How to Compare Stainless Steel Suppliers: The Ultimate Checklist for Exporters

Choosing the wrong stainless steel supplier can disrupt your entire operation. These mistakes risk your project deadlines, product quality, and your company's reputation. This checklist ensures you find a reliable partner.

To compare stainless steel suppliers, you must create a comprehensive checklist. This list should evaluate their production capacity, quality certifications, pricing structures, logistical efficiency, and service capabilities. A multi-dimensional approach ensures you select a resilient and reliable long-term partner, not just a low-cost vendor.

Selecting the right partner is one of the most critical decisions you'll make as an exporter. It's about more than just securing material; it's about building a resilient supply chain that can weather market volatility and drive your competitive edge. As the Global Business Director at MFY, I've seen firsthand how a strategic evaluation process separates successful exporters from those who struggle. Let's walk through the essential steps to build your own ultimate supplier checklist.

Why Is Identifying Your Stainless Steel Requirements the First Step?

Unclear project needs lead to incorrect quotes and material mismatches. This ambiguity causes costly delays and sourcing errors, derailing your project from the start. Clearly define your needs first.

Identifying your specific stainless steel requirements is the foundational first step. It allows you to communicate precise needs for grade, finish, dimensions, and quantity, ensuring potential suppliers can provide accurate quotes and confirm their capability to deliver exactly what your project demands.

Before you can evaluate a supplier, you must have a perfect understanding of what you need. This seems obvious, but it's a step where many companies falter, leading to significant issues down the line. A detailed specification is your primary tool for communication and evaluation. It’s not just about the grade of steel; it’s a comprehensive picture of your project’s demands. At MFY, we always begin our client conversations by building this detailed profile, because it eliminates guesswork and establishes a clear benchmark for success.

Building Your Specification Profile

Your technical requirements form the basis of any request for quotation (RFQ). Be as detailed as possible.

- Grade and Standard: Are you looking for 304, 316L, 430, or another specific grade? What international standard must it comply with (e.g., ASTM, EN)?

- Dimensions and Tolerances: Specify the required thickness, width, and length. Crucially, what are the acceptable tolerances? A supplier’s ability to meet tight tolerances is a key indicator of their technical prowess.

- Finish and Processing: Do you need a standard 2B finish, or something more specialized like No. 4, Hairline, or Mirror? Do you require secondary processing like slitting, cut-to-length, or surface polishing?

Quantifying Your Demand

Beyond the technical specs, your business needs are just as important.

| Requirement | Description | Why It Matters |

|---|---|---|

| Order Volume | What is your typical order quantity? Is it a full container load (FCL) or less than container load (LCL)? | This determines if you need a large mill or a more flexible trading partner. |

| Frequency | How often will you be placing orders? Is this a one-time project or a recurring need? | A supplier's inventory strategy and production planning must align with your cycle. |

| Target Market | Where is the final destination? (e.g., India, Southeast Asia, Middle East) | This impacts shipping logistics, documentation, and potential import duties. |

By defining these parameters first, you create a clear scorecard to measure every potential supplier against.

How Should You Research Potential Suppliers?

A quick online search yields hundreds of suppliers, but many lack credibility. Relying on surface-level results can lead you to inexperienced or unreliable partners. You need a deeper research strategy.

Effective research involves a multi-pronged approach. Go beyond search engines and utilize industry directories, attend trade shows, and seek referrals. Scrutinize their digital presence, looking for evidence of their operational scale, market experience, and customer testimonials to create a qualified shortlist.

Once you know what you need, the hunt for the right partner begins. In today's digital world, a supplier's online footprint is a direct reflection of their professionalism and integration capabilities. A company that invests in a clear, informative, and transparent digital presence is more likely to be a modern, efficient operator. I always advise clients to look for suppliers who are not just selling a product, but are also sharing knowledge and demonstrating their expertise. This is a sign of a true partner. Your research should aim to filter the vast market down to a handful of candidates who appear to have the scale, experience, and professionalism to meet your needs. Look for evidence of a fully integrated supply chain, from raw material sourcing to production and export logistics. This integration is a hallmark of a resilient supplier.

Digital and Traditional Vetting

A robust research process combines modern tools with timeless business practices.

- Digital Deep Dive: Don't just visit their homepage. Explore their "About Us" section to understand their history and scale. Look for case studies or project galleries that showcase their work in your target industry or region. Check for a blog or resource center—this signals a commitment to industry leadership and client education.

- Industry Networks: Are they members of reputable industry associations? Do they exhibit at major international trade fairs like those in Düsseldorf or Shanghai? Physical presence at these events is a significant investment and a strong indicator of a serious, globally-focused company.

- Request for Information (RFI): Before sending a formal RFQ, send a brief RFI to your shortlisted candidates. Their response time, professionalism, and the clarity of their answers will tell you a lot about their customer service culture.

I remember a client in Southeast Asia who was about to partner with a supplier based on a slick website alone. I urged them to dig deeper. We discovered the "supplier" was just a small trading office with no direct control over production, a risk my client couldn't afford. Thorough research prevented a potential disaster.

What Credentials and Certifications Should You Evaluate?

A low price from an uncertified supplier is a huge gamble. Without verified credentials, you have no guarantee of quality, consistency, or ethical production practices. This exposes you to massive risk.

You must evaluate internationally recognized certifications. Prioritize suppliers with ISO 9001 for quality management and ISO 14001 for environmental standards. Also, request mill test certificates (MTCs) for every batch to verify chemical composition and mechanical properties against your specifications.

Credentials are the proof behind the promises. In the global stainless steel market, certifications are not just "nice-to-haves"; they are essential indicators of a supplier's commitment to quality, safety, and operational excellence. A supplier who has invested in achieving and maintaining these standards is demonstrating a long-term vision and a disciplined approach to business. This is particularly crucial for exporters who are accountable to their own customers for quality and compliance. When we at MFY provide our partners with our certification portfolio, it's not just a formality. It's our way of providing tangible assurance that our processes, from raw material procurement to final product inspection, are managed to the highest global standards. This focus on verifiable quality is a cornerstone of building trust and a resilient partnership.

The Non-Negotiable Certifications

Certain credentials should be mandatory on your checklist. A supplier who cannot provide them should be disqualified immediately.

| Certification/Credential | What It Verifies | Why It's Critical for Exporters |

|---|---|---|

| ISO 9001:2015 | A robust Quality Management System (QMS) is in place. | Ensures process consistency, continuous improvement, and a systematic approach to quality. |

| ISO 14001 | Compliance with environmental management standards. | Demonstrates corporate responsibility and mitigates risks for buyers in eco-conscious markets. |

| Mill Test Certificate (MTC) | The specific chemical and physical properties of the material batch. Conforms to EN 10204 3.1. | Provides absolute traceability and proof that the material meets your technical specifications. |

| Business License | Legal registration and authority to operate and export. | Confirms you are dealing with a legitimate, legally compliant entity. |

Assessing Production and Technical Capacity

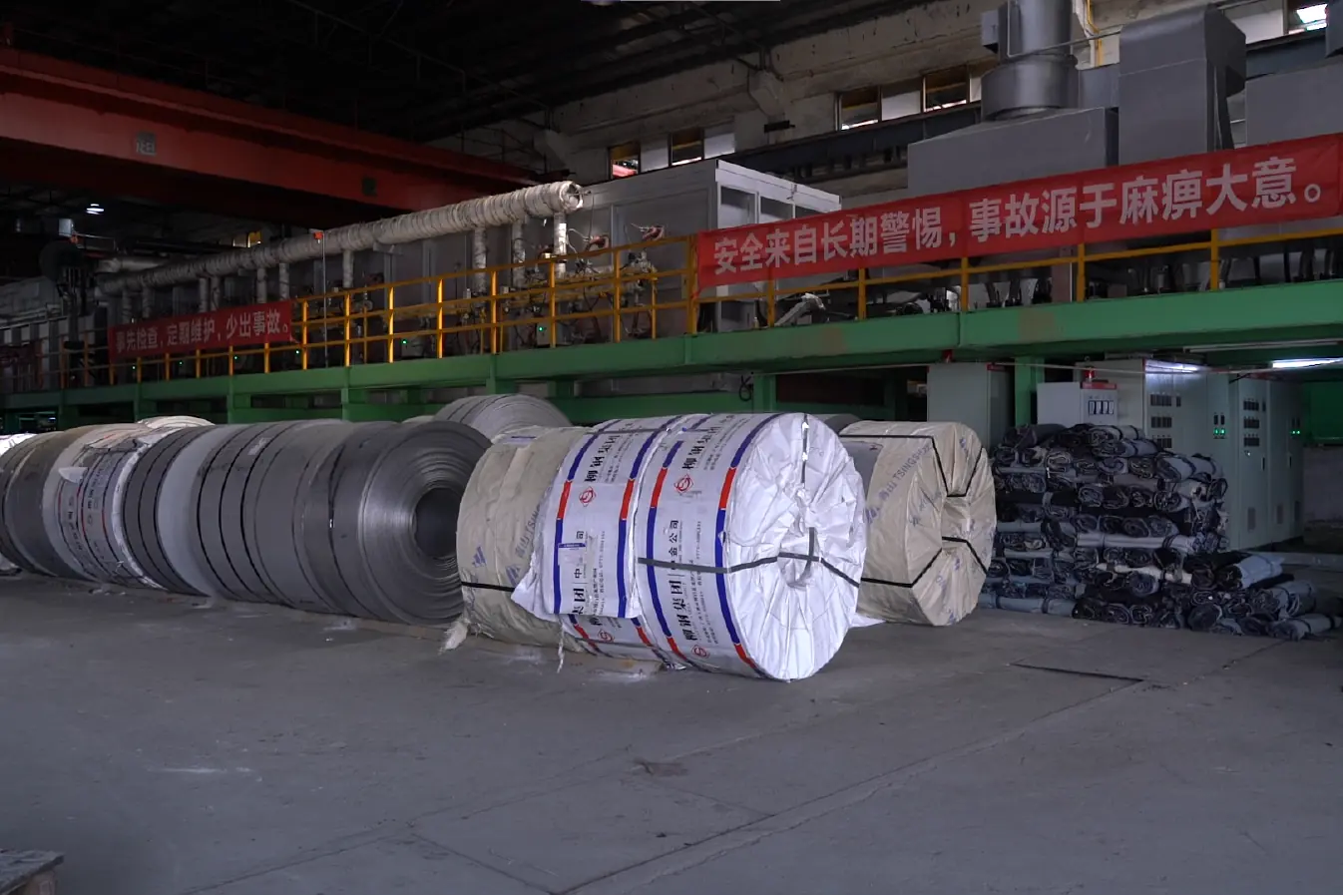

Beyond paperwork, you need to assess their real-world capabilities. Ask for a virtual or, if possible, an in-person tour of their facilities. Look for modern equipment, organized workflows, and evidence of a strong safety culture. A supplier with advanced processing technologies, like high-precision slitters or laser cutters, can offer more value and act as a one-stop shop, simplifying your supply chain.

How Do You Assess Pricing and Payment Terms Fairly?

Focusing only on the lowest unit price is a common mistake. This ignores hidden costs like poor quality, shipping delays, and unfavorable payment terms that can destroy your project budget.

Assess the total cost of ownership, not just the price per ton. Compare pricing alongside payment terms, shipping costs (Incoterms), and the supplier's inventory capacity. A slightly higher price from a reliable supplier with flexible terms is often more profitable.

Price is always a factor, but it should never be the only one. The smartest exporters I work with understand the concept of Total Cost of Ownership (TCO)[^1]. The initial quote is just one piece of a much larger puzzle. You must factor in logistics, financing costs, and the potential cost of failure. What is the cost of a delayed shipment? What is the cost of receiving a batch of material that is out-of-spec? These risks have real financial implications. A credible supplier like MFY understands this. We work with clients to find a balance between competitive pricing and secure, flexible payment terms that support their cash flow. We know that a partnership built on mutual financial stability is one that will last.

Deconstructing the Quote

When you receive a quote, break it down to ensure you are comparing apples to apples.

- Unit Price vs. Incoterms: Is the price quoted Ex-Works (EXW), Free on Board (FOB), or Cost, Insurance, and Freight (CIF)? An FOB price might look cheaper than a CIF price, but once you add your own freight and insurance costs, it could end up being more expensive. Always compare using the same Incoterm.

- Validity Period: How long is the quote valid for? In a volatile market, a short validity period can be a major risk. A supplier willing to offer a longer validity period demonstrates confidence in their supply chain.

- Payment Terms: A supplier demanding 100% payment upfront may signal a lack of financial stability. Look for partners offering more balanced terms, such as 30% deposit and 70% against a bill of lading (B/L) copy. This shows they are confident in their product and service.

I recall a new client from the Middle East who had previously been burned by a supplier offering a rock-bottom price but demanding 100% T/T in advance. The shipment was delayed by two months, tying up his capital and delaying his project. He now understands that fair payment terms are a critical sign of a trustworthy partner.

Why Are Delivery and Service Capabilities So Critical?

A great product is useless if it doesn't arrive on time. Poor logistics and unresponsive service can cause production shutdowns, penalty clauses, and damage your reputation with your end customer.

Delivery and service are critical because they ensure your material arrives on time and that any issues are resolved quickly. A supplier with a strong, integrated logistics team and responsive customer service minimizes disruptions, protecting your project timelines and profitability.

In the world of global trade, logistics is not an afterthought—it's a core competency. This is where a supplier's true capabilities are tested, especially when exporting to complex markets across India, Southeast Asia, or Latin America. An integrated supplier with deep logistical expertise can navigate customs, optimize shipping routes, and provide accurate tracking. This is the final, and perhaps most important, piece of the puzzle. At MFY, our agility comes from our complete control over the supply chain. Our dedicated logistics and service teams work as an extension of our clients' teams. We don't just sell steel; we deliver solutions. We understand that our success is directly tied to our ability to deliver the right product to the right place at the right time, every time.

Evaluating Logistical Prowess

Look for tangible evidence of a supplier's delivery capabilities.

- Lead Times: What is their standard production and delivery lead time? Do they have a track record of meeting these timelines? Ask for references you can speak to about their delivery performance.

- Inventory Strategy: Does the supplier maintain a significant inventory of standard products? A strong inventory position, like MFY's, allows for rapid dispatch and can be a lifesaver for urgent orders.

- Documentation Expertise: Exporting requires a mountain of paperwork. A good supplier will have an experienced team that can provide accurate and timely shipping documents (Bill of Lading, Commercial Invoice, Packing List, Certificate of Origin) to ensure smooth customs clearance.

The Service Difference

Finally, assess the quality of their service. During your evaluation process, how responsive have they been? Do you have a single, dedicated point of contact? A supplier who communicates clearly, proactively, and honestly—especially when challenges arise—is an invaluable asset. This is the foundation of a true, long-term partnership that can help you navigate the complexities of the global stainless steel market and drive sustainable growth.

Conclusion

Choosing the right stainless steel supplier is a strategic decision that impacts your entire business. By moving beyond price and using this comprehensive checklist, you can identify partners who offer quality, reliability, and long-term value, safeguarding your supply chain and boosting your competitive advantage.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.