Current Market Trends in Stainless Steel Coil Production?

The market is shifting rapidly, and outdated information can lead to poor sourcing decisions. This volatility creates risk. Staying updated on production trends helps you anticipate supply and price changes.

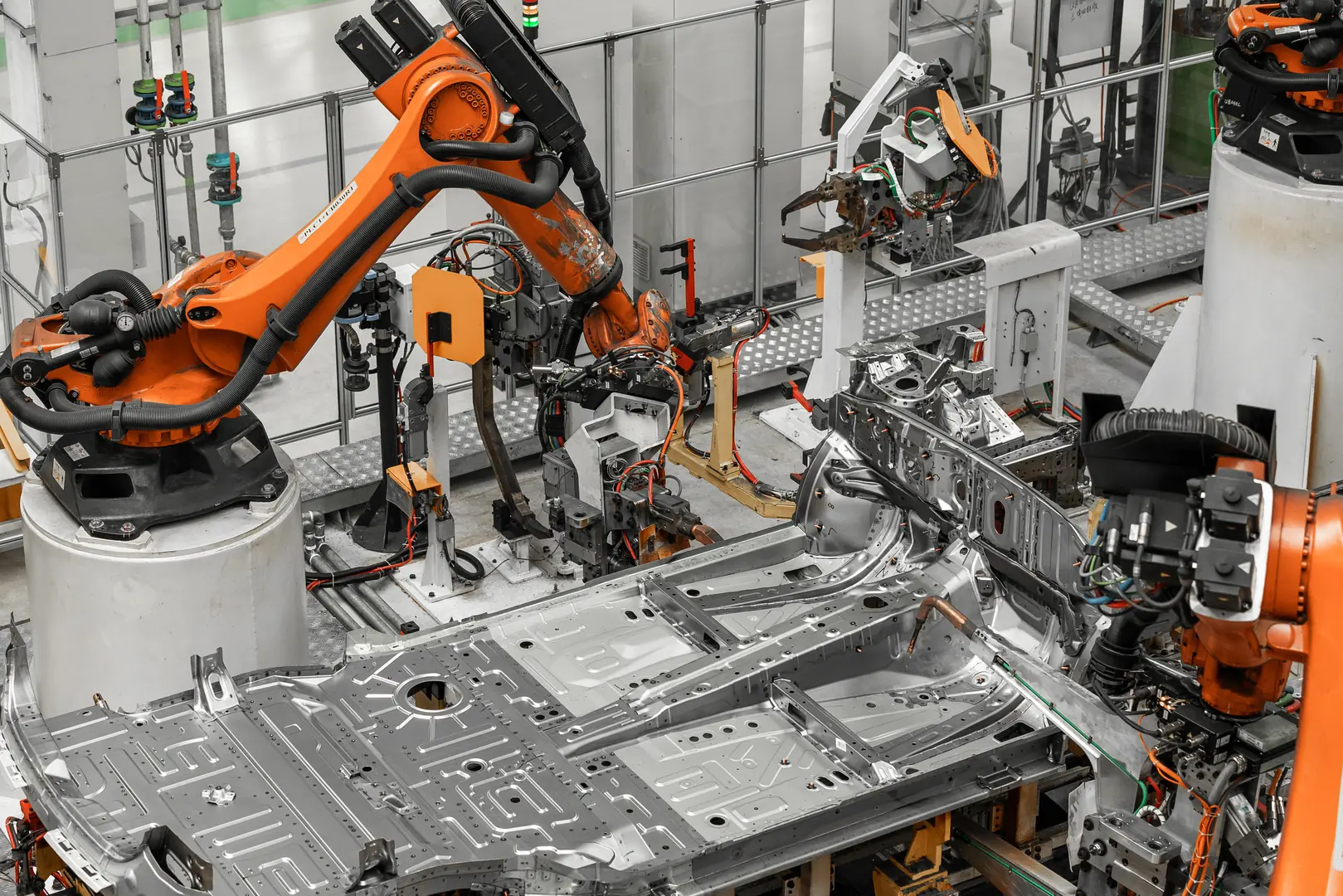

Current trends show a growing demand for high-strength, lightweight cold-rolled coils for the automotive and tech sectors. Simultaneously, a push for sustainable, recycled content is influencing both hot-rolled and cold-rolled production methods globally.

In my role, I travel frequently to our production facilities and speak with partners across the globe. The conversations today are vastly different from five years ago. Two major trends are reshaping our industry: sustainability and specialization. The "green steel" movement is no longer a buzzword; it's a real commercial driver. Clients, especially in Europe and North America, are increasingly asking for Environmental Product Declarations (EPDs)[^1] and data on recycled content. This is pushing mills like ours at MFY to innovate, optimizing energy consumption in the high-heat hot-rolling process and increasing the use of scrap in our melts. This focus on sustainability is affecting cost structures but also opening up new markets. On the other hand, we're seeing incredible specialization. The demand for advanced cold-rolled products is surging. Think about the sleek body of an electric vehicle or the casing of a new smartphone. These products require stainless steel that is not only incredibly thin and strong but also has a perfect surface. This is driving massive investment in advanced cold-rolling and finishing technologies. We are actively expanding our capacity for producing high-tensile, ultra-thin gauge cold-rolled coils to meet this specific demand from the EV and electronics industries.

Key Market Drivers

- Sustainability Push: Demand for steel with a lower carbon footprint is growing. This favors producers who use electric arc furnaces (EAFs)[^2] and have a high percentage of recycled content. It impacts the entire supply chain, from raw material sourcing for hot-rolling to the energy used in cold-rolling mills.

- Sector-Specific Demand: The automotive industry's shift to EVs requires lightweight yet strong materials, boosting demand for specific grades of cold-rolled stainless steel. Conversely, massive infrastructure projects in developing regions continue to drive strong, consistent demand for cost-effective hot-rolled structural steel.

- Digitalization and Automation: At MFY, we've integrated digital tracking from order to delivery. This isn't just for our benefit. It gives our clients unprecedented transparency into their supply chain, helping them manage inventory and production schedules more effectively. This level of service is becoming a new competitive standard.

What Are the Main Challenges in Selecting the Right Stainless Steel Coil?

Picking a coil based only on price can be a disaster. The technical specs are complex, leading to costly mistakes. The solution is a balanced approach considering application, performance, and budget.

The primary challenges are balancing cost against performance, understanding complex technical specifications, and forecasting long-term durability. Misjudging the required surface finish or mechanical strength for the application is a common and expensive pitfall.

One of the biggest challenges I see clients face is what I call "specification paralysis." They are confronted with a long data sheet of mechanical properties, chemical compositions, and finishing options, and it becomes overwhelming. I once worked with a large construction contractor in the Middle East who was building a major water desalination plant. They were focused purely on the corrosion resistance and initial cost, so they chose a premium cold-rolled coil for the internal piping framework. While the material was excellent, it was complete overkill. The internal pipes were not visible and did not require a perfect finish or tight dimensional tolerance. They could have used a specific grade of hot-rolled coil, properly pickled and oiled, and saved nearly 30% on their material costs without sacrificing performance or longevity. Their challenge was not a lack of options, but a lack of clarity on what truly mattered for their specific application. This is where a good supply partner adds value beyond just shipping a product. We help dissect the project's real needs.

Navigating the Core Dilemmas

- Cost vs. Quality Trade-off: The most common hurdle. The lower price of hot-rolled is tempting, but will the cost of secondary processing (like grinding the surface) negate the savings? Conversely, is the premium for cold-rolled justified if the part is hidden from view? The true cost is the total cost of ownership, not just the per-kilogram price.

- Technical Misinterpretation: Understanding the difference between tensile strength[^3] and yield strength, or knowing how a specific finish (like 2B vs. BA) will behave during fabrication, is crucial. A mistake here can lead to material failure or unexpected problems in your production line, causing downtime.

- Supply Chain Reliability: Even if you choose the perfect coil, can you get it on time? Market volatility, shipping delays, and production schedules can all disrupt your project. Choosing a partner with a robust, integrated supply chain like MFY's is a strategic move to mitigate this risk.

What Strategies Can You Use to Make an Informed Decision?

Making a choice under pressure can lead to regret. You need a reliable framework, not a guess. A structured evaluation process ensures you select the optimal coil for your project every time.

A key strategy is to create a project checklist. Define your application's requirements for surface finish, dimensional tolerance, mechanical strength, and corrosion resistance first. Then, compare these needs against the properties and cost of hot-rolled versus cold-rolled options.

Over the years, I've developed a simple but effective method to help our partners clarify their needs. We build a "Project Requirements Profile" together. It’s not a complex document, just a clear checklist that forces a methodical evaluation. Instead of starting with "What coil should I buy?", we start with "What does this part need to do?". This shifts the focus from the product to the application, which is the key to making the right choice. For instance, a manufacturer of commercial kitchen equipment needed coils for worktables. By using the checklist, we quickly identified the priorities: excellent corrosion resistance (food safety), a smooth and easy-to-clean surface (hygiene), and high durability. The choice immediately became clear: a cold-rolled 304-grade coil with a 2B finish was the perfect intersection of performance and cost. A cheaper hot-rolled option would have failed on the surface finish requirement, and a more expensive, highly polished finish was unnecessary. This simple, structured approach removes emotion and guesswork from the equation.

Your Coil Selection Checklist

Use this table as a starting point for your next project. Be honest and specific in your answers.

| Requirement Category | Your Project's Specific Need | Hot-Rolled Fit? (Yes/No/Maybe) | Cold-Rolled Fit? (Yes/No/Maybe) |

|---|---|---|---|

| 1. Primary Function | e.g., Structural support, decorative panel, container, pipe | ||

| 2. Surface Finish | e.g., Hidden, must be smooth, requires painting, polished look | ||

| 3. Dimensional Accuracy | e.g., Loose tolerance OK, must fit precisely with other parts | ||

| 4. Mechanical Needs | e.g., High formability, high tensile strength, impact resistance | ||

| 5. Post-Processing | e.g., Welding, deep drawing, bending, machining | ||

| 6. Budget Constraint | e.g., Cost-sensitive, performance is priority |

This framework makes the decision-making process transparent and defensible within your organization.

What Is the Best Technical Advice for Optimizing Coil Performance?

Even the right coil can underperform if handled incorrectly. This wastes material and time. Proper post-processing and application-specific adjustments are key to unlocking a coil's full potential.

For hot-rolled coils, consider pickling and oiling for a better surface and corrosion resistance. For cold-rolled, ensure your fabrication processes, like welding or forming, are adjusted for its higher hardness to prevent cracking and ensure longevity.

Your responsibility doesn't end once the coil is delivered. Maximizing its value happens on your factory floor. I often tell my clients that the material is only half the solution; the other half is how you work with it. A few years ago, an equipment integrator in India was having issues with their stamping process. They switched to a stronger, thinner gauge of cold-rolled steel to reduce weight, but their stamping dies were wearing out quickly and they saw micro-cracks forming at the bends. They were about to blame the material. After a quick call, we realized they hadn't adjusted their process. Cold-rolled steel is less ductile due to work hardening. We advised them to increase the bending radius slightly and adjust the pressure on their stamping machine. It was a simple fix that solved the problem instantly, saving them from costly downtime and material waste. This is the kind of practical, on-the-ground advice that turns a good material choice into a great business outcome.

Optimizing Your Chosen Coil

- For Hot-Rolled Coils: The dark, scaly oxide layer that forms during cooling (mill scale) can interfere with painting and welding. The most common and effective way to remove it is through a process called pickling, which involves an acid bath. After pickling, a light coating of oil is often applied to prevent rust from forming on the clean surface. If you’re using hot-rolled for structural parts, ensure your welding parameters account for its chemical composition to achieve a strong, reliable bond.

- For Cold-Rolled Coils: Because cold-rolling makes the steel harder, it's more resistant to bending and forming. This is known as work hardening. When designing your parts, be mindful of this. Use larger bend radii compared to what you would use for hot-rolled steel to avoid cracking. During welding, the smooth surface of cold-rolled steel provides a clean base, but its lower ductility requires careful heat management to prevent distortion or brittleness in the heat-affected zone.

Conclusion

The choice between hot-rolled and cold-rolled coil isn’t just technical; it’s a strategic business decision. By understanding their core differences and aligning them with your project's specific needs using a clear framework, you optimize both cost and performance, securing a competitive advantage in your market.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.