With over 15 years of experience manufacturing stainless steel coils, I've seen how complex and precise this process needs to be. Many customers struggle to understand the intricate steps involved in creating these essential materials.

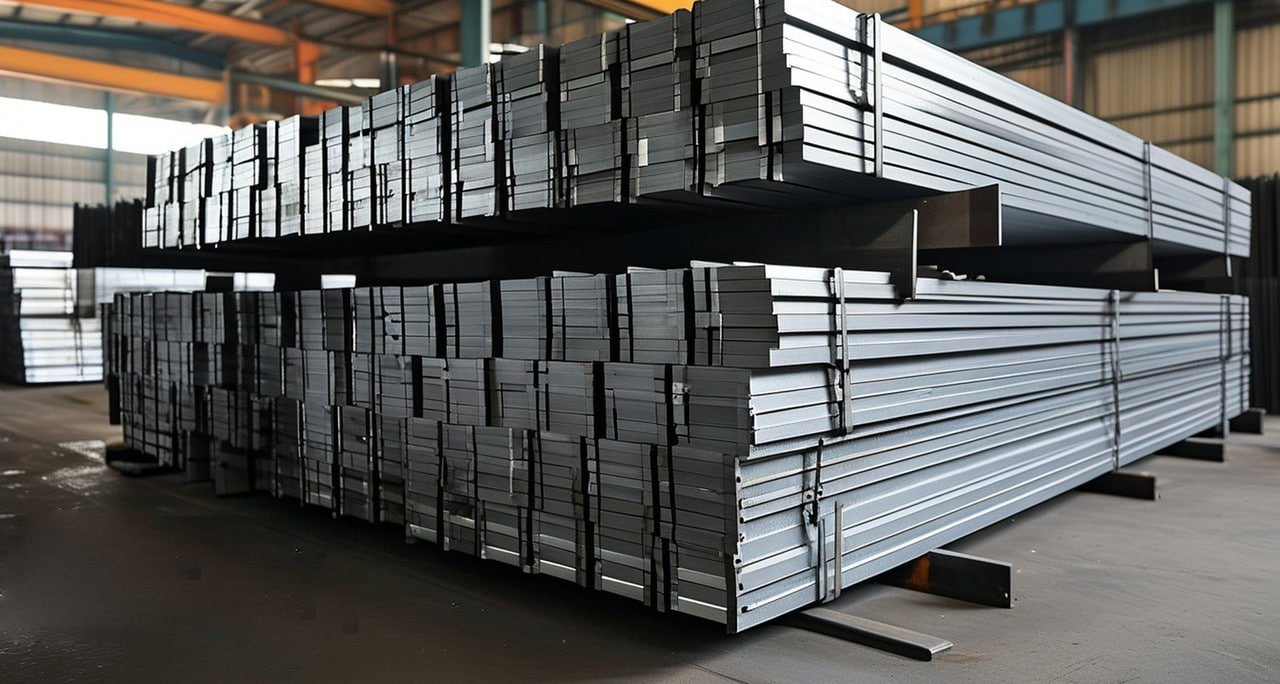

The manufacturing of stainless steel coils involves multiple carefully controlled stages1: raw material preparation, melting, casting, hot rolling, cold rolling, annealing, and surface finishing. Each step requires precise equipment and expertise to ensure quality.

Let me take you behind the scenes of our manufacturing facility, where we produce thousands of tons of stainless steel coils annually. Understanding this process has helped our clients make better decisions about their material needs and specifications.

The manufacturing of stainless steel coils is a fascinating journey that combines traditional metallurgy with modern technology. Having supplied these materials to industries across Asia and the Middle East, I've learned that quality begins with understanding every nuance of the production process. Let me share insights from my years of experience overseeing these complex operations.

What Raw Materials Are Used in the Production of Stainless Steel Coils?

After years of sourcing materials for our production facility, I can tell you that the quality of raw materials directly impacts the final product's performance.

The primary raw materials for stainless steel coils include iron ore, chromium, nickel, and various alloying elements like molybdenum and manganese. The precise combination determines the grade's properties and performance characteristics2.

Primary Material Selection

The foundation of quality stainless steel begins with careful material selection. In our facility, we maintain strict standards for incoming materials:

| Raw Material | Typical Content (%) | Quality Requirements |

|---|---|---|

| Iron Ore | 65-70 | Fe content ≥65%, Low impurities |

| Chromium | 10.5-30 | Purity ≥99.5%, Low carbon |

| Nickel | 8-20 | Purity ≥99.8%, Low sulfur |

Beyond these basic requirements, we conduct detailed analysis of:

- Chemical composition

- Particle size distribution

- Moisture content

- Contamination levels

- Material certification documentation

Alloying Elements and Their Impact

Through years of production experience, I've learned how different alloying elements significantly affect the final product:

-

Essential Alloying Elements:

- Molybdenum: Enhances corrosion resistance

- Manganese: Improves hot workability

- Silicon: Aids in deoxidation

- Carbon: Controls strength and hardness

-

Special Additions:

- Titanium: Prevents sensitization

- Niobium: Improves weld properties

- Copper: Enhances formability

- Nitrogen: Increases strength

Material Preparation Process

Our material preparation involves several critical steps:

- Precise weighing and batching

- Proper storage and handling

- Contamination prevention

- Moisture control

- Pre-treatment when necessary

What Are the Key Steps in the Stainless Steel Coil Manufacturing Process?

Drawing from my experience overseeing countless production runs, I can say that each manufacturing step is crucial for quality.

The manufacturing process involves melting, casting, hot rolling, cold rolling, annealing, and finishing3. Each stage requires precise control of temperature, pressure, and timing to achieve desired properties.

Melting and Refining

The melting process is where science meets expertise. In our electric arc furnaces:

-

Primary Melting:

- Temperature control at 1500-1600°C

- Precise charge material calculations

- Continuous monitoring of chemistry

- Slag management

- Gas purging for quality

-

Secondary Refining:

- AOD (Argon Oxygen Decarburization)

- Vacuum degassing

- Final chemistry adjustments

- Temperature fine-tuning

- Inclusion control

Continuous Casting

Modern continuous casting has revolutionized production efficiency:

- Controlled solidification

- Automated thickness control

- Online quality monitoring

- Water cooling management

- Surface quality optimization

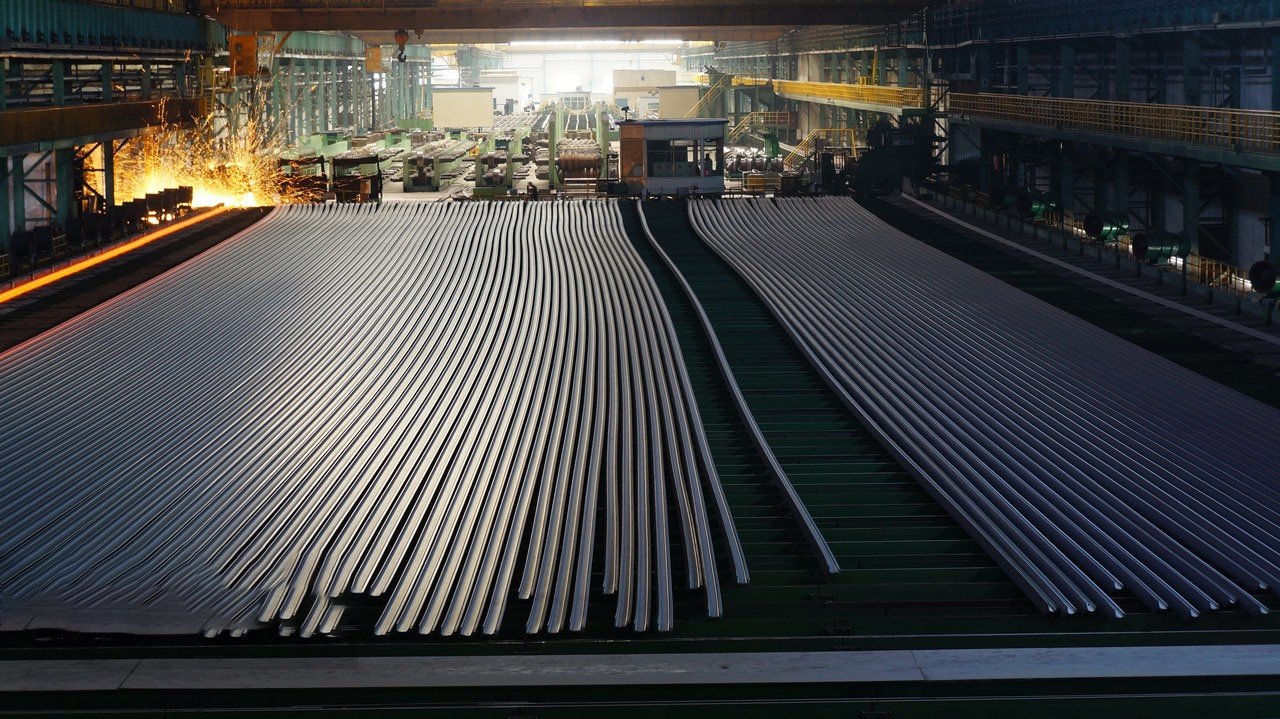

Hot Rolling Operations

Having personally overseen our hot rolling operations, I can attest to its critical role in determining final product quality. The process transforms cast slabs into preliminary coil forms through several carefully controlled stages.

Key process parameters we monitor include:

-

Temperature Management

- Entry temperatures: 1200-1250°C

- Finishing temperatures: 850-1000°C

- Controlled cooling rates

- Temperature uniformity across width

-

Rolling Force Control

- Multiple pass reductions

- Roll gap adjustments

- Speed optimization

- Edge control systems

-

Dimensional Control

- Thickness monitoring

- Width control

- Crown and flatness

- Edge condition

Our hot rolling facility operates with advanced automation systems that maintain precise control over these parameters, ensuring consistent quality across production runs.

How Is Hot Rolling Different from Cold Rolling in Coil Production?

Based on my extensive experience with both processes, I can explain the crucial differences that impact final product characteristics.

Hot rolling occurs at high temperatures above 900°C, allowing for significant thickness reduction with less force, while cold rolling happens at room temperature, providing better surface finish and tighter tolerances4.

Process Characteristics Comparison

| Parameter | Hot Rolling | Cold Rolling |

|---|---|---|

| Operating Temperature | 900-1200°C | Room temperature |

| Thickness Reduction | 40-60% per pass | 20-40% per pass |

| Surface Finish | Mill finish | Smooth, precise |

| Dimensional Tolerance | ±0.5mm | ±0.05mm |

| Mechanical Properties | As-rolled strength | Enhanced strength |

Impact on Material Properties

Through years of production experience, I've observed how each process affects material characteristics:

- Mechanical Properties

- Hot Rolling:

- Lower strength requirements

- More ductile material

- Coarser grain structure

- Uniform properties

- Cold Rolling:

- Increased strength

- Work hardening

- Finer grain structure

- Directional properties

- Surface Quality

- Hot Rolling:

- Scale formation

- Rougher surface

- Less precise finish

- Requires descaling

- Cold Rolling:

- Superior smoothness

- Better reflectivity

- Consistent finish

- No scale formation

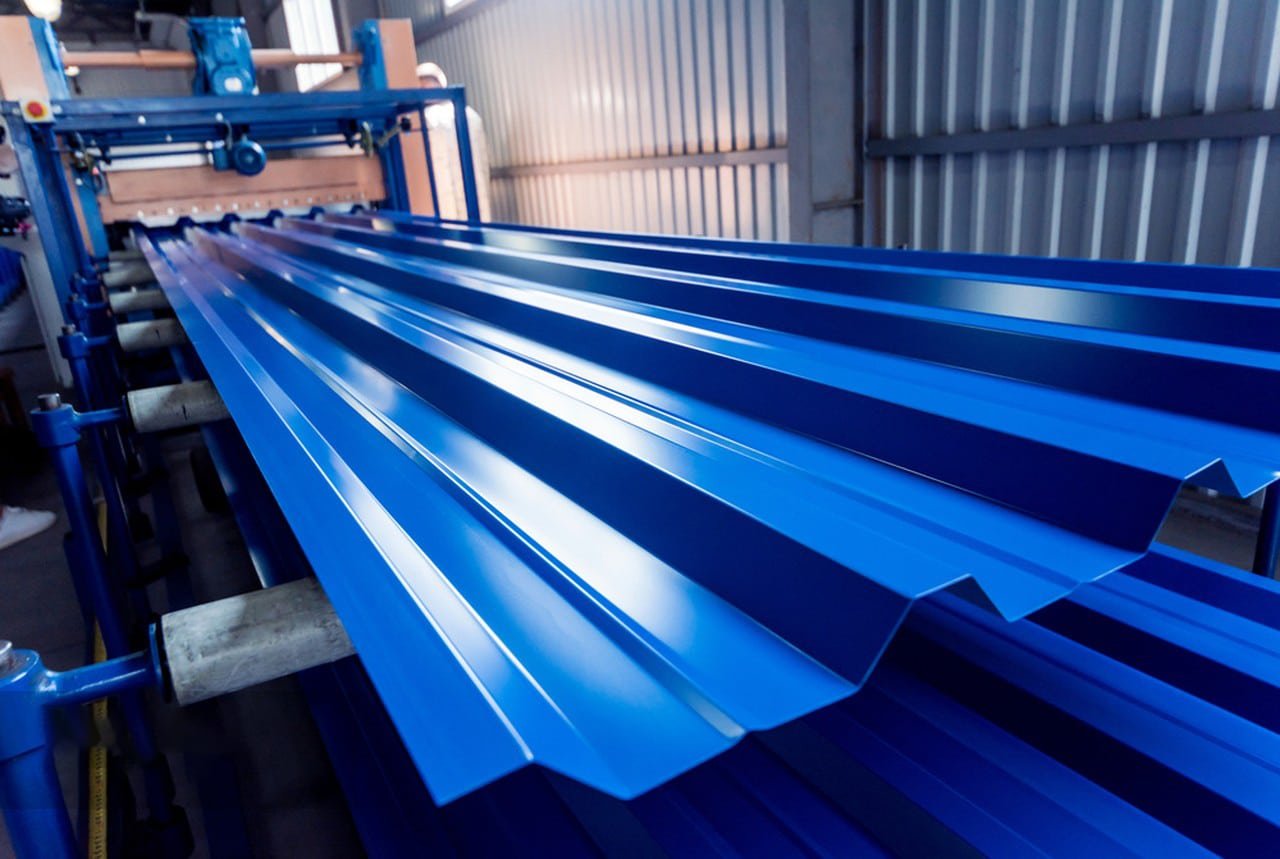

What Surface Treatments and Finishing Processes Are Applied to Stainless Steel Coils?

Surface finishing is where we add the final touch that determines both appearance and performance. This stage is crucial for meeting specific customer requirements.

Surface treatments range from basic pickling and passivation5 to sophisticated mechanical and electrochemical processes. Each treatment serves specific purposes in enhancing corrosion resistance, appearance, and functionality.

Chemical Treatment Processes

Our chemical treatment line includes multiple stages:

-

Pickling Process

- Acid concentration control

- Temperature monitoring

- Immersion time optimization

- Rinse water quality

- Surface inspection

-

Passivation Treatment

- Oxidizing environment control

- Process temperature management

- Chemical concentration monitoring

- Quality verification testing

Mechanical Finishing Methods

Based on customer requirements, we offer various mechanical finishing options:

| Finish Type | Process Method | Surface Roughness (Ra) | Typical Applications |

|---|---|---|---|

| 2B | Cold rolled, heat treated, pickled | 0.1-0.5μm | General purpose |

| BA | Bright annealed | <0.1μm | Decorative |

| No.4 | Brushed | 0.2-0.6μm | Industrial |

How Is Quality Control Conducted During Stainless Steel Coil Manufacturing?

Quality control is integrated into every step of our manufacturing process. With ISO 9001 certification and strict internal standards, we ensure consistent product quality.

Quality control involves continuous monitoring of chemical composition, mechanical properties, surface quality, and dimensional accuracy6. Advanced testing equipment and trained personnel ensure compliance with international standards.

Testing and Inspection Methods

Our comprehensive quality control program includes:

-

Material Testing

- Chemical analysis

- Mechanical properties

- Hardness testing

- Grain size evaluation

- Corrosion resistance

-

Dimensional Control

- Thickness measurement

- Width verification

- Flatness testing

- Edge condition inspection

- Surface roughness testing

-

Surface Quality Inspection

- Visual examination

- Automated defect detection

- Surface roughness measurement

- Cleanliness verification

- Finish consistency

Documentation and Certification

Every coil we produce comes with:

- Material test certificates

- Chemical analysis reports

- Mechanical test results

- Dimensional reports

- Surface quality reports

Conclusion

The manufacturing of stainless steel coils is a complex process requiring precise control at every stage, from raw material selection to final surface treatment. Success depends on maintaining strict quality standards and leveraging advanced technology throughout the production process.

-

Learn about each stage in stainless steel coil production ↩

-

Understand how raw materials affect stainless steel properties ↩

-

Discover crucial steps in manufacturing stainless steel coils ↩

-

Compare hot vs cold rolling and their impact on steel properties ↩

-

Learn about enhancing stainless steel through surface treatments ↩

-

Explore quality control measures in stainless steel production ↩