As a stainless steel manufacturer, I've noticed increasing anxiety among buyers about volatile coil prices. Many struggle to make informed purchasing decisions in this uncertain market.

Current stainless steel coil prices range from $2,000 to $4,500 per metric ton, varying by grade, thickness, and market location1. Prices have shown significant fluctuation due to raw material costs and market dynamics.

Having spent over 15 years in the stainless steel industry, I've witnessed numerous price cycles and their impact on businesses. Let me share insights that will help you understand the current market situation and make better purchasing decisions.

The pricing of stainless steel coils is more complex than most buyers realize. Recent market analysis shows that prices can vary by up to 40% across different regions and grades. Understanding these variations and their underlying causes is crucial for both buyers and sellers in today's dynamic market.

What Factors Determine the Price of Stainless Steel Coils?

In my experience managing pricing strategies, I've seen how multiple factors interplay to influence final costs, often surprising even seasoned buyers.

The price of stainless steel coils is primarily determined by raw material costs (particularly nickel and chromium)2, production expenses, market demand, and global economic conditions.

Cost Component Analysis

Our comprehensive breakdown of pricing factors reveals interesting patterns:

| Component | Percentage of Total Cost | Impact Level | Volatility |

|---|---|---|---|

| Raw Materials | 60-65% | High | Very High |

| Production Costs | 20-25% | Medium | Moderate |

| Transportation | 5-8% | Low | Medium |

| Market Factors | 10-15% | High | High |

Recent data from our factory operations shows that raw material fluctuations can impact final prices by up to 40% within a single quarter.

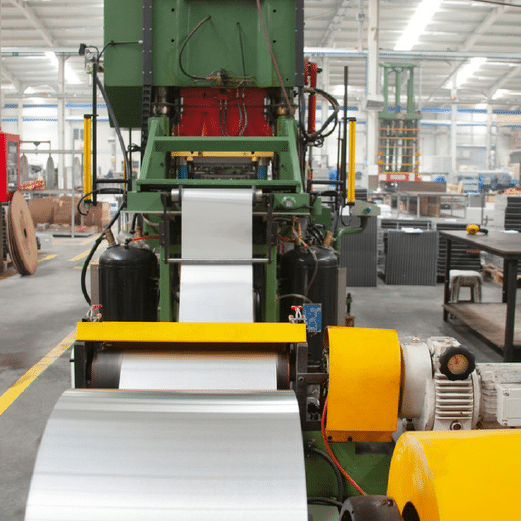

Production Technology Impact

Manufacturing efficiency plays a crucial role:

- Modern production lines reduce costs by 15-20%

- Energy efficiency improvements save 8-12%

- Automation decreases labor costs by 25-30%

Quality Grade Variations

Different grades command different prices:

- 304 grade3 serves as the market benchmark

- 316 grade typically costs 25-35% more

- 430 grade usually costs 15-20% less

Our market research indicates that grade selection can impact total project costs by up to 40%.

How Do Market Trends Affect the Price of Stainless Steel Coils?

Through years of market analysis, I've observed how global trends can create ripple effects throughout the industry.

Market trends4 significantly influence stainless steel coil prices, with factors like global economic conditions, industrial demand, and trade policies causing price fluctuations of up to 30% within months.

Global Economic Indicators

Key economic factors affecting prices:

| Indicator | Impact Level | Price Sensitivity | Trend Duration |

|---|---|---|---|

| GDP Growth | High | 15-20% | Long-term |

| Industrial Production | Very High | 20-25% | Medium-term |

| Construction Activity | Medium | 10-15% | Short-term |

Our data shows strong correlation between global GDP growth and price movements.

Trade Policy Effects

International trade dynamics:

- Tariff changes impact prices by 10-30%

- Trade agreements5 affect regional pricing

- Export/import regulations influence availability

Industry Sector Demand

Demand variations by sector:

- Automotive industry influences 25% of demand

- Construction sector affects 30% of market

- Industrial applications drive 35% of consumption

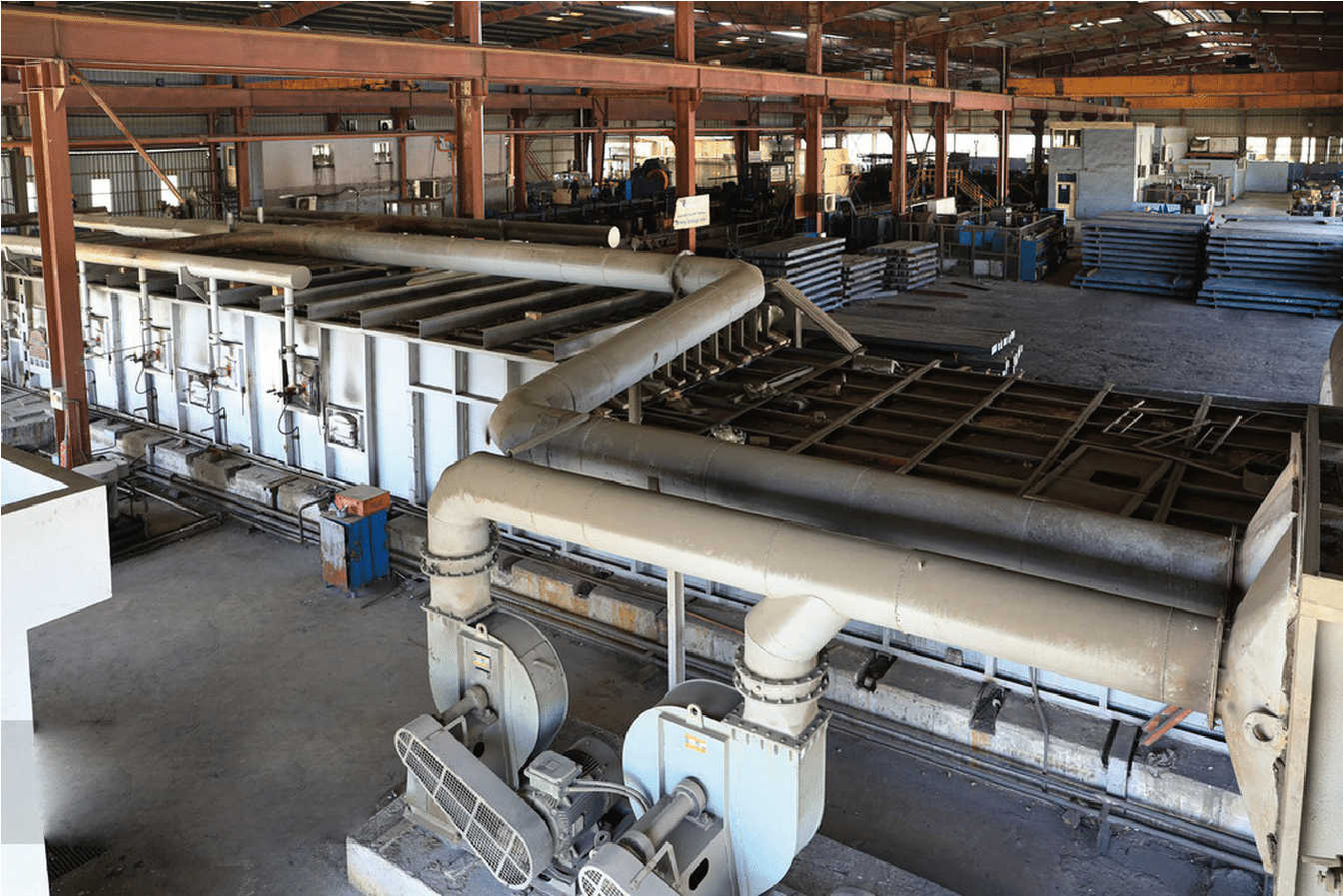

What Role Do Raw Material Costs Play in Stainless Steel Coil Pricing?

Managing our supply chain has taught me the critical importance of raw material costs in pricing dynamics.

Raw materials account for 60-65% of stainless steel coil prices, with nickel, chromium, and molybdenum6 being the primary cost drivers. Price fluctuations in these materials can cause significant changes in final product pricing.

Key Material Cost Analysis

Breakdown of material impacts:

| Material | Cost Share | Price Volatility | Supply Risk |

|---|---|---|---|

| Nickel | 35-40% | Very High | High |

| Chromium | 20-25% | Medium | Medium |

| Molybdenum | 5-10% | High | Medium |

Our procurement data shows nickel price fluctuations can affect final product cost by up to 25%.

Supply Chain Factors

Critical supply chain elements:

- Mining production affects availability

- Processing capacity influences costs

- Transportation logistics7 impact pricing

Market Speculation Impact

Financial market influences:

- Commodity trading affects short-term prices

- Future contracts impact long-term pricing

- Investment patterns affect availability

How Does Supply and Demand Influence Stainless Steel Coil Prices?

My experience in market analysis has shown that supply-demand dynamics are often the primary price drivers.

Supply and demand balances can cause price variations of 20-30% within a single quarter. Current market conditions show strong demand growth in developing markets while supply adjusts to new capacity additions.

Market Balance Analysis

Supply-demand relationship:

| Factor | Current Status | Price Impact | Market Response |

|---|---|---|---|

| Production Capacity | Increasing | Moderate | Price Stability |

| Consumption Rate | Growing | High | Price Increase |

| Inventory Levels | Varying | Medium | Short-term Fluctuation |

Our market research indicates a 15% annual growth in global demand.

Regional Demand Patterns

Geographical demand variations:

- Asian markets show 20% annual growth

- European demand remains stable

- North American consumption increasing by 10%

Supply Chain Disruptions

Impact of supply interruptions:

- Production delays affect prices by 10-15%

- Transportation issues cause 5-10% variations

- Raw material shortages impact costs by 20-25%

What Are the Regional Variations in Stainless Steel Coil Pricing?

Operating globally has given me unique insights into regional price differences and their causes.

Regional price variations can reach up to 25% due to local market conditions, transportation costs, and trade policies. Asian markets typically offer lower prices, while European and North American markets command premium rates.

Regional Price Comparison

Market price analysis:

| Region | Price Range | Market Share | Growth Rate |

|---|---|---|---|

| Asia | $2,000-3,000/MT | 60% | 8-10% |

| Europe | $2,500-3,500/MT | 20% | 3-5% |

| Americas | $2,300-3,300/MT | 15% | 5-7% |

Our global sales data shows consistent regional price patterns with seasonal variations.

Local Market Factors

Key regional influences:

- Labor costs affect production expenses

- Energy prices impact manufacturing costs

- Local demand patterns influence pricing

Trade Flow Impact

International trade considerations:

- Shipping costs affect final prices

- Import duties vary by region

- Local regulations impact availability

Conclusion

Current stainless steel coil prices reflect a complex interplay of raw material costs, market dynamics, and regional factors, requiring careful consideration of multiple variables for optimal purchasing decisions.

-

Understand how grades and locations affect price differences ↩

-

Learn the impact of raw materials on pricing ↩

-

Discover why 304 grade is a common standard ↩

-

Explore how economic factors influence pricing ↩

-

Understand how trade policies affect pricing ↩

-

Learn about critical materials in production ↩

-

Find out logistic impacts on pricing ↩