How to Find and Verify a Trustworthy Stainless Steel Supplier

Choosing the wrong supplier puts your entire project at risk. Delays, poor quality, and broken promises can cripple your business. A systematic verification process is your best defense.

To find a trustworthy stainless steel supplier, you must conduct thorough research, verify certifications and references, assess their production capacity and delivery capabilities, and establish clear communication and terms. This multi-step process mitigates risk and ensures a reliable supply chain partner for your business.

Finding the right partner is more than a simple transaction; it's about building a resilient supply chain that can withstand global pressures. As the Global Business Director at MFY, I've seen firsthand how a reliable supplier can be a powerful competitive advantage. Let’s walk through the essential steps I use to ensure we partner with only the best.

How Should You Research Potential Suppliers and Create a Shortlist?

The global market is flooded with suppliers. It's overwhelming to know where to begin your search. A structured research plan helps you identify the top contenders efficiently.

Start by leveraging online B2B marketplaces, attending industry trade shows, and seeking referrals from your network. Compile a shortlist of 5-7 suppliers who appear to meet your initial criteria for further, more detailed evaluation.

In today's interconnected world, your research must be both broad and deep. The proliferation of digital marketplaces has been a game-changer, offering unprecedented transparency if you know where to look. I remember a few years ago, we needed a specialized grade of stainless steel for a client in Germany. Instead of relying solely on old contacts, we used a combination of industry-specific digital platforms and referrals. This dual approach allowed us to discover a fantastic supplier we would have otherwise missed. Your initial research is about casting a wide net but using smart filters to narrow the catch. This is not just about finding names; it’s about finding potential partners who align with your company's scale, quality requirements, and values.

Leveraging Digital Platforms

Modern B2B platforms provide more than just a directory. Look for suppliers who have a strong digital presence, complete with detailed product specifications, virtual factory tours, and transparent customer reviews. A supplier who invests in digital transparency is often more confident in their operations and more prepared for the demands of international trade. This digital footprint is your first clue to their professionalism and operational maturity.

Building Your Initial List

As you gather names, organize them in a simple comparison table. This helps you objectively assess them against your core needs.

| Supplier Name | Country of Origin | Key Products | Years in Business | Initial Red Flags |

|---|---|---|---|---|

| Supplier A | China | 304/316L Coil | 15+ | None Noted |

| Supplier B | Vietnam | Pipes & Tubes | 5 | Limited Reviews |

| Supplier C | China | All Grades | 20+ | None Noted |

This simple tool transforms a long list of possibilities into a manageable shortlist of high-potential partners ready for the next stage of verification.

Why is Evaluating Certifications and Quality Standards Crucial?

A supplier's claims about quality can be empty. Non-compliance with standards can lead to catastrophic product failures. Verifying certifications confirms their real commitment to quality and safety.

Evaluating certifications like ISO 9001 ensures the supplier adheres to international quality management standards. This verification is crucial because it directly correlates to product consistency, reliability, and the integrity of your final product, protecting your reputation and investment.

Certifications are the universal language of quality in our industry. They are the baseline, the non-negotiable proof that a supplier has a system in place to deliver what they promise. In an increasingly complex global supply chain, the risk of counterfeit or substandard materials is very real. I've seen projects delayed by months because a contractor tried to save a few cents per kilogram with an uncertified supplier, only to receive material that failed quality control. This is why at MFY, we don't just ask for a certificate; we verify its authenticity and scope. A commitment to quality is a commitment to your success. It’s a foundational element of trust and a key indicator of a supplier’s long-term viability as a partner.

Key Certifications to Look For

While ISO 9001 (Quality Management) is the most common, other certifications may be relevant depending on your industry. For example, if you're in the food and beverage or medical equipment sector, you'll need suppliers who can meet specific sanitary standards. For construction projects in Europe, the CE marking[^1] is essential. Don't just look for a logo on their website; ask for the certificate number and verify it with the issuing body.

Beyond the Certificate: The Culture of Quality

A certificate on the wall is one thing, but a deeply ingrained culture of quality is another. During your conversations, ask about their quality control processes. How do they handle non-conforming products? What is their procedure for material traceability? A truly great supplier can talk about their quality systems with passion and detail because it's central to their identity, not just a box they had to check. This aligns with the growing demand for traceability that defines our modern industry.

How Do You Conduct a Thorough Background Check and Verify References?

A polished website can easily hide a troubled history. Partnering with an unstable or disreputable company is a massive risk. Due diligence uncovers their true reputation and financial health.

Conduct a background check by reviewing their business registration, financial statements, and online reputation. Crucially, contact their provided references to ask specific questions about product quality, communication, and on-time delivery performance to get a real-world view of their operations.

This is where you move from what the supplier says about themselves to what the evidence and other people say about them. It's an essential step in building trust. I always tell my team that a supplier who is hesitant to provide references is a major red flag. A confident, reliable company will be proud of their partnerships and happy for you to speak with their clients. I remember a time we were considering a new supplier who looked perfect on paper. However, a call to one of their references revealed a consistent pattern of minor but frustrating shipping delays. That single conversation saved us from a partnership that would have caused constant friction for our logistics team. This is not about being suspicious; it's about being diligent to protect your own operations.

Financial Stability Assessment

You need a partner who will be in business for the long haul. Ask for a copy of their business license and, if possible, review their financial health through a third-party credit reporting agency. Are they profitable? Do they have a history of stable growth? A financially sound supplier is less likely to cut corners on quality or face disruptions that could impact your supply.

The Power of Real-World References

When you speak to a reference, go beyond generic questions. Prepare specific, insightful questions that get to the heart of the partnership.

- "Can you describe a time when there was a problem and how they handled it?"

- "How would you rate their communication and responsiveness on a scale of 1 to 10?"

- "Has their product quality remained consistent over the life of your partnership?"

The answers to these questions will give you a far more accurate picture than any marketing brochure ever could.

What's the Best Way to Assess a Supplier's Production Capacity and Timelines?

Promises of production capacity don't always match reality. Unexpected production delays can halt your entire operation. A clear, honest assessment of their capabilities prevents costly surprises later.

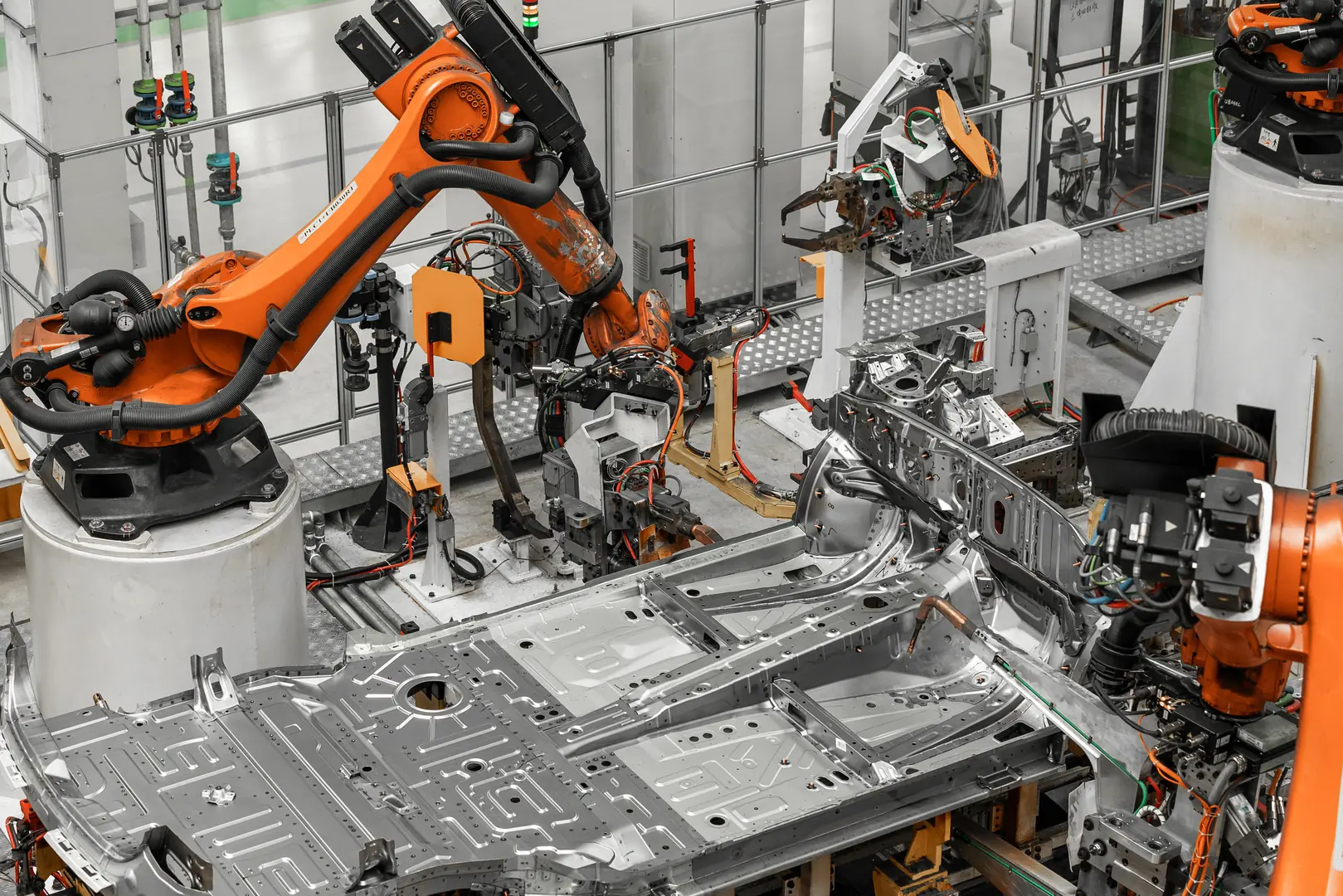

Assess production capacity by requesting a factory tour (virtual or in-person) and reviewing their equipment lists and output data. Scrutinize their logistics and supply chain management processes to verify their claimed delivery timelines and ensure they can meet your project's schedule.

A supplier's ability to deliver on time, every time, is the bedrock of a successful supply chain. This is where operational agility and resilience are truly tested. In today's global market, your supplier isn't just a producer; they are a critical logistics partner. We at MFY have built our reputation on a fully integrated supply chain, from raw materials to rapid export delivery, because we understand that our clients’ success depends on it. When evaluating a potential partner, you must look at their entire process. Do they have modern equipment? Is their warehouse organized and efficient? How do they manage inventory? The answers reveal their true capacity to handle your orders, especially during peak demand or unexpected market shifts.

From the Production Floor to Your Door

A factory tour, even a virtual one, is invaluable. It allows you to see their operations with your own eyes. Pay attention to the condition of the machinery, the workflow, and the general level of organization. Also, dig into their logistics. Who are their shipping partners? What is their process for export documentation? A supplier who has a weak grasp of international logistics is a significant risk. They must demonstrate a robust, transparent system for getting the product from their factory to your facility.

The Digital Edge in Logistics

The best suppliers are embracing digital tools to enhance transparency and efficiency. Ask if they offer real-time order tracking or use a digital inventory management system. Suppliers who leverage technology in their operations are better equipped to provide accurate timelines and proactively manage potential delays. This digital integration is no longer a luxury; it's becoming a key indicator of a forward-thinking, reliable partner.

How Can You Establish Clear Communication and Negotiate Favorable Terms?

Simple miscommunications can lead to expensive errors. Vague or incomplete terms can result in serious disputes later on. Proactive communication and clear contracts build a strong, lasting foundation.

Establish clear communication channels from the start and test their responsiveness. When negotiating, go beyond price to discuss payment terms, quality assurance protocols, and contingency plans for delays. A comprehensive contract is essential for a successful, long-term partnership.

This final step is about formalizing the relationship and setting clear expectations for both sides. The quality of your communication during the negotiation phase is often a strong indicator of what the partnership will be like. Are they responsive? Are they willing to listen to your needs? Or are they rigid and focused only on price? I've always found that the best partnerships are built on mutual understanding and respect, not just a signature on a purchase order. A supplier who treats you like a true partner will work with you to find solutions. This is the ultimate goal: to move beyond a simple transactional relationship to a strategic alliance that benefits both companies.

The Human Element: Building Rapport

Before you even talk about numbers, establish a primary point of contact. This person will be your lifeline. Test their responsiveness with a few non-urgent email inquiries. A quick, clear response is a great sign. A good relationship with your account manager can solve problems before they even begin. This human connection is the grease that keeps the gears of a global supply chain turning smoothly.

Key Contractual Considerations

Your final agreement should be comprehensive. It needs to cover all the key aspects of your partnership to avoid any future ambiguity.

| Contract Element | Key Points to Define |

|---|---|

| Product Specifications | Exact grade, finish, dimensions, and tolerances. |

| Pricing & Payment | Unit price, currency, payment terms (e.g., 30% T/T, 70% LC). |

| Delivery Terms | Incoterms (e.g., FOB, CIF), lead times, port of loading. |

| Quality Assurance | Inspection procedures, Mill Test Certificate (MTC) requirements. |

| Contingency Plans | Penalties for delays, procedures for handling defects. |

A detailed contract isn't about a lack of trust; it's about creating a clear roadmap for a successful and predictable partnership.

Conclusion

Finding and verifying a supplier requires diligence. By systematically researching, verifying quality, checking backgrounds, assessing capacity, and communicating clearly, you build a resilient supply chain. This structured approach transforms a major business risk into a powerful strategic advantage, ensuring you have a trustworthy partner for years to come.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.