Stainless Steel Coil Slitting Service at Best Price: Global Export Service

Struggling with high costs and inconsistent quality for custom-sized coils? This uncertainty disrupts your production. We offer precision slitting[^1] at competitive prices, delivered globally.

A best-price global export service for stainless steel coil slitting combines precision machinery, efficient logistics, and lean manufacturing. This integration minimizes waste and shortens lead times, delivering custom-sized coils cost-effectively to international clients.

In my role as Global Business Director at MFY, I’ve seen firsthand how a reliable, cost-effective slitting service can transform a client's entire production process. It’s not just about cutting steel; it's about providing a foundational component that is precise, dependable, and economical. So, let's explore how we navigate the complexities of providing this top-tier service for the global market and what you should look for in a partner.

What Exactly is a Stainless Steel Coil Slitting Service?

Need specific coil widths for your manufacturing line? Using standard sizes creates waste and adds cost. Slitting services provide the exact dimensions you require, optimizing material use.

Stainless steel coil slitting is a precision manufacturing process. A master coil is unwound and fed through a slitter machine, which uses rotary knives to cut it into narrower strips of specific widths. These strips are then rewound into smaller coils, or "mults."

At its core, slitting is a value-added service that transforms a large, standardized raw material into a semi-finished product ready for a specific application. I remember a client in the automotive sector in Mexico who was generating significant scrap by stamping parts from standard-width sheets. By providing them with coils slit to their exact required width, we eliminated a huge source of material waste and improved their production efficiency overnight. It's a simple change with a massive impact. The process is more than just cutting; it's about precision engineering that ensures the final product meets tight specifications.

The Core Process Explained

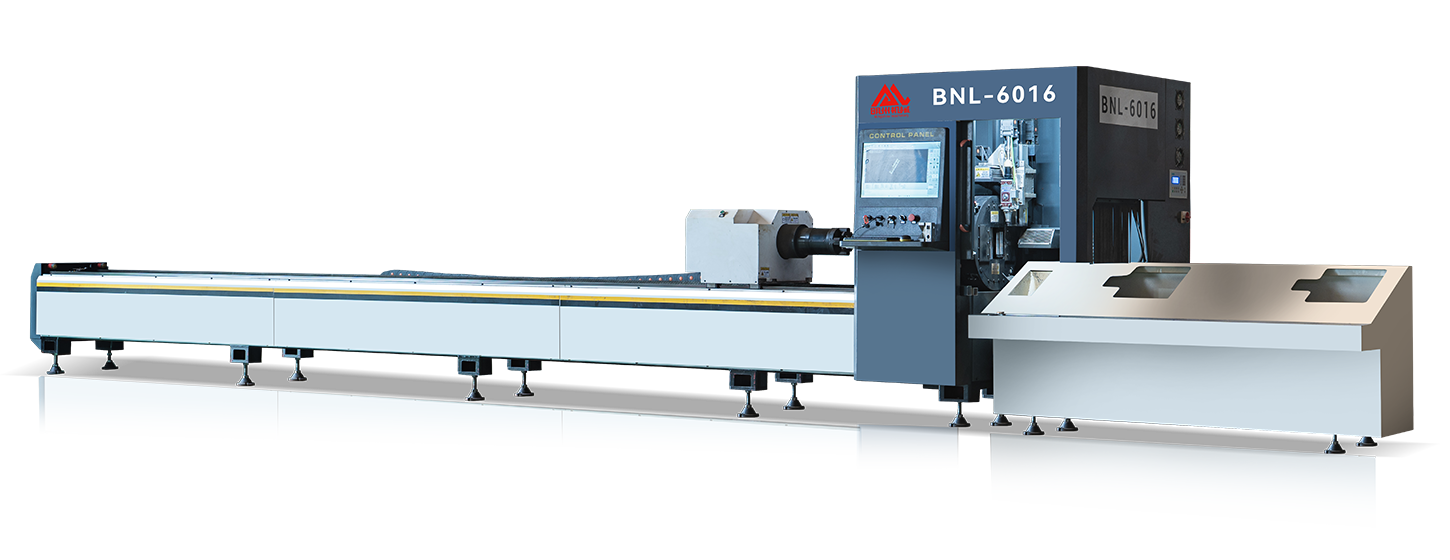

The slitting line is a sophisticated setup. It starts with an uncoiler that carefully handles the master coil. The steel then passes through the slitter head, where circular knives, positioned with extreme accuracy, make the cuts. The tension and speed are carefully controlled to prevent any defects like camber[^2] or edge burr[^3]. Finally, the newly slit strips are wound onto a recoiler, ready for packaging and shipping. Each step is critical for maintaining the integrity and quality of the steel.

Why Precision Matters

For our clients in manufacturing, construction, or equipment integration, dimensional accuracy is non-negotiable. A coil that is even a millimeter off-spec can cause major downstream problems, leading to equipment jams, production delays, and finished goods that fail quality control. This is why we invest in state-of-the-art machinery and rigorous quality checks.

| Feature | Standard Coil | Custom Slit Coil |

|---|---|---|

| Width | Standardized (e.g., 1219mm) | Custom, to exact specification |

| Material Waste | High, from trimming/stamping | Minimal, optimized for process |

| Production Setup | Requires in-house cutting | Ready for immediate use |

| Overall Cost | Lower initial price, higher total cost | Higher service price, lower total cost |

What are the Key Trends in Global Stainless Steel Coil Exports Today?

Is your supply chain agile enough for today's market? Global demand is shifting rapidly. Understanding current trends is essential for staying competitive and securing reliable supply.

Current trends include a rising demand for customized, ready-to-use materials and a shift towards just-in-time (JIT) inventory models. There's also a growing emphasis on supply chain resilience and digital tracking for enhanced transparency from order to delivery.

The global market is evolving. Ten years ago, the focus was primarily on exporting large volumes of standard-sized coils. Today, our most successful partnerships are with clients who need more than just a commodity; they need a service. They want a partner who can deliver slit coils that feed directly into their production lines with minimal prep work. This shift reflects a broader industry move towards efficiency and lean manufacturing. It's no longer enough to just produce steel; we must deliver solutions. This means integrating our services deeply into our clients' supply chains, anticipating their needs, and providing the flexibility they require to thrive.

From Commodity to Customization

The biggest trend I see is the demand for value-added services. Clients don't want to hold large inventories of master coils and manage the slitting process themselves. It's inefficient and ties up capital. They prefer to order specific widths and quantities as needed, aligning with JIT principles. This "on-demand" model places a huge responsibility on us as the supplier to be agile and responsive, which is a challenge we at MFY have built our business around.

The Rise of Digital Supply Chains

Transparency is everything in global trade. Our clients want to know where their order is at every moment. That’s why integrating digital tracking systems[^4] has become standard practice. From the moment an order is placed to the time it arrives at their port, our clients have visibility. This digital thread builds trust and allows them to plan their production schedules with much greater confidence, reducing the risk of costly shutdowns due to material shortages.

| Trend | Old Model | New Model |

|---|---|---|

| Product Focus | Standard Master Coils | Custom-Slit, Ready-to-Use Coils |

| Inventory Strategy | Large, on-site inventory | Just-in-Time (JIT) delivery |

| Supplier Role | Raw material provider | Integrated supply chain partner |

| Visibility | Opaque, manual updates | Real-time digital tracking |

What Makes Providing Cost-Effective Slitting Services So Challenging?

Wondering why slitting service prices vary so much? Hidden costs and inefficiencies can inflate the final price. The challenge is balancing precision, speed, and cost control.

The main challenges are managing material waste (scrap), high operational costs from energy and tooling, and complex logistics for global export. Fluctuating raw material prices and maintaining consistent quality across different batches also add significant pressure on pricing.

Delivering a slit coil at a competitive price is a complex balancing act. Anyone can cut steel, but doing it efficiently, with minimal waste, and to a consistently high standard is where the real expertise lies. The price you see on an invoice is the result of a long chain of cost-management decisions. We have to account for the cost of the raw material, the energy consumed by the machinery, the wear and tear on the slitting knives, the labor involved, and the intricate dance of international logistics. Every fraction of a percentage in waste we can reduce, or every hour we can shave off a delivery time, translates directly into a more competitive price for our clients.

The Battle Against Scrap

Material yield is the single most important factor in cost-effective slitting. The portion of the master coil that becomes scrap (edge trim) is a direct loss. Our focus on lean manufacturing techniques is relentless. We use advanced software to plan the slitting layout for maximum efficiency, ensuring we get the most usable strips from every single master coil. This optimization is a key part of how we keep our prices competitive.

Navigating Global Logistics

For export services, the job isn't done until the coils are at the client's facility. Shipping costs, customs duties, and port fees can add significantly to the final price. Managing this requires a deep understanding of international trade routes and regulations. Our integrated supply chain at MFY gives us a major advantage here, as we can streamline the process from our factory floor to the client's door.

| Cost Component | Description | Impact on Final Price |

|---|---|---|

| Material Yield | Percentage of master coil converted to finished product. | High (Scrap is a direct cost) |

| Operational Costs | Energy, labor, and tooling (knives). | Medium |

| Logistics & Shipping | Freight, insurance, customs, and port fees. | High (Especially for export) |

| Quality Control | Inspection and testing to prevent defects. | Medium (Cost of failure is very high) |

How Can a Supplier Overcome These Export Challenges?

Worried about supply chain disruptions affecting your international orders? Exporting slit coils involves many risks. A strategic approach is needed to ensure smooth, on-time delivery.

Overcoming export challenges requires a multi-faceted strategy. This includes optimizing logistics partnerships, implementing robust quality control at every stage, using digital platforms for real-time tracking, and maintaining flexible production schedules to absorb market shocks.

Successfully exporting a precision product like slit stainless steel coils requires more than just a good price; it requires resilience. The global supply chain is full of potential disruptions, from shipping delays to sudden changes in trade policy. I've seen companies struggle because their supply chain was too rigid. At MFY, we’ve built our export model on a foundation of agility and proactive problem-solving. We don't just react to issues; we build systems designed to anticipate and mitigate them. This approach is what allows us to deliver on our promises of quality, speed, and cost-effectiveness, no matter where in the world our clients are located.

Integrated Logistics for Seamless Delivery

We don't just hand our product off to the lowest-bidding freight forwarder. We have built strong, long-term relationships with a network of trusted logistics partners. This integration allows us to have greater control and visibility over the entire shipping process. We can optimize routes, consolidate shipments to reduce costs, and navigate complex customs procedures more efficiently. This seamless flow is crucial for ensuring that our clients receive their materials on time and without any unexpected fees or delays.

Proactive Quality Assurance

Quality control shouldn't be a final inspection; it must be embedded in every step. Our process includes checks on the raw master coil, continuous monitoring during the slitting process, and a final inspection of the rewound coils before they are packaged. This multi-layered approach ensures that any potential issue is caught and corrected early, long before it becomes a problem for the client.

| Challenge | MFY's Strategic Solution |

|---|---|

| Shipping Delays | Diversified logistics network and real-time tracking. |

| Customs Complexity | In-house expertise and strong local partnerships. |

| Damage in Transit | Robust, export-grade packaging and container loading protocols. |

| Quality Inconsistency | Multi-stage quality control from raw material to final product. |

What Technologies are Making Slitting Services More Efficient?

Are you leveraging the latest technology in your supply chain? Outdated processes lead to higher costs and slower delivery. Modern tech is a game-changer for efficiency.

Key technological innovations include automated slitting lines with high-precision sensors for minimal burr and exact width tolerance. Digital tracking systems and lean manufacturing software also optimize material flow, reduce waste, and provide clients with real-time order visibility.

Technology is the engine driving efficiency in our industry. The difference between a modern, automated slitting line and an older, manual one is night and day. It’s not just about speed; it's about precision and consistency. I recently toured one of our new facilities where a fully automated line was running. The level of control was incredible. Sensors monitored the steel's tension, thickness, and width in real-time, making micro-adjustments to ensure every meter of the slit coil was perfectly within spec. This is how we guarantee quality while also operating at a speed and efficiency that keeps costs down. This investment in technology is a direct investment in the value we provide to our customers.

The Power of Automation and Precision

Modern slitting machines use computer numerical control (CNC)[^5] systems to position the knives with microscopic accuracy. This drastically reduces setup times between jobs and ensures repeatable, consistent results. High-precision sensors detect any deviation from the set parameters, allowing for immediate correction. This level of automation minimizes human error and produces a cleaner edge with less burr, which is a critical quality factor for many of our clients' applications.

Digitalization: From Order to Delivery

Beyond the factory floor, technology connects our entire operation. When a client places an order, it's entered into an integrated system that schedules production, allocates material, and plans the logistics. As I mentioned earlier, this digital backbone provides complete transparency. Our clients can log in to a portal and see the status of their order, from slitting to shipping. This isn't just a convenience; it's a critical tool for modern supply chain management.

| Feature | Traditional Slitting Line | Modern Automated Line |

|---|---|---|

| Setup | Manual, time-consuming | Automated, CNC-controlled |

| Precision | Dependent on operator skill | Sensor-monitored, highly consistent |

| Waste | Higher due to setup errors | Minimized via software optimization |

| Data & Tracking | Manual paperwork | Real-time digital tracking |

Conclusion

Ultimately, securing the best price for global coil slitting isn't just about the cost per ton. It's about partnering with a supplier who uses technology, lean processes, and integrated logistics to deliver unmatched value, precision, and reliability directly to your production line.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.