Through my experience at MFY Steel, I've seen how improper cutting techniques can lead to material waste and quality issues. The right approach can significantly improve efficiency and product quality.

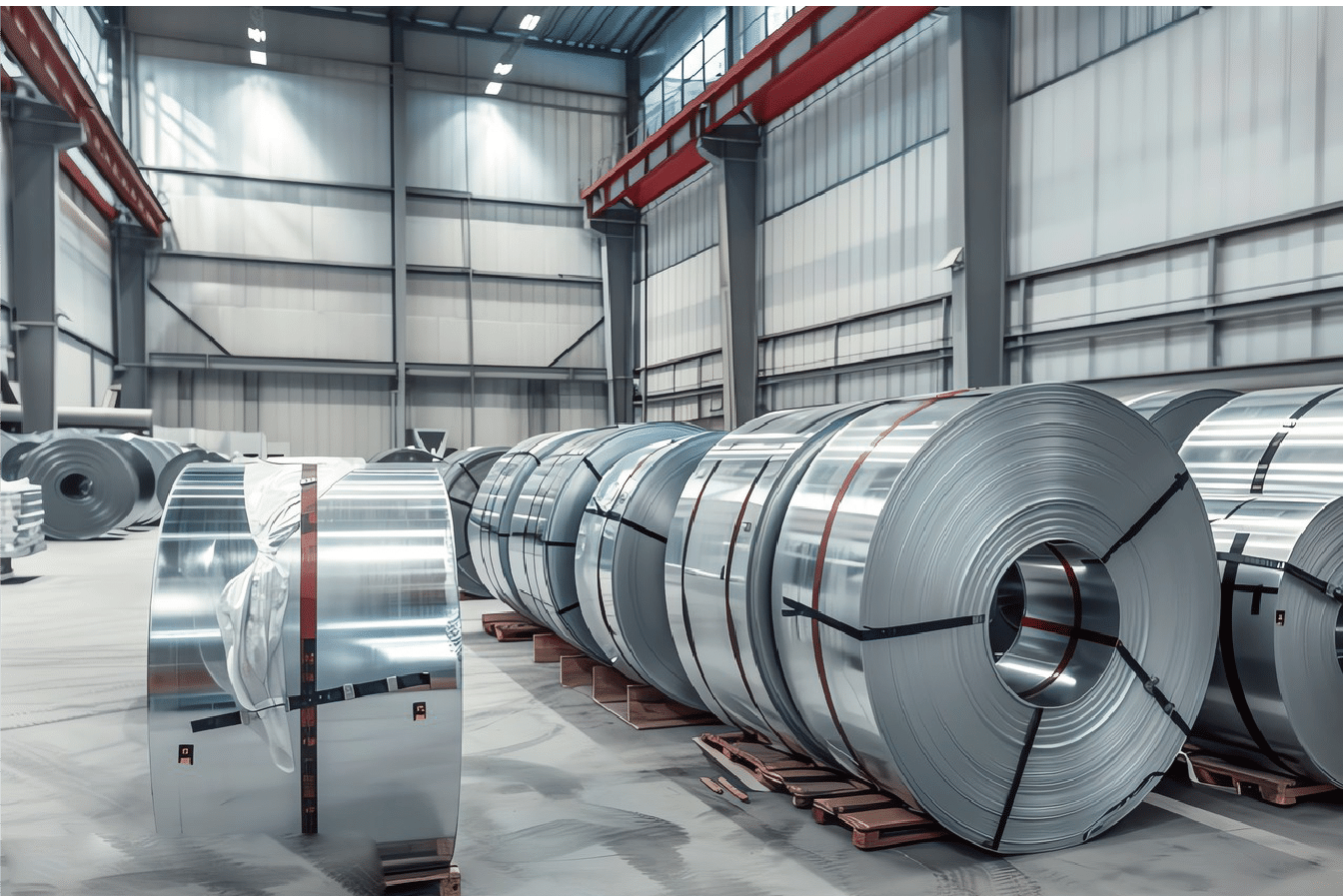

Cutting stainless steel plates from coils involves various methods including slitting, cut-to-length lines, and precision shearing1, each chosen based on specific requirements for thickness, width, and end-use applications.

Having overseen countless cutting operations, I've learned that successful plate cutting requires more than just the right equipment. Let me share insights that could help you optimize your cutting processes and avoid common pitfalls.

The precision of cutting operations directly impacts material utilization and product quality. Our data shows that optimized cutting processes can reduce waste by 30% and improve productivity by 25%.

What Methods Are Used to Cut Stainless Steel Plates from Coils?

After years of managing cutting operations, I've found that selecting the right cutting method is crucial for achieving desired results and maintaining efficiency.

Common cutting methods include rotary shearing, precision slitting, and cut-to-length processing2, each offering specific advantages for different plate specifications and production requirements.

Primary Cutting Methods

Our production experience reveals key method characteristics:

| Cutting Method | Thickness Range | Edge Quality | Production Speed |

|---|---|---|---|

| Rotary Shearing | 0.3-6.0mm | Excellent | High |

| Precision Slitting | 0.1-3.0mm | Superior | Very High |

| Cut-to-Length | 0.5-12.0mm | Good | Medium |

Method Selection Criteria

-

Material Considerations

- Thickness requirements

- Grade specifications

- Surface finish needs

- Edge quality demands

-

Production Requirements

- Volume expectations

- Tolerance specifications

- Speed requirements

- Cost considerations

-

Quality Parameters

- Edge condition

- Dimensional accuracy

- Surface protection

- Burr control

Through careful method selection and optimization, we've achieved:

- 95% first-pass yield rates

- ±0.2mm tolerance accuracy

- Minimal edge burr formation

- Consistent surface quality

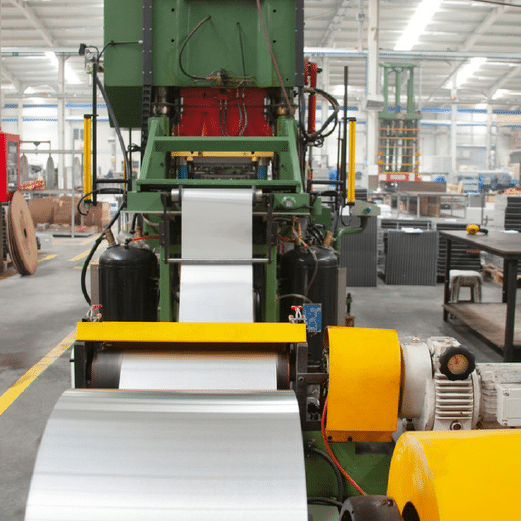

What Equipment Is Essential for Cutting Stainless Steel Plates from Coils?

In my years overseeing equipment procurement and maintenance, I've learned that investing in the right cutting equipment is crucial for consistent quality and operational efficiency.

Essential cutting equipment includes precision slitting lines, cut-to-length machines, decoiling systems, and material handling equipment3, all requiring regular maintenance and calibration for optimal performance.

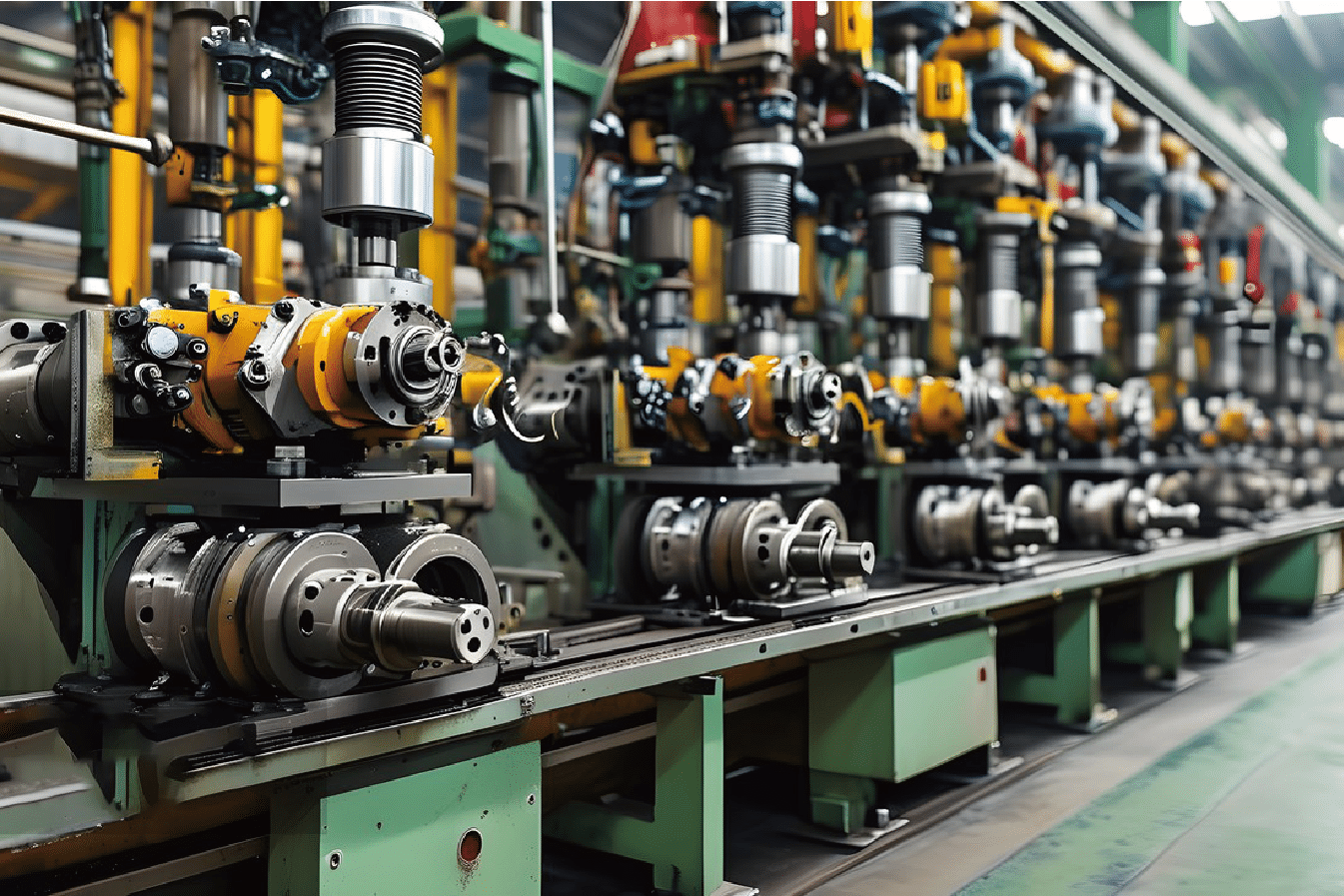

Core Equipment Requirements

Our facility's equipment configuration shows:

| Equipment Type | Function | Key Features | Maintenance Interval |

|---|---|---|---|

| Slitting Line | Width control | Multiple arbors | Monthly |

| CTL Machine | Length cutting | Flying shear | Bi-weekly |

| Decoiler | Material feed | Tension control | Weekly |

| Leveler | Flatness control | Multi-roll design | Monthly |

Support Equipment Needs

-

Material Handling Systems

- Overhead cranes

- Coil cars

- Storage racks

- Transfer tables

-

Quality Control Equipment

- Measuring devices

- Surface inspection systems

- Edge monitoring tools

- Thickness gauges

-

Safety Equipment

- Emergency stops

- Safety barriers

- Light curtains

- Personal protection gear

How to Ensure Precision When Cutting Stainless Steel Plates from Coils?

Through extensive experience with precision cutting operations, I've developed systematic approaches to maintain consistent accuracy.

Precision cutting requires careful control of machine parameters, regular calibration, proper material handling, and continuous monitoring of cutting conditions.

Precision Control Measures

Our quality control data demonstrates:

| Control Parameter | Tolerance Range | Monitoring Method | Correction Action |

|---|---|---|---|

| Length Accuracy | ±0.5mm | Laser measurement | Parameter adjustment |

| Width Tolerance | ±0.2mm | Optical sensors | Tool positioning |

| Squareness | 0.1% | Digital gauging | Alignment correction |

| Surface Quality | Ra 0.8 | Visual inspection | Speed optimization |

Quality Assurance Protocols

-

Pre-Cutting Checks

- Material verification

- Tool condition assessment

- Machine calibration

- Parameter verification

-

In-Process Controls

- Real-time monitoring

- Dimensional checking

- Surface inspection

- Edge quality control

-

Post-Cutting Verification

- Measurement validation

- Documentation review

- Sample testing

- Quality certification

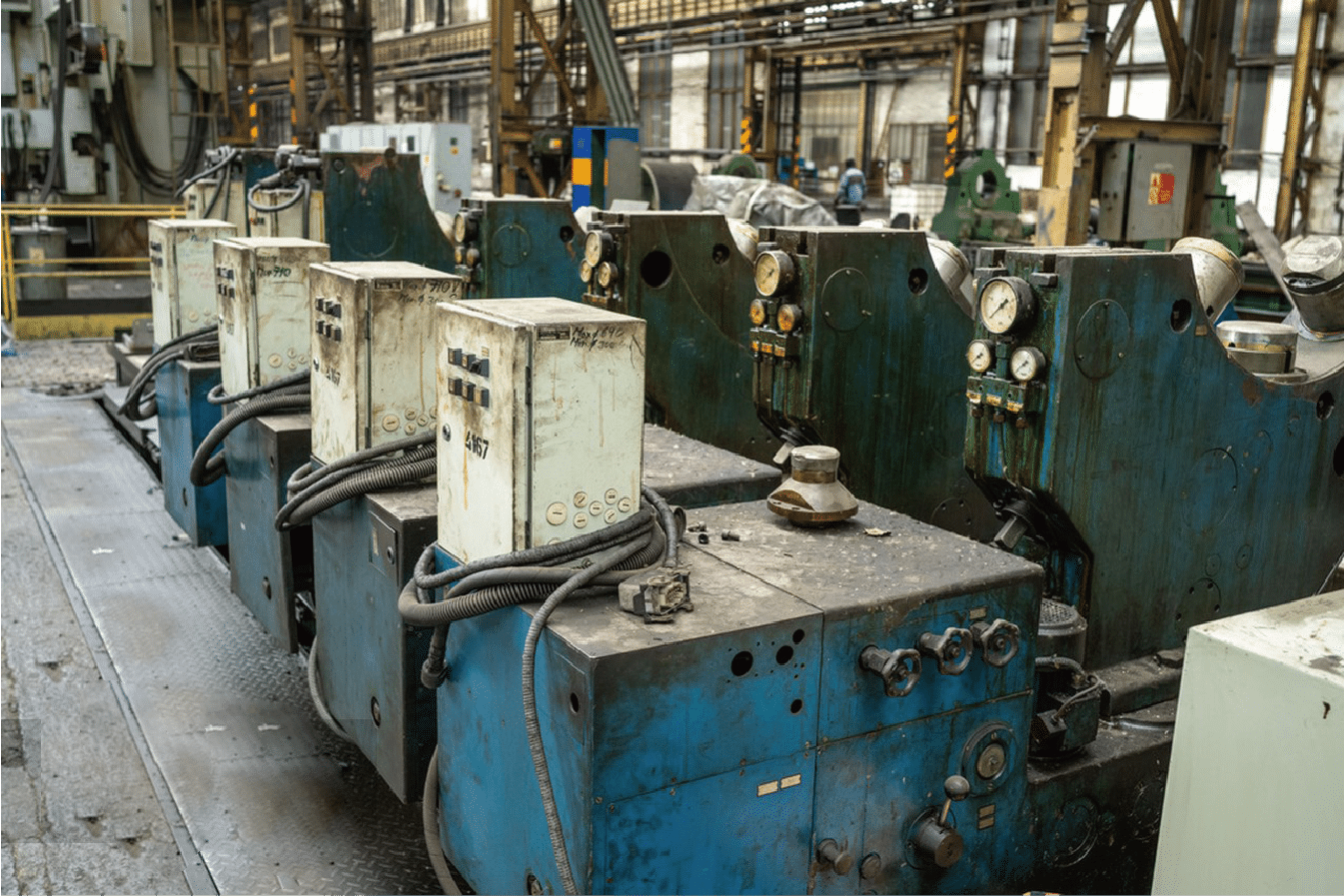

What Are the Common Challenges in Cutting Stainless Steel Plates from Coils?

Having faced numerous production challenges, I understand the importance of anticipating and addressing common cutting issues.

Common challenges include maintaining edge quality, controlling dimensional accuracy, managing material stress, and preventing surface damage during cutting operations.

Challenge Analysis Matrix

Our problem-solving database shows:

| Challenge Type | Root Causes | Prevention Methods | Solution Approach |

|---|---|---|---|

| Edge Burrs | Tool wear | Regular maintenance | Tool replacement |

| Dimensional Variation | Tension control | Parameter monitoring | System adjustment |

| Surface Scratching | Material handling | Protective measures | Process modification |

| Flatness Issues | Residual stress | Proper leveling | Equipment tuning |

Problem Resolution Strategies

-

Technical Solutions

- Tool optimization

- Process adjustment

- Equipment modification

- Parameter fine-tuning

-

Operational Improvements

- Operator training

- Maintenance schedules

- Quality checks

- Documentation systems

-

Quality Management

- Defect tracking

- Root cause analysis

- Corrective actions

- Preventive measures

How to Optimize the Cutting Process for Stainless Steel Plates from Coils?

My experience in process optimization has shown that continuous improvement is key to maintaining competitive advantage.

Optimization involves analyzing production data, implementing efficient workflows, maintaining equipment effectiveness, and training personnel for maximum productivity.

Process Optimization Framework

Our optimization results show:

| Optimization Area | Target Improvement | Implementation Method | Results Achieved |

|---|---|---|---|

| Production Speed | +20% | Process automation | 25% increase |

| Material Yield | +15% | Nesting optimization | 18% improvement |

| Quality Rate | +10% | Enhanced monitoring | 12% better |

| Setup Time | -30% | Standard procedures | 35% reduction |

Implementation Strategies

-

Operational Excellence

- Standard operating procedures

- Best practice sharing

- Performance monitoring

- Continuous improvement

-

Technology Integration

- Automated systems

- Digital controls

- Data analytics

- Predictive maintenance

-

Resource Management

- Operator training

- Tool inventory

- Maintenance planning

- Quality control

Conclusion

Successful cutting of stainless steel plates from coils requires proper equipment selection, precise control measures, effective problem-solving, and continuous process optimization to ensure quality and efficiency.