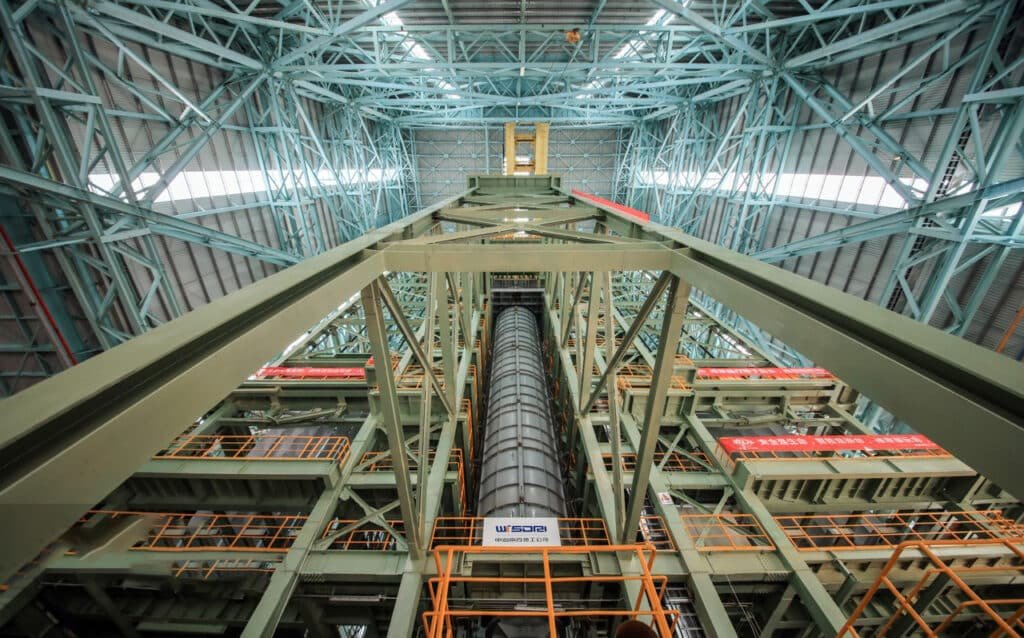

What Are the Manufacturing Processes for Stainless Steel?

After 15 years in stainless steel manufacturing, I’ve witnessed how production challenges can significantly impact final product quality. Poor process control often leads to material defects and inconsistent properties. Stainless steel manufacturing combines multiple sophisticated processes including melting, casting, forming, and finishing1. Each step requires precise control to achieve the desired mechanical properties and surface […]

Why Are Stainless Steel Pipes Used in Automotive Exhaust Systems?

After 15 years supplying stainless steel to automotive manufacturers, I’ve seen firsthand how crucial material selection is for exhaust systems. The wrong choice can lead to premature failure and costly warranty claims. Stainless steel pipes are the preferred choice for automotive exhaust systems due to their superior heat resistance up to 850°C, excellent corrosion resistance, […]

How to Prevent Scratches on Stainless Steel Sheets?

As a stainless steel manufacturer, I’ve seen how surface scratches can impact both aesthetics and performance. The challenge of maintaining pristine surfaces during handling and installation is a common concern among our clients. Preventing scratches on stainless steel sheets requires proper protective measures, careful handling procedures, and appropriate storage methods. These practices, combined with suitable […]

What Is the Role of Nickel in Stainless Steel Coils?

Throughout my years managing MFY’s stainless steel production, I’ve witnessed how nickel content dramatically influences material performance, particularly in demanding applications where corrosion resistance is crucial. Nickel plays a vital role in stainless steel coils by enhancing corrosion resistance, improving mechanical properties, and maintaining austenitic structure. Its content typically ranges from 8-35%, significantly affecting material […]