In my 15 years of manufacturing stainless steel sheets, I've witnessed countless innovative applications that continue to amaze me. The versatility of this material never ceases to expand.

Stainless steel sheets are extensively used across multiple industries, from automotive and construction1 to medical and aerospace sectors. Their corrosion resistance, durability, and aesthetic appeal make them ideal for diverse applications.

Having supplied stainless steel sheets to various industries worldwide, I've gained unique insights into their applications. Let me share how these versatile materials are transforming different sectors and why they might be perfect for your next project.

The applications of stainless steel sheets represent a fascinating intersection of engineering, aesthetics, and practicality. Through my experience working with clients across different industries, I've observed how these materials consistently deliver superior performance while meeting increasingly demanding specifications.

How Are Stainless Steel Sheets Utilized in the Automotive Industry?

During a recent collaboration with a major automotive manufacturer, I witnessed firsthand how stainless steel sheets are revolutionizing vehicle design and performance.

In automotive applications, stainless steel sheets are crucial for exhaust systems, structural components, and decorative trim2. Their high strength-to-weight ratio and corrosion resistance make them ideal for modern vehicle manufacturing.

Automotive Applications Overview

Based on our supply data and industry experience:

| Component | Grade Used | Benefits | Typical Thickness (mm) |

|---|---|---|---|

| Exhaust Systems | 409, 439 | Heat resistance | 1.0 - 2.0 |

| Body Panels | 304, 316 | Corrosion resistance | 0.8 - 1.5 |

| Fuel Tanks | 316L | Chemical resistance | 1.5 - 2.5 |

| Structural Parts | 301 | High strength | 1.2 - 3.0 |

Performance Requirements

Through our testing and quality control processes, we focus on:

-

Mechanical Properties

- Tensile strength requirements

- Impact resistance

- Fatigue performance

- Formability characteristics

-

Environmental Resistance

- Salt spray resistance

- Temperature tolerance

- Chemical resistance

- Weather exposure durability

-

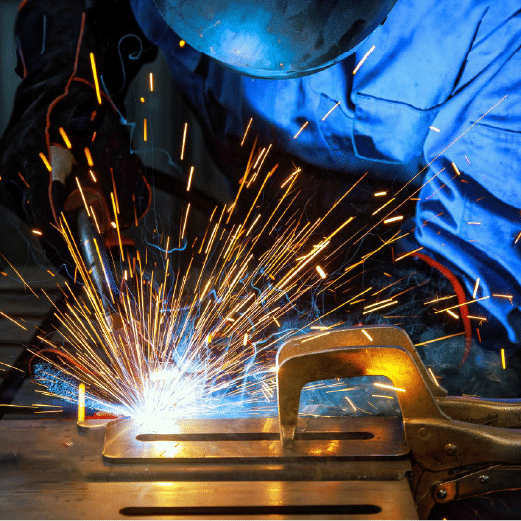

Manufacturing Considerations

- Weldability factors

- Forming capabilities

- Surface finish options

- Cost-effectiveness

What Role Do Stainless Steel Sheets Play in the Construction Sector?

As someone who's supplied materials to numerous construction projects, I've seen stainless steel sheets transform modern architecture and building practices.

In construction, stainless steel sheets are essential for facades, roofing, structural elements, and architectural features3. Their durability and low maintenance requirements make them cost-effective over the building's lifetime.

Construction Applications Matrix

Our market analysis reveals:

| Application | Preferred Grade | Key Features | Life Expectancy (Years) |

|---|---|---|---|

| Facades | 316, 304 | Aesthetic appeal | 50+ |

| Roofing | 444, 316L | Weather resistance | 40+ |

| Structural | 2205 | High strength | 100+ |

| Interior | 304 | Easy maintenance | 30+ |

Design Considerations

Our engineering team emphasizes:

-

Architectural Requirements

- Aesthetic appearance

- Load-bearing capacity

- Installation methods

- Maintenance access

-

Environmental Factors

- Local climate conditions

- Pollution exposure

- Coastal considerations

- UV radiation resistance

-

Economic Aspects

- Initial investment

- Maintenance costs

- Replacement intervals

- Energy efficiency

Success Stories

We've documented numerous successful implementations:

-

Commercial Building Project

- Challenge: Coastal environment

- Solution: 316L facade panels

- Result: Zero corrosion after 10 years

-

Stadium Construction

- Challenge: Complex curved surfaces

- Solution: Custom-formed 304 sheets

- Result: Award-winning design

-

Industrial Facility

- Challenge: Aggressive environment

- Solution: 2205 duplex structural elements

- Result: Superior performance in harsh conditions

How Are Stainless Steel Sheets Applied in the Food Processing Industry?

Throughout my career supplying materials to food processing facilities, I've seen how critical proper stainless steel selection is for maintaining hygiene standards and operational efficiency.

Stainless steel sheets are fundamental in food processing, used in equipment, storage tanks, and preparation surfaces4. Their non-porous surface, corrosion resistance, and easy cleaning properties make them essential for maintaining food safety standards.

Food Industry Applications

Our experience with food processing clients shows:

| Application | Recommended Grade | Surface Finish | Certification Required |

|---|---|---|---|

| Prep Tables | 304, 316L | 2B, No.4 | FDA, HACCP |

| Storage Tanks | 316L | 2B, BA | 3-A Sanitary |

| Processing Equipment | 316L, 304L | No.4, EP | USDA, FDA |

| Transport Containers | 304 | 2B, BA | FDA, ISO 22000 |

Sanitary Requirements

Through our quality control processes, we ensure:

-

Surface Properties

- Smoothness measurements

- Porosity testing

- Finish consistency

- Crevice elimination

-

Material Performance

- Chemical resistance

- Temperature tolerance

- Impact resistance

- Wear resistance

-

Compliance Standards

- FDA regulations

- HACCP requirements

- ISO certifications

- Industry-specific standards

What Are the Uses of Stainless Steel Sheets in the Medical Field?

My experience working with medical facility projects has shown me the critical importance of material selection in healthcare environments.

In medical applications, stainless steel sheets are vital for surgical equipment, sterilization units, and hospital furniture5. Their ability to withstand repeated sterilization while maintaining sterility makes them indispensable in healthcare settings.

Medical Application Requirements

Based on our medical sector supply data:

| Application | Grade Used | Critical Properties | Sterilization Method |

|---|---|---|---|

| Surgical Tables | 316L | High polish | Steam/Autoclave |

| Medical Cabinets | 304 | Easy cleaning | Chemical |

| Laboratory Equipment | 316L | Chemical resistant | UV/Chemical |

| Sterilization Units | 316Ti | Heat resistant | High-temperature |

Performance Specifications

Our medical grade products focus on:

-

Sterility Maintenance

- Surface finish requirements

- Bacterial resistance

- Cleaning protocols

- Contamination prevention

-

Durability Factors

- Chemical resistance

- Wear resistance

- Impact strength

- Fatigue performance

-

Safety Considerations

- Non-toxic properties

- Non-magnetic options

- Biocompatibility

- Traceability requirements

How Are Stainless Steel Sheets Employed in the Aerospace Industry?

Having worked with aerospace manufacturers, I've witnessed the demanding requirements for materials in this sector.

Aerospace applications utilize stainless steel sheets in aircraft structures, engine components, and cabin equipment6. Their high strength-to-weight ratio and excellent fatigue resistance make them crucial for aviation safety.

Aerospace Applications Overview

Our aerospace sector experience shows:

| Component | Grade Selection | Key Requirements | Testing Standards |

|---|---|---|---|

| Engine Parts | 17-4PH | Heat resistance | AMS 5604 |

| Structural Components | 301 | High strength | AMS 5517 |

| Cabin Equipment | 304L | Light weight | AMS 5513 |

| Fuel Systems | 316L | Corrosion resistance | AMS 5524 |

Technical Requirements

Our aerospace materials meet:

-

Performance Standards

- Fatigue resistance

- Stress tolerance

- Temperature limits

- Weight specifications

-

Safety Certifications

- FAA requirements

- EASA standards

- Material traceability

- Quality documentation

-

Manufacturing Controls

- Precision tolerances

- Surface quality

- Heat treatment

- Non-destructive testing

Success Stories

Notable aerospace implementations include:

-

Commercial Aircraft Project

- Challenge: Weight reduction

- Solution: Custom thin-gauge 301 sheets

- Result: 15% weight savings

-

Engine Component Manufacturing

- Challenge: High-temperature exposure

- Solution: Specialized 17-4PH grade

- Result: Extended service life

-

Fuel System Design

- Challenge: Corrosion prevention

- Solution: Modified 316L composition

- Result: Zero corrosion incidents

Conclusion

Stainless steel sheets demonstrate remarkable versatility across industries, from medical and aerospace to food processing, providing reliable solutions for demanding applications while meeting strict industry standards.

-

Learn about diverse industry applications of stainless steel sheets ↩

-

Explore their role in enhancing vehicle design and performance ↩

-

Understand their importance in modern architecture and building ↩

-

Discover the hygiene benefits in food processing applications ↩

-

Find out about its role in maintaining sterility in healthcare ↩

-

Learn about their application in aviation safety and engineering ↩