In my 15 years of supplying stainless steel pipes, I've seen their crucial role across diverse industries. Their unique combination of corrosion resistance and strength makes them indispensable for critical applications.

Stainless steel pipes are extensively used in oil and gas, pharmaceutical, construction, food processing, and automotive industries1, where their corrosion resistance, durability, and hygienic properties are essential for safe and reliable operations.

Through my experience serving various industries, I've gained deep insights into how stainless steel pipes meet specific application requirements. Let me share how different sectors leverage these versatile products for optimal performance.

The versatility of stainless steel pipes continues to expand with technological advancements. Having supplied pipes for countless applications, I understand how material selection impacts operational success2 across industries.

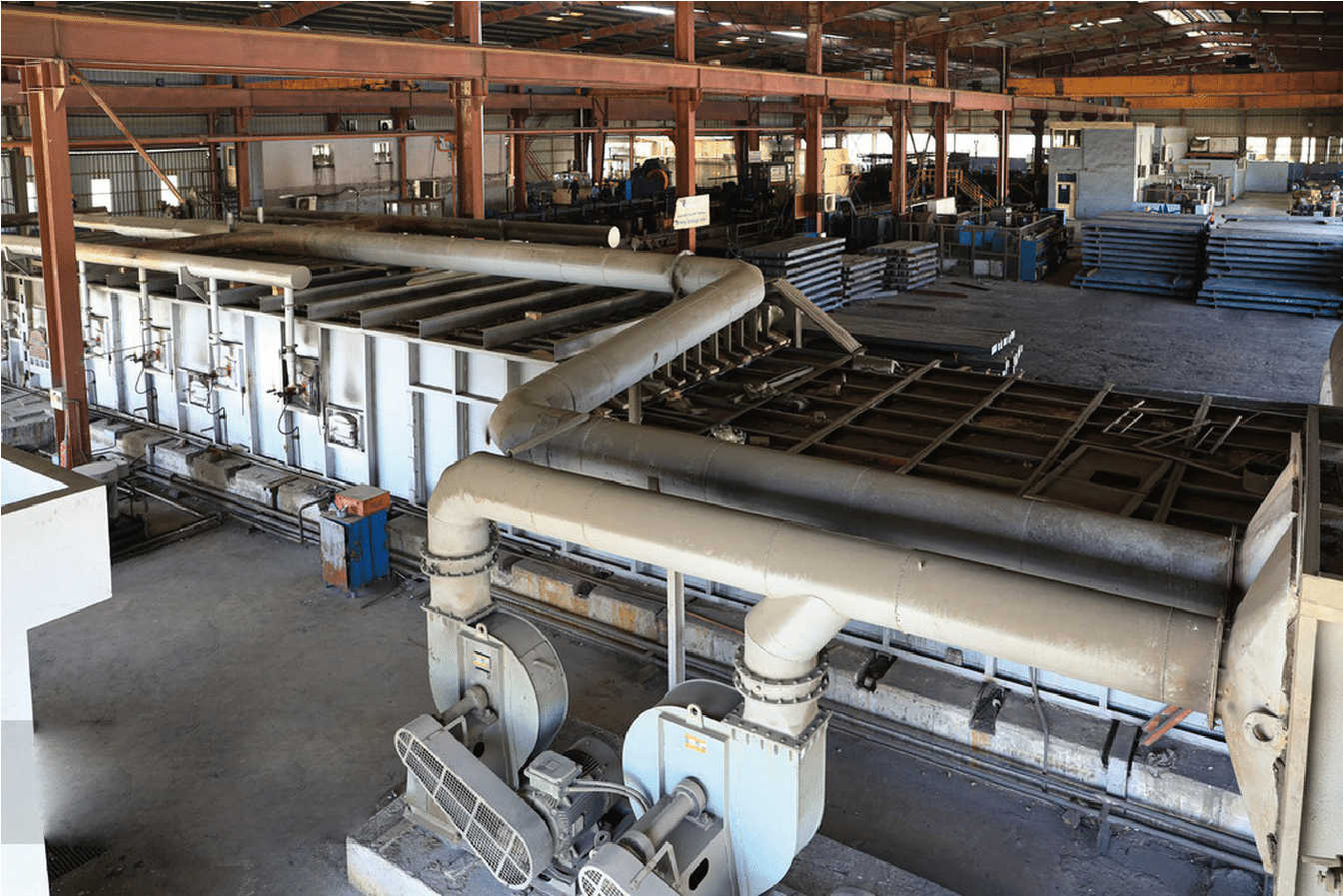

How Are Stainless Steel Pipes Used in the Oil and Gas Industry?

Drawing from extensive experience with oil and gas clients, I've seen how crucial proper pipe selection is for this demanding sector.

In the oil and gas industry, stainless steel pipes are used for process piping, transportation lines, offshore platforms, and refinery equipment3, where their corrosion resistance and high-pressure capabilities are essential.

Upstream Applications

-

Offshore Platforms:

- Production risers

- Flow lines

- Injection systems

- Process piping

-

Drilling Operations:

- Drill string components

- Casing systems

- Production tubing

- Well completion

| Application | Grade | Key Requirements |

|---|---|---|

| Sour Service | 316L/317L | H2S resistance |

| Seawater | Super Duplex | Chloride resistance |

| High Pressure | Duplex | Strength/corrosion |

Downstream Processing

-

Refinery Systems:

- Process lines

- Heat exchangers

- Storage systems

- Transfer piping

-

Chemical Processing:

- Reaction vessels

- Distillation units

- Cooling systems

- Product transfer

What Role Do Stainless Steel Pipes Play in the Pharmaceutical Sector?

The pharmaceutical industry demands the highest standards of cleanliness and material purity.

Stainless steel pipes in pharmaceuticals are used for ultra-pure water systems, process piping, clean steam distribution, and product transfer lines4, where maintaining product purity is paramount.

Clean Utility Systems

-

Pure Water Distribution:

- WFI systems

- Purified water

- Clean steam

- CIP/SIP systems

-

Process Requirements:

- Surface finish Ra ≤0.5μm

- Zero dead legs

- Full drainability

- Cleanability

| System Type | Grade | Surface Finish |

|---|---|---|

| WFI | 316L | Ra ≤0.5μm |

| Clean Steam | 316L | Ra ≤0.8μm |

| Process | 316L | Ra ≤1.2μm |

Production Systems

-

Manufacturing Lines:

- Product transfer

- Batch processing

- Sterile barriers

- Waste handling

-

Quality Requirements:

- Material certification

- Surface validation

- Installation qualification

- Performance verification

How Are Stainless Steel Pipes Utilized in the Construction Industry?

Construction applications demand durability and aesthetic appeal.

In construction, stainless steel pipes serve both functional and architectural purposes, including structural supports, handrails, drainage systems, and decorative elements5.

Structural Applications

-

Support Systems:

- Load-bearing columns

- Structural frames

- Tension members

- Connection elements

-

Building Services:

- Water supply

- Fire protection

- HVAC systems

- Drainage networks

| Application | Grade | Design Considerations |

|---|---|---|

| Structural | 304/316 | Load capacity |

| External | 316 | Weather resistance |

| Internal | 304 | Cost-effectiveness |

Architectural Features

-

Decorative Elements:

- Handrails

- Balustrades

- Façade elements

- Interior features

-

Performance Requirements:

- Aesthetic finish

- Durability

- Maintenance ease

- Weather resistance

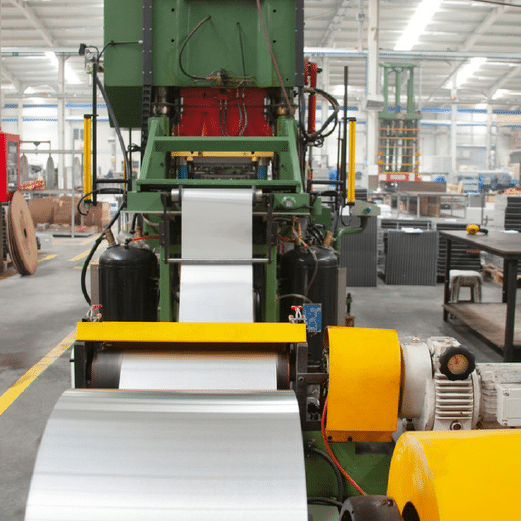

What Applications in Food Processing Require Stainless Steel Pipes?

Food processing demands materials that maintain product safety and quality.

Food processing applications utilize stainless steel pipes for product transfer, CIP systems, steam distribution, and process equipment6, where hygiene and cleanability are critical.

Process Systems

-

Product Transfer Lines:

- Raw material handling

- Processing systems

- Packaging lines

- Storage transfer

-

Cleaning Systems:

- CIP circuits

- Sanitization

- Steam cleaning

- Waste handling

-

Utility Services:

- Steam distribution

- Cooling systems

- Water supply

- Process air

Quality Requirements

-

Material Standards:

- FDA compliance

- 3-A certification

- EHEDG guidelines

- ISO requirements

-

Surface Specifications:

- Internal finish

- External finish

- Joint quality

- Cleanability

-

Maintenance Protocols:

- Cleaning procedures

- Inspection requirements

- Validation methods

- Documentation needs

How Are Stainless Steel Pipes Employed in the Automotive Industry?

The automotive sector requires reliable and efficient fluid handling systems.

Automotive applications use stainless steel pipes in exhaust systems, fuel lines, brake lines, and various fluid handling systems7 where corrosion resistance and durability are essential.

Exhaust Systems

-

System Components:

- Headers

- Catalytic converters

- Mufflers

- Tailpipes

-

Performance Requirements:

- Heat resistance

- Corrosion protection

- Durability

- Weight optimization

-

Design Considerations:

- Flow efficiency

- Noise reduction

- Thermal expansion

- Installation constraints

Fluid Systems

-

Critical Applications:

- Fuel lines

- Brake lines

- Cooling systems

- Hydraulic systems

-

Safety Standards:

- Pressure ratings

- Temperature limits

- Fatigue resistance

- Chemical compatibility

-

Manufacturing Requirements:

- Precision bending

- Clean assembly

- Quality testing

- Documentation

Conclusion

Stainless steel pipes serve critical roles across multiple industries, from ensuring process safety in oil and gas to maintaining product purity in pharmaceuticals. Their versatility, durability, and corrosion resistance make them essential for modern industrial applications.

-

Discover the diverse industrial applications of stainless steel pipes ↩

-

Learn about the impact of material choice on industry operations ↩

-

Explore specific applications of pipes in oil and gas sector ↩

-

Understand purity maintenance in pharmaceutical piping systems ↩

-

Learn about functional and architectural uses in construction ↩

-

Understand the importance of pipes for hygiene in food industry ↩

-

Discover the role of pipes in automotive fluid handling ↩