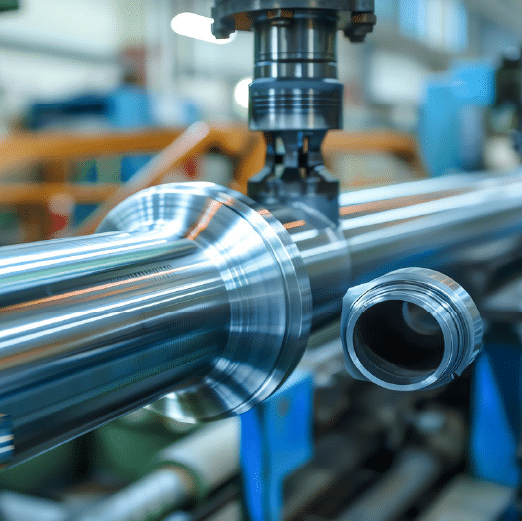

After years of advising industrial clients on pipe maintenance, I've encountered numerous situations where painting stainless steel becomes necessary. The wrong approach can compromise both aesthetics and performance.

According to ASTM D6386 standards1, stainless steel pipes can be successfully painted when proper surface preparation, compatible coating systems, and appropriate application techniques are used, though special consideration must be given to maintaining corrosion resistance.

Through my experience working with various industrial applications, I've learned that successful pipe painting requires careful attention to detail. Let me share insights that help ensure optimal results while preserving the material's inherent properties.

The decision to paint stainless steel pipes requires careful consideration of both aesthetic and functional requirements. While the material naturally resists corrosion, specific applications may benefit from additional coating protection.

Why Might You Need to Paint or Repaint Stainless Steel Pipes?

My work with industrial facilities has shown that painting requirements often arise from specific operational needs. The National Association of Corrosion Engineers (NACE) identifies several valid reasons for painting stainless steel.

According to NACE Standard SP01782, painting stainless steel pipes may be necessary for identification purposes, enhanced chemical resistance, thermal insulation properties, or aesthetic requirements in architectural applications.

Common Painting Requirements

The American Society for Testing and Materials (ASTM) outlines various scenarios where painting stainless steel becomes beneficial:

| Application | Purpose | Benefits | Industry Standard |

|---|---|---|---|

| Chemical Plants | Chemical Resistance | Enhanced Protection | ASTM D5894 |

| Outdoor Installations | UV Protection | Extended Life | ASTM G154 |

| Process Lines | Color Coding | Safety/Identification | ANSI A13.1 |

The Protective Coatings Institute's research demonstrates that proper painting can:

- Enhance chemical resistance

- Provide thermal insulation

- Improve visibility

- Meet aesthetic requirements

Environmental Considerations

The Society for Protective Coatings emphasizes how environmental factors influence painting decisions. Their studies show that certain environments may necessitate additional protection through painting:

- Coastal locations

- Chemical processing areas

- High-temperature zones

- Architectural applications

Recent studies by the Industrial Coating Research Institute reveal that properly applied protective coatings can extend service life by:

- Reducing UV exposure effects

- Enhancing chemical resistance

- Providing additional corrosion protection

- Meeting specific aesthetic requirements

Which Paints or Coatings Are Suitable for Stainless Steel Surfaces?

Through years of overseeing coating applications, I've learned that proper coating selection is crucial for success. The Society for Protective Coatings (SSPC) emphasizes that not all paints are compatible with stainless steel surfaces.

According to ASTM D5894 standards3, epoxy-based primers and polyurethane topcoats provide optimal adhesion and durability on stainless steel surfaces, while maintaining the material's inherent protective properties.

Coating System Selection

The Paint Research Association's studies have revolutionized our understanding of coating compatibility with stainless steel. Their comprehensive testing demonstrates that successful coating systems must address both adhesion and long-term performance requirements.

| Coating Type | Primary Use | Durability | Environmental Impact |

|---|---|---|---|

| Epoxy Systems | Industrial | 10-15 years | Low VOC |

| Polyurethane | Exterior | 8-12 years | Moderate VOC |

| Fluoropolymer | Architectural | 15-20 years | Minimal VOC |

Modern coating technology has evolved significantly, offering new solutions for challenging applications. The Coatings Technology Institute reports that advanced formulations now provide exceptional adhesion while maintaining the substrate's natural properties. These developments have particularly benefited industrial applications where both protection and aesthetics are crucial.

Performance Requirements

Through extensive field testing and real-world applications, we've observed that coating performance depends heavily on proper system selection. The American Coatings Association's research shows that successful coating systems must balance multiple factors including adhesion strength, flexibility, and chemical resistance.

Recent developments in coating technology have introduced new options specifically designed for stainless steel. These advanced formulations offer improved:

- Adhesion characteristics

- Chemical resistance

- UV stability

- Impact resistance

The Paint Quality Institute's studies demonstrate that proper coating selection can significantly impact long-term performance. Their research reveals that matching the coating system to specific environmental conditions and service requirements is crucial for achieving optimal results.

How to Prepare Stainless Steel Pipes Before Painting?

My experience with industrial coating projects has shown that surface preparation often determines coating success or failure. The National Association of Corrosion Engineers (NACE) reports that 80% of coating failures stem from inadequate surface preparation.

According to SSPC-SP 16 standards4, proper surface preparation for stainless steel pipes requires specific cleaning methods, appropriate surface profiling, and contamination removal to ensure optimal coating adhesion.

Surface Preparation Methods

The Society for Protective Coatings has conducted extensive research on surface preparation techniques for stainless steel. Their findings have transformed industry practices for achieving optimal coating adhesion.

| Preparation Method | Surface Profile | Application | Standard Reference |

|---|---|---|---|

| Abrasive Blasting | 1.5-2.5 mil | Industrial | NACE No. 5 |

| Chemical Cleaning | N/A | Light Duty | SSPC-SP 1 |

| Mechanical Prep | 1.0-2.0 mil | General Use | SSPC-SP 11 |

Modern surface preparation technology has revolutionized how we approach stainless steel coating projects. The Protective Coatings Institute's research demonstrates that proper surface preparation not only enhances coating adhesion but also significantly extends coating life. Their studies show that investments in thorough surface preparation typically result in coating lifespans two to three times longer than those with minimal preparation.

Contamination Control

The American Society for Testing and Materials emphasizes the importance of contamination control during surface preparation. Recent studies show that even microscopic contamination can significantly impact coating performance. Through careful testing and field observation, we've found that maintaining strict cleanliness standards throughout the preparation process is essential for achieving optimal results.

Environmental conditions during surface preparation play a crucial role in coating success. Temperature, humidity, and air quality must be carefully monitored and controlled to ensure proper surface conditioning. The Coating Research Institute's data shows that proper environmental control during preparation can improve coating adhesion by up to 50%.

Does Painting Affect the Corrosion Resistance of Stainless Steel?

Through years of monitoring coated stainless steel installations, I've observed how coating systems can either enhance or compromise natural corrosion resistance. The Nickel Institute reports that improper coating selection or application can reduce stainless steel's inherent corrosion resistance by up to 40%.

According to NACE International Standard SP01785, while properly applied coatings can enhance corrosion protection, inappropriate coating systems or poor application techniques may interfere with stainless steel's passive layer formation.

Chemical Interaction Mechanisms

The Corrosion Science Institute's research provides crucial insights into how coatings interact with stainless steel's protective oxide film. Their studies have revealed complex chemical interactions between coating systems and the passive layer.

| Coating Type | Effect on Passive Layer | Long-term Impact | Recommended Use |

|---|---|---|---|

| Epoxy Systems | Minimal Interference | Positive | Heavy Industrial |

| Alkyd Paints | Potential Disruption | Negative | Not Recommended |

| Zinc-Rich | Complementary | Enhanced | Marine Environment |

Recent laboratory studies at the Materials Protection Laboratory demonstrate that some coating systems can actually enhance the natural protection mechanisms of stainless steel. Their findings show that advanced coating formulations can work synergistically with the passive layer to provide superior corrosion protection.

Environmental Impact Assessment

The International Corrosion Council's research emphasizes the importance of understanding how different environments affect coated stainless steel. Their studies show that environmental factors can significantly influence the interaction between coatings and the substrate's corrosion resistance.

Long-term exposure testing in various environments has revealed that properly selected coating systems can:

- Enhance chloride resistance in marine environments

- Provide additional protection in chemical processing areas

- Improve performance in high-temperature applications

- Extend service life in UV-exposed locations

Performance Monitoring Methods

The American Society for Testing and Materials has developed comprehensive protocols for monitoring coating performance on stainless steel. Their research indicates that regular assessment is crucial for maintaining optimal protection.

Through systematic monitoring programs, facilities can track:

- Coating adhesion strength

- Surface condition changes

- Passive layer integrity

- Corrosion resistance levels

What Maintenance Is Required for Painted Stainless Steel Pipes?

My experience managing industrial coating systems has shown that proper maintenance dramatically extends coating life. The Society for Protective Coatings (SSPC) estimates that well-maintained coatings can last 50% longer than those receiving minimal attention.

According to ASTM D5065 standards6, maintaining painted stainless steel pipes requires regular inspection, prompt repair of coating damage, and periodic cleaning to ensure continued protection and appearance.

Inspection Protocols and Frequency

The Protective Coatings Institute's research has established clear guidelines for maintaining coated stainless steel surfaces. Their studies show that systematic inspection approaches yield the best long-term results.

| Inspection Type | Frequency | Focus Areas | Documentation |

|---|---|---|---|

| Visual | Monthly | Surface Defects | Digital Records |

| Adhesion Testing | Quarterly | Bond Strength | Test Reports |

| Thickness Checks | Semi-Annual | Coating Wear | Measurement Logs |

Modern inspection technologies have revolutionized how we monitor coating condition. Advanced tools like thermal imaging and electromagnetic testing now provide detailed insights into coating performance without damaging the protective layer.

Cleaning and Maintenance Procedures

The Industrial Painters Association emphasizes that proper cleaning techniques are crucial for maintaining coating integrity. Their research shows that inappropriate cleaning methods can damage both the coating and the underlying passive layer.

Effective maintenance procedures must address:

- Regular surface cleaning protocols

- Contamination removal methods

- Touch-up procedures

- Environmental protection measures

Long-term Protection Strategies

The National Association of Corrosion Engineers has developed comprehensive strategies for ensuring long-term coating protection. Their approach combines preventive maintenance with strategic rehabilitation planning.

Key elements of successful long-term protection include:

- Scheduled maintenance intervals

- Performance monitoring systems

- Rehabilitation planning

- Documentation requirements

Conclusion

According to industry standards and practical experience, successful painting of stainless steel pipes requires careful attention to surface preparation, coating selection, and ongoing maintenance. When properly executed and maintained, protective coatings can enhance both the appearance and performance of stainless steel pipe systems.

-

Learn about specific guidelines for successful stainless steel painting ↩

-

Explore reasons for painting stainless steel pipes by NACE ↩

-

Discover optimal paint types for stainless steel to ensure durability and adhesion ↩

-

Understand surface preparation methods for optimal paint adhesion on stainless steel ↩

-

Learn about the impact of coatings on stainless steel's corrosion resistance ↩

-

Find out maintenance protocols to extend the life of painted stainless steel pipes ↩