Can stainless steel be cold-formed?

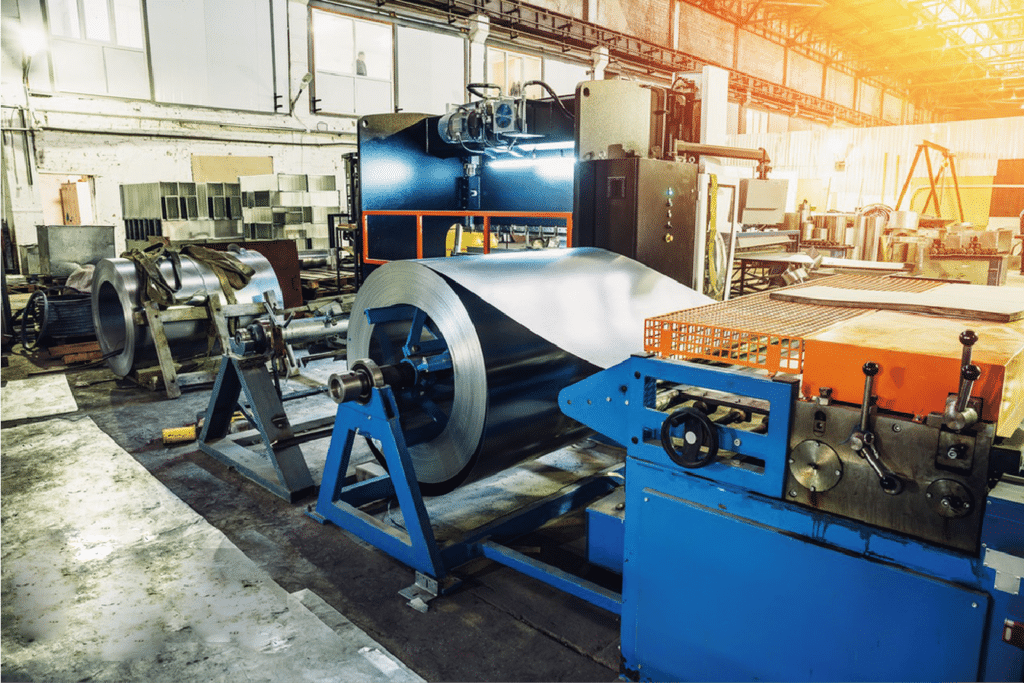

Many manufacturers struggle with finding cost-effective ways to shape stainless steel while maintaining its properties. Cold-forming offers a solution, but questions about its effectiveness persist. Cold-forming1 is a metalworking process that shapes stainless steel at room temperature, enhancing its strength and durability while maintaining corrosion resistance. This method proves more economical than hot-forming and is […]

How Do Stainless Steel Pipes Handle Extreme Heat?

In my extensive experience in the stainless steel industry, I’ve often encountered clients who are unsure about the capabilities of stainless steel pipes in high-temperature applications. The stakes are high, and the right material choice can make all the difference. Stainless steel pipes are highly suitable for high-temperature applications, maintaining their strength and structural integrity […]

What are the lead times for stainless steel sheet orders?

As a stainless steel manufacturer, I’ve seen countless clients struggle with uncertain delivery schedules, causing production delays and financial losses. The anxiety of not knowing when materials will arrive can be overwhelming. Lead times for stainless steel sheet orders typically range from 2-12 weeks1, depending on specifications, quantity, and market conditions. Standard grades with common […]

Can stainless steel coils be used in medical equipment?

As a stainless steel manufacturer, I’ve witnessed countless medical equipment makers struggle with material selection. The wrong choice can lead to contamination risks and equipment failure, potentially compromising patient safety. Stainless steel coils1 are extensively used in medical equipment manufacturing due to their exceptional corrosion resistance, durability, and biocompatibility. These materials meet stringent medical standards, […]