Global Stainless Steel Slit Coil Supplier

Sourcing precision slit coil[^1] is complex. Quality issues can halt production. We provide reliable, high-grade materials globally, ensuring your operations run smoothly and efficiently.

Choosing the right global stainless steel slit coil supplier involves evaluating their production capabilities, quality control systems, supply chain reliability, and ability to provide customized, precision-engineered solutions. A focus on technological integration and transparency is crucial for a successful partnership.

Making the right choice in a supplier is one of the most critical decisions for any manufacturing or construction business. It directly impacts your product quality, production timelines, and bottom line. As the Global Business Director at MFY, I’ve seen firsthand how a strong supplier partnership can drive success, and how a weak one can create endless problems. Let's dive into the key factors that define a top-tier supplier in today's demanding market.

What is the current global market landscape for stainless steel slit coil?

The market feels crowded and fragmented. It's hard to identify the true leaders from the noise. We see a clear shift towards specialized, high-value suppliers.

The current global market is highly competitive, characterized by a mix of large-scale mills and specialized service centers. Key trends include a growing demand for high-precision, customized coils and a geographical shift in production towards Asia, particularly China.

The global landscape for stainless steel slit coil is more dynamic than ever. For years, the market was dominated by traditional players, but now we see a significant concentration of production capacity and innovation in Asia. As a company deeply rooted in China’s integrated supply chain, we at MFY have a front-row seat to this evolution. The core of the market is no longer just about volume; it's about value. This value comes from the ability to provide precision-engineered materials that meet the demanding specifications of modern industries. OEMs[^2] and large manufacturers are not just buying a commodity; they are sourcing a critical component. They need a partner who understands the nuances of different grades, finishes, and tolerances. I remember a conversation with a potential client who was frustrated with their previous supplier's inability to deliver consistent slit-edge quality, causing major issues on their automated production line. This is a common story and highlights the growing need for suppliers who are not just traders, but true technical partners.

Key Market Players and Their Roles

The market consists of different types of suppliers, each with distinct advantages. Understanding them is key to making an informed choice.

| Supplier Type | Primary Focus | Best For |

|---|---|---|

| Integrated Mills | High-volume production of standard coils. | Large, predictable orders of common grades. |

| Service Centers | Precision slitting, custom finishing, and logistics. | Businesses needing specific widths and just-in-time delivery. |

| Global Traders | Sourcing and logistics management. | Companies needing access to a wide range of global sources. |

| Integrated Groups (like MFY) | End-to-end control from raw material to delivery. | Clients who need reliability, quality control, and customization. |

How has the demand for stainless steel slit coil evolved in recent years?

Old material specs are no longer enough. Industries demand higher performance and precision. We see this firsthand in the complexity of our clients' requests every day.

Demand has evolved from standard-grade coils to highly specialized products. Growth is driven by sectors like automotive (for lightweighting), electronics (for miniaturization), and renewable energy, all requiring materials with superior durability and specific mechanical properties.

The evolution in demand is remarkable. A decade ago, a significant portion of our orders were for standard 304 or 316 coils. Today, the conversations are far more specific. We are discussing materials for EV battery casings that require exceptional formability and corrosion resistance, or components for 5G base stations that need precise electromagnetic shielding properties[^3]. This shift is driven by innovation at the end-user level. As products become more sophisticated, the materials used to build them must keep pace. This is where the real value of a knowledgeable supplier comes in. We work with our clients not just to fulfill an order, but to find the optimal material solution that balances performance, cost, and manufacturability. I recall a client in the medical device industry who needed an incredibly thin, yet strong, stainless steel strip. Our ability to slit to their exact, tight tolerance specifications was the key factor that won their business and helped them launch a groundbreaking new product.

Sector-Specific Demand Drivers

- Automotive: The push for electric vehicles and lightweighting has created a huge demand for advanced high-strength stainless steels that offer safety without adding weight.

- Electronics: As devices get smaller and more powerful, the need for thin-gauge, precision-slit stainless steel for casings, connectors, and internal components has soared.

- Construction: Architects and engineers are increasingly using stainless steel for its durability, corrosion resistance, and aesthetic appeal in high-performance building facades and structural elements.

What challenges do suppliers face in the global stainless steel slit coil market?

Volatile raw material prices are a constant threat. Supply chain disruptions add even more risk. Suppliers must be incredibly agile to survive and thrive in this environment.

Suppliers face significant challenges, including volatile raw material costs, complex global logistics, intense price competition, and the increasing technical demand for tighter tolerances and consistent quality. Maintaining profitability while investing in new technology is a key struggle.

Navigating the global market is a constant balancing act. On one hand, we have the fluctuating costs of nickel and other raw materials, which can change dramatically in a short period. On the other, we face the logistical complexities of moving heavy materials across continents, dealing with shipping delays, port congestion, and customs regulations. I've spent many late nights on calls with our logistics teams and partners around the world to solve unexpected problems and keep our clients' shipments on track. These external pressures are compounded by intense competition. In a crowded market, there's always a temptation to compete solely on price, but that's a race to the bottom that ultimately compromises quality and service. The real challenge is to deliver consistent value and reliability in an unpredictable world. This means absorbing some of the volatility to provide stable pricing for our partners and having contingency plans in place to mitigate supply chain disruptions. It requires significant investment, experience, and a robust operational backbone.

Impact of Challenges on Customers

| Challenge | Direct Impact on the Customer |

|---|---|

| Raw Material Volatility | Unpredictable pricing and potential for sudden cost increases. |

| Logistical Disruptions | Production delays and line-down situations due to late material delivery. |

| Intense Competition | Risk of receiving lower-quality materials from suppliers cutting corners. |

| Technical Demands | Inconsistent quality or inability to meet specs from less capable suppliers. |

What strategies can suppliers adopt to overcome these challenges?

Simply competing on price is a losing game. True value is in reliability and partnership. At MFY, we focus on building a resilient and transparent supply chain.

Successful strategies include vertical integration to control costs, strategic inventory management to buffer against volatility, and investing in advanced slitting technology for precision. Building strong, transparent client relationships is also crucial for long-term success.

The only way to win in this market is to build a business model centered on resilience and customer value. This is the philosophy that drives us at MFY. We've invested heavily in creating a fully integrated supply chain, which gives us a level of control that many of our competitors lack. By managing everything from raw material sourcing to final production and export delivery, we can better manage costs, ensure quality at every step, and provide our clients with a reliable flow of materials. Another key strategy is maintaining a strong inventory of common grades. This allows us to act as a buffer for our clients against market shocks and offer rapid delivery times that keep their production lines moving. But technology and inventory are only part of the solution. The most important strategy is building true partnerships. We strive to understand our clients' businesses deeply, so we can anticipate their needs and function as an extension of their own team. This client-centric approach is what turns a simple transaction into a long-term, mutually beneficial relationship.

Pillars of a Resilient Supply Strategy

- Vertical Integration: Control over the supply chain from start to finish reduces dependency on third parties and ensures quality.

- Strategic Inventory: Holding key materials in stock provides a cushion against market volatility and shortens lead times for customers.

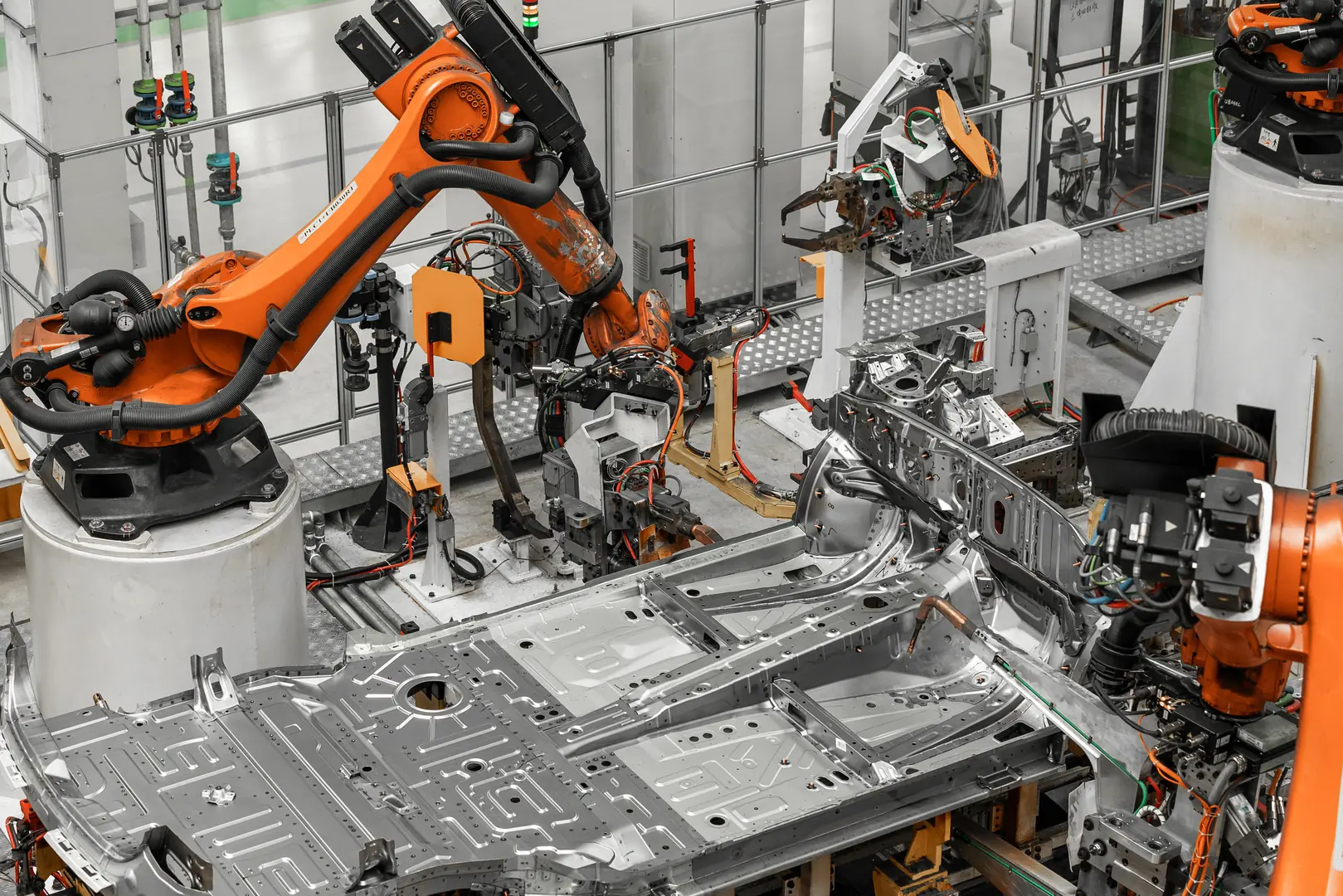

- Technological Investment: Modern equipment ensures precision, efficiency, and the ability to meet the most demanding technical specifications.

How can technological advancements improve the supply chain for stainless steel slit coil?

Tracking international orders is often a black box. Clients are left in the dark, causing anxiety. Technology is the definitive answer to this problem.

Technology, particularly digitalization, transforms the supply chain. Advanced tracking systems, real-time inventory management, and data analytics provide unprecedented transparency, improve efficiency, reduce lead times, and enable highly customized, just-in-time delivery models.

This is the area I am most passionate about because it represents the future of our industry. For too long, the steel supply chain has been opaque. A client places an order and then waits, hoping it shows up on time. Digitalization changes everything. At MFY, we are integrating digital systems that provide our clients with real-time visibility into their orders. They can see where their material is in the production process, when it has been loaded onto a vessel, and track its journey to their port. This transparency builds trust and allows them to plan their production schedules with much greater confidence. Internally, these systems allow us to optimize our own operations. By analyzing data, we can predict demand patterns, manage our inventory more effectively, and streamline our logistics. This digital pivot is not just about efficiency; it's about agility. It allows us to offer more customized solutions and respond faster to our clients' needs, moving from a traditional supplier to a responsive, integrated supply chain partner.

The Digital vs. Traditional Supply Chain

| Feature | Traditional Supply Chain | Digital Supply Chain (The MFY Way) |

|---|---|---|

| Order Tracking | Manual updates via email/phone. | Real-time, 24/7 online tracking portal. |

| Inventory | Based on historical estimates. | Data-driven, predictive inventory management. |

| Communication | Reactive, often initiated by the client. | Proactive alerts and transparent communication. |

| Flexibility | Rigid and slow to adapt to changes. | Agile and responsive to client needs. |

Conclusion

Choosing the right supplier is about more than price. It's about finding a partner with a resilient, transparent, and technologically advanced supply chain. This ensures you get the precision materials you need, exactly when you need them to keep your business moving forward.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.