Why the Automotive Industry is Adopting Stainless Steel Coils for Enhanced Safety and Durability?

Automakers face intense pressure for safer, longer-lasting cars. Traditional materials are reaching their limits. Stainless steel coils provide the strength and resilience needed for the future of mobility.

The automotive industry is adopting stainless steel coils because their high tensile strength, corrosion resistance, and superior energy absorption meet rising safety regulations and consumer demands for durability. This makes them ideal for critical components in both traditional and electric vehicles, ensuring longevity and reliability.

This shift isn't just a trend; it's a fundamental change in how we build cars. In my role at MFY, I see this transformation firsthand every day. Let's break down why this is happening and what it means for the industry.

Why are safety and durability more critical than ever in the automotive industry?

The road is more demanding than ever. Consumers expect cars to protect them and last longer. This forces manufacturers to seek out superior materials that can meet these high stakes.

Safety and durability are paramount due to stricter global safety regulations, higher consumer expectations for vehicle longevity, and the structural demands of new technologies like heavy EV battery packs. These factors drive the need for stronger, more resilient materials.

Let's dive a little deeper into these driving forces. The landscape of automotive design is being reshaped by two powerful currents: evolving expectations and technological disruption. At MFY, we are in constant dialogue with our automotive partners, and these topics dominate our conversations.

The Push from Regulators and Consumers

Global safety standards, like the NCAP ratings[^1], are becoming increasingly stringent. A five-star safety rating is no longer a luxury feature; it's a baseline expectation for most car buyers. Consumers are more informed than ever and they are demanding vehicles that not only protect their families in a crash but also withstand the test of time without succumbing to rust and degradation. This dual demand for active and passive safety, combined with a desire for long-term value, puts immense pressure on material selection. The material must be strong enough to create a rigid safety cell around passengers and durable enough to maintain that integrity for years.

The Impact of New Vehicle Technologies

The transition to electric vehicles (EVs) introduces a completely new set of structural challenges. The large, heavy battery packs that form the floor of most EVs require an incredibly strong and rigid frame to support them and protect them from impact. Stainless steel provides the necessary strength-to-weight ratio to manage this load without adding excessive weight. Furthermore, as advanced driver-assistance systems (ADAS)[^2] become standard, the vehicle's underlying structure must be robust and stable to ensure the sensors and cameras function correctly.

How are stainless steel coils being used in today's vehicles?

You might not see it, but stainless steel is there. It’s working hard in unseen but critical areas. We are providing the backbone for modern vehicle performance and safety.

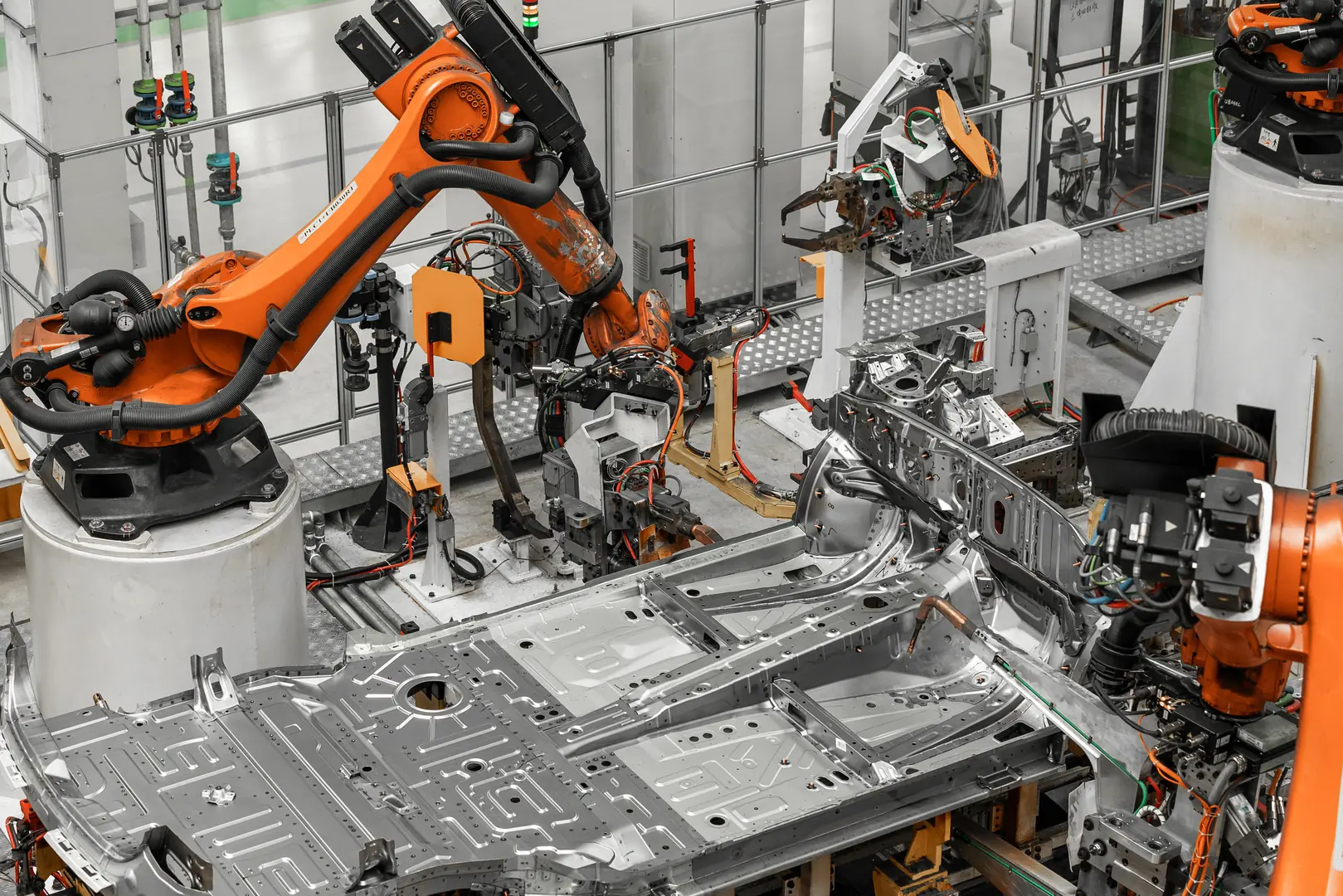

Stainless steel coils are used to manufacture key components like exhaust systems, fuel tanks, and structural reinforcements in the chassis and body-in-white. Their strength is also vital for crash-resistant structures like A-pillars, B-pillars, and side-impact beams.

The application of stainless steel in modern cars is both strategic and widespread. It's chosen for specific parts where its unique properties can provide the greatest benefit. This isn't about replacing every component, but about using the right material in the right place for maximum impact.

From Exhausts to Electric Vehicle Enclosures

Historically, stainless steel's most common automotive application was in exhaust systems, where its resistance to high temperatures and corrosion is essential. Ferritic grades[^3], like 409 and 439, became the industry standard. However, today's applications are far more advanced. We now see stainless steel used for fuel tanks, where it prevents corrosion from modern biofuels, and for critical fluid lines. A major growth area is in EV battery enclosures. These enclosures must protect the battery cells from physical impact and contain a potential thermal event. High-strength stainless steel is one of the best materials for this job.

Structural Integrity and Crash Performance

This is where stainless steel truly shines. Advanced high-strength stainless steels are engineered to absorb enormous amounts of energy during a collision. They are used to form the "safety cage" of the vehicle, including the A and B pillars, roof rails, and side-impact beams. By using stainless steel in these areas, automakers can design components that are stronger yet thinner, which helps reduce overall vehicle weight while simultaneously improving passenger protection. This is the core of modern, safe vehicle design.

What are the limitations of traditional automotive materials?

For years, mild steel and aluminum were the go-to. But they have weaknesses, especially with corrosion and strength-to-weight ratios. These limitations create challenges for modern car design.

Traditional materials like mild steel are prone to corrosion, adding long-term maintenance costs and compromising structural integrity. While aluminum is lightweight, it can be less durable and more expensive to repair, posing challenges for high-stress safety applications.

To understand why stainless steel is gaining ground, we must first look at the challenges presented by the materials it's often replacing. Every material has trade-offs, but in the context of today's automotive demands, the weaknesses of traditional choices are becoming more apparent.

The Material Trade-Off

For decades, the choice was simple: use low-cost carbon steel and protect it with coatings. But these coatings can be compromised by stone chips and scratches, leading to rust that weakens the vehicle's structure over time. Aluminum was introduced as a lightweight alternative, but it comes with its own set of issues, including higher material costs and more complex, expensive repair procedures. The real challenge is finding a material that balances strength, weight, cost, and long-term durability.

A Quick Comparison

Here's a simplified look at how these materials stack up. As you can see, stainless steel offers a compelling blend of properties that directly addresses the shortcomings of the others.

| Feature | Mild Carbon Steel | Aluminum | Stainless Steel |

|---|---|---|---|

| Corrosion Resistance | Low (requires coating) | High | Very High |

| Tensile Strength | Moderate | Moderate | High to Very High |

| Repairability | Easy / Inexpensive | Difficult / Expensive | Moderate |

| Lifecycle Cost | Low initial, high maint. | High initial, high repair | Moderate initial, low maint. |

This table makes it clear. While the initial cost of stainless steel might be higher than mild steel, its superior performance and longevity make it a more valuable and reliable choice for building safe and durable vehicles.

What specific advantages do stainless steel coils offer for automotive applications?

Manufacturers need a material that is strong, durable, and sustainable. This seems like a difficult balance to strike. Stainless steel coils deliver on all three fronts, offering a comprehensive solution.

Stainless steel coils provide superior corrosion resistance, high tensile strength for better crash performance, and excellent energy absorption. They also offer a longer lifecycle and are 100% recyclable, aligning with industry sustainability goals and reducing long-term ownership costs.

The case for stainless steel is built on a foundation of clear, measurable benefits that align perfectly with the automotive industry's current and future needs. It’s not just about one single feature, but about the powerful combination of safety, durability, and sustainability.

Unmatched Durability and Safety

The inherent corrosion resistance of stainless steel means that its structural integrity does not degrade over time due to rust. A safety component made of stainless steel will perform just as well ten years from now as it did on day one. This is a huge advantage over coated carbon steel. Furthermore, its high ductility and work-hardening characteristics mean it can absorb a massive amount of crash energy before failing. This allows engineers to design safer vehicles without adding unnecessary bulk or weight, which is a critical aspect of modern lightweighting strategies.

Lifecycle Cost and Sustainability

While the upfront material cost may be a consideration, the total lifecycle cost is where stainless steel provides exceptional value. The lack of corrosion reduces warranty claims and enhances brand reputation for quality. At the end of the vehicle's life, stainless steel is 100% recyclable without any loss of its original properties. This makes it a key component of the circular economy and helps automakers meet increasingly strict environmental and sustainability targets. It’s a material that is not only good for the car but also good for the planet.

How can manufacturers optimize their use of stainless steel coils?

Simply switching materials isn't enough. You need the right strategy to get the most benefit. We can help you integrate stainless steel effectively into your production lines.

Manufacturers can optimize by selecting the right grade of stainless steel for each specific application, leveraging advanced forming techniques like hot stamping and hydroforming, and integrating it early in the design phase. Collaborating with an experienced supplier is key to success.

Successfully integrating stainless steel into automotive production is a science. It requires a deep understanding of material properties, manufacturing processes, and design principles. Simply substituting it for another material won't unlock its full potential.

Grade Selection is Critical

There is no "one-size-fits-all" stainless steel. The family of stainless steels is vast, with different grades offering different balances of strength, formability, and corrosion resistance. For example, an austenitic grade might be chosen for a complex structural part requiring high ductility, while a less expensive ferritic grade is perfect for an exhaust component. Working with a knowledgeable supplier like MFY is crucial to navigate these choices and select the optimal grade that meets performance targets without over-engineering the cost.

Modern Manufacturing Processes

I remember a client in Germany who was developing a new EV platform. They struggled with the battery enclosure design using traditional materials. It was either too heavy or not strong enough. We worked with their engineers to select a specific high-strength austenitic grade and advised them on using hot stamping techniques. This process allowed them to form a complex, incredibly strong, yet lightweight part. It not only improved crash safety but also simplified their assembly process, saving them time and money. This is a perfect example of how the right material combined with the right process leads to a breakthrough. It’s about a true partnership, not just supplying a product.

Conclusion

Adopting stainless steel coils is no longer just an option but a strategic necessity for the automotive industry. It is the key material for building the safer, more durable, and sustainable vehicles that both customers and regulators demand. At MFY, we are ready to help you make this transition smoothly.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.