As a stainless steel manufacturer, I've often encountered confusion about the magnetic properties of our products. Many assume all stainless steel is non-magnetic, but that's not always the case.

The magnetic properties of stainless steel sheets vary depending on their crystal structure. Austenitic stainless steels1 are generally non-magnetic, while ferritic and martensitic grades are magnetic. These properties are determined by the steel's composition and manufacturing process.

In my years working with stainless steel, I've seen how crucial understanding these magnetic properties can be for various applications. From industrial equipment to consumer products, the magnetic behavior of stainless steel sheets plays a significant role in their performance and suitability for specific uses.

Let's dive deeper into the fascinating world of stainless steel magnetism. We'll explore the science behind these properties, how they differ among various types of stainless steel, and why this matters for real-world applications. Whether you're a manufacturer, engineer, or simply curious about materials science, understanding these concepts can open up new possibilities and help you make more informed decisions.

What Are the Basic Magnetic Properties of Stainless Steel Sheets?

In my experience working with various industries, I've found that understanding the basics of stainless steel's magnetic properties is crucial for proper material selection and application.

The magnetic properties of stainless steel sheets are primarily determined by their crystalline structure and composition. Austenitic stainless steels2, which contain high levels of nickel, are typically non-magnetic. In contrast, ferritic and martensitic stainless steels, with higher iron and lower nickel content, exhibit magnetic properties.

This fundamental difference in magnetic behavior has significant implications for how these materials are used in various applications. Let me share some insights I've gained from working with clients across different industries.

The Science Behind Magnetism in Stainless Steel

To truly understand the magnetic properties of stainless steel, we need to delve into its atomic structure. In my discussions with metallurgists and engineers, I've learned that the key lies in the arrangement of iron atoms within the steel's crystal lattice.

Austenitic stainless steel3, like the widely used 304 and 316 grades, has a face-centered cubic (FCC) crystal structure. This arrangement of atoms results in a material that is essentially non-magnetic under normal conditions. However, it's important to note that even austenitic stainless steel can become slightly magnetic when subjected to cold working or welding due to the formation of martensite.

On the other hand, ferritic and martensitic stainless steels4 have a body-centered cubic (BCC) crystal structure, similar to pure iron. This structure allows for the alignment of magnetic domains, resulting in ferromagnetic behavior.

Permeability and Magnetic Susceptibility

Two key concepts in understanding the magnetic properties of stainless steel are magnetic permeability and susceptibility. Magnetic permeability refers to how easily a material can be magnetized, while susceptibility measures the degree of magnetization in response to an applied magnetic field.

| Stainless Steel Type | Relative Magnetic Permeability | Magnetic Susceptibility |

|---|---|---|

| Austenitic (e.g., 304, 316) | 1.003 - 1.005 | Very low |

| Ferritic (e.g., 430) | 500 - 1000 | High |

| Martensitic (e.g., 410) | 750 - 950 | High |

Real-World Implications

In my work with a food processing equipment manufacturer, we encountered an interesting challenge related to these magnetic properties. The client needed stainless steel sheets for a conveyor system in a facility that used magnetic sensors for quality control. Initially, they were using 304 grade austenitic stainless steel, assuming all stainless steel was non-magnetic.

However, they found that some areas of the conveyor were interfering with the sensors. Upon investigation, we discovered that the cold working during fabrication had induced some magnetism in the austenitic steel. We solved this by switching to a more stable austenitic grade (316L) and implementing stress-relieving heat treatments after fabrication.

This experience highlights the importance of understanding not just the basic magnetic properties of stainless steel, but also how these properties can change under different conditions.

Ferritic stainless steel is magneticTrue

Ferritic stainless steels have a body-centered cubic structure, which allows magnetic domains to align.

Austenitic stainless steel is always non-magneticFalse

Austenitic stainless steel can become slightly magnetic when subjected to cold working or welding.

How Do Different Types of Stainless Steel Sheets Vary in Their Magnetic Properties?

Throughout my career, I've witnessed how the varying magnetic properties of different stainless steel types can significantly impact their applications. This diversity is one of the reasons stainless steel is such a versatile material.

Different types of stainless steel sheets exhibit varying magnetic properties based on their composition and structure. Austenitic stainless steels5 are generally non-magnetic, ferritic stainless steels are strongly magnetic, and martensitic stainless steels are magnetic and can be magnetized. Duplex stainless steels have intermediate magnetic properties.

Let's explore these differences in more detail, drawing from my experiences working with various industries and applications.

Austenitic Stainless Steel

Austenitic stainless steels, which include popular grades like 304 and 316, are known for being non-magnetic in their annealed state. However, it's crucial to understand that this can change under certain conditions.

I recall a project with a medical equipment manufacturer who needed non-magnetic components for MRI machines. We initially supplied them with 304 grade sheets, but they found some parts were slightly affecting the magnetic field. Upon investigation, we discovered that the cold forming process used in manufacturing had induced some magnetism.

To solve this, we switched to a higher nickel content grade (316L) and implemented a solution annealing heat treatment after forming. This ensured the material remained truly non-magnetic even after processing.

Ferritic Stainless Steel

Ferritic stainless steels, such as 430 grade, are strongly magnetic due to their high iron content and low nickel content. This property makes them ideal for certain applications but unsuitable for others.

One of our clients in the automotive industry uses ferritic stainless steel for exhaust system components. The magnetic properties allow for easier handling during automated manufacturing processes and don't interfere with the vehicle's electronic systems.

Duplex Stainless Steel

Duplex stainless steels, with their mixed austenitic-ferritic structure, exhibit intermediate magnetic properties. This can be advantageous in applications requiring a balance of corrosion resistance and magnetic response.

One interesting application I encountered was with a client in the oil and gas industry. They needed a material for pipeline components that could withstand corrosive environments but also be detectable by magnetic inspection tools. Duplex stainless steel provided the perfect solution, offering excellent corrosion resistance while still allowing for magnetic detection.

| Stainless Steel Type | Magnetic Properties | Typical Applications |

|---|---|---|

| Austenitic (e.g., 304, 316) | Non-magnetic (annealed) | Food processing, chemical tanks |

| Ferritic (e.g., 430) | Strongly magnetic | Automotive exhaust, kitchen appliances |

| Martensitic (e.g., 410) | Magnetic, can be magnetized | Cutlery, turbine blades |

| Duplex (e.g., 2205) | Moderately magnetic | Oil and gas equipment, marine applications |

Understanding these differences is crucial for selecting the right material for specific applications. It's not just about corrosion resistance or strength – the magnetic properties can play a significant role in how the material performs in its intended use.

Duplex stainless steel has intermediate magnetismTrue

Duplex stainless steels have a mixed austenitic-ferritic structure, leading to intermediate magnetic properties.

Martensitic stainless steel is non-magneticFalse

Martensitic stainless steels are magnetic and can be magnetized due to their high iron content.

What Factors Influence the Magnetic Properties of Stainless Steel Sheets?

In my years of experience in the stainless steel industry, I've learned that the magnetic properties of stainless steel sheets are not static. They can be influenced by various factors, which is crucial to understand for proper material selection and application.

The magnetic properties of stainless steel sheets are influenced by their chemical composition, microstructure, and processing history. Factors such as cold working, heat treatment, and welding can significantly alter the magnetic behavior of stainless steel, particularly in austenitic grades.

Let's delve into these factors and explore how they impact the magnetic properties of stainless steel sheets, drawing from real-world examples I've encountered in my work.

Chemical Composition

The chemical composition of stainless steel is the primary factor determining its magnetic properties. The balance of ferrite-forming elements (like chromium and molybdenum) and austenite-forming elements (like nickel and manganese) plays a crucial role.

I recall a project with a client in the chemical processing industry who needed non-magnetic tanks for a specific process. We initially supplied 304L grade sheets, but they found some areas were slightly magnetic. Upon investigation, we discovered that the steel's composition was at the lower end of the nickel specification range. By adjusting the composition to increase the nickel content slightly, we were able to ensure consistent non-magnetic properties across all sheets.

Welding and Fabrication

Welding and other fabrication processes can alter the microstructure of stainless steel, potentially changing its magnetic properties. This is particularly true for austenitic grades, where the heat from welding can induce martensite formation in the heat-affected zone.

I encountered this issue with a client in the pharmaceutical industry who was constructing large, non-magnetic vessels. They found that the welded areas were showing slight magnetic properties. We addressed this by recommending a post-weld heat treatment to restore the austenitic structure and non-magnetic properties.

| Factor | Effect on Magnetic Properties | Mitigation Strategies |

|---|---|---|

| Chemical Composition | Determines base magnetic behavior | Careful control of alloying elements |

| Cold Working | Can induce magnetism in austenitic grades | Stress-relieving heat treatment |

| Heat Treatment | Can alter microstructure and magnetic properties | Precise control of heating and cooling |

| Welding | Can create magnetic zones in non-magnetic grades | Post-weld heat treatment |

Understanding these factors is crucial for maintaining consistent magnetic properties in stainless steel sheets. It's not just about selecting the right grade – how the material is processed, fabricated, and treated can significantly impact its final magnetic behavior.

Cold working can induce magnetismTrue

Cold working can alter the microstructure of austenitic stainless steel, making it slightly magnetic.

Welding does not affect magnetismFalse

Welding can create magnetic zones in non-magnetic grades due to changes in microstructure.

How Do the Magnetic Properties of Stainless Steel Sheets Impact Their Applications?

Throughout my career in the stainless steel industry, I've seen firsthand how the magnetic properties of stainless steel sheets can significantly influence their applications across various sectors. This aspect of stainless steel is often overlooked but can be crucial in determining a material's suitability for specific uses.

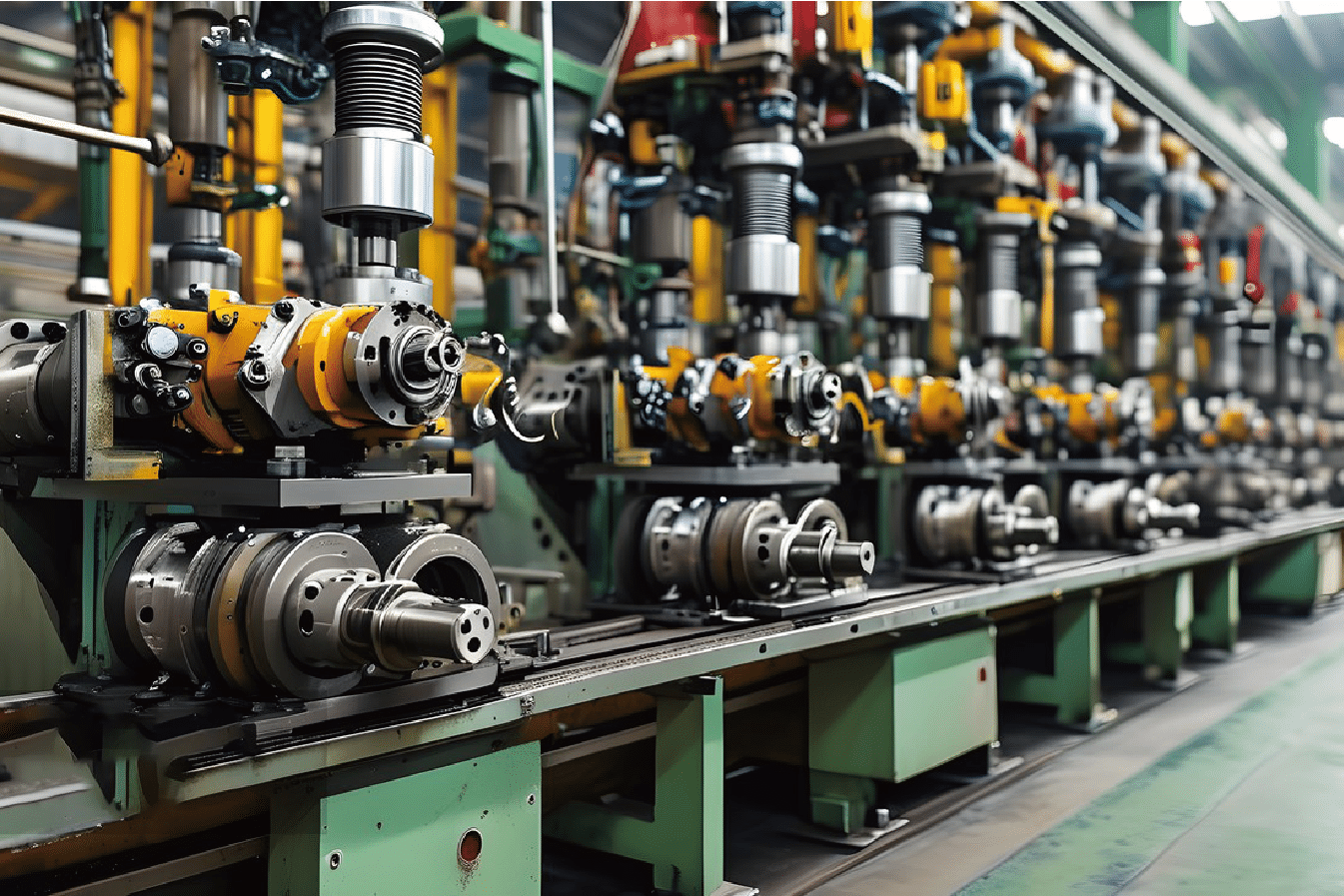

The magnetic properties of stainless steel sheets directly impact their suitability for various applications. Non-magnetic austenitic grades are essential in environments sensitive to magnetic fields, while magnetic ferritic and martensitic grades are useful in applications requiring magnetic attraction or detection. These properties influence everything from medical equipment to industrial machinery.

Let's explore some specific applications where the magnetic properties of stainless steel play a crucial role, based on my experiences working with clients across different industries.

Medical and Scientific Equipment

In the medical field, the non-magnetic properties of austenitic stainless steel are critical. I worked with a manufacturer of MRI machines who required absolutely non-magnetic materials for components near the scanning area. We supplied them with specially processed 316L grade sheets, ensuring zero magnetic interference with the sensitive equipment.

Similarly, in scientific research facilities, non-magnetic stainless steel is often used in equipment where magnetic fields could interfere with experiments or measurements. One of our clients, a particle physics research center, used our non-magnetic stainless steel sheets in their particle accelerator components to maintain the integrity of their experiments.

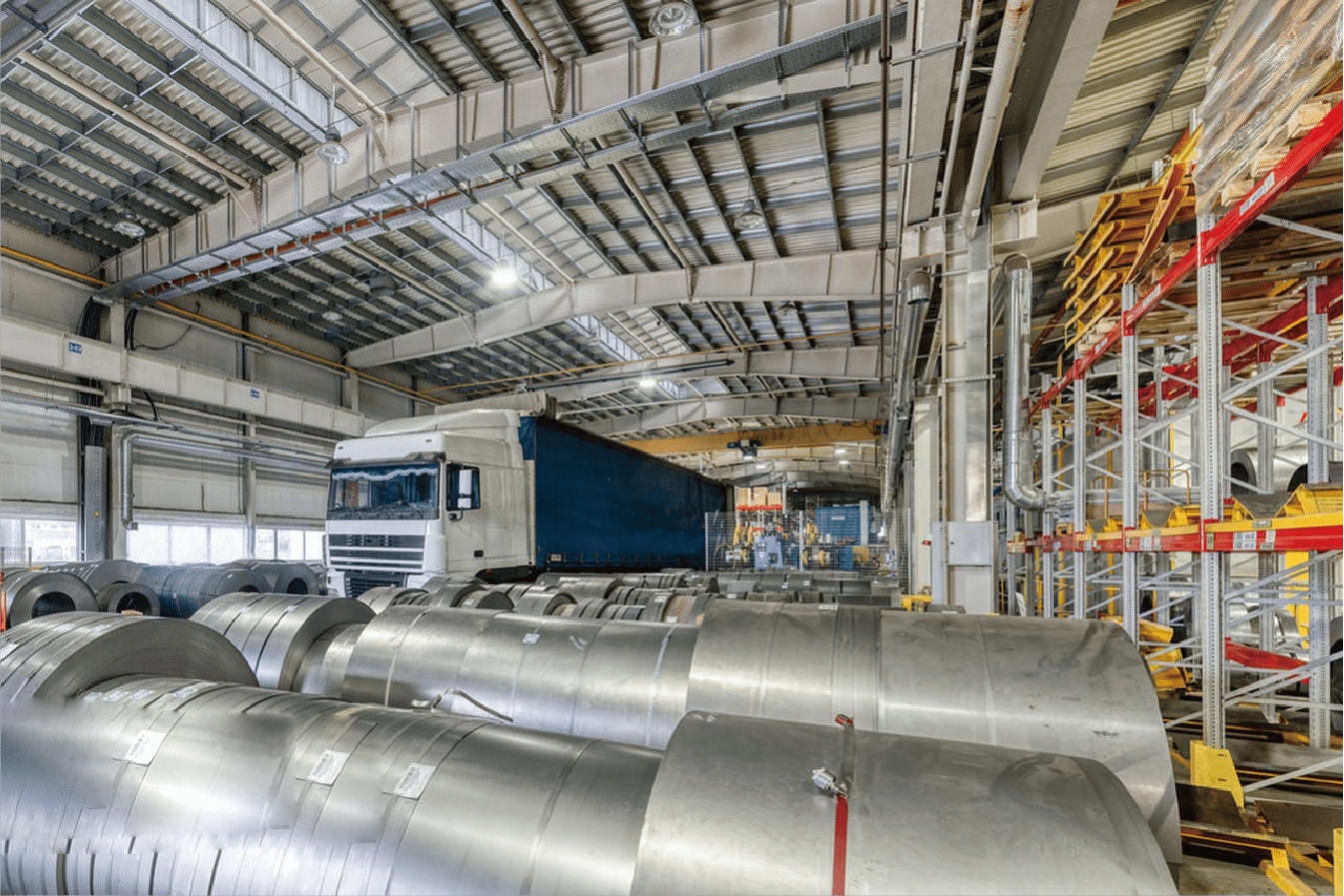

Food and Beverage Industry

The food and beverage industry often requires both magnetic and non-magnetic stainless steel, depending on the application. In one project, we supplied ferritic 430 grade sheets for the exterior of refrigerators, taking advantage of their magnetic properties for attaching decorative panels and signage.

Conversely, for food processing equipment where magnetic particles need to be detected and removed from the product stream, we recommended non-magnetic austenitic grades. This ensures that the equipment itself doesn't interfere with the magnetic detection systems.

Non-magnetic steel is used in MRI machinesTrue

Non-magnetic austenitic stainless steel is essential to avoid interference with magnetic fields in MRI machines.

All food processing equipment is magneticFalse

Non-magnetic austenitic grades are used in food processing to ensure equipment doesn't interfere with magnetic detection systems.

What Are the Best Practices for Selecting and Using Stainless Steel Sheets Based on Their Magnetic Properties?

Over the years, I've learned that selecting and using stainless steel sheets based on their magnetic properties requires careful consideration and a thorough understanding of both the material and the application. It's not just about choosing magnetic or non-magnetic steel; it's about finding the right balance of properties for your specific needs.

Best practices for selecting and using stainless steel sheets based on magnetic properties include thorough application analysis, consideration of environmental factors, proper handling and fabrication techniques, and regular testing to ensure maintained performance. These practices help ensure optimal material performance and longevity.

Let me share some key insights I've gained from working with various clients across different industries, particularly focusing on practical implementation and real-world solutions.

Selection Criteria and Analysis

Through my experience working with clients like David Zhang's manufacturing company in India, I've developed a comprehensive approach to material selection based on magnetic properties.

| Selection Factor | Consideration Points | Recommended Action |

|---|---|---|

| Environment | Magnetic field presence | Conduct field strength testing |

| Processing | Manufacturing methods | Evaluate impact on magnetic properties |

| End-use | Application requirements | Define magnetic tolerance limits |

| Cost efficiency | Long-term performance | Calculate total ownership cost |

Handling and Processing Guidelines

Working with stainless steel sheets requires specific handling procedures to maintain their intended magnetic properties. Here are key practices I've implemented with successful results:

-

Storage and Transportation

- Keep magnetic and non-magnetic materials separated

- Use non-magnetic handling equipment for austenitic grades

- Monitor environmental conditions to prevent stress-induced changes

-

Fabrication Considerations

- Choose appropriate welding techniques that minimize magnetic property changes

- Implement proper heat treatment procedures when required

- Regular testing during fabrication to ensure property maintenance

-

Quality Control Measures

- Establish clear magnetic property specifications

- Implement regular testing protocols

- Document any changes in magnetic properties during processing

Testing and Verification

Based on my experience with quality control in our manufacturing facility, I recommend implementing a comprehensive testing protocol:

-

Initial Material Testing

- Magnetic permeability measurements

- Chemical composition verification

- Microstructure analysis

-

In-Process Testing

- Regular magnetic property checks during fabrication

- Documentation of any property changes

- Adjustment of processing parameters as needed

-

Final Verification

- Comprehensive testing of finished products

- Certification of magnetic properties

- Documentation for quality assurance

Regular testing is essentialTrue

Regular testing ensures that the magnetic properties of stainless steel sheets are maintained throughout processing.

Heat treatment has no effect on magnetismFalse

Heat treatment can significantly alter the microstructure and magnetic properties of stainless steel.

Conclusion

Successful implementation of stainless steel sheets based on magnetic properties requires careful selection, proper handling, and ongoing monitoring. Understanding these factors ensures optimal performance and longevity while meeting specific application requirements and industry standards.

-

Understand the crystal structure and composition that make austenitic stainless steels non-magnetic ↩

-

Learn about the role of nickel and other elements in determining magnetic properties ↩

-

Explore the atomic arrangement in austenitic stainless steels and its impact on magnetism ↩

-

Compare the magnetic behaviors of ferritic and martensitic stainless steels ↩

-

Understand the mixed austenitic-ferritic structure of duplex stainless steels and its effects on magnetism ↩