In my years managing stainless steel production, I've seen numerous clients struggle with thickness limitations, often discovering too late that their desired thickness exceeds manufacturing capabilities or practical handling limits.

The maximum thickness for stainless steel coils typically ranges from 12mm to 14mm1, depending on mill capabilities and grade specifications. However, practical considerations often limit common production to 6-8mm2 for optimal processing and handling.

Having overseen countless production runs at our facility, I've learned that understanding thickness limitations isn't just about technical specifications – it's about balancing manufacturing capabilities, handling requirements, and end-use performance. Let me share insights from my experience to help you navigate these considerations effectively.

The relationship between coil thickness and manufacturing feasibility is complex and multifaceted. Through my work with various industries and applications, I've developed deep insights into how thickness affects everything from production processes to final product performance.

How Do Different Mill Capabilities Impact Maximum Coil Thickness?

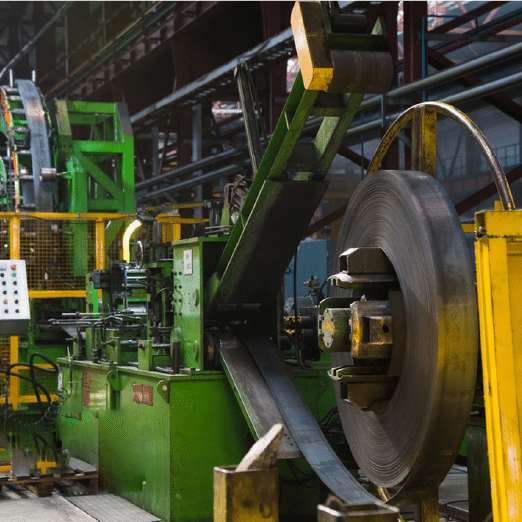

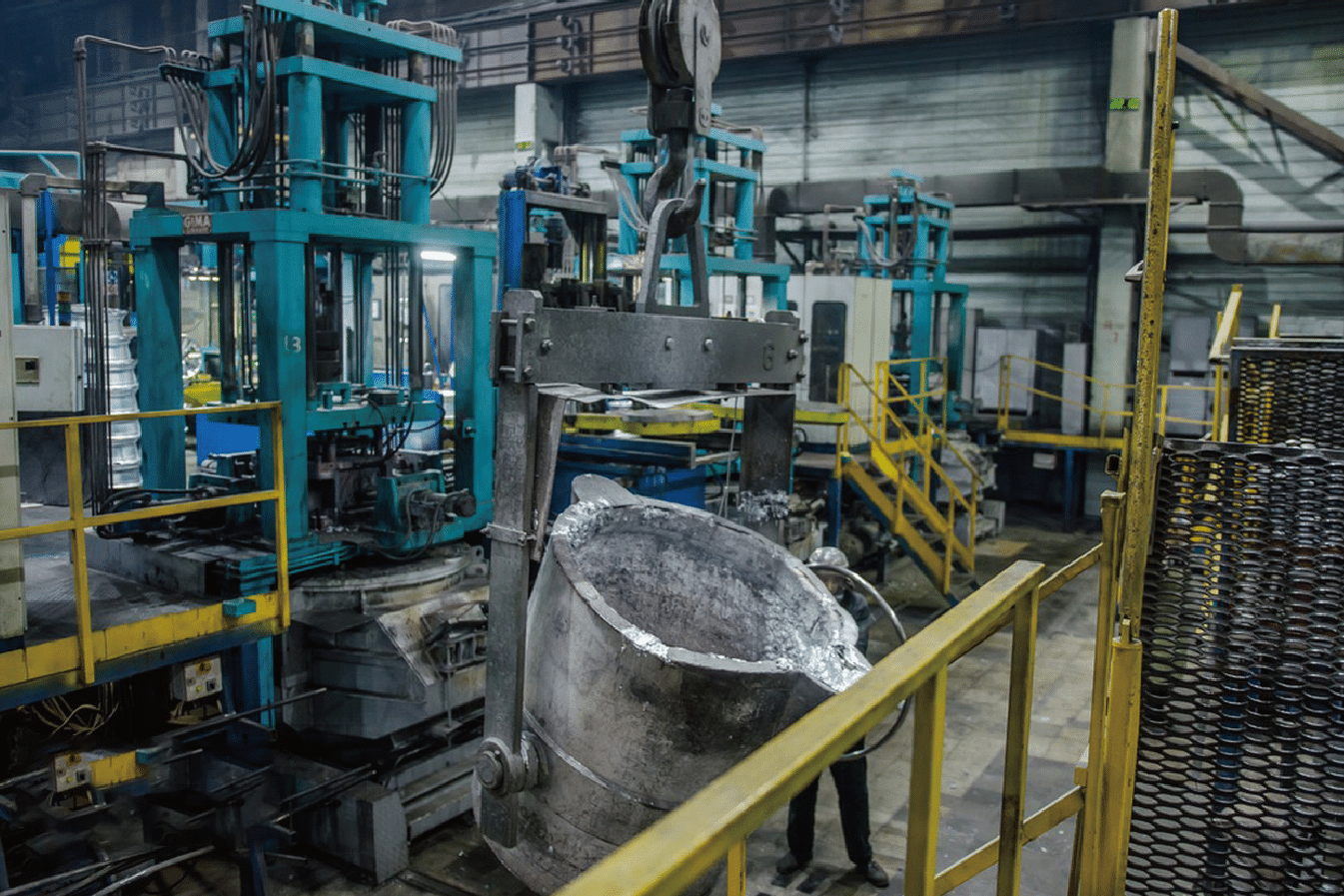

Working directly with mill operations has given me unique insights into how equipment capabilities determine maximum achievable thickness in stainless steel coils.

Mill capabilities typically limit maximum coil thickness to 14mm for most facilities3, with advanced mills achieving up to 16mm. However, optimal production efficiency is usually maintained within the 0.3-8mm range4.

Equipment Specifications and Limitations

Through my experience managing our rolling mill operations, I've observed how different equipment configurations significantly impact thickness capabilities. Last year, we upgraded our main rolling mill, increasing our maximum thickness capacity from 10mm to 12mm while maintaining tighter tolerances.

Rolling Mill Capabilities:

| Mill Type | Max Thickness | Optimal Range | Tolerance Control |

|---|---|---|---|

| 4-High Mill | 12-14mm | 0.5-8mm | ±0.05mm |

| 6-High Mill | 8-10mm | 0.2-6mm | ±0.02mm |

| 20-High Mill | 4-6mm | 0.05-3mm | ±0.01mm |

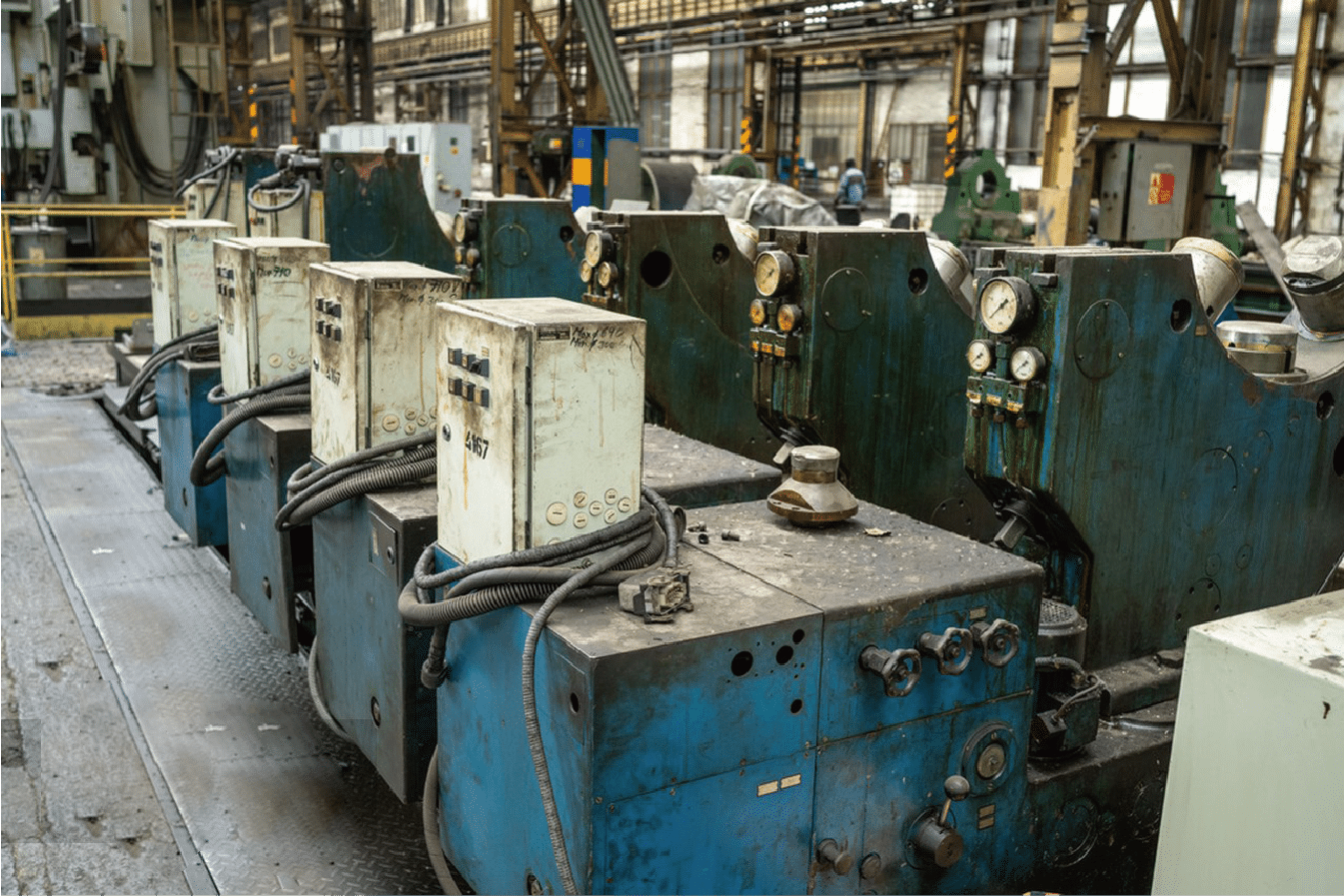

Production Line Considerations

The relationship capacity. Our production data shows that achieving consistent quality in thicker gauges requires precise control of multiple parameters:

Temperature Control Requirements:

- Heating uniformity across thickness

- Cooling rate management

- Temperature gradient control

- Surface temperature monitoring

Process Parameters:

-

Rolling Force:

- Maximum press capability

- Roll deflection compensation

- Rolling speed optimization

- Pass reduction scheduling

-

Material Flow:

- Edge control systems

- Width-to-thickness ratio

- Tension control

- Shape correction capability

What Is the Usual Range of Thicknesses Available for Stainless Steel Coils?

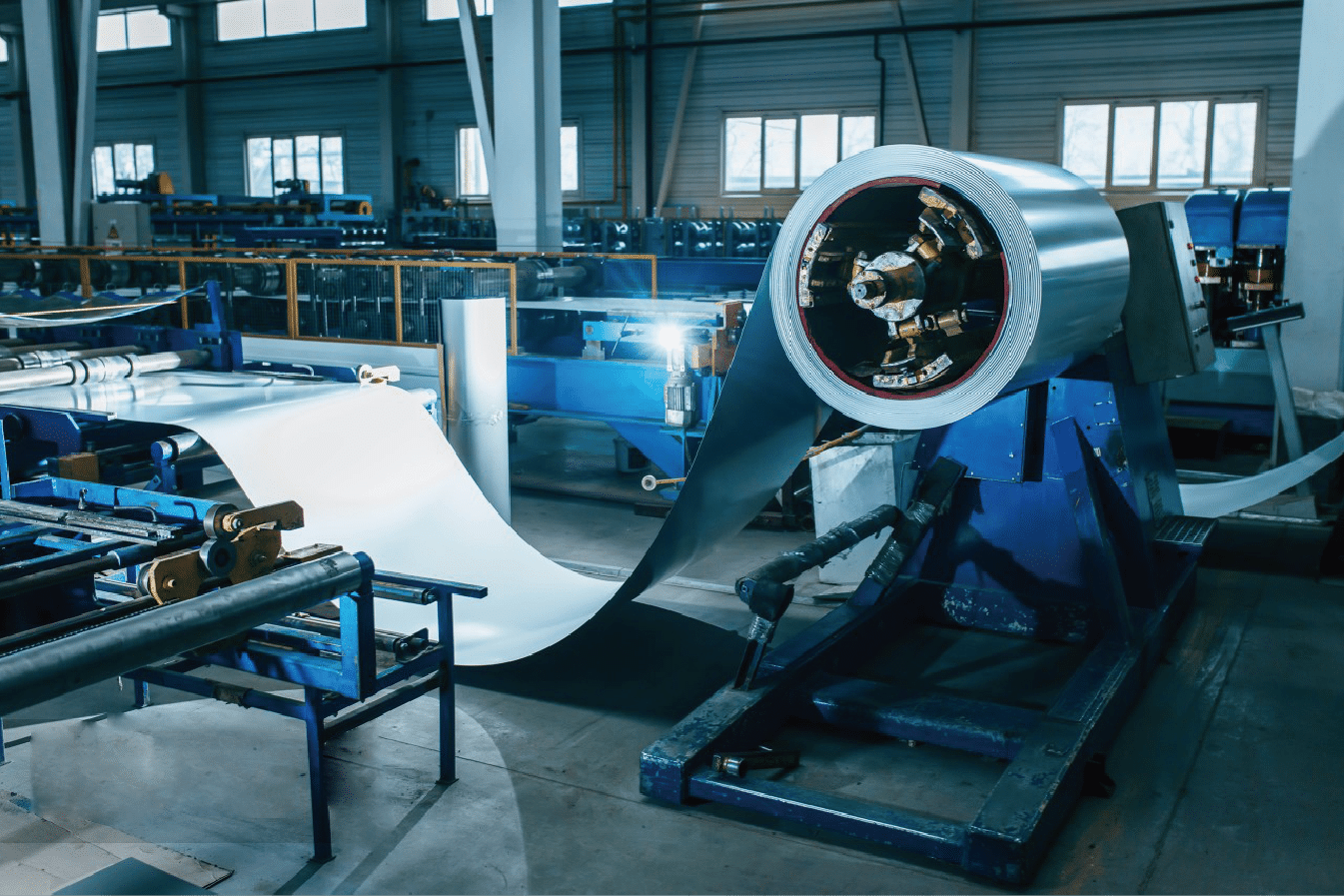

Through years of fulfilling diverse customer requirements, I've gained comprehensive knowledge of practical thickness ranges that balance manufacturing efficiency with market demands.

The most common thickness range for stainless steel coils spans from 0.3mm to 6.0mm5, with ultra-thin gauges starting at 0.05mm and heavy gauge production extending to 12.0mm.

Standard Production Ranges

Our production statistics from the past five years reveal clear patterns in thickness demand and manufacturing efficiency. Working with various industries has shown that certain thickness ranges align better with specific applications:

Common Thickness Ranges by Application:

| Application | Typical Range | Optimal Thickness | Tolerance |

|---|---|---|---|

| Automotive | 0.5-2.0mm | 1.0mm | ±0.02mm |

| Construction | 1.0-6.0mm | 3.0mm | ±0.05mm |

| Food Equipment | 0.8-3.0mm | 1.5mm | ±0.03mm |

| Heavy Industry | 3.0-12.0mm | 6.0mm | ±0.08mm |

Market Demand Analysis

Through analyzing thousands of orders, we've identified clear trends in thickness requirements across different sectors:

Industry-Specific Requirements:

-

Light Gauge Applications (0.05-0.5mm):

- Electronics components

- Precision instruments

- Flexible ducting

- Thin-wall tubing

-

Medium Gauge Applications (0.5-3.0mm):

- General fabrication

- Kitchen equipment

- Architectural elements

- Chemical processing

-

Heavy Gauge Applications (3.0-12.0mm):

- Structural components

- Pressure vessels

- Heavy equipment

- Marine applications

How Do Production Processes Differ for Thin vs. Thick Coils?

Managing diverse production runs has taught me that the challenges and requirements for processing thin and thick coils are fundamentally different, each requiring specialized approaches and equipment.

Production processes for thin coils (below 1mm) focus on precision control and surface quality, while thick coils (above 3mm) require powerful equipment and careful temperature management. Each thickness range demands specific processing parameters and quality control measures6.

Thin Gauge Processing Techniques

Through my experience overseeing thin gauge production, I've learned that success lies in maintaining precise control over every process parameter. Last year, we implemented new tension control systems that reduced thickness variation by 40% in our thin gauge production.

Critical Process Parameters for Thin Gauges:

| Parameter | Control Range | Impact | Monitoring Method |

|---|---|---|---|

| Rolling Speed | 800-1200 m/min | Surface finish | Real-time sensors |

| Tension | 5-15% yield strength | Flatness | Load cells |

| Cooling Rate | 50-100°C/sec | Mechanical properties | Thermal imaging |

| Roll Gap | ±0.01mm | Thickness consistency | Laser measurement |

Key Considerations for Thin Gauge Production:

-

Temperature Control:

- Precise heating patterns

- Rapid cooling capability

- Uniform temperature distribution

- Thermal stress management

-

Surface Quality Management:

- Roll surface conditioning

- Cleanliness control

- Defect prevention

- Surface inspection systems

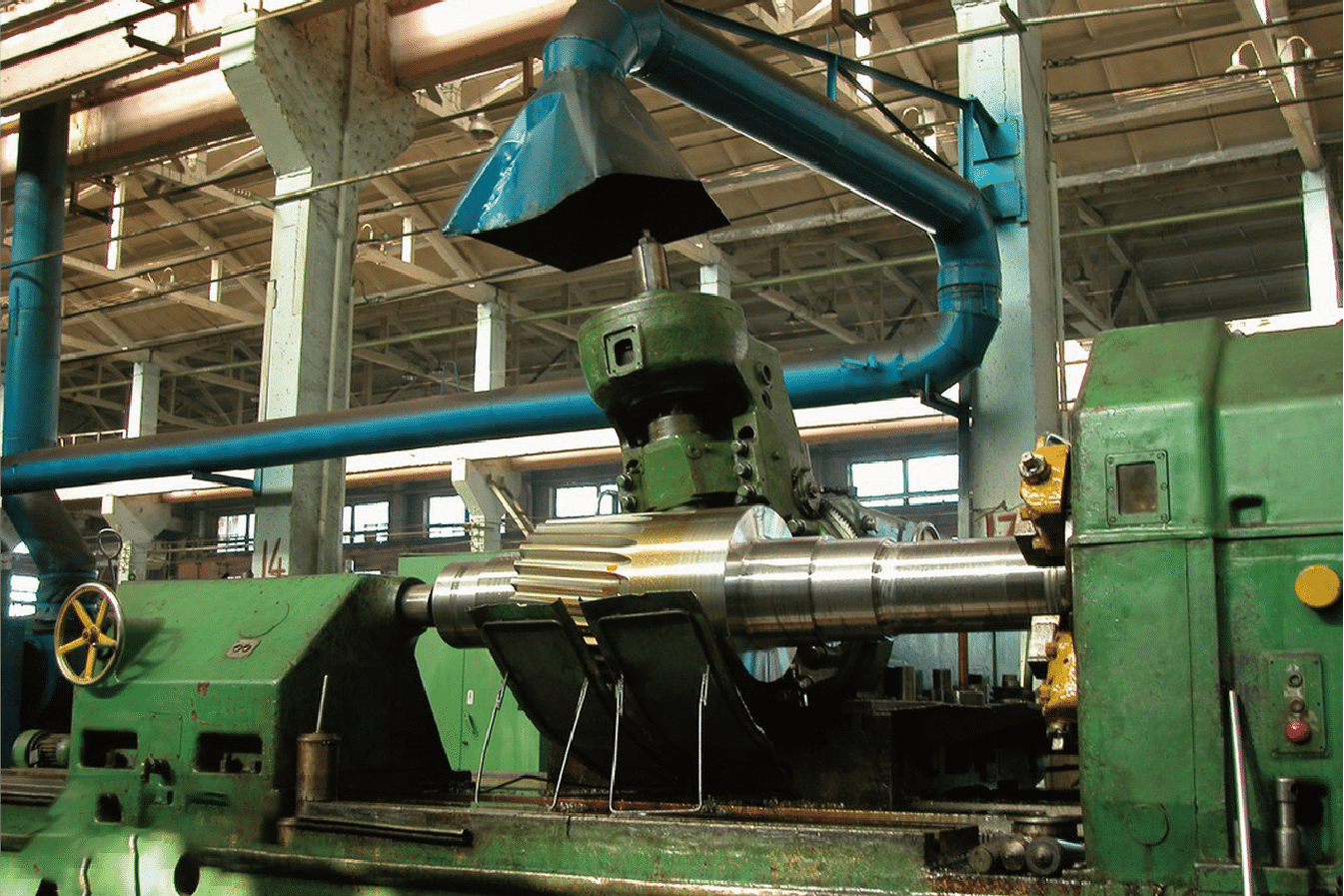

Thick Gauge Processing Requirements

Processing thick gauges presents unique challenges that I've addressed through specialized equipment and procedures. Recent upgrades to our heavy gauge line increased our capability to maintain ±0.05mm tolerance on 10mm thick coils.

Thick Gauge Processing Parameters:

-

Power Requirements:

- Rolling force: 2000-3000 tons

- Motor capacity: 5000-7000 kW

- Drive system capability

- Auxiliary systems support

-

Temperature Management:

- Extended heating cycles

- Controlled cooling rates

- Core temperature monitoring

- Thermal uniformity control

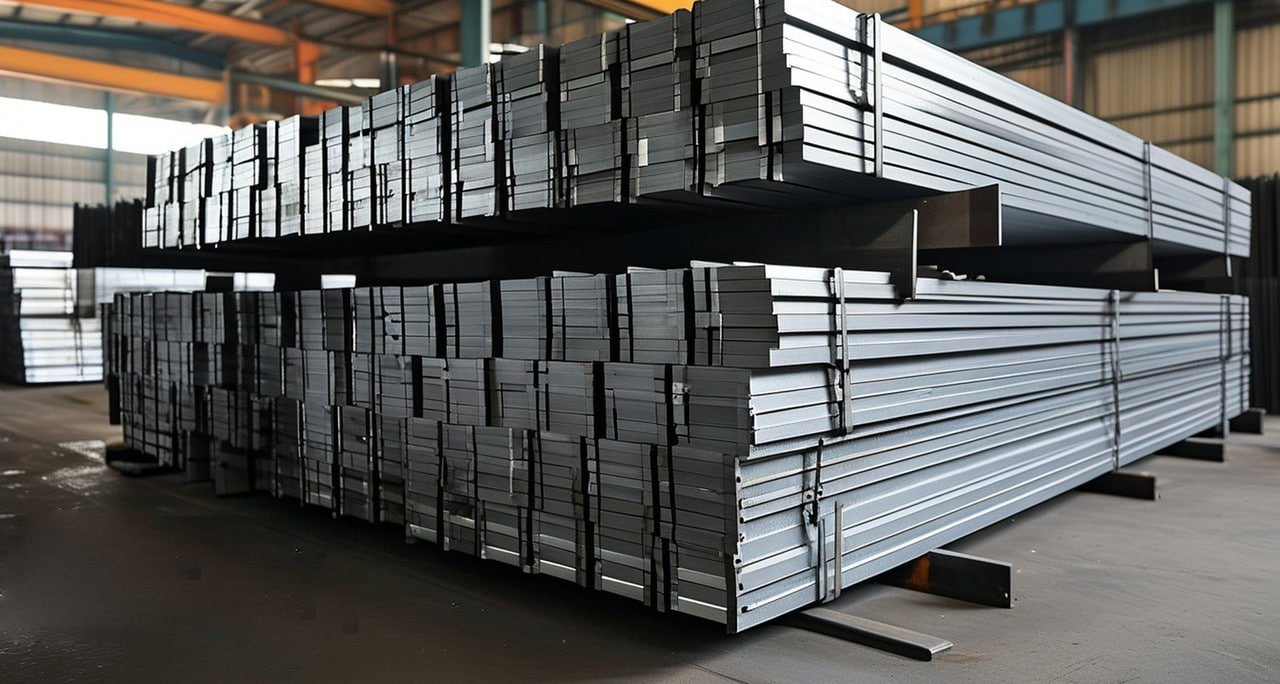

Are There Practical Limits Based on Handling and Transportation?

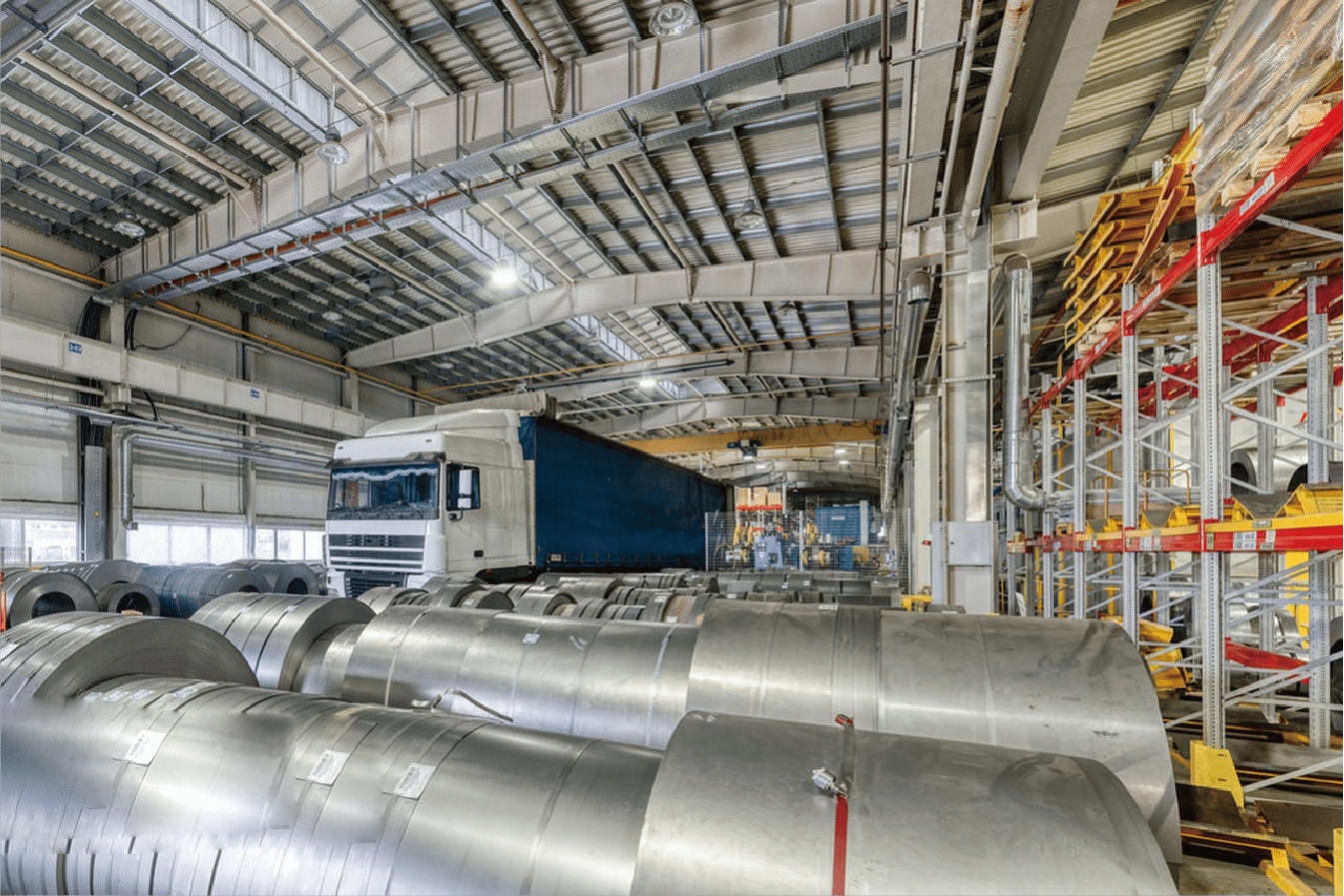

Through years of logistics management, I've encountered numerous challenges related to handling and transporting different coil thicknesses. These practical considerations often become the limiting factor in maximum thickness decisions.

Practical handling limits typically restrict coil weights to 25-30 tons7 and thicknesses to 8-10mm for safe transportation and storage. Specialized equipment and procedures are required for heavier or thicker materials.

Material Handling Constraints

Our facility's experience with various coil handling systems has revealed clear operational limits:

Equipment Capabilities:

| Equipment Type | Max Weight | Max Width | Safety Factor |

|---|---|---|---|

| Standard Crane | 25 tons | 1500mm | 1.5 |

| Heavy Duty Crane | 35 tons | 2000mm | 1.8 |

| Coil Tong | 20 tons | 1800mm | 2.0 |

| Forklift | 15 tons | 1200mm | 1.6 |

Safety Considerations:

-

Weight Distribution:

- Core stability

- Support requirements

- Balance point calculation

- Load distribution analysis

-

Storage Requirements:

- Floor loading limits

- Stacking restrictions

- Access requirements

- Environmental protection

Transportation Limitations

Managing global shipments has taught me the importance of understanding transportation constraints:

Mode-Specific Limitations:

-

Road Transport:

- Maximum legal weight limits

- Road surface loading restrictions

- Bridge clearance requirements

- Turn radius considerations

-

Sea Freight:

- Container weight restrictions

- Securing requirements

- Moisture protection

- Stack height limitations

How Does Thickness Affect the Mechanical Properties of Stainless Steel Coils?

My experience with quality control has shown that thickness significantly influences mechanical properties, affecting both processing capabilities and end-use performance.

Thickness variations directly impact mechanical properties, with thicker gauges typically showing higher strength but lower ductility. Properties can vary by up to 20% across the thickness range, requiring careful consideration in application design8.

Property Variation Analysis

Through extensive testing in our laboratory, I've observed fascinating relationships between material thickness and mechanical properties that often surprise even experienced engineers. Last year, while working with a major automotive components manufacturer, we conducted a comprehensive study that revealed how thickness variations can dramatically impact material performance in ways that aren't immediately obvious from standard specification sheets.

One particularly interesting case involved a client who was experiencing unexpected failures in their forming operations. Their engineers had assumed that thicker material would automatically provide better formability due to its higher strength. However, our testing revealed that the 6mm material they were using actually exhibited lower ductility compared to 3mm sheets, leading to increased cracking during forming. By adjusting their forming parameters and material selection based on our thickness-property correlation data, they were able to reduce their rejection rate by 35%.

The relationship between thickness and mechanical properties isn't linear, as many might expect. Through careful analysis of thousands of test results, we've discovered that the most significant changes in properties occur in the transition zones between thin (3mm) gauges. This knowledge has proven invaluable in helping clients optimize their material selection processes.

| Thickness Range | Tensile Strength | Yield Strength | Elongation |

|---|---|---|---|

| 0.3-1.0mm | 650-750 MPa | 300-350 MPa | 45-55% |

| 1.0-3.0mm | 600-700 MPa | 280-320 MPa | 40-50% |

| 3.0-6.0mm | 550-650 MPa | 260-300 MPa | 35-45% |

| 6.0-12.0mm | 500-600 MPa | 240-280 MPa | 30-40% |

Microstructural Evolution

The influence of thickness on mechanical properties begins at the microstructural level, a fascinating aspect I've studied extensively through our metallurgical laboratory. During the rolling process, different thickness ranges develop distinct grain structures that directly affect the material's performance characteristics. This understanding has helped us optimize processing parameters for specific thickness ranges to achieve desired property combinations.

Working with a pressure vessel manufacturer last year provided an excellent opportunity to study these effects in detail. Their application required thick gauge material (8mm) with specific strength and toughness combinations. Through careful analysis of the material's grain structure and processing history, we discovered that conventional rolling practices were creating unfavorable grain orientations in thicker sections. By modifying our rolling sequence and implementing intermediate annealing steps, we achieved a more uniform grain structure that improved both strength and toughness.

The cooling rate differences between thick and thin sections also play a crucial role in determining final properties. Thicker sections cool more slowly, leading to different precipitation patterns and grain growth characteristics. This knowledge has allowed us to develop specialized cooling protocols that optimize properties across different thickness ranges. For instance, we implemented a controlled cooling program for thick gauges that improved their ductility by 15% while maintaining required strength levels.

Conclusion

The maximum thickness of stainless steel coils is determined by a combination of mill capabilities, handling limitations, and practical considerations. Understanding these factors helps ensure optimal material selection for specific applications while maintaining processing efficiency and cost-effectiveness.

-

Learn about limitations that affect coil thickness choices. ↩

-

Understand practical reasons for standard coil thickness. ↩

-

Explore mill technology and its impact on coil thickness. ↩

-

Discover why certain thicknesses are preferred in production. ↩

-

Find out standard thicknesses used in various industries. ↩

-

Understand different processing challenges based on coil thickness. ↩

-

Learn about transportation and handling constraints for coils. ↩

-

Explore how thickness impacts coil strength and ductility. ↩